Choosing the wrong technical textile can compromise the structural integrity of a high-end design, leading to sagging seams and diminished garment lifespan. You know the frustration of a prototype that looks impeccable on the mannequin but loses its compressive power after only a few hours of wear. To protect your brand’s reputation for quality, you require a material that offers both sophisticated aesthetics and engineered resilience. High-performance power mesh is the professional solution for durable, body-contouring designs that require consistent 4-way stretch and superior elastic recovery.

What exactly defines the structure of power mesh?

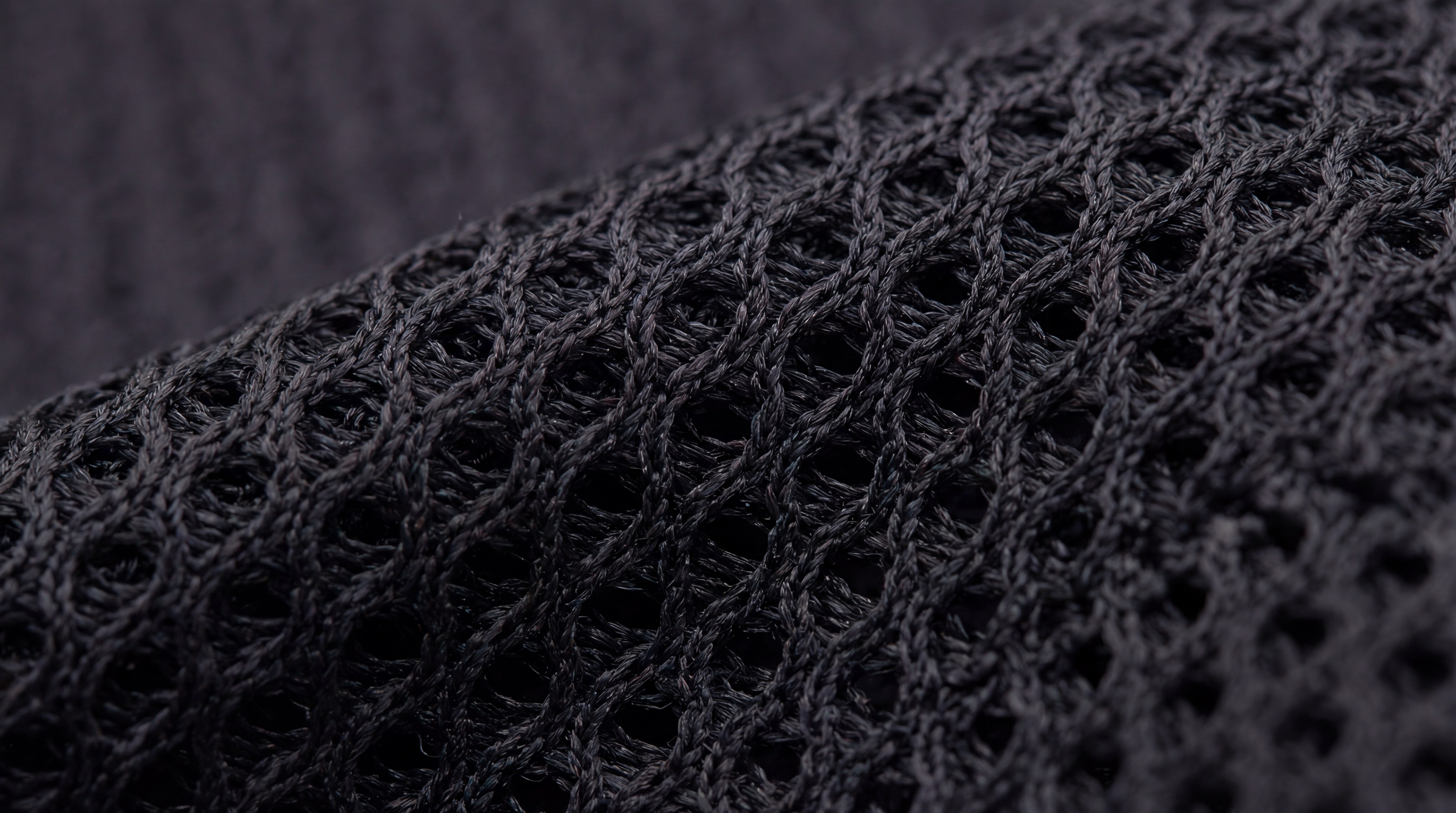

Power mesh is a specialized warp-knitted fabric characterized by its unique hexagonal open-knit structure and high spandex content. This construction method ensures that the material does not run or fray when cut, providing a stable foundation for intricate apparel. You will typically find this fabric composed of a blend of nylon or polyester with approximately 10% to 20% elastane.

The mechanics of the warp-knit system

Think about the difference between a standard knit and a technical warp-knit. Warp knitting involves loops that run vertically along the length of the fabric, which creates a much more stable and durable mesh than traditional weft knitting.

- Increased resistance to pilling and snagging.

- Enhanced structural memory for long-term wear.

- Superior stability under high-tension sewing.

But here is the real kicker. Because of this vertical loop structure, the fabric can maintain its shape even when used in high-stress applications like sports bras or medical-grade compression garments.

