The technical term for what is tutu material called is tulle, a lightweight, fine netting that serves as the backbone of voluminous fashion. You might find it frustrating when your designs lack the necessary “lift” or structure. Without the right material, even the most beautiful sketches fail to translate into striking silhouettes. By selecting premium tulle, you solve the structural challenges of haute couture while maintaining an ethereal aesthetic.

What is tutu material called and how did it begin?

In technical textile terms, what is tutu material called is tulle, which traces its origins back to 18th-century France. This delicate fabric was originally handmade to create intricate lace patterns and royal veils. Today, it has evolved into a staple for both theatrical performance and high-end retail production.

How did the industrial revolution change its use?

Think about this: the move from handmade silk to machine-made polymers changed everything. You can now access various stiff tulle options that were impossible to produce centuries ago.

- Machines allowed for consistent hexagonal weave patterns.

- Production speeds increased, making the fabric accessible to everyone.

- New synthetic fibers improved the fabric’s overall lifespan.

Why is history relevant to your sourcing today?

Look: knowing the heritage of your fabric helps you identify quality. Modern manufacturing still relies on the same basic principles of open-weave netting established in the city of Tulle.

- Heritage weaves provide a blueprint for modern sheerness.

- Understanding origins helps in categorizing luxury vs. mass-market grades.

- Classic techniques inform how current designers layer for volume.

Key Takeaway: The historical evolution of tulle from silk to synthetic polymers has made it the primary choice for structural volume.

| Era | Material Basis | Primary Application | |

|---|---|---|---|

| 1700s | Hand-woven Silk | Royal veils and lace bases | |

| 1800s | Cotton/Machine | Romantic ballet tutus | |

| 1950s+ | Nylon/Polyester | Industrial-strength apparel |

This progression shows how the fabric shifted from a luxury rarity to a versatile industrial powerhouse.

What is tutu material called in luxury bridal wear?

In the world of high-end wedding fashion, what is tutu material called is usually referred to as bridal illusion or silk tulle. You need a fabric that drapes perfectly while remaining almost invisible against the skin. These luxury variants provide a sophisticated matte finish that synthetic alternatives often struggle to replicate.

What makes bridal tulle different from standard mesh?

Here is the deal: bridal grades prioritize a soft hand-feel and extreme sheerness. You don’t want your clients to feel itchy or restricted on their wedding day.

- Finer thread counts create a smoother surface.

- The fabric is designed to photograph beautifully without glare.

- It supports delicate embroidery and heavy beadwork effortlessly.

How do you choose the right drape for veils?

The best part? You can select specific weights to achieve either a flowing or structured look. A veil needs to be light enough to catch the wind but strong enough to hold its shape.

- Low GSM tulle offers a liquid-like movement.

- Medium weights provide enough body for tiered designs.

- Silk options offer the most prestigious aesthetic for couture.

Key Takeaway: Luxury bridal tulle focuses on the intersection of transparency, softness, and the ability to support intricate embellishments.

| Feature | Luxury Specification | Benefit | |

|---|---|---|---|

| Texture | Ultra-soft / Non-irritant | Comfort for long-term wear | |

| Opacity | 80-95% Transparent | Creates “illusion” necklines | |

| Luster | Matte to Low-Sheen | Professional photographic quality |

Premium bridal fabrics ensure that the final garment meets the high expectations of the luxury market.

