Stiff Tulle That Holds Shape — Not Just on Day One

Your petticoats lose volume after the first wear. Your tutu skirts collapse in storage. Your fabric arrives with an unpleasant smell. These aren't quality issues you should accept — they're engineering problems we've solved.

KARL MAYER Equipment

German Precision Manufacturing

What Is Stiff Tulle?

Stiff tulle is a structural fabric engineered to provide lasting support and shape retention. Unlike decorative tulle, it's designed to bear weight and maintain form across repeated use.

Structural Fabric for Professional Applications

Stiff tulle features a precisely engineered hexagonal mesh that creates three-dimensional stability. This construction allows garment makers to achieve dramatic silhouettes in bridal wear, ballet tutus, and theatrical costumes without adding excessive weight.

Multi-Layer Support System

Creates volume through strategic layering while minimizing bulk and weight

Long-Term Shape Memory

Maintains structural integrity through storage, transport, and extended wear

Lightweight Construction

Delivers maximum support with minimal fabric weight for wearer comfort

Understanding the Difference

Soft Tulle

Decorative fabric designed for draping and aesthetic layering. Provides visual effect without structural support.

Stiff Tulle

Structural fabric engineered for support layers. Creates volume and maintains shape under stress.

Crinoline

Heavy-weight netting with maximum stiffness. Often too rigid and bulky for refined applications.

Common Misconceptions Clarified

"Stiff means thick and heavy"

Stiffness comes from structure, not weight

"All stiff tulle scratches skin"

Proper finishing creates smooth edges

"Stiffness fades over time"

Quality tulle maintains shape for years

Need help selecting the right stiffness level for your application?

Consult Our Technical TeamThe Real Problems With Stiff Tulle Today

Most manufacturers face the same four challenges when sourcing stiff tulle. These issues stem from production shortcuts and inconsistent quality standards — problems we've systematically eliminated.

Structure Won't Hold

Petticoats that impress on delivery but flatten within weeks. This structural failure happens when mesh geometry is inconsistent or drying processes leave moisture trapped in the fiber matrix.

Uncomfortable & Odorous

Fabric that scratches skin or carries chemical odors cannot be used in close-body applications. These problems trace back to low-quality finishing processes and inadequate post-treatment.

Batch Inconsistency

Every shipment feels different from the last. Production teams waste time adjusting patterns, and final products lack uniformity. This happens when suppliers lack standardized processes.

Cost Out of Control

Quality stiff tulle seems prohibitively expensive, especially for smaller production runs. High MOQs lock out growing brands, and pricing lacks transparency across the supply chain.

These Four Challenges Share a Common Root

Inconsistent manufacturing processes and outdated equipment create a cycle of quality problems that cost you time, money, and customer trust.

Which of these challenges is impacting your production most?

Tell Us Your SituationHow Structural Support Gets Compromised

When stiff tulle fails to hold its shape, the root cause isn't the material itself — it's how it was manufactured. Understanding these failure points helps you identify quality suppliers and avoid costly production delays.