Understanding the 4-way stretch capability

When you pull a piece of this fabric, it expands both horizontally and vertically with equal ease. This 4-way stretch is what allows the garment to move in sync with the human body, providing a “second-skin” feel that is essential for modern athleisure.

- Horizontal expansion for width-wise comfort.

- Vertical expansion for height-wise flexibility.

- Simultaneous diagonal stretch for complex movements.

Now, consider the following. Without this multi-directional flexibility, garments would feel restrictive and prone to tearing at the seams during physical activity.

The role of synthetic fiber blends

The performance of the mesh is largely determined by the ratio of polyester to spandex. Most industrial-grade options utilize an 88/12 or 90/10 blend to balance softness with high-tensile strength.

- Polyester provides the durability and color fastness.

- Spandex provides the necessary elastic force.

- The combination results in a breathable, lightweight textile.

Key TakeawayThe structural integrity of power mesh stems from its warp-knitted hexagonal grid and balanced synthetic fiber blend.

| Structural Element | Technical Specification | Functional Benefit | |

|---|---|---|---|

| Knit Type | Warp-Knitted Hexagonal | Prevents runs and increases durability | |

| Stretch Axis | 4-Way Multi-directional | Ensures unrestricted body movement | |

| Fiber Blend | Polyester/Nylon + Spandex | Balances soft hand-feel with compression |

The unique hexagonal geometry of the knit allows for maximum airflow while maintaining a firm grip on the body’s contours.

Why is the recovery of power mesh so essential?

