Heavy-duty knit mesh fabric: Nylon & Polyester provides the ultimate structural foundation for high-stress industrial environments. Conventional textiles often succumb to mechanical fatigue, causing catastrophic equipment failure and expensive operational delays in manufacturing sectors. This vulnerability puts personnel at risk and drains corporate resources through constant repair cycles and material waste. By integrating a specialized thick mesh fabric, engineers can finally achieve a perfect balance between breathable airflow and extreme tensile durability.

Why use thick mesh fabric for industrial jobs?

Industries utilize this material because it offers an unparalleled combination of ventilation, visibility, and high-tenacity strength that standard solid weaves cannot match. Heavy-duty mesh is engineered to survive environments where high-tensile stress and abrasive contact are daily occurrences. It allows for heat dissipation while maintaining the structural integrity needed to support heavy loads or high-pressure airflow.

Defining the heavy-duty fabric grade

Think about it.

A heavy-duty grade is determined by the denier of the yarn and the specific density of the knit pattern used during production. These fabrics use high-tenacity synthetic polymers that are designed specifically to resist stretching under static weight. Unlike standard craft mesh, industrial grades undergo rigorous testing to ensure they meet safety certifications for load-bearing tasks.

The thickness of the yarn directly correlates to the fabric’s ability to resist piercing and tearing during rugged use. Manufacturers often apply specialized coatings to these thick fibers to enhance their resistance to chemicals and extreme temperatures. This ensures that the material does not degrade when exposed to the harsh realities of a factory floor or a construction site.

- High Denier Count: Utilizes thicker yarns for maximum puncture resistance.

- Warp-Knit Structure: Provides a stable base that resists unravelling.

- Reinforced Apertures: Ensures the holes in the mesh do not expand under tension.

- Polymer Density: Increases the overall weight-to-strength ratio of the material.

Survival against abrasive contact

It gets even better.

Abrasive resistance is a core requirement for any textile used in debris containment or protective barrier applications. Thick mesh creates a sacrificial layer that can withstand constant friction without losing its primary shape or structural capacity. This is particularly important in mechanical environments where moving parts may occasionally brush against the fabric housing.

The interlocking loops of the knit distribute the force of friction across a wider surface area to prevent localized thinning. By using high-resilience nylon or polyester, the fabric maintains a smooth profile that reduces the “catch” factor during contact. This longevity translates to fewer replacements and a significantly lower total cost of ownership for industrial facilities.

- Friction Distribution: Spreads wear across the entire knit surface.

- Smooth Fiber Finish: Reduces snags and premature fiber breakage.

- Heat Friction Resistance: Prevents the mesh from melting during high-speed contact.

- Impact Absorption: Softens the blow from flying industrial debris.

| Feature | Industrial Requirement | Performance Impact | |

|---|---|---|---|

| Fiber Strength | High-tenacity polymers | Prevents structural failure | |

| Knit Type | Warp-knitted Raschel | Ensures dimensional stability | |

| Airflow | High ventilation | Prevents overheating of equipment | |

| Abrasion | High-rub cycles | Extends lifespan in friction zones |

Key Takeaway: Thick mesh fabric provides the necessary mechanical strength to withstand industrial wear while maintaining essential ventilation.

How does thick mesh fabric improve durability?