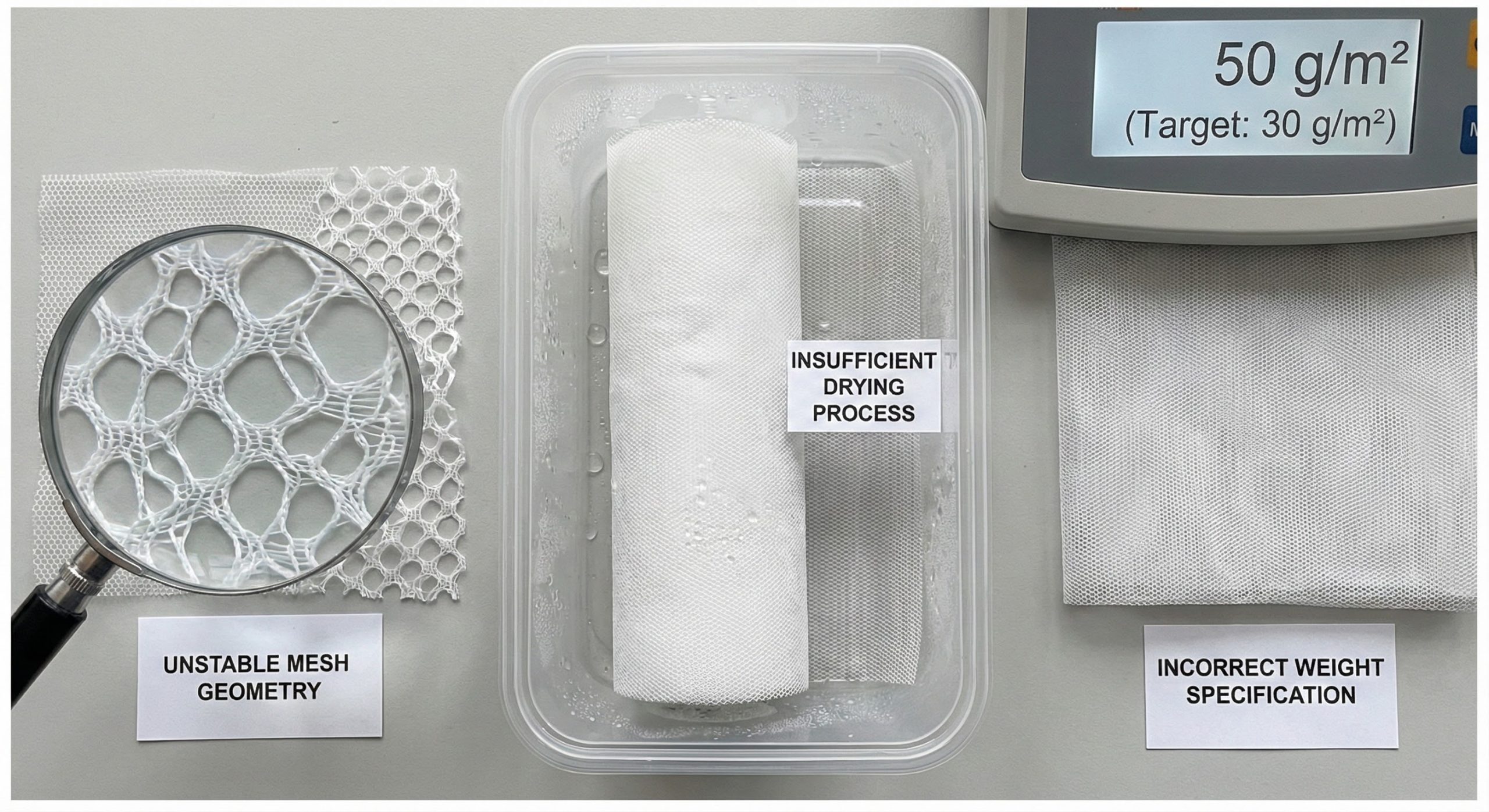

Three Manufacturing Shortcuts That Destroy Structure

Volume loss and structural collapse trace back to specific production decisions. Factories under cost pressure often cut corners in these three critical areas, delivering fabric that performs well initially but degrades within weeks.

Unstable Mesh Geometry

Inconsistent tension during weaving creates irregular hexagonal openings. These weak points collapse under stress, causing uneven volume distribution and premature sagging.

Insufficient Drying Process

Single-pass drying leaves moisture trapped in fiber cores. This residual moisture softens the stiffening agents over time, especially in humid storage conditions.

Incorrect Weight Specification

Using lighter GSM fabric than the application requires saves material costs but guarantees structural failure. Each use case demands a specific weight range.

The Real Cost of Structural Failure

These manufacturing shortcuts create cascading problems across your operation

Rework & Returns

Finished garments returned for structural reinforcement, doubling labor costs per piece

Production Delays

Waiting for replacement fabric shipments while orders back up and deadlines slip

Customer Loss

End buyers receive products that fail within months, damaging your brand reputation

Experiencing structural issues with your current supplier? Let's diagnose the problem together.