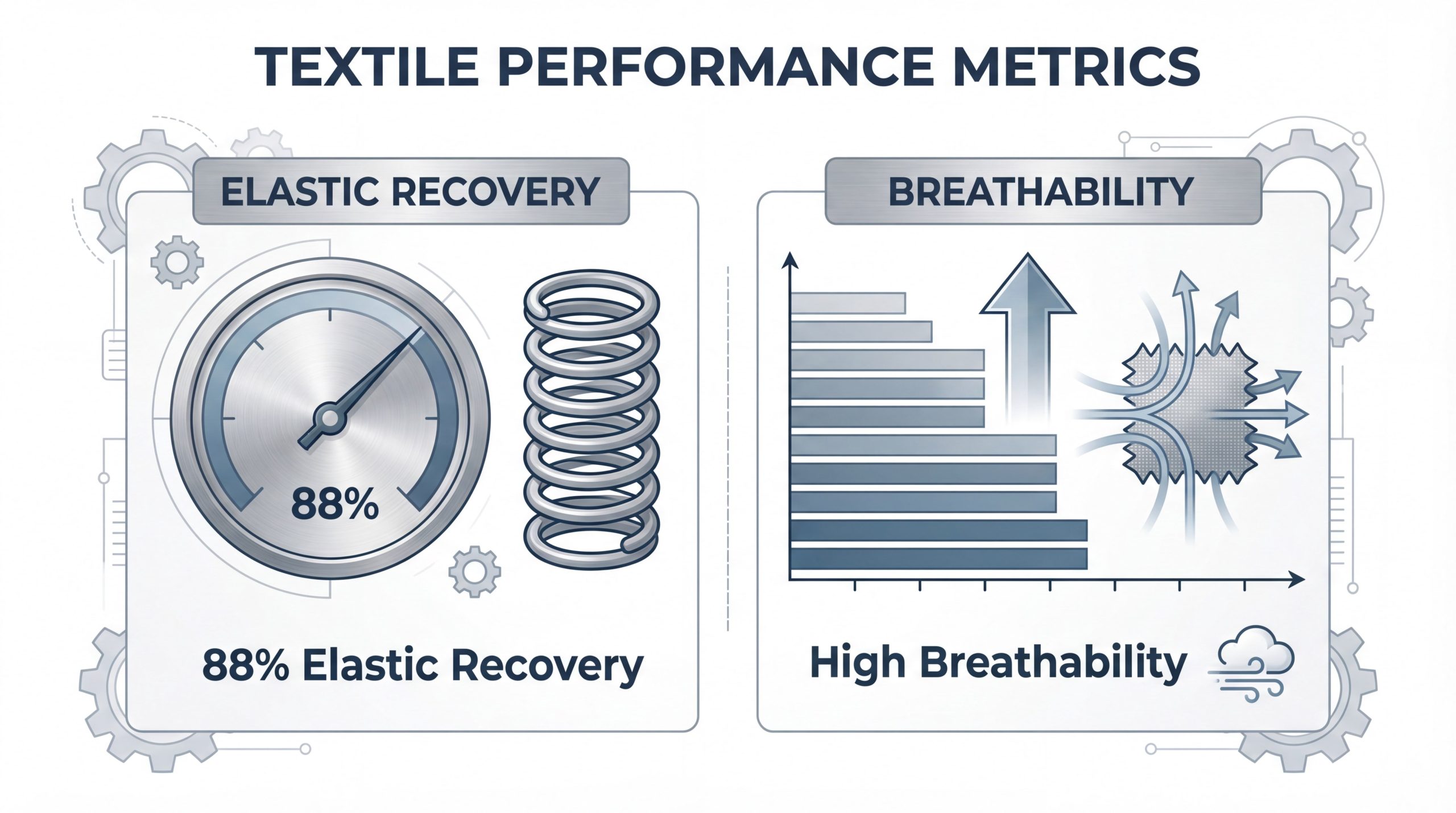

Elastic recovery refers to the ability of power mesh to return to its original dimensions immediately after being stretched. In the B2B garment manufacturing sector, recovery is the primary metric used to distinguish premium textiles from budget alternatives. High-quality variants boast a recovery rate of up to 88%, ensuring that the garment never looks “stretched out” or loose.

Avoiding the common “bagging” effect

Have you ever seen a pair of leggings that develops saggy knees after just one workout? That is the result of poor elastic recovery in the mesh panels or primary fabric.

- Prevents permanent deformation of the textile fibers.

- Maintains the original silhouette of the designer’s vision.

- Extends the commercial lifespan of the end product.

Believe it or not, recovery is just as important as the initial stretch. If a fabric stretches but does not snap back, it fails to provide the necessary support for the wearer.

Compression consistency over long-term use

Consistency is the cornerstone of professional apparel production. You need to know that a garment sold today will provide the same level of compression after fifty wash cycles.

- High-grade spandex fibers resist degradation from sweat and oils.

- The warp-knit structure locks the fibers in place to prevent shifting.

- Dimensional stability remains intact even under extreme heat.