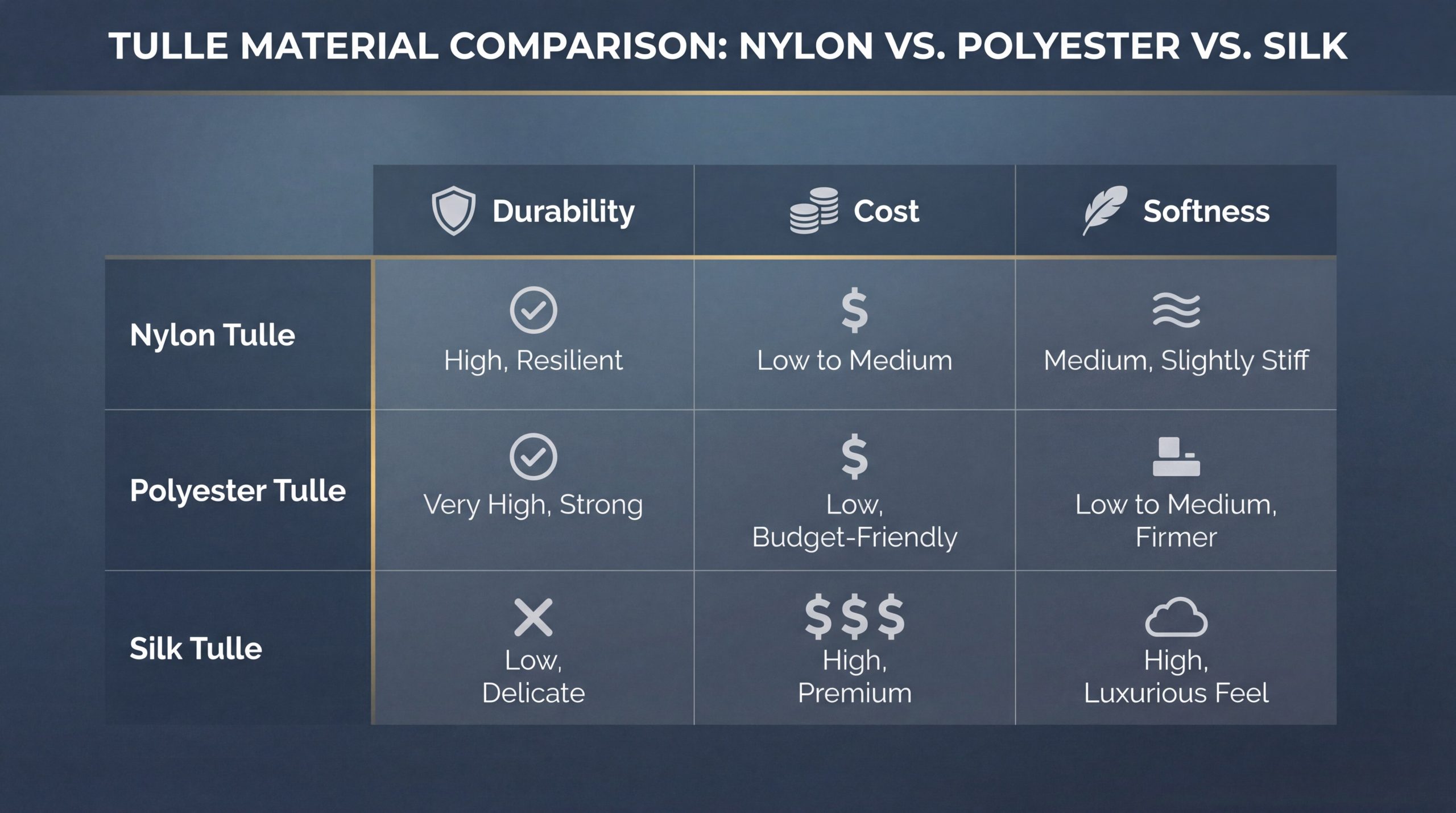

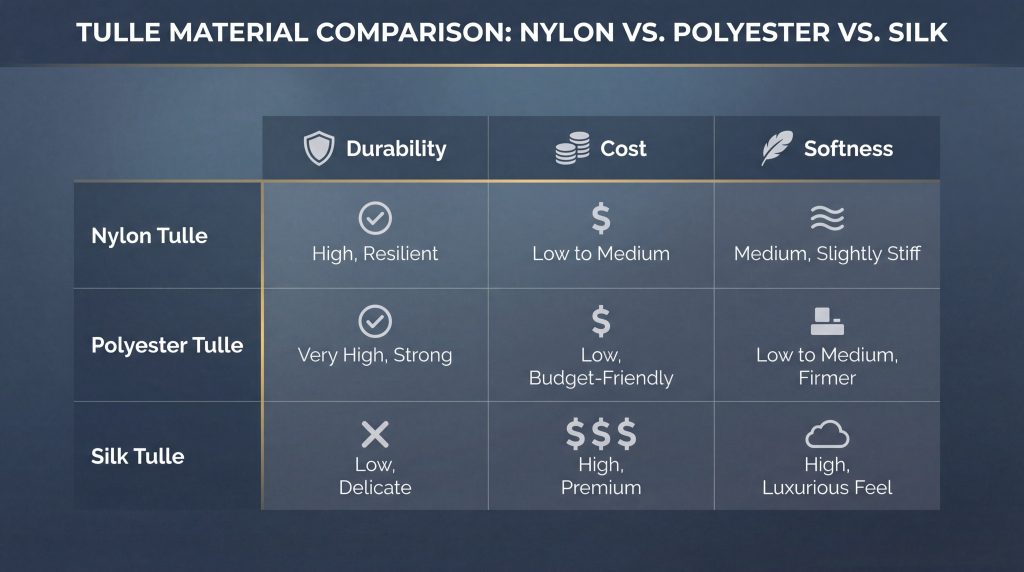

What is tutu material called across synthetic fibers?