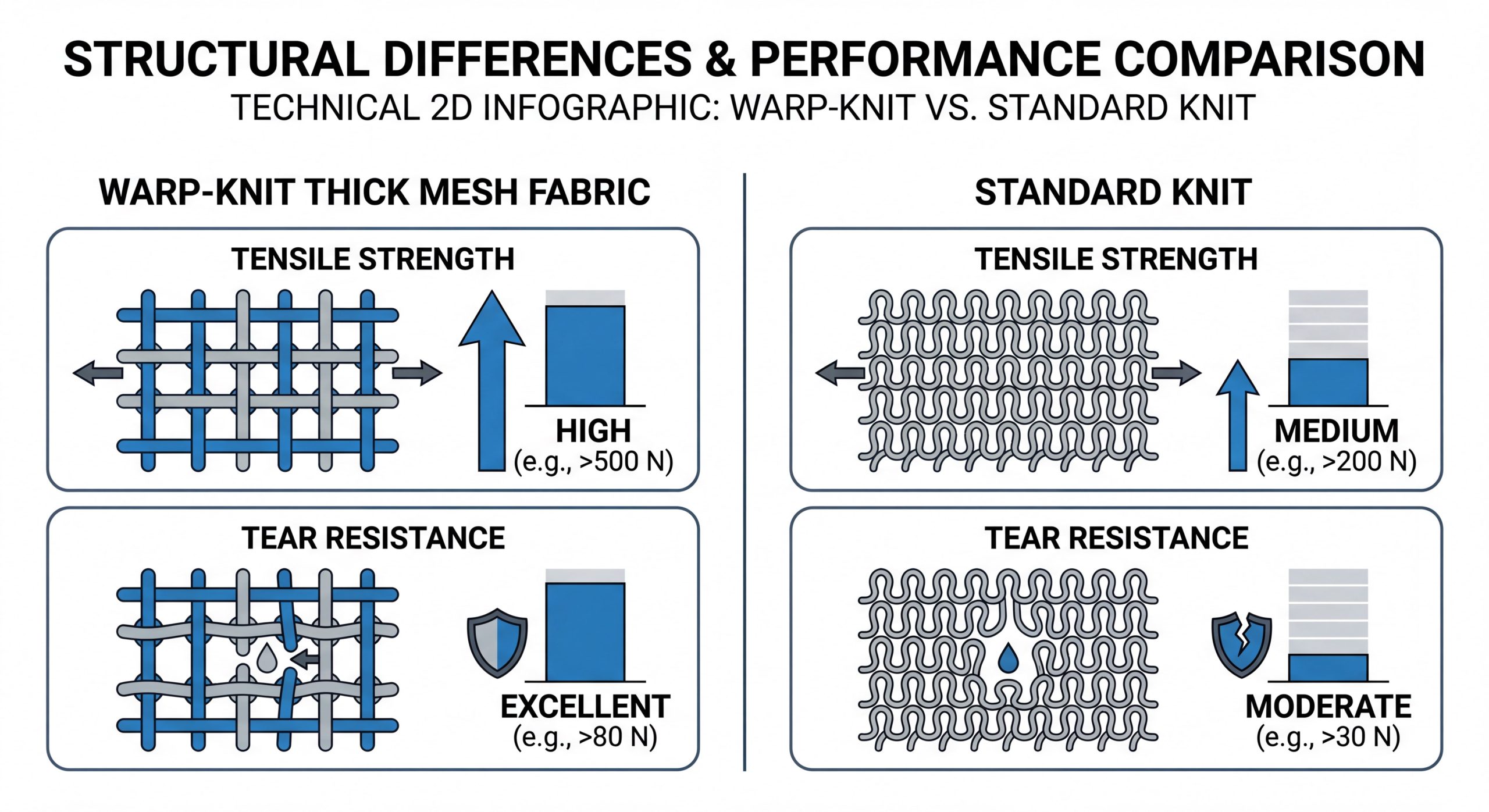

Durability is enhanced through the warp-knitting process which creates interlocking loops that prevent a thick mesh fabric from unravelling if a strand is damaged. This geometric configuration ensures that any localized tear remains isolated rather than propagating across the entire sheet. The result is a material that maintains its safety rating even after minor surface abrasions.

The science of warp knitting

But there is more to the story.

Warp knitting involves feeding multiple yarns simultaneously into the knitting machine to create a complex, zig-zagging pattern. This differs from standard weft knitting because the yarns run lengthwise, mimicking the strength of a woven fabric. The resulting “lock-stitch” effect means that every loop is supported by its neighbors in multiple directions.

This technique allows for the creation of various aperture shapes, such as hexagonal or diamond patterns, without sacrificing the edges. Because the loops are interlocked, the fabric can be cut into specific shapes without the need for immediate edge binding or hemming. This versatility makes it a favorite for custom-engineered industrial components.

- Multi-Yarn Feed: Enhances the density and strength of the mesh.

- Lock-Stitch Geometry: Prevents “runs” or catastrophic unravelling.

- Directional Stability: Provides equal strength across both horizontal and vertical axes.

- Custom Apertures: Allows for tailored airflow and visibility levels.

Why interlocked loops prevent tearing

Let’s dive deeper.

In a traditional textile, a single cut can lead to a complete structural collapse as the tension pulls the weave apart. Warp-knitted mesh resists this through its complex loop-within-loop architecture that traps the loose end of a broken fiber. Even under high tension, the surrounding loops tighten around the break to maintain the overall load path.

This “rip-stop” capability is vital for safety netting and cargo securing where a single failure could lead to loss of life or property. The thick nature of the fibers adds a secondary layer of protection by requiring significant force to actually sever a strand. This dual-layer defense makes it the most reliable choice for heavy-duty protection.

- Tension Redirection: Moves stress away from the site of a tear.

- Fiber Trapping: Holds broken strands in place to prevent spreading.

- Mechanical Locking: Uses the fabric’s own tension to secure the knit.

- Load Continuity: Maintains a path for weight distribution despite damage.

| Durability Factor | Impact on Longevity | Technical Benefit | |

|---|---|---|---|

| Tear Resistance | Prevents small snags from spreading | Isolated damage control | |

| Dimensional Stability | Maintains shape under heavy loads | No sagging or deformation | |

| Edge Integrity | Allows for clean cutting | Simplified manufacturing | |

| Knit Density | Resists piercing | Enhanced worker protection |

Key Takeaway: The structural complexity of a warp-knitted thick mesh fabric ensures it remains intact under extreme mechanical stress.