It gets better. By utilizing high-recovery mesh, you reduce the rate of customer returns and increase overall brand loyalty.

Testing protocols for industrial recovery

Manufacturers use standardized mechanical tests to measure how quickly and completely a fabric snaps back. This involves stretching the material to a specific percentage of its width and measuring the residual deformation after release.

- The fabric is clamped in a tensile testing machine.

- It is extended to a pre-determined limit for multiple cycles.

- The “permanent set” is calculated to determine the recovery percentage.

Key TakeawaySuperior elastic recovery ensures that garments maintain their shape and compression levels through rigorous use and repeated laundering.

| Recovery Metric | Industry Standard | Importance Level | |

|---|---|---|---|

| Recovery Rate | 85% – 90% | Critical for shapewear and sports | |

| Cycle Resistance | 50+ Wash Cycles | Essential for consumer durability | |

| Tension Load | Variable by GSM | Determines the “firmness” of the fit |

High-recovery textiles are the only viable option for brands targeting the performance-driven athleisure and medical compression markets.

How do you sew and handle power mesh professionally?

Sewing power mesh requires specialized tools and techniques to prevent the material from puckering or snagging during the production process. Because the fabric is sheer and highly elastic, standard sewing methods often lead to uneven seams and broken threads. You must prioritize the use of ballpoint needles and stretch-specific threads to achieve a professional finish.

Essential needle and thread selection

The most important rule is to never use a standard sharp needle on a knit fabric. Sharp needles can pierce the delicate fibers of the mesh, causing small holes that eventually turn into large runs.

- Use 70/10 or 80/12 ballpoint (stretch) needles.

- Select high-quality textured polyester or nylon threads.

- Ensure the thread has its own degree of elasticity.

Here is the secret. A ballpoint needle slides between the fibers rather than cutting through them, which preserves the integrity of the hexagonal knit.

Managing fabric tension during cutting

Cutting is often the stage where most mistakes happen when working with high-stretch materials. If you pull the fabric even slightly while cutting, the resulting pieces will be smaller than intended once the tension is released.

- Use a rotary cutter and a self-healing mat for precision.

- Keep the fabric completely flat without any overhang on the table.

- Weigh down patterns with fabric weights rather than using pins.

Make no mistake, precision at the cutting table is the only way to ensure that your finished garment meets the specified size requirements.

Adjusting machine settings for stretch seams

Your sewing machine needs to be calibrated specifically for the “rebound” of the mesh. If the stitch length is too short, the seam will become rigid and snap when the garment is put on.

- Increase the stitch length slightly to allow for expansion.

- Use a narrow zigzag stitch or a dedicated serger (overlocker).

- Reduce the presser foot pressure to prevent the fabric from stretching.

Key TakeawayProfessional handling of power mesh requires specialized needles, tension-free cutting, and elasticized stitching techniques.

| Handling Factor | Recommended Tool/Action | Expected Outcome | |

|---|---|---|---|

| Needle Type | Ballpoint / Stretch Needle | Prevents snags and fiber breakage | |

| Cutting Tool | Rotary Cutter & Weights | Ensures dimensional accuracy | |

| Stitch Pattern | Zigzag or Serged Seams | Allows the seam to stretch with the fabric |

By mastering these technical nuances, your production team can produce high-quality garments with clean, durable finishes that withstand heavy use.

What are the performance metrics of power mesh?