Schedule Technical ConsultationOur Structural Engineering Approach

We've engineered a complete system for lasting structural integrity — from mesh design to weight selection to application-specific recommendations. Every variable is controlled to deliver predictable, reliable support.

Three Mesh Structures, Engineered for Purpose

Each mesh pattern delivers specific structural characteristics. Choose based on your support requirements and visual preferences.

Precision Support

Tighter hexagonal pattern creates smoother surface texture with enhanced stability. Ideal when the tulle layer may be visible or semi-visible in the final product.

Balanced Performance

Our most versatile option balances structural support with weight efficiency. The standard choice for most petticoat and underskirt applications.

Maximum Volume

Wider openings reduce weight while maintaining strong structural lines. Best for dramatic silhouettes where multiple layers build extreme volume.

Weight Selection Guide

Different applications demand different GSM levels. Use this reference to match weight specifications to your structural requirements.

Engineered for Specific Structural Demands

Petticoat & Underskirt

Multi-layer construction maintains A-line or ball gown silhouettes through extended wear and storage

Tutu & Dance Costume

Horizontal support layers that spring back after movement, maintaining form throughout performance

Stage & Installation

Architectural-grade stiffness for three-dimensional structures that hold shape without armature

Not sure which mesh and weight combination fits your project?

Request Sample SetWhy "Stiff" Often Means Uncomfortable

The stiff tulle industry has normalized problems that should never reach your production floor. Unpleasant odors, scratchy textures, and skin irritation aren't inherent to the material — they're symptoms of inadequate processing.

Three Processing Failures Behind Uncomfortable Fabric

When fabric arrives with chemical odors or rough edges, the manufacturer prioritized speed over finish quality. These shortcuts create immediate problems for close-body applications.

Low-Grade Stiffening Agents

Cheap chemical treatments create the infamous "fishy" smell. These compounds off-gas for weeks, making fabric unsuitable for enclosed retail environments or immediate use.

Single-Pass Drying

One-time drying fails to fully cure the stiffening treatment. Residual chemicals remain active, producing odors and causing skin sensitivity in some wearers.

Unfinished Edge Treatment

Cut edges without heat-sealing create sharp filament ends that scratch skin. This becomes a critical issue in petticoats and any fabric layer touching the body.

Where These Problems Hurt Most

Certain applications have zero tolerance for odor and texture issues. If you serve these markets, material quality is non-negotiable.

Bridal & Formal Wear

Brides notice every detail. Chemical odors on the wedding day create lasting negative memories associated with your product.

Children's Garments

Parents prioritize safety above all. Scratchy fabric or chemical smells trigger immediate product rejection and returns.

Performance Costumes

Dancers wear costumes for hours under hot stage lights. Any skin irritation affects performance and creates fitting complaints.

Tired of explaining fabric odors to frustrated customers?

See Our SolutionOdor-Free, Skin-Safe Stiff Tulle

We've eliminated the compromise between structural performance and wearer comfort. Our triple-process finishing system delivers stiff tulle that passes the strictest sensory standards for close-body applications.

Dual-Pass Drying

Our two-stage drying process fully cures stiffening agents and eliminates trapped moisture. No chemical residue means no off-gassing and no odor surprises when you open the shipment.

Odor-Controlled Formula

Premium stiffening agents replace the low-grade chemicals that cause fishy smells. Our formula achieves the same structural performance without the sensory problems that plague cheaper alternatives.

Soft-Edge Finishing

Heat-sealed cut edges eliminate sharp filament ends that scratch skin. This finishing step adds processing time but transforms usability for any application where fabric contacts the body.

The Bridal & Children's Wear Conversion Point

In high-sensitivity markets, fabric comfort isn't a feature — it's a requirement. Brides remember every detail of their wedding day. Parents reject any product that might irritate their child's skin. Our odor-free, soft-edge tulle converts these demanding buyers into repeat customers.

Perfect For Sensitivity-Critical Markets

When your end customers have zero tolerance for comfort issues, our processing standards protect your reputation.