To understand what is tutu material called in mass production, you must compare the performance of nylon and polyester. You will find that most professional dancewear relies on nylon for its superior “memory” and strength. Conversely, polyester serves as an excellent budget-friendly alternative for decorative projects.

Why is nylon the standard for performance?

In fact, nylon is the gold standard because it resists tearing during high-energy movements. You can use soft tulle made of nylon to ensure the dancer stays comfortable and the garment stays intact.

- Nylon fibers have higher abrasion resistance than polyester.

- The material “springs back” to its original shape after being crushed.

- It takes dyes more deeply, resulting in vibrant stage colors.

When should you opt for polyester instead?

The truth is: polyester is the king of affordability and event decor. If you are producing thousands of party favors or table runners, this is your best bet.

- Lower cost per yard allows for high-volume scaling.

- It is naturally more resistant to UV fading in outdoor settings.

- The material is often stiffer, which is great for “one-time use” volume.

Key Takeaway: Nylon offers professional durability and recovery, while polyester provides a cost-effective solution for decoration.

| Fiber | Durability | Best Use | |

|---|---|---|---|

| Nylon | High | Ballet Tutus & Performance | |

| Polyester | Medium | Event Decor & Party Costumes | |

| Silk | Low | Couture Veils & Luxury Gowns |

Matching the fiber to the application is the most critical step in professional textile procurement.

What is tutu material called during industrial testing?

In a laboratory setting, what is tutu material called is analyzed as a technical mesh with specific tensile properties. You cannot afford to have a production batch fail during the final assembly of a garment. Testing ensures that the hexagonal structure can withstand the stresses of sewing and wearing.

How is the strength of tulle measured?

Look: technicians use mechanical arms to pull the fabric until it reaches its breaking point. You need to know the exact load your material can handle before it deforms.

- Tensile strength measures the force required to snap the fibers.

- Elongation tests determine how much the mesh stretches.

- The “burst test” evaluates the strength of the hexagonal weave.

Why is consistency vital for B2B buyers?

Here is the bottom line: inconsistent batches lead to wasted time and resources. You must ensure that every roll of fabric meets the same technical specifications.

- Prevents machine jams during high-speed industrial sewing.

- Ensures color uniformity across different production runs.

- Reduces the risk of consumer returns due to fabric failure.

Key Takeaway: Industrial testing verifies that the tulle can handle the mechanical demands of both manufacturing and daily use.

| Test Type | Metric Measured | Importance | |

|---|---|---|---|

| Tensile Test | Force in Newtons | Prevents tearing at seams | |

| GSM Weighing | Grams per Square Meter | Ensures consistent thickness | |

| Recovery Test | Percentage of Return | Maintains garment silhouette |

Rigorous testing protocols are the only way to guarantee a high-quality finished product for your brand.

What is tutu material called in color laboratories?

When you are matching shades for a new collection, what is tutu material called is a substrate that interacts uniquely with light. Because of its open-weave nature, the color can appear different depending on how many layers you stack. You need a color matching station to ensure your “blush” doesn’t look like “peach” under stage lights.

How do you ensure color accuracy?

Think about this: lighting changes everything. You should always use how to select types of tulle fabric guides to understand how different fibers absorb pigment.

- Spectrophotometers measure the exact light reflected by the mesh.

- Digital swatches allow for global color consistency.

- Lab dips help you approve the shade before mass production begins.

Does layering change the final hue?

The best part? You can create custom colors simply by layering different shades of tulle. This technique allows for a depth of color that solid fabrics cannot achieve.

- Layering white over a color softens the intensity.

- Two different shades create a shimmering, iridescent effect.

- More layers always result in a more saturated, darker appearance.