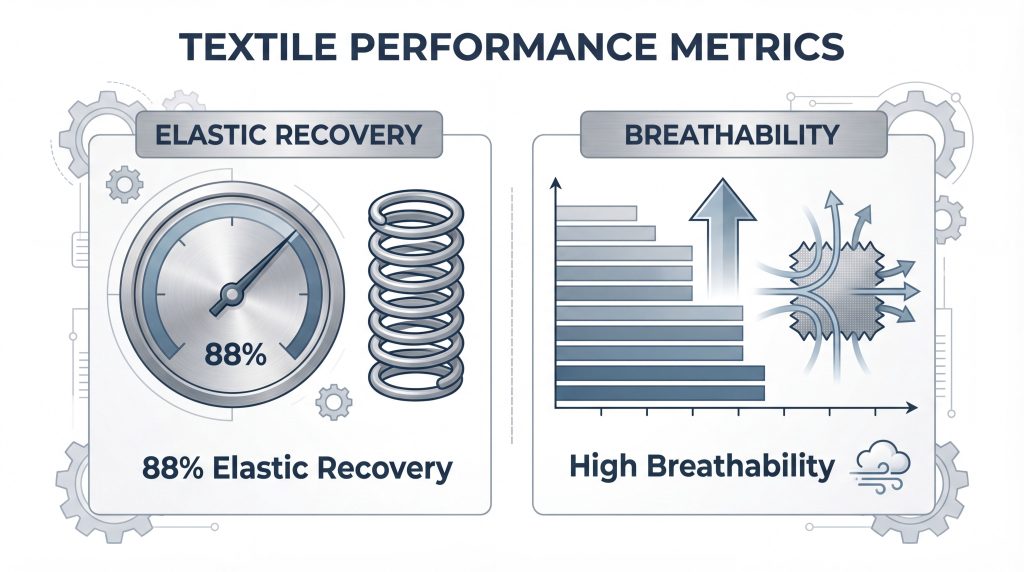

Performance metrics for power mesh are defined by weight (GSM), breathability, and moisture-wicking capabilities. In a B2B context, these specifications allow designers to select the exact variant needed for a specific application, whether it is a lightweight lining or a heavy-duty compression panel. Understanding these numbers is essential for ensuring the functionality of your final product.

Decoding the GSM weight categories

GSM, or grams per square meter, tells you exactly how much fabric you are getting in a specific area. Power mesh is available in a wide range of weights, typically spanning from 40 GSM to 250 GSM.

- 40-80 GSM: Ultra-lightweight, used for sheer panels and lingerie.

- 100-150 GSM: Medium weight, ideal for standard activewear and bras.

- 180-250 GSM: Heavyweight, designed for maximum compression and shapewear.

Now, consider this. A higher GSM does not always mean a “better” fabric; it simply means a higher density of fibers and more intense compression.

Analyzing breathability and airflow

The open-knit hexagonal structure is engineered specifically to facilitate thermal regulation. This allows body heat to dissipate quickly, which is a major selling point for summer activewear and base layers.

- High air permeability prevents sweat accumulation.

- The mesh structure creates a micro-climate between the skin and clothing.

- Rapid evaporation keeps the wearer cool during high-intensity training.

The truth is, breathability is the primary reason designers choose mesh over solid knit fabrics for ventilation zones in athletic apparel.

Moisture management and drying speed

Because polyester and nylon are naturally hydrophobic, they do not absorb large amounts of water. This means the fabric stays light even when wet and dries much faster than cotton-based alternatives.

- Capillary action pulls moisture away from the skin.

- The large surface area of the mesh holes promotes fast drying.

- The fabric resists the growth of odor-causing bacteria.

Key TakeawayPower mesh performance is quantified by its GSM weight, air permeability, and hydrophobic moisture management properties.

| Performance Metric | Range / Value | Application Context | |

|---|---|---|---|

| Weight (GSM) | 40 – 250 | Determines compression level | |

| Breathability | High Permeability | Essential for thermal regulation | |

| Drying Time | < 30 Minutes (Standard) | Critical for swimwear and activewear |

Selecting the correct GSM is the most important decision you will make when sourcing mesh for a new product line.

Is power mesh different from standard bridal tulle?

While they may look similar to the untrained eye, power mesh and bridal tulle serve completely different functional purposes in garment construction. Tulle is primarily a decorative material used to create volume and structure in skirts and veils, whereas mesh is a performance fabric designed for body-contouring and stretch. If your design requires movement and compression, power mesh is the superior choice.

Comparing elasