Mesh fabric is a versatile, porous textile characterized by an open-weave or knit structure that creates a consistent pattern of interconnected holes. You may find that selecting the appropriate material for a specific project becomes overwhelming when standard textiles fail to provide the necessary breathability or structural transparency required for high-end applications. This technical gap often leads to product failure, where insufficient airflow causes discomfort in apparel or inadequate drainage complicates industrial processes. By exploring the vast array of different types of mesh fabric, you can identify specialized solutions that balance aesthetic elegance with rigorous mechanical performance.

How do different types of mesh fabric gain their structure?

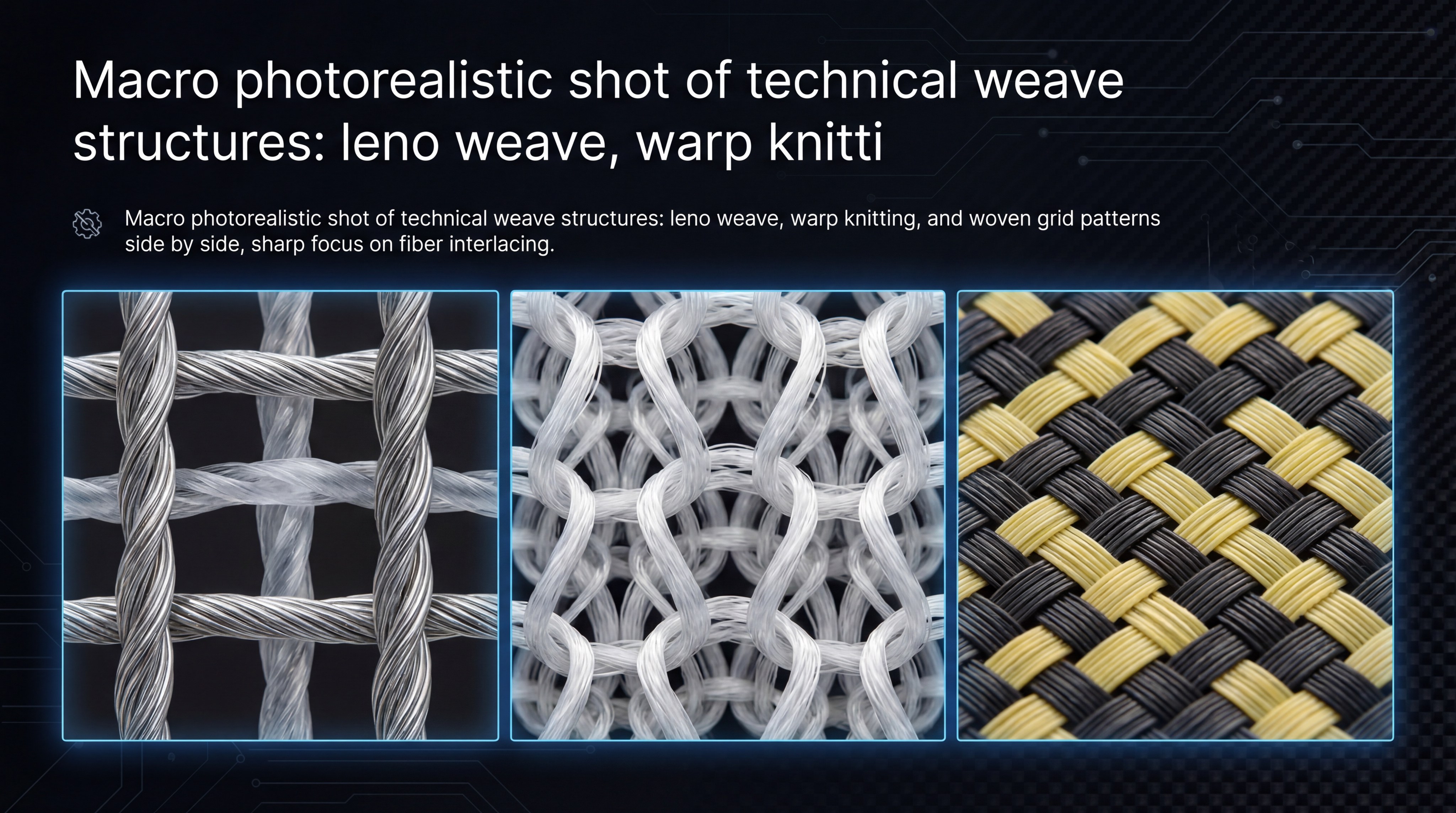

Different types of mesh fabric derive their fundamental structure from specialized weaving or knitting techniques that intentionally leave spaces between the yarns to form a grid-like appearance. You will notice that most modern mesh is produced through warp knitting, a process where the yarn zigzags along the length of the fabric rather than following a single row. This method ensures that the material remains ravel-resistant even when the open pores are subjected to significant stretching or friction during use. High-tenacity fibers are typically used to maintain the integrity of these holes, ensuring they do not collapse or distort under the physical pressure of manufacturing or daily wear.

Is the open weave essential for mesh?

The open weave is the defining characteristic of mesh because it facilitates maximum ventilation and lightness while retaining the structural strength of a solid textile. You should consider how the density of these openings dictates the fabric’s transparency and weight, which are critical factors in both fashion and technical design.

Check this out:

- Open-weave structures allow for immediate thermal regulation.

- The spacing of yarns determines the level of filtration or screening.

- Interconnected loops prevent the fabric from tearing easily at the edges.