Key Takeaway: Professional color management is essential because the transparency of tulle significantly affects its visual saturation.

| Factor | Impact on Color | Strategy | |

|---|---|---|---|

| Fiber Type | Nylon dyes deeper than Poly | Choose Nylon for neon/dark shades | |

| Layering | Increases color density | Use multiple layers for richness | |

| Light Source | Shifts perceived hue | Always check under LED and Daylight |

Precise color control ensures that your collection looks cohesive across all retail environments and lighting conditions.

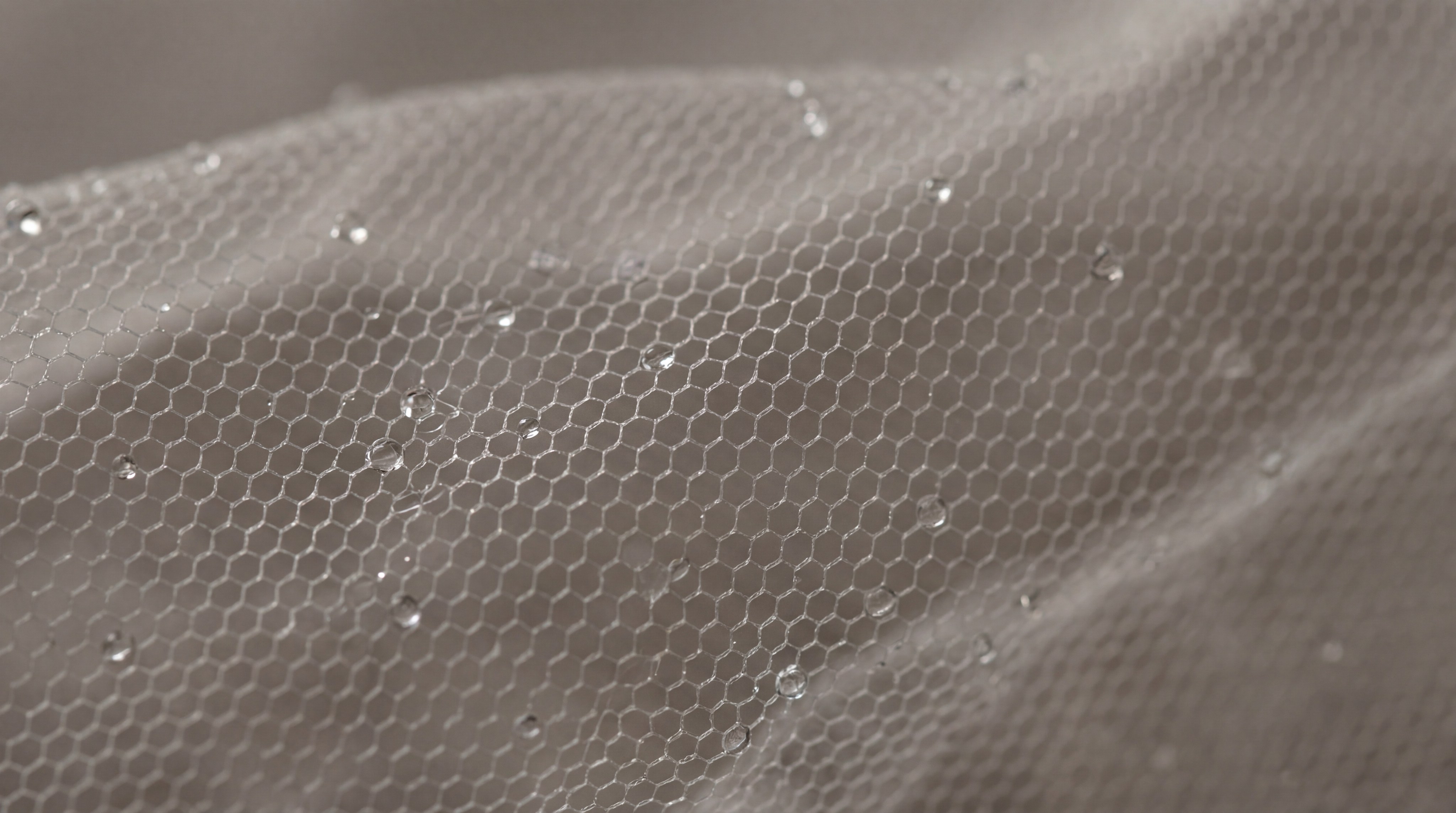

What is tutu material called under macro lenses?