Is nylon the best thick mesh fabric for stretch?

Nylon is the premier choice for stretch applications because its polyamide fibers possess a unique molecular “memory” that allows them to return to their original shape. This elasticity is essential for products that must expand to accommodate a load and then contract for secure storage. It offers a soft hand-feel that makes it suitable for wearable safety gear and ergonomic supports.

Elasticity and physical recovery

You might be wondering how.

The molecular structure of nylon allows it to elongate significantly before reaching its breaking point. This high elongation factor means the fabric can absorb sudden shocks, such as a falling object being caught in a safety net. Once the force is removed, the internal bonds of the nylon pull the fibers back into their resting state.

This recovery capability prevents the “sagging” effect often seen in cheaper materials after they have been loaded. For industries that require repetitive stretching, such as in conveyor systems or flexible barriers, nylon provides a longer service life. It remains pliable even in cold environments where other synthetics might become brittle.

- High Elongation: Stretches further than polyester before failing.

- Shape Memory: Returns to original dimensions after load removal.

- Shock Absorption: Dampens the force of sudden impacts.

- Cold-Weather Pliability: Maintains flexibility in sub-zero temperatures.

Why bounce-back matters for safety gear

Here is the bottom line.

In safety applications like fall protection, the ability of a fabric to catch a person without snapping is the difference between safety and tragedy. The “bounce-back” or recovery ensures that the gear is ready for the next use without permanent deformation. Nylon’s high abrasion resistance also means that as it stretches and rubs against other components, it won’t thin out.

Safety harnesses and patient lift slings rely on this elasticity to provide a comfortable yet secure fit. The material contours to the shape of the object or person it is supporting, distributing pressure evenly. This reduces the risk of pressure points that could lead to injury or material failure under concentrated stress.

- Pressure Distribution: Contours to shapes for even weight loading.

- Reduced Peak Force: Lowers the impact on the anchor points.

- Surface Resilience: Resists thinning during the expansion phase.

- Ergonomic Comfort: Provides a softer interface for human contact.

| Property | Nylon Mesh Performance | Industrial Application | |

|---|---|---|---|

| Elasticity | Excellent recovery rate | Flexible safety barriers | |

| Softness | High comfort level | Wearable harnesses | |

| Abrasion | Very High resistance | Moving mechanical covers | |

| Dyeability | Absorbs color well | High-visibility safety gear |

Key Takeaway: When projects require flexibility and impact absorption, nylon-based thick mesh fabric is the industry standard.

Is polyester the right thick mesh fabric for UV?

Polyester is the superior choice for outdoor environments because it is inherently resistant to ultraviolet degradation and moisture absorption. When you need a thick mesh fabric for long-term sun exposure, polyester maintains its tensile strength far longer than nylon. It is a hydrophobic material, meaning it will not swell or lose its shape when saturated with water.

Shielding against sun and moisture

It is a game-changer.

The chemical bonds in polyester are exceptionally stable when bombarded by UV rays, preventing the “yellowing” and brittleness associated with sun damage. This makes it the ideal candidate for agricultural shading, truck tarps, and outdoor equipment covers. Because it does not absorb water, it also resists the growth of mold and mildew in humid climates.

In rain or heavy maritime spray, polyester mesh stays lightweight because it does not hold onto liquid. This prevents the overall system from becoming heavy and sagging under the weight of absorbed water. Its rapid-dry properties mean that maintenance crews can pack up equipment quickly without worrying about rot during storage.

- UV Stabilization: Naturally resists the breaking of polymer chains.

- Hydrophobic Nature: Repels water to prevent weight gain and rot.

- Color Fastness: Maintains high-visibility dyes even in direct sun.

- Thermal Stability: Resists shrinking or expanding with temperature shifts.

Maintaining strength in humid climates

That is just the beginning.