The bottom line? Without this specific geometric spacing, a textile loses the moisture-management properties and the unique visual depth that professional designers rely on for complex layering.

Key Takeaway: The structural essence of mesh lies in its engineered porosity which facilitates airflow without sacrificing the mechanical durability of the textile grid.

How does warp knitting create mesh?

Warp knitting creates mesh by looping multiple parallel yarns simultaneously to form a stable, non-fraying structure that can support various hole shapes like hexagons or squares. You can observe this technique in high-durability applications where the fabric must stretch in multiple directions without losing its original shape or dimensions.

Think about this:

- Warp-knit machines handle thousands of individual yarns at once for efficiency.

- The resulting fabric is significantly more stable than weft-knit materials.

- Specialized patterns can be programmed to create varied aesthetic effects.

Simply put: Warp knitting is the gold standard for producing industrial-grade mesh because it offers the perfect combination of high-speed production and superior dimensional stability.

Key Takeaway: Warp knitting is the preferred manufacturing method for mesh due to its ability to create complex, stable, and tear-resistant open-pore patterns.

Why does hole size matter?

Hole size matters because it directly influences the fabric’s breathability, filtration capacity, and visual opacity in any given application. You must match the aperture dimensions to your specific needs, whether you are designing a fine bridal veil or a heavy-duty industrial safety net.

Believe it or not:

- Smaller holes provide more surface area for embellishments or printing.

- Larger holes maximize airflow for high-intensity athletic environments.

- Consistent hole size is a primary indicator of high-quality manufacturing.

Now, consider this: If the hole size is inconsistent across the roll, the fabric will suffer from weak points that lead to premature tearing under load.

Key Takeaway: Selecting the correct aperture size is critical for balancing the functional requirements of ventilation against the aesthetic needs of the final product.

| Structural Feature | Impact on Performance | Common Application | |

|---|---|---|---|

| Warp Knit | High stability and ravel resistance | Performance activewear | |

| Hexagonal Pore | Superior multidirectional stretch | Luxury bridal veils | |

| Large Aperture | Maximum airflow and lightness | Industrial filtration |

The structural integrity of mesh is determined by the precision of its knitting pattern, which ensures that the open pores remain functional and aesthetically pleasing over time.

Why use different types of mesh fabric in activewear?

Different types of mesh fabric are utilized in activewear primarily because they provide unparalleled ventilation and moisture management for athletes performing under high physical stress. When you incorporate different types of mesh fabric from into sportswear designs, you are effectively creating “chimneys” for heat to escape the body. This prevents the buildup of sweat and reduces the risk of overheating, which is a major factor in maintaining peak athletic performance during long training sessions. Furthermore, the lightweight nature of synthetic mesh ensures that the garment does not become heavy or restrictive even when it is damp with perspiration.

Does breathability improve performance?

Breathability directly improves performance by regulating the wearer’s core temperature and reducing the physiological strain caused by heat retention. You will find that athletes can sustain high levels of exertion for longer periods when their clothing facilitates the rapid evaporation of moisture from the skin’s surface.

The best part?

- Improved airflow leads to a lower perceived rate of exertion.

- Drier skin reduces the likelihood of chafing and skin irritation.

- Lightweight materials allow for a full, unrestricted range of motion.

Truth be told: If you ignore the breathability of your fabric, you are essentially asking your users to perform in a vacuum-sealed environment that stifles their natural cooling mechanisms.

Key Takeaway: High breathability is the most critical performance metric for activewear, as it maintains thermal comfort and prevents early fatigue.

How does moisture-wicking work?

Moisture-wicking works by utilizing capillary action to pull sweat away from the body and toward the outer surface of the fabric where it can evaporate quickly. You can enhance this effect by choosing mesh made from hydrophobic fibers like polyester, which do not absorb water into the core of the yarn.

Check this out:

- Hydrophobic fibers push water toward the large pores of the mesh.

- The open structure increases the surface area exposed to the air.

- Fast drying times keep the garment feeling light throughout the workout.

The bottom line? Combining moisture-wicking fibers with a mesh weave creates a dual-action system that manages sweat far more effectively than traditional solid-knit textiles.

Key Takeaway: Effective moisture management in mesh depends on the combination of hydrophobic synthetic fibers and an open-weave structure that promotes evaporation.

| Property | Benefit for Athletes | Fiber Type | |

|---|---|---|---|

| Air Permeability | Prevents heat exhaustion | Polyester Mesh | |

| Low Absorbency | Keeps clothing light and dry | Nylon Mesh | |

| High Elasticity | Allows for dynamic movement | Spandex Blends |

Activewear depends on the specific ventilating properties of mesh to ensure that high-intensity movements do not lead to discomfort or thermal failure.

How are different types of mesh fabric manufactured?