If you look closely at the fabric, what is tutu material called reveals its characteristic honeycomb or hexagonal weave. You can see how the tiny holes provide the breathability and tension required for activewear. Under magnification, the difference between high-quality and low-grade mesh becomes immediately apparent.

What defines a “high-quality” weave?

Here is the deal: consistency is king. You want to see perfectly uniform hexagons with no loose threads or warped sections.

- Uniform hole size ensures a smooth visual appearance.

- Consistent knotting prevents the fabric from unravelling.

- Clean edges make the cutting and sewing process easier.

Why is the hexagonal shape so important?

Look: this specific geometry is nature’s strongest design. It allows the fabric to be incredibly light while maintaining a high level of structural integrity.

- The shape distributes tension evenly across the surface.

- It provides the perfect balance of open space and fiber.

- The weave allows moisture to evaporate quickly from the skin.

Key Takeaway: The hexagonal structure of tulle is a masterpiece of textile engineering that provides strength without adding weight.

| Structure Metric | Standard Grade | Premium Grade | |

|---|---|---|---|

| Hole Uniformity | 85-90% | 98-100% | |

| Fiber Integrity | May have fraying | Zero-shedding filaments | |

| Surface Tension | Low | High / Resilient |

A macro-level inspection is the fastest way to verify the quality of a new fabric supplier’s samples.

What is tutu material called in modern warehouses?

In the logistics sector, what is tutu material called is typically managed as high-volume roll stock. You need to understand how to store these rolls to prevent permanent creasing or damage. Large-scale warehouses use climate control and specialized racking to keep the mesh in pristine condition for your order.

How should you store bulk tulle rolls?

Think about this: pressure is the enemy of volume. You must use how to choose the right mesh fabric for your project principles to store rolls horizontally rather than vertically.

- Horizontal storage prevents the weight from crushing the bottom.

- Avoid stacking rolls too high to protect the inner layers.

- Keep the fabric in its protective plastic wrap to avoid dust.

Why is climate control necessary for nylon?

The truth is: nylon is sensitive to extreme heat and humidity. You want your warehouse to stay cool and dry to prevent the fabric from becoming brittle or losing its dye.

- High humidity can cause nylon to “relax” and lose its stiffness.

- Extreme heat may damage the resin finishes on stiff tulle.

- Dark environments prevent UV rays from yellowing white mesh.

Key Takeaway: Proper logistics and storage are vital to maintaining the fabric’s shape-memory and color integrity before production.

| Storage Factor | Ideal Condition | Risk of Neglect | |

|---|---|---|---|

| Temperature | 18°C – 24°C | Fiber degradation | |

| Orientation | Horizontal / Racked | Permanent crushing | |

| Packaging | Sealed Poly-bags | Dust and contamination |

By managing your inventory correctly, you ensure that the fabric you use is as fresh as the day it was woven.

What is tutu material called for professional care?

Once a garment is finished, what is tutu material called requires specific maintenance to retain its volume. You should never toss a professional tutu into a standard washing machine. Instead, industrial steaming and hand-washing are the standard protocols for preserving the mesh’s structural integrity.

What is the safest way to remove wrinkles?

The best part? Steam is your best friend. You can instantly restore the “fluff” of a skirt by using a vertical steamer without ever touching the fabric with a hot iron.

- Steam relaxes the fibers without melting them.

- It allows the layers to expand and separate.

- High-pressure steam can also sanitize the garment between uses.

Why avoid traditional dry cleaning?

Look: the chemicals used in dry cleaning can be too harsh for synthetic resins. You risk losing the stiffness that gives the tutu its signature horizontal lift.

- Harsh solvents can dissolve the coatings on stiff tulle.

- Tumbled drying creates static and tangles the mesh.

- Mechanical agitation in machines leads to snags and holes.

Key Takeaway: Gentle steaming and careful hand-washing are the only ways to prolong the life of professional tulle garments.

| Care Step | Recommended Method | Why? | |

|---|---|---|---|

| Washing | Hand wash in cool water | Protects resin and fibers | |

| Drying | Air dry flat | Prevents stretching | |

| Wrinkles | Vertical Steaming | Avoids heat damage/melting |

Educating your clients on these care steps will significantly improve their satisfaction and the garment’s longevity.