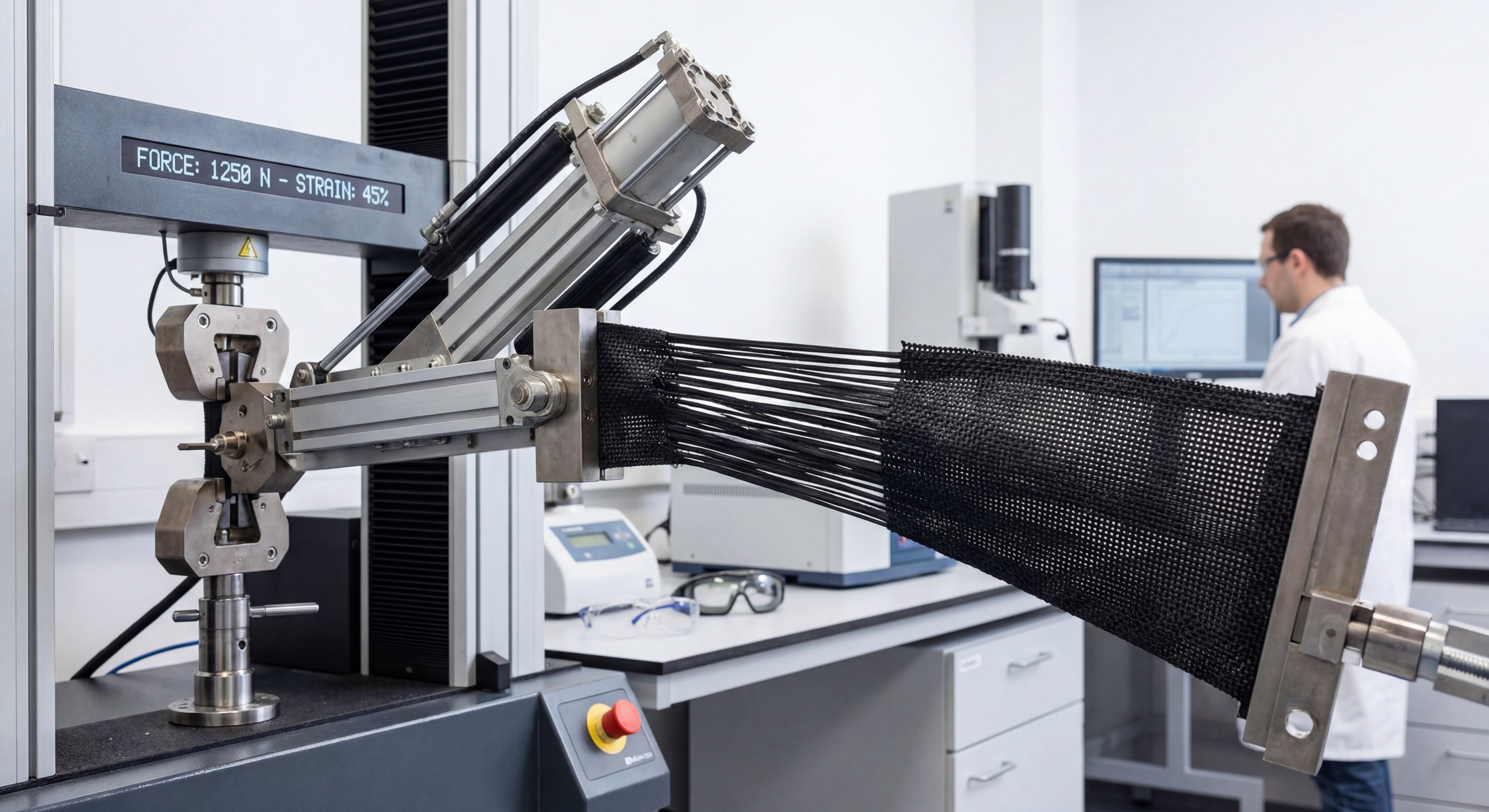

Humidity can cause many natural and some synthetic fibers to swell, which alters the aperture size and weakens the knit. Polyester remains dimensionally stable regardless of the moisture levels in the air. This precision is critical for filtration systems and architectural screens where the hole size must remain constant for performance.

The lack of moisture absorption also means that chemicals dissolved in water are less likely to penetrate the fiber core. This provides an additional layer of chemical resistance in industrial wash-down areas or chemical processing plants. Polyester continues to perform at peak capacity even in the most unforgiving tropical or marine environments.

- Dimensional Precision: Aperture sizes remain constant in wet air.

- Rot Resistance: Inorganic fibers provide no food for fungi.

- Chemical Shielding: Limits the penetration of aqueous contaminants.

- Tensile Retention: Loses virtually no strength when fully submerged.

| Environmental Factor | Polyester Resistance Level | Long-term Benefit | |

|---|---|---|---|

| UV Exposure | High (Resists degradation) | 5+ year outdoor lifespan | |

| Moisture | Hydrophobic (Dries rapidly) | Prevents mold and mildew | |

| Mildew/Mold | Naturally resistant | Reduced cleaning frequency | |

| Stability | Excellent (Low stretch) | Maintains tight fit on frames |

Key Takeaway: Polyester-based thick mesh fabric is the optimal solution for outdoor equipment, tents, and marine environments.

Can thick mesh fabric handle 1,500 lbs of weight?