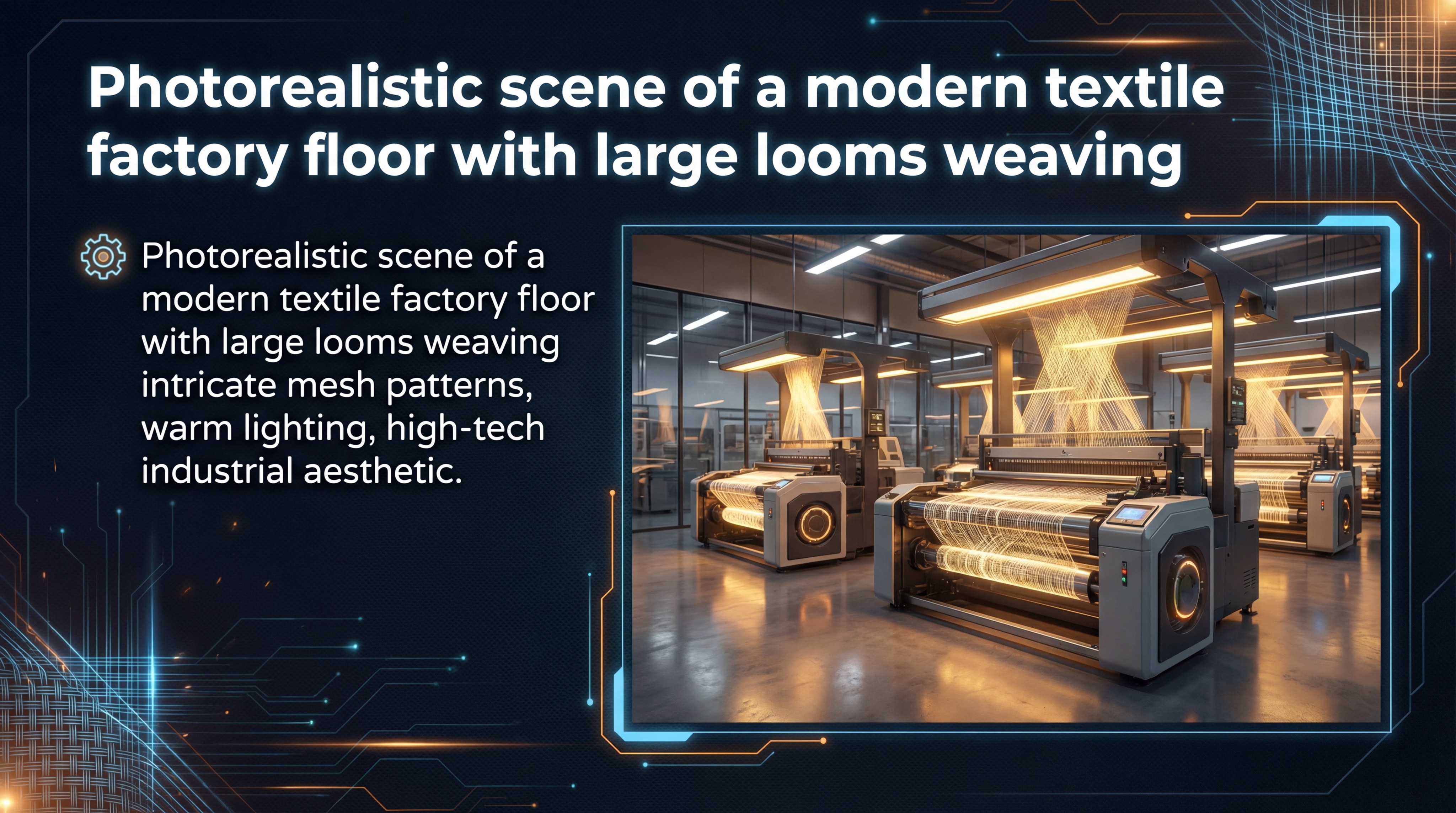

Different types of mesh fabric are manufactured using high-speed industrial looms and knitting machines that precisely interlace synthetic or natural yarns into an open-grid pattern. You will see that the production line often begins with the extrusion of polymer resins into long, continuous filaments of polyester or nylon. These filaments are then wound onto large beams and fed into warp-knitting machines, where thousands of needles work in unison to create the interconnected loops of the mesh. After the knitting phase, the fabric undergoes a heat-setting process to ensure that the hole shapes remain permanent and the material does not shrink during future washing cycles.

What is the role of heat setting?

Heat setting is a crucial post-knitting process that uses high temperatures to stabilize the molecular structure of synthetic fibers, locking the mesh pattern into its final dimensions. You must understand that without heat setting, a mesh fabric would likely distort or lose its elasticity the first time it is exposed to heat in a dryer.

Here’s the deal:

- It prevents the fabric from curling at the edges during cutting.

- It ensures that hexagonal or diamond pores maintain their symmetry.

- It improves the overall “hand” or softness of the synthetic material.

Simply put: Heat setting is the difference between a professional-grade textile and a cheap material that loses its shape after a single use.

Key Takeaway: Thermal stabilization through heat setting is essential for maintaining the dimensional integrity and aesthetic consistency of synthetic mesh products.

How is the dyeing process managed?

The dyeing process for mesh is typically managed through high-pressure “jet dyeing” or “beam dyeing,” where the fabric is submerged in a heated dye bath to ensure complete color penetration. You will find that because mesh is so porous, it accepts dyes very evenly, resulting in vibrant colors that resist fading over time.

Wait, there’s more:

- Pre-treating the fibers can increase their affinity for specific pigments.

- Pressure dyeing allows the color to reach the very center of the knit loops.

- Special coatings can be applied during this stage for UV or water resistance.

The best part? Modern dyeing techniques are increasingly efficient, reducing water consumption while delivering deep, saturated tones across even the largest production runs.

Key Takeaway: High-pressure dyeing techniques ensure that mesh fabrics achieve uniform color saturation and long-lasting vibrancy across their open-weave structure.

| Production Stage | Purpose | Technical Detail | |

|---|---|---|---|

| Extrusion | Creating the base fiber | Melt-spinning polymer resins | |

| Warp Knitting | Forming the mesh grid | Multi-needle loop interlacing | |

| Finishing | Surface optimization | Anti-microbial or flame-retardant treatments |

The manufacturing of mesh is a highly technical sequence of extrusion, knitting, and stabilization that results in a high-performance material with specific geometric properties.