Bridal Wear

All-day comfort for the most important dress

Children's Formal

Parent-approved safety for young wearers

Dance Costumes

Performs under stage lights without irritation

Retail Display

No off-gassing in enclosed showroom spaces

Want to test the difference for yourself? Request a sensory sample kit.

Order Sample KitWhere Batch Inconsistency Comes From

Every reorder feels like gambling. Stiffness levels shift, weights vary, colors don't match. These inconsistencies force your production team to constantly readjust — wasting time and creating quality variance in your finished products.

Typical Supplier: Batch-to-Batch Variation

Up to 50% weight variance on same SKU

Three Root Causes of Inconsistency

Multi-Factory Sourcing

Small suppliers subcontract to different factories per order. Each facility has different equipment, different calibration, different results.

Ad-Hoc Process Adjustments

Operators adjust machine settings based on intuition rather than documented standards. Yesterday's settings don't match today's.

No Structural Standards

Without documented specifications for mesh tension, GSM targets, and finishing parameters, "same product" means nothing.

The Hidden Costs of Batch Variance

Tired of re-testing every shipment? See how we guarantee consistency.

View Our SolutionOur Batch Control System

Consistency isn't luck — it's engineering. Our production system combines precision equipment with documented standards and pre-shipment verification to deliver identical results order after order.

KARL MAYER

German Precision

German KARL MAYER Warp Knitting

Our production runs exclusively on KARL MAYER warp knitting machines — the global standard for precision textile manufacturing. Computer-controlled tension systems maintain exact mesh geometry across millions of meters, eliminating the human error that causes batch variance.

Four-Step Consistency Protocol

Every order follows the same verification pathway to ensure batch-to-batch uniformity.

Recipe Lock

Machine parameters saved digitally for each SKU — tension, speed, temperature, timing

In-Line Testing

Automated GSM and tension checks during production catch variance before it compounds

Bulk Verification

Full batch sampling against reference standards before packaging begins

Pre-Ship QC

Final comparison to your approved sample with documented test results

Same Specs, Every Shipment — Guaranteed

We maintain reference samples for every SKU you order. Each bulk shipment is tested against your approved standard before release. If a batch doesn't match specification, we reproduce it at no additional cost. Your production team can rely on consistent inputs without re-testing every delivery.

Ready for predictable quality on every order?

Start With a Test OrderWhy Quality Stiff Tulle Seems Too Expensive

You've found suppliers with great samples, but the pricing doesn't work. MOQs force you to over-order. Unit costs eat your margins. This isn't because quality is inherently expensive — it's because most suppliers operate inefficiently.

Three Factors Inflating Your Costs

Traditional stiff tulle pricing reflects outdated production methods and fragmented supply chains. Understanding these cost drivers reveals opportunities for significant savings.

Inefficient Production Lines

Older equipment runs slower, wastes more material, and requires more manual intervention — costs passed directly to you.

Non-Replicable Processes

Without documented standards, every production run requires setup from scratch. This hidden time cost inflates your per-unit price.

Artificially High MOQs

Suppliers set high minimums to offset their inefficiency. You're forced to order more than needed, tying up capital in inventory.

Typical Cost Breakdown: Where Your Money Goes

25% of your cost is pure waste from inefficiency

How High Costs Limit Your Business

Can't Test New Products

High MOQs prevent small trial runs for new designs. You're stuck with proven sellers, missing market opportunities.

Margin Pressure

Material costs eat into profits, forcing price increases that make you less competitive in your market.

Capital Tied in Inventory

Over-ordering to meet MOQs locks cash in fabric sitting on shelves instead of growing your business.

Believe quality should be accessible at fair prices? So do we.

See Our Pricing ApproachLow Cost ≠ Low Standard

Quality stiff tulle doesn't have to break your budget. Our specialized production system eliminates the inefficiencies that inflate traditional pricing, delivering premium performance at accessible price points.

Our Philosophy: Efficiency Funds Quality

We don't cut corners on materials or processing to lower prices. Instead, we've invested in modern equipment, documented processes, and dedicated production lines that eliminate waste and rework. These efficiency gains translate directly to better pricing for you — without compromising the structural performance your products require.