Specially engineered mesh can easily support weights exceeding 1,500 lbs, making it a critical component in the medical and safety industries. While the fabric itself is lightweight and breathable, the high-tenacity fibers are woven into a structure that can support massive static and dynamic loads. This capability is most famously utilized in patient lift slings and heavy-duty industrial safety nets.

Engineering for patient lift slings

But wait, there’s more.

In a medical setting, a patient lift sling must be breathable to prevent skin irritation while being strong enough to lift bariatric patients safely. The mesh allows for water drainage during bathing and airflow during transport, ensuring the patient remains comfortable. Designers use multi-layer warp knitting to ensure that even if one layer is compromised, the secondary structure holds the weight.

These slings are tested to rigorous safety factors, often requiring them to hold several times their rated capacity before failure. The use of thick mesh ensures that the edges of the sling do not cut into the patient’s skin under tension. This combination of “soft” ergonomics and “hard” industrial strength is unique to high-grade synthetics.

- Bariatric Support: Rated for loads well over half a ton.

- Fluid Drainage: Essential for use in hospital bathing systems.

- Skin Breathability: Prevents heat rash and pressure sores.

- Double-Stitch Reinforcement: Adds security at critical load points.

Safety metrics for heavy lifting gear

The results are impressive.

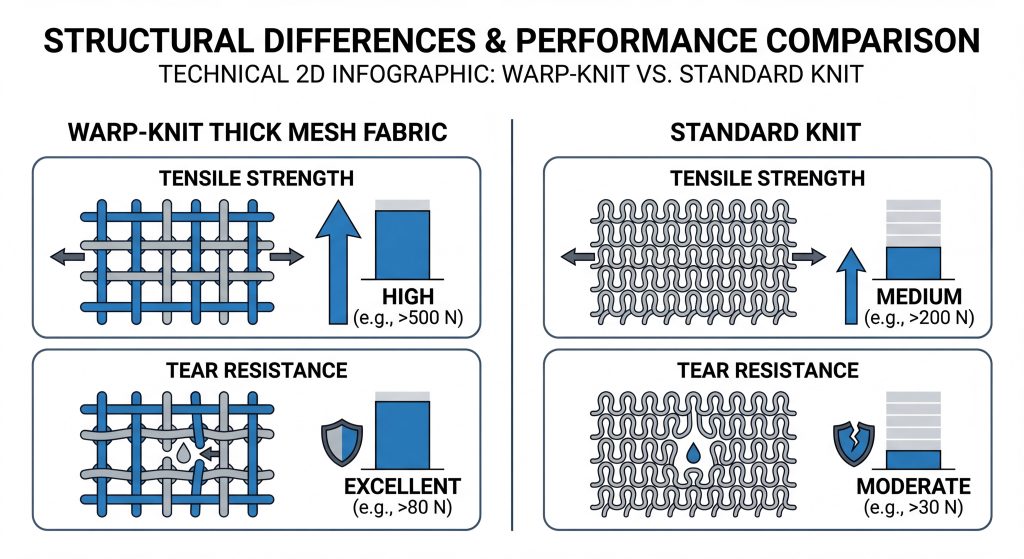

Safety metrics for mesh are calculated based on the break strength of individual strands multiplied by the density of the knit. For lifting gear, the material must also demonstrate low creep, meaning it won’t slowly stretch out over time while holding a load. Polyester is often favored here for its lack of stretch, providing a more predictable lift for operators.

Every batch of industrial mesh intended for lifting undergoes tensile testing to verify its “breaking point” in pounds per square inch. This data allows engineers to specify the exact type of mesh needed for overhead lifting versus side-loading barriers. The lightweight nature of the fabric reduces the strain on the mechanical lifting equipment itself.

- Creep Resistance: Maintains height and position under load.

- Breaking Point Testing: Verified through laboratory tensile pulls.

- Static Load Rating: Ensures safety during long-term suspension.

- Dynamic Load Rating: Accounts for movement and shifting weights.

| Application | Load Capacity (Typical) | Critical Metric | |

|---|---|---|---|

| Patient Slings | 600 – 1,500 lbs+ | Burst strength | |

| Safety Barriers | 2,000 lbs+ impact | Force absorption | |

| Industrial Netting | Multi-ton static | Tensile tenacity | |

| Harness Mesh | 310 lbs (standard) | Ergonomic fit |

Key Takeaway: Despite its lightweight appearance, engineered thick mesh fabric can support weights exceeding 1,500 lbs, making it vital for medical safety.

How to source thick mesh fabric for cargo nets?

Sourcing the right material involves choosing a thick mesh fabric that matches the specific weight and dimensions of the cargo being secured. Logistics managers prioritize polyester for cargo netting due to its minimal stretch, which keeps loads from shifting during transit. The aperture size must be small enough to contain the items but large enough to allow for easy inspection and airflow.