Which different types of mesh fabric suit luxury bridal?

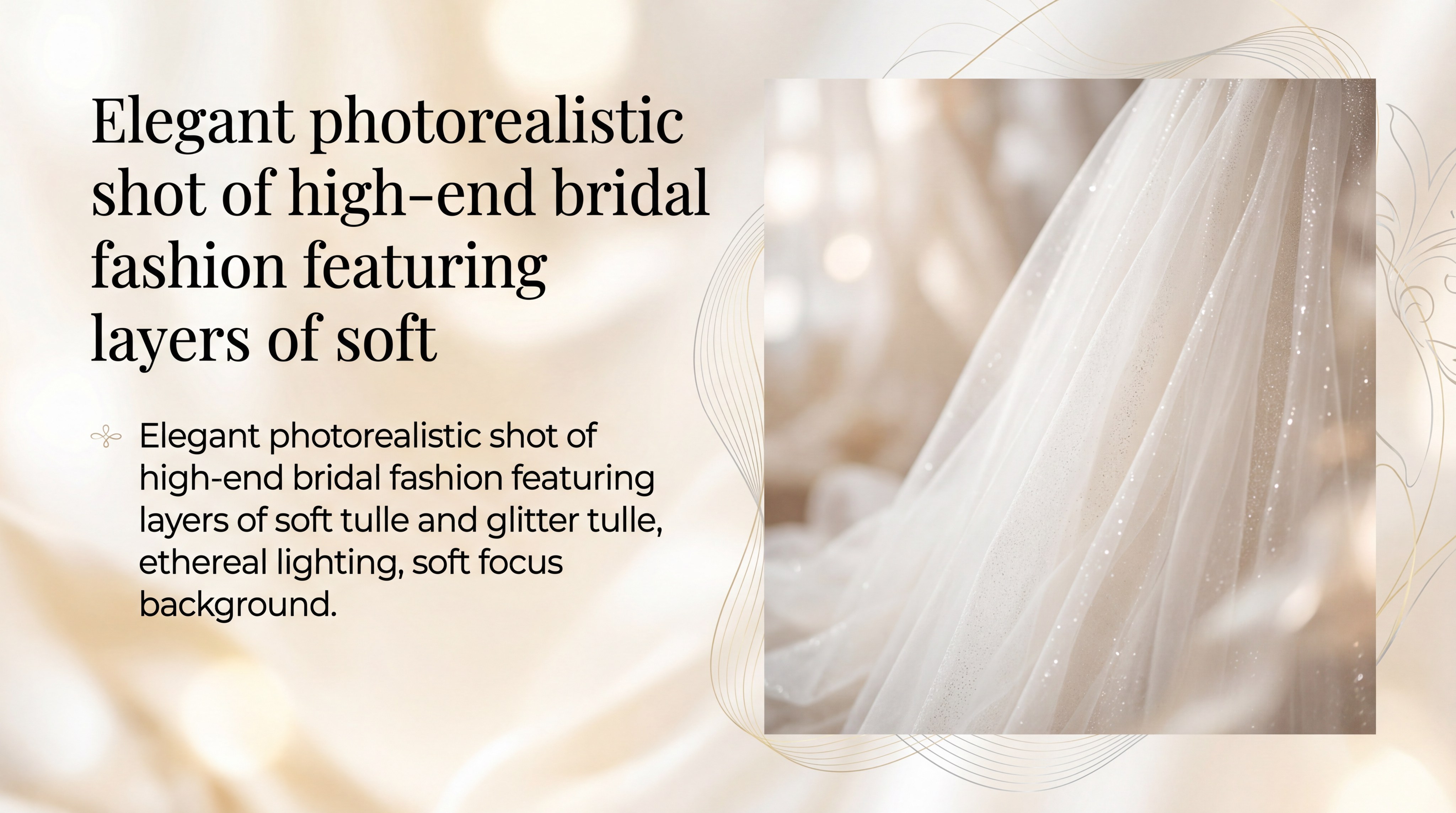

Which different types of mesh fabric suit luxury bridal designs often depends on the desired level of “poof,” transparency, and the specific drape required for the gown’s silhouette. When you explore the bridal tulle fabric , you will discover that soft tulle and fine netting are the primary choices for high-end wedding attire. These fabrics offer a delicate, ethereal quality that can be layered to create volume without adding excessive weight to the wearer’s ensemble. Additionally, premium bridal mesh is often treated to have a silk-like feel, ensuring that it is comfortable against the skin while maintaining its architectural shape.

Why is soft tulle so popular?

Soft tulle is popular because it provides a romantic, cloud-like aesthetic that is perfect for veils, overlays, and voluminous skirts in bridal fashion. You will appreciate how this fine-gauge mesh catches the light, creating a soft-focus effect that enhances the overall elegance of a wedding gown.

Believe it or not:

- Soft tulle has a much finer mesh count than standard craft netting.

- It drapes gracefully without the “crunchy” feel of cheaper materials.

- The material is incredibly strong despite its sheer, delicate appearance.

Now, consider this: Using a high-quality soft tulle ensures that the bridal veil flows naturally with the bride’s movement rather than standing stiffly.

Key Takeaway: Soft tulle’s unique combination of extreme lightness and graceful drape makes it the indispensable fabric for creating high-end bridal silhouettes.