What is tutu material called within high-end fashion studios?

Inside a couture atelier, what is tutu material called is a canvas for three-dimensional design. You use it to build “inner architecture” that supports heavy outer fabrics. Designers spend hours inspecting the mesh for imperfections because, in high fashion, the details are everything.

How is tulle used as a structural support?

In fact, many famous silhouettes rely on hidden layers of stiff netting. You can hide these layers under silk or satin to create a dramatic bell shape that stays up all night.

- Internal petticoats provide the “foundation” for gowns.

- Stacked layers create a gradient of volume.

- It acts as a lightweight alternative to heavy crinoline.

Why do designers prefer fine-hole mesh?

Here is the deal: the smaller the hole, the more invisible the fabric becomes. You want your “illusion” panels to blend seamlessly with the wearer’s skin tone.

- Fine mesh creates a “nude” effect on sleeves and bodices.

- It provides a stable base for hand-sewn lace appliqués.

- Smaller holes are less likely to snag on jewelry.

Key Takeaway: In haute couture, tulle is valued both as a visible decorative element and as a hidden structural necessity.

| Couture Use | Material Choice | Goal | |

|---|---|---|---|

| Illusion Panels | Ultra-fine Soft Tulle | Seamless transparency | |

| Structural Skirts | Multi-layered Stiff Tulle | Permanent volume | |

| Embellishment | Fine Mesh | Support for heavy beads |

Mastering the use of tulle allows you to engineer garments that defy gravity and impress the most discerning clients.

What is tutu material called for global supplier networks?

For B2B procurement, what is tutu material called represents a partnership between design and logistics. You need a supplier who can provide thousands of yards with zero color variance. A modern logistics hub ensures that your premium mesh arrives on time, whether you are a local boutique or a global fashion house.

How do you vet a reliable tulle manufacturer?

Think about this: a good supplier is more than just a vendor. You need a partner who understands GSM, fiber content, and the specific needs of your production line.

- Check for OEKO-TEX or ISO quality certifications.

- Request sample books to test the “hand” of the fabric.

- Ensure they can handle custom-dye requests for your brand.

Why is factory-direct sourcing beneficial?

The best part? Cutting out the middleman saves you money and improves communication. You can speak directly to the factory about the resin stiffness or the specific weave pattern you need.

- Lower Minimum Order Quantities (MOQs) for testing.

- Faster turnaround times for bulk orders.

- Better pricing on high-volume shipments.

Key Takeaway: Establishing a direct relationship with a specialized manufacturer is the most effective way to secure high-quality tulle at a competitive price.

| Sourcing Step | Key Question | Success Metric | |

|---|---|---|---|

| Inquiry | Can you match this specific GSM? | Accurate technical data sheet | |

| Sampling | Does the hand-feel match my needs? | Physical approval of swatch | |

| Ordering | What is the lead time for 5,000 yards? | On-time delivery schedule |

Your supply chain is only as strong as the fabric it delivers; choose a partner that values precision and reliability.

FAQ: Professional Tulle Sourcing

Can I use polyester tulle for a professional ballet tutu?While polyester is affordable, it lacks the “recovery” of nylon. For a professional performance, nylon is highly recommended because it won’t sag after hours of movement on stage.

What’s the best way to remove wrinkles from bulk tulle rolls?Vertical steaming is the industry standard. Never use a traditional iron directly on synthetic tulle, as it can melt the fibers instantly.

Can I dye tulle at home for custom projects?Nylon tulle takes acid dyes very well, but polyester requires specialized disperse dyes and high heat. For professional results, it is always better to order custom-dyed rolls from the manufacturer.

How do I determine if a tulle is “quality mesh” just by feeling it?Check for a crisp “crunch” and immediate spring-back. High-quality structural tulle should feel resilient and not leave permanent creases when squeezed in your hand.

Can I wash tulle in a machine on a delicate cycle?It is not recommended for stiff tulle, as the agitation can break down the resin coatings. Hand-washing in cool water is always the safest way to maintain the fabric’s integrity.

We believe that the right fabric is the foundation of every great design. Our vision is to provide designers and manufacturers with the highest-grade mesh materials that combine traditional beauty with modern durability. Whether you are building a classical tutu or a luxury bridal veil, our technical expertise ensures your success. Contact us today to request a custom sample kit and elevate your next collection.