Securing loads with polyester netting

Here’s why this matters.

When a truck turns a corner or a ship encounters rough seas, the cargo inside experiences significant G-forces. If the netting stretches too much, the cargo will shift, potentially leading to a dangerous imbalance or damage to the goods. Polyester mesh acts as a rigid wall that “breathes,” keeping items firmly in place while allowing gas or moisture to escape.

The high-tenacity fibers are often treated with a resin finish to increase their stiffness and prevent the net from tangling during deployment. This makes it easier for workers to throw the net over a load and secure it quickly. The durability of the thick fibers ensures that the net can be used hundreds of times without fraying or losing its containment strength.

- Load Stabilization: Prevents shifting in high-vibration environments.

- Tangle Resistance: Resin coatings keep the net manageable.

- Quick Deployment: Lightweight material allows for one-person use.

- UV Durability: Essential for nets used on open truck beds.

Reducing damage during transport

The story gets even better.

Mesh is often preferred over solid tarps for cargo because it does not act like a sail in the wind. This reduces the “drag” on the vehicle, improving fuel efficiency and preventing the net from being ripped off by high-speed gusts. The open apertures allow wind to pass through while the thick strands keep the cargo locked down.

Furthermore, the soft nature of the synthetic fibers prevents the netting from scratching or denting the cargo itself. Unlike metal chains or wire rope, thick mesh distributes its holding force over a larger area of the cargo’s surface. This “soft-touch” security is vital for transporting electronics, finished furniture, or fragile industrial components.

- Wind Permeability: Reduces drag and prevents wind-rip.

- Surface Protection: Soft fibers will not mar delicate cargo.

- Force Distribution: Prevents crushing of the load’s corners.

- Visibility: Allows inspectors to see cargo without removing the net.

| Netting Feature | Benefit for Logistics | Operational Impact | |

|---|---|---|---|

| Small Apertures | Prevents small item loss | 100% containment | |

| Large Apertures | Maximum visibility | Faster inspections | |

| Polyester Fiber | Low stretch under tension | High load stability | |

| Resin Coating | Stiffness/Anti-tangle | Faster loading cycles |

Key Takeaway: Polyester thick mesh fabric is the top choice for cargo securing due to its dimensional stability and low-stretch properties.

Which thick mesh fabric works best for filtration?

The best fabric for filtration depends on the chemical nature of the fluid, with polyester excelling in acidic environments and nylon performing better in alkaline conditions. Industrial filtration requires absolute precision in aperture size to ensure that only particles of a specific micron level are allowed to pass. The thick strands of the mesh provide the structural support needed to withstand high-pressure fluid flow without deforming the holes.

Precision in aperture openings

Here is the deal.

Manufacturing a filtration mesh requires high-end warp-knitting machinery that can maintain tolerances down to the millimeter. Each hole must be identical to ensure consistent flow rates and filtration efficiency across the entire surface. If the apertures vary in size, the filter will fail to catch the target contaminants or will clog prematurely in specific areas.

Thick mesh is used in the “pre-filter” stage to catch large debris before it reaches finer, more delicate membranes. By using a heavy-duty material, the filter can be cleaned and reused multiple times using high-pressure air or water. This reduces the operational cost of the filtration system and minimizes the environmental impact of disposable filter cartridges.

- Micron Consistency: Ensures uniform particle separation.

- Flow Rate Control: Predictable apertures allow for precise engineering.

- Structural Reinforcement: Supports finer mesh layers under pressure.

- Reusability: High-strength fibers survive repeated cleaning cycles.

Chemical resistance in manufacturing

Think about it.

In chemical processing, the mesh is often exposed to caustic fluids that would dissolve standard fabrics in minutes. Polyester is highly resistant to most acids and organic solvents, making it the workhorse of the chemical industry. Nylon, conversely, is the go-to material for filtering bleach, soaps, and other alkaline substances that would degrade polyester.

The choice of material also affects how the mesh reacts to heat during the filtration process. Polyester has a higher melting point and better thermal stability, allowing it to be used in hot oil or steam filtration. Selecting the wrong material can lead to the filter melting into the product, causing expensive contamination and machine downtime.

- Acid Resistance: Polyester survives low-pH environments.

- Alkali Stability: Nylon handles high-pH cleaning agents.

- Thermal Range: Polyester supports high-temperature processing.

- Solvent Compatibility: Resists breakdown from industrial chemicals.

| Requirement | Material Choice | Industrial Context | |

|---|---|---|---|

| Acid Resistance | Polyester | Chemical processing | |

| Alkali Resistance | Nylon | Cleaning & Food service | |

| Uniformity | High-precision Warp Knit | Precision manufacturing | |

| Hot Filtration | Polyester | Oil & Steam systems |

Key Takeaway: The choice between nylon and polyester thick mesh fabric for filtration depends entirely on the chemical environment of the application.