Can glitter mesh be used elegantly?

Glitter mesh can be used elegantly by incorporating microscopic shimmer particles into the mesh structure during the manufacturing process, rather than simply spraying them on the surface. You should look for glitter tulle that uses bonded sparkle to ensure that the effect is subtle and does not shed excessively during the event.

Check this out:

- Bonded glitter provides a multi-dimensional sparkle under evening lights.

- It adds a layer of modern luxury to traditional ballgown designs.

- High-end versions maintain the softness of the base mesh fabric.

The bottom line? When applied correctly, glitter mesh transforms a simple garment into a show-stopping piece of wearable art that sparkles with every step.

Key Takeaway: Elegant glitter mesh relies on advanced bonding techniques to provide a sophisticated shimmer that enhances rather than overwhelms the bridal design.

| Bridal Mesh Type | Visual Effect | Best Used For | |

|---|---|---|---|

| Soft Tulle | Matte, ethereal glow | Multi-layered skirts and veils | |

| Glitter Mesh | Sparkling, radiant finish | Bodice overlays and accent layers | |

| Point d’Esprit | Vintage, textured dots | Retro-style veils and sleeves |

Luxury bridal fashion utilizes the delicate transparency of specialized mesh to create volume and visual interest that would be impossible to achieve with solid textiles.

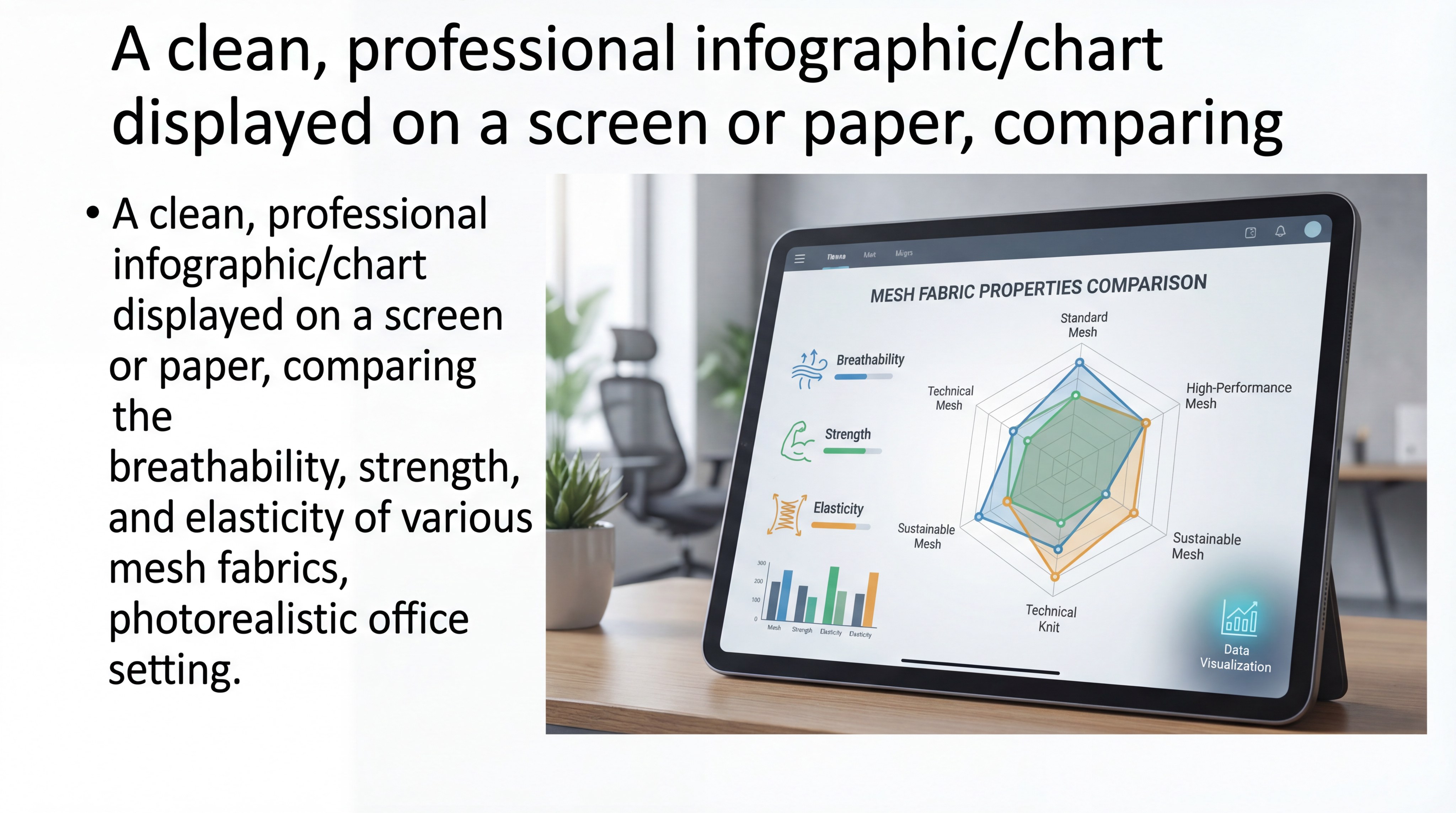

What defines different types of mesh fabric performance?