Dedicated Production Lines

Our structural tulle runs on specialized equipment optimized for this product category. No changeover time, no calibration drift, no learning curve waste.

Structural Tulle at Scale

We've built volume in this specific category, achieving economies of scale that boutique suppliers can't match. Volume efficiency benefits every order size.

Flexible MOQ Structure

Our efficiency allows us to accept smaller orders profitably. You can test new products, serve niche markets, and manage inventory without forced over-ordering.

Cost Structure Comparison

Flexible MOQ Options

Order sizes that match your actual needs

Ready to see real pricing for your specific requirements?

Request Custom QuoteWhere Stiff Tulle Performs

Our structural tulle serves industries far beyond traditional bridal. Wherever three-dimensional shape and lasting support matter, our fabric delivers predictable, professional results.

Core Applications

These categories represent the majority of our production volume, with proven specifications for each use case.

Bridal & Formal Petticoats

Multi-layer underskirts that maintain ball gown silhouettes through ceremonies, receptions, and beyond. Our tulle holds volume without adding uncomfortable bulk.

Ballet Tutus & Dance Costumes

Horizontal support layers that spring back after every movement. Performance-grade stiffness for professional companies and dance academies worldwide.

Theatrical & Stage Productions

Dramatic costume structures that read from the back row. Heavy-duty construction for touring shows where durability matches visual impact.

Expanded Applications

Beyond fashion and performance, structural tulle solves three-dimensional challenges across diverse industries.

Window Display

Retail installations & visual merchandising

Exhibition Structures

Trade show booths & event architecture

Photography Props

Studio backgrounds & styled shoots

Bag & Hat Shaping

Internal structure for accessories

Home Décor

Decorative structures & lampshades

Children's Costumes

Recital & party dress support

Have a unique application? We'll help you find the right specification.

Discuss Your ProjectWho We Work Best With

Our products and processes are optimized for specific buyer profiles. We want to be transparent about where we add the most value — and where other suppliers might serve you better.

Ideal Customers

Structure-Critical Applications

You need fabric that maintains shape over time, not just on day one. Structural performance is non-negotiable.

Predictable Quality Requirements

You value consistency across orders. Your production relies on stable inputs to maintain product standards.

Professional Manufacturing Operations

You're a factory, workshop, or brand with ongoing production needs — not one-time craft projects.

Long-Term Partnership Mindset

You're looking for a reliable supplier relationship, not just the lowest spot-market price.

Not The Best Fit

Soft Drape Priority

If you need flowing, delicate fabric with minimal body, soft tulle or illusion is a better choice.

Extreme Budget Constraints

If absolute lowest cost matters more than performance, we're probably not the cheapest option available.

Retail/Consumer Purchases

We're set up for B2B wholesale, not small retail quantities for individual consumers.

One-Time Craft Projects

For single DIY projects, local craft stores offer more convenient small-quantity access.

Looking for soft tulle instead?

View Soft Tulle OptionsSound like a match? Let's start the conversation.

Check If We're Right For YouRelated Resources

Dive deeper into specific topics with our case studies and industry analysis. All content is organized around the same four core challenges you've seen on this page.

Case Studies

Real-world examples of how manufacturers solved specific challenges with our stiff tulle. Filterable by the problem they addressed.

Industry Analysis

Deep dives into why these problems exist across the stiff tulle industry, and the systemic factors that perpetuate them.

Product Category Navigation

Explore our complete structural fabric range

Can't find what you need? Our team can guide you.

Ask Our Product ExpertsWhich Challenge Are You Facing?

Tell us about your structural tulle requirements. Our technical team will analyze your needs and recommend the right specification within 24 hours.

What's Your Primary Concern?

Select all that apply — we'll address each one

Structure collapses or loses volume over time

Fabric has odor or uncomfortable hand feel

Batch-to-batch quality varies too much

Cost too high or MOQ doesn't fit my needs

Pro tip: The more detail you provide about your challenges, the more precisely we can match you with the right fabric specification.

Request Consultation

Get expert recommendations within 24 hours

Prefer to reach us directly?