Does thick mesh fabric offer antimicrobial benefits?

Thick mesh fabric can be infused with silver ions or treated with specialized coatings to inhibit the growth of bacteria, mold, and odor-causing microbes. This is particularly valuable when you need to thick mesh fabric for medical apparel or long-term outdoor use where hygiene is a concern. The open structure of the mesh already aids hygiene by allowing moisture to evaporate, but the antimicrobial treatment provides a secondary chemical barrier.

Silver ions and health safety

But there is more to the story.

Silver is a naturally occurring antimicrobial agent that disrupts the metabolic processes of bacteria upon contact. Manufacturers can embed silver particles directly into the polymer melt before the fibers are even extruded. This “built-in” protection does not wash off or wear out, providing permanent hygiene for the life of the fabric.

In healthcare settings, this technology is used in privacy curtains, equipment covers, and orthopedic braces. Because the mesh is thick and durable, it can withstand the harsh laundering protocols required in hospitals without losing its antimicrobial efficacy. This helps reduce the risk of cross-contamination in high-traffic patient areas.

- Permanent Integration: Silver ions are part of the fiber itself.

- Odor Control: Prevents the breakdown of sweat into smelly gasses.

- Biofilm Prevention: Stops bacteria from forming colonies on the mesh.

- Launderable: Withstands high-heat sterilization cycles.

Cleaning protocols for heavy mesh

It gets even better.

The open apertures of heavy-duty mesh make it much easier to clean than solid fabrics because soap and water can pass through the entire structure. Dirt and contaminants are not trapped between fibers, which reduces the time and energy required for maintenance. For industrial applications, a simple pressure wash is often enough to restore the mesh to its original condition.

If the fabric is treated with a hydrophobic coating, it will also resist staining from oils and dyes. This is vital for industrial scrub pads or filtration bags that are exposed to heavy pigments or greasy waste. A quick rinse removes the bulk of the material, while the antimicrobial agents ensure that any remaining residue does not become a breeding ground for germs.

- High-Flow Cleaning: Water flushes through the holes for deep cleaning.

- Stain Resistance: Specialized coatings repel industrial oils.

- Drying Speed: Open mesh prevents moisture from being trapped.

- Chemical Tolerance: Withstands strong disinfectants and bleaches.

| Benefit | Implementation | User Value | |

|---|---|---|---|

| Odor Control | Antimicrobial fiber finishes | Fresher gear for longer | |

| Pathogen Reduction | Infusion of silver ions | Enhanced medical safety | |

| Sterilization | Heat-resistant polymers | Hospital-grade hygiene | |

| Maintenance | Open-cell structure | 50% faster cleaning time |

Key Takeaway: Thick mesh fabric can be treated or infused with agents to prevent microbial growth, making it suitable for high-contact environments.

How to customize your thick mesh fabric order?

Customization allows you to specify the exact aperture shape, fabric weight, and chemical finishes needed for your unique industrial application. Manufacturers can adjust the tension of the knitting machines to create mesh that ranges from highly flexible to extremely rigid. You can also request specialized color-coding to help workers identify different weight-rated nets or filtration levels at a glance.

Choosing the right hole dimensions

Let’s dive deeper.

The shape of the hole—whether it is a square, a diamond, or a hexagon—affects the way the fabric stretches and its overall visual transparency. Hexagonal holes are often chosen for their aesthetic appeal and high strength-to-weight ratio, while square holes provide the best dimensional stability. A custom order allows you to match the aperture to the specific size of the particles you need to filter or the cargo you need to contain.

Furthermore, the “open area” percentage can be tuned to meet specific airflow requirements. If you are designing a cover for a cooling fan, you might need a 70% open area to prevent backpressure. For a sunshade, you might reduce that to 30% to maximize UV blockage while still allowing a breeze to pass through.

- Aperture Geometry: Square, Diamond, or Hexagonal options.

- Open Area Percentage: Tailors airflow and visibility levels.

- Micron Rating: Precise sizing for filtration needs.

- Edge Finishing: Request heat-slit or ultrasonic welded edges.

Selecting finishes and coatings

Think about it.

Raw nylon and polyester are excellent, but chemical finishes can transform them into high-performance tools. Flame retardant (FR) coatings are essential for any material used in construction or indoor industrial settings. You can also request stiffening resins that make the mesh act more like a rigid screen, or softening agents that make it comfortable against the skin.

Water-repellent coatings can be added to nylon to give it some of the hydrophobic properties of polyester. For military or high-security applications, infrared (IR) reflective coatings can be used to hide the mesh from night-vision devices. These custom additions ensure that your fabric order meets every technical specification of your project.

- Flame Retardancy: Meets NFPA or FAA safety standards.