Different types of mesh fabric performance are defined by a combination of tensile strength, elasticity, air permeability, and resistance to environmental degradation. You can evaluate these metrics by looking at the fabric’s denier, which measures the thickness of the individual fibers used in the weave. A higher denier typically indicates a stronger, more durable mesh that can withstand industrial loads, while a lower denier suggests a softer, more breathable material suitable for apparel. Furthermore, the chemical composition of the fibers—whether they are polyester, nylon, or a recycled polymer—determines how the fabric reacts to UV exposure and moisture.

How is tensile strength measured?

Tensile strength is measured by determining the maximum amount of pulling force a mesh fabric can withstand before it breaks or permanently deforms. You must prioritize this metric if you are selecting different types of mesh fabric for load-bearing applications like safety nets or heavy-duty gear bags.

Think about this:

- High-tenacity yarns significantly boost the overall strength of the grid.

- Reinforced edges can prevent the mesh from unraveling under high tension.

- The density of the knit loops determines the distribution of the force.

Simply put: A mesh fabric with high tensile strength is an insurance policy against product failure in demanding physical environments.

Key Takeaway: Tensile strength is the primary indicator of a mesh fabric’s ability to endure mechanical stress without compromising its structural grid.

Does UV resistance matter for mesh?

UV resistance matters immensely because the high surface area of mesh makes it particularly susceptible to “sun-rotting,” where the plastic bonds in the fibers break down under sunlight. You will find that polyester mesh inherently offers better UV resistance than untreated nylon, making it the superior choice for outdoor applications.

Check this out:

- UV-stabilized coatings can double the lifespan of outdoor mesh.

- Color fading is often the first sign of UV damage in synthetic fabrics.

- Polyester maintains its strength longer when exposed to direct sunlight.

The bottom line? If your project will be used outdoors, ignoring UV resistance will lead to a brittle, faded material that fails within a few months of exposure.

Key Takeaway: Selecting UV-resistant fibers or treatments is essential for any mesh fabric intended for long-term outdoor or high-exposure use.

| Performance Metric | Evaluation Method | High-Performance Standard | |

|---|---|---|---|

| Air Permeability | Cubic feet per minute (CFM) | > 200 CFM for activewear | |

| Burst Strength | Ball burst test (PSI) | > 100 PSI for industrial netting | |

| Color Fastness | ISO 105-B02 Grade | Grade 4 or higher |

Evaluating mesh performance requires a detailed look at the mechanical and chemical properties that allow the fabric to function in its intended environment.

Where are different types of mesh fabric used in industry?

Different types of mesh fabric are used in industry for a wide range of technical applications including filtration, safety containment, and heavy-duty cargo transport. When you source different types of mesh fabric, you are often looking for materials that can handle extreme temperatures or chemical exposure. In the automotive sector, mesh is frequently used as a substrate for seat reinforcement or as a protective barrier in engine compartments to allow for airflow while blocking debris. Similarly, the construction industry relies on high-visibility mesh for debris netting and safety fences that must withstand harsh weather conditions on the job site.

Why is mesh used in filtration?

Mesh is used in filtration because its precisely engineered hole sizes allow it to act as a sieve, capturing specific particles while letting liquids or gases pass through freely. You can customize the filtration level by selecting a mesh with a specific “micron rating,” which indicates the size of the smallest particle the fabric will trap.

The best part?

- Synthetic mesh is resistant to most oils and chemicals.

- It can be easily cleaned and reused in many industrial settings.

- The rigid structure of the weave prevents the filter from collapsing.

Truth be told: Without the precision of modern mesh weaving, many industrial purification processes would be significantly less efficient and more expensive.

Key Takeaway: The ability of mesh to provide consistent, repeatable particle separation makes it the ideal material for high-precision industrial filtration.

How does safety netting protect workers?

Safety netting protects workers by providing a high-strength, flexible barrier that can catch falling objects or prevent personnel from falling into dangerous areas. You will find that these nets are made from high-tenacity polyester or nylon, which can absorb the kinetic energy of a fall without snapping.

Wait, there’s more:

- The open weave allows wind to pass through, reducing the load on the structure.

- Bright colors ensure that the safety barrier is visible from a distance.

- Knotless mesh designs are often preferred for their superior impact resistance.

Now, consider this: A properly installed safety mesh is one of the most cost-effective ways to manage risk on a large-scale industrial or construction project.

Key Takeaway: Industrial safety mesh uses its structural flexibility and high tensile strength to provide a reliable life-saving barrier in hazardous environments.

| Industrial Use | Key Requirement | Preferred Mesh Type | |

|---|---|---|---|

| Automotive | Heat resistance | Glass-fiber reinforced mesh | |

| Construction | High visibility | PVC-coated polyester mesh | |

| Agriculture | Pest control | Fine-gauge insect mesh |

Industrial applications leverage the unique mechanical advantages of mesh to solve complex challenges in safety, transport, and manufacturing.

Can different types of mesh fabric be sustainable?

Different types of mesh fabric can be sustainable when they are manufactured from recycled post-consumer plastics or bio-based polymers that reduce the reliance on virgin petroleum. You can now find high-performance mesh made from “rPET” (recycled polyester), which is created by melting down old water bottles and spinning them into new textile fibers. This process uses significantly less energy and water than traditional manufacturing and helps divert plastic waste from landfills and oceans. Furthermore, many textile factories are now adopting “closed-loop” systems where water and dyes are recycled within the plant to minimize the environmental footprint of the production process.

Is recycled polyester as strong?

Recycled polyester is just as strong as virgin polyester because the chemical structure of the polymer remains unchanged during the recycling process. You should feel confident using recycled mesh for high-stress applications, as it undergoes the same rigorous testing for tensile strength and durability as its non-recycled counterparts.

Check this out:

- rPET fibers have the same moisture-wicking properties as virgin fibers.

- They can be dyed in the same vibrant colors without any loss in quality.

- Using recycled materials significantly lowers your brand’s carbon footprint.

The bottom line? Choosing recycled mesh is a “win-win” that provides high-performance results while supporting global sustainability initiatives.

Key Takeaway: Recycled polyester mesh offers identical performance characteristics to virgin materials while providing a much more sustainable life cycle.

What are bio-based mesh options?

Bio-based mesh options are made from renewable resources like corn starch, sugarcane, or castor oil instead of fossil fuels. You will find that these materials are often biodegradable or compostable, offering a “cradle-to-grave” solution for temporary applications like agricultural netting or event decorations.

Here’s the deal:

- Bio-based polymers reduce greenhouse gas emissions during production.

- They offer a soft, natural hand-feel compared to traditional synthetics.

- Innovation in this field is rapidly expanding the strength of bio-fibers.

Simply put: Bio-based mesh represents the future of the textile industry, moving away from petroleum-based plastics toward renewable, earth-friendly alternatives.

Key Takeaway: Bio-based mesh materials provide an eco-friendly alternative for brands looking to minimize their environmental impact through renewable sourcing.

| Sustainability Feature | Environmental Impact | Key Advantage | |

|---|---|---|---|

| Recycled Content (rPET) | Reduces plastic waste | Same strength as virgin polyester | |

| Water-Free Dyeing | Eliminates chemical runoff | Better for the local ecosystem | |

| Biodegradability | Prevents long-term landfill build-up | Ideal for temporary use |

Sustainability in the mesh industry is no longer a niche market but a core requirement for modern brands looking to combine performance with ethical production.

How to select different types of mesh fabric by fiber?

To select different types of mesh fabric by fiber, you must first understand the fundamental differences between the two most common materials: polyester and nylon. When you browse different types of mesh fabric at https://tullemesh.com/soft-tulle , you should consider that polyester is typically stiffer, more UV-resistant, and better at moisture-wicking. In contrast, nylon is generally softer to the touch, more elastic, and offers superior abrasion resistance, making it the ideal choice for items that will rub against the skin. By identifying whether your priority is structural stability or tactile comfort, you can make an informed decision that enhances the longevity and usability of your product.

When is polyester the best choice?

Polyester is the best choice when your project requires a material that will not stretch out of shape and must endure significant exposure to sunlight or moisture. You will find that polyester does not absorb water, which means it dries faster and remains lightweight even in humid or rainy environments.

The best part?

- Polyester is more affordable than high-quality nylon for large-scale runs.

- It holds vibrant colors and printed designs exceptionally well.

- The fibers are naturally resistant to mildew and biological growth.

Truth be told: For outdoor gear and industrial applications, polyester is almost always the superior fiber due to its “workhorse” durability and environmental resistance.

Key Takeaway: Polyester mesh is the preferred choice for applications requiring high dimensional stability, UV resistance, and cost-effectiveness.

Why choose nylon for apparel?

Nylon is the preferred choice for apparel because its fibers are smoother and more flexible, providing a luxurious “hand” that feels comfortable against the body. You should opt for nylon mesh for lingerie, high-end sportswear, or any garment where the fabric needs to move and stretch with the wearer.

Check this out:

- Nylon has a natural sheen that gives a premium look to fashion items.

- It is more resistant to pilling than many other synthetic fibers.

- The superior stretch-and-recovery ensures the garment keeps its fit.

The bottom line? If comfort and aesthetics are your top priorities, nylon mesh provides a level of sophistication that polyester simply cannot match.

Key Takeaway: Nylon mesh’s softness and elasticity make it the gold standard for intimate apparel and high-end fashion garments.

| Fiber Property | Polyester Mesh | Nylon Mesh | |

|---|---|---|---|

| Stretch | Low to Moderate | High | |

| UV Resistance | Excellent | Moderate | |

| Hand Feel | Textured/Stiff | Smooth/Soft |

Choosing the right fiber is a strategic decision that balances the mechanical requirements of the project against the sensory experience of the end-user.

What textures do different types of mesh fabric offer?

Different types of mesh fabric offer a diverse range of textures from the abrasive roughness of heavy-duty industrial screens to the silky smoothness of fine bridal tulle. You will find that the texture is largely determined by the thickness of the yarn (denier) and the specific pattern of the knit or weave. A “honeycomb” mesh, for instance, provides a three-dimensional depth that feels padded and structured, making it popular for backpack straps and shoe linings. Conversely, a “flat” mesh has a more two-dimensional surface that is ideal for screen printing or as a base for intricate embroidery.

What is 3D spacer mesh?

3D spacer mesh is a specialized textile that consists of two layers of mesh joined by a vertical layer of spacer yarns, creating a breathable, cushioned structure. You will encounter this texture in high-performance applications where air circulation must be maintained even under compression, such as in ergonomic office chairs or athletic footwear.

Think about this:

- It acts like a shock absorber while remaining completely breathable.

- The internal air pocket provides natural thermal insulation.

- It is much lighter than solid foam padding and won’t trap moisture.

Simply put: Spacer mesh is an engineering marvel that replaces traditional foam with a more hygienic and ventilating alternative.

Key Takeaway: 3D spacer mesh provides essential cushioning and airflow in a single, lightweight textile layer, revolutionizing ergonomic design.