- Stiffness Control: From soft drape to rigid screen-like feel.

- UV Boosters: Enhances the lifespan of nylon in the sun.

- Antistatic Finishes: Prevents sparks in explosive environments.

| Customization Option | Resulting Property | Target Industry | |

|---|---|---|---|

| Flame Retardancy | Self-extinguishing | Construction/Aviation | |

| Stiffness | Structural rigidity | Industrial screening | |

| Color Coding | Visual identification | Safety & Logistics | |

| Aperture Shape | Variable stretch | Fashion & Industrial |

Key Takeaway: Customizing thick mesh fabric allows for the optimization of specific traits like flame resistance or specialized stiffness.

Why choose thick mesh fabric for outdoor gear?

Outdoor gear designers choose this material because it provides the durability of a solid shell with the ventilation required for high-intensity activity. Whether it is used in tent panels, backpack suspension systems, or cooling vests, thick mesh ensures that the user remains protected without overheating. It is a lightweight solution that reduces the overall pack weight for hikers and professionals who work in the field.

Performance in tents and screens

Here is the bottom line.

A tent panel made from heavy-duty polyester mesh is strong enough to resist the claws of animals and the force of high winds. At the same time, it provides a crystal-clear view of the environment and allows for maximum cross-ventilation. This prevents the buildup of condensation inside the tent, which is a major cause of discomfort and gear degradation during long-term camping.

The “no-see-um” variants of thick mesh use a very tight knit to keep out the smallest insects while still being incredibly tough. Unlike cheap screen materials, industrial-grade tent mesh won’t sag or “bag out” over time. It maintains its tension on the tent poles, ensuring that the structure remains aerodynamic and visually appealing.

- Insect Protection: Keeps out pests without blocking the view.

- Condensation Control: Maximizes airflow to keep gear dry.

- Claw Resistance: Survives contact with wildlife and pets.

- Aerodynamic Stability: Maintains tension in high-wind zones.

Managing airflow and visibility

But there is more to the story.

Visibility is a safety feature in many outdoor applications, such as hunting or forest management. Thick mesh can be printed with camouflage patterns that hide the user while allowing them to see through the fabric perfectly. This “one-way” visibility is achieved by printing on the outer surface of the thick strands while keeping the apertures open.

For industrial workers in hot climates, mesh vests provide a way to carry heavy tools without trapping body heat. The thick strands provide the structural support needed for pockets and attachment loops, while the holes allow the body to cool through evaporation. It is the ultimate merger of heavy-duty utility and physiological comfort.

- Camouflage Integration: Supports high-detail outdoor printing.

- One-Way Visibility: See out clearly without being seen.

- Evaporative Cooling: Essential for high-heat labor.

- Load-Bearing Vests: Supports heavy tools via reinforced knit.

| Outdoor Metric | Performance | User Experience | |

|---|---|---|---|

| Airflow | High (Prevents condensation) | Cooler, drier interior | |

| Weight | Low (Ideal for trekking gear) | Faster movement, less fatigue | |

| Visuals | Clear (High-transparency) | Better situational awareness | |

| Strength | Rip-stop warp knit | Gear that lasts decades |

Key Takeaway: For outdoor applications, thick mesh fabric provides a breathable barrier that withstands the elements without adding bulk.

Conclusion

Heavy-duty nylon and polyester mesh fabrics represent the pinnacle of textile engineering for industrial, medical, and commercial use. Whether the priority is the UV resistance of polyester or the high-stretch recovery of nylon, selecting the correct material is the foundation of product safety and longevity. For those ready to source high-performance materials, exploring a comprehensive range of solutions and deciding to contact us today ( tullemesh.com ) is the first step toward project success.

FAQ

Can I use polyester mesh for high-temperature environments?Yes, polyester mesh is highly resistant to heat, though it is important to verify the specific melting point of the grade you are using, as most synthetics will melt under direct flame without FR treatment.

What’s the best way to clean heavy-duty nylon mesh?Nylon is hydrophilic and easy to clean with mild detergents; however, it should be dried at low temperatures to avoid damaging the fiber’s elasticity or causing the material to shrink.

How do I know if I need nylon or polyester for my project?If your project requires stretch, impact absorption, and abrasion resistance, choose nylon; if it requires UV resistance, low stretch, and dimensional stability in wet environments, choose polyester.

Can I get thick mesh fabric with flame-retardant properties?Yes, both nylon and polyester can be treated with flame-retardant (FR) finishes during the manufacturing process to meet specific safety standards like NFPA 701 or FAA requirements for aviation.

What is the most durable aperture shape for heavy loads?While all warp-knitted shapes are strong, hexagonal patterns often offer the best balance of strength-to-weight, whereas square apertures provide the highest level of dimensional stability for cargo containment.