How does power mesh feel?

Power mesh has a distinct, firm texture with a high percentage of spandex, providing a strong “compression” feel that is used to shape and support the body. You will notice that while it is sheer and lightweight, it has a significant amount of “kickback” or resistance when stretched.

Believe it or not:

- It is a staple in the swimwear and shapewear industries.

- The fine knit structure is smooth enough to go under other fabrics.

- It provides support without the bulk of traditional elastic bands.

Now, consider this: The unique texture of power mesh allows it to perform the work of a heavy support garment while remaining virtually invisible to the eye.

Key Takeaway: Power mesh combines transparency with high-recovery elasticity, making it the perfect material for body-sculpting and support garments.

| Texture Type | Physical Sensation | Common Use Case | |

|---|---|---|---|

| Honeycomb | Structured, grippy | Sports equipment lining | |

| Diamond Tulle | Fine, slightly crisp | Wedding veils | |

| Tricot Mesh | Smooth, flat | Inner lining of jackets |

Texture plays a vital role in both the functionality and the perceived quality of a mesh fabric, influencing everything from grip to skin comfort.

How to care for different types of mesh fabric properly?

How to care for different types of mesh fabric properly involves protecting the open-weave structure from snagging or melting during the cleaning and drying process. When you wash, you must avoid high heat and sharp objects like zippers or Velcro that can easily catch on the holes. It is generally recommended to use a delicate cycle with cold water and a mild detergent to preserve the integrity of the synthetic fibers. For high-end bridal or decorative mesh, hand washing is often the safest method to ensure that delicate embellishments or fine pores are not damaged by the mechanical action of a washing machine.

Should you use a laundry bag?

Using a mesh laundry bag is the single most important step you can take to prevent your mesh garments from being ruined during a wash cycle. You will find that the bag acts as a protective shield, keeping the fabric from twisting or getting snagged on the machine’s agitator or other clothing items.

Wait, there’s more:

- It prevents fine tulle from getting tangled with heavy jeans or towels.

- Small laundry bags can also be used to keep pairs of socks together.

- A high-quality bag is a tiny investment that saves expensive apparel.

The best part? You can use a larger mesh bag to wash multiple items at once, ensuring that all your delicates stay in pristine condition.

Key Takeaway: A dedicated laundry bag is essential for protecting the delicate open-pore structure of mesh fabrics from mechanical damage during washing.

Can mesh be dried in a machine?

Mesh should generally be air-dried because the high heat of a commercial dryer can melt or permanently distort the synthetic fibers used in its construction. You should lay the fabric flat on a clean towel or hang it up in a well-ventilated area where it can dry naturally within a short period.

Check this out:

- Mesh dries incredibly fast due to its high air permeability.

- Air drying prevents the build-up of static electricity.

- Avoiding the dryer significantly extends the lifespan of the elastic fibers.

The bottom line? If you must use a dryer, always select the lowest heat setting and remove the item while it is still slightly damp to avoid thermal damage.

Key Takeaway: Air-drying is the safest and most effective method for maintaining the shape and performance of all synthetic mesh textiles.

| Care Action | Recommended Method | Reason | |

|---|---|---|---|

| Washing | Cold water, delicate cycle | Prevents fiber shrinkage | |

| Drying | Hang dry or lay flat | Avoids heat-related melting | |

| Ironing | Low heat or steamer only | Protects against hole distortion |

Proper care and maintenance are the keys to ensuring that mesh fabric retains its functional properties and aesthetic appeal over years of use.

Frequently Asked Questions

Can I sew mesh fabric with a regular sewing machine?Yes, but you should use a ballpoint needle and a zigzag stitch to accommodate the fabric’s stretch. This prevents the needle from cutting the delicate fibers and allows the seam to move with the mesh.

What’s the best way to prevent mesh from fraying?Most synthetic mesh is warp-knit and will not fray, but for woven mesh, you should use a serger or a “fray check” liquid on the raw edges. This ensures the grid remains intact during the assembly of your project.

Is it possible to print custom designs on mesh?Absolutely, sublimation printing is the most effective method for polyester mesh because the dye bonds directly with the fibers at a molecular level. This results in a permanent, high-resolution image that will not crack or peel as the fabric stretches.

Why should I choose mesh over solid fabric for my lining?Mesh lining provides superior airflow and reduces the overall weight of the garment, making it much more comfortable for the wearer. It also adds a layer of professional finish that hides internal seams without adding bulk.

How do I identify a high-quality mesh vs. a cheap one?Check for consistency in the hole size and a “soft” hand-feel; high-quality mesh will have no irregular gaps or scratchy textures. Furthermore, a premium mesh should immediately snap back to its original shape after being stretched.

Conclusion

Navigating the complex world of mesh fabric requires a deep understanding of how material choice, weave structure, and manufacturing precision intersect to create a high-performance textile. Whether you are seeking the ethereal beauty of soft tulle for a bridal masterpiece or the rugged durability of polyester mesh for industrial safety, the right fabric choice is the foundation of a successful project. By prioritizing technical specifications like tensile strength, UV resistance, and air permeability, you ensure that your designs not only look exceptional but also perform reliably in real-world conditions. For expert guidance and a curated selection of premium materials, we invite you to contact us today to discuss your specific textile requirements and explore our full range of solutions. Our commitment to textile innovation ensures that every yard of fabric we provide meets the highest standards of the global B2B industry, empowering you to create products that lead the market in both form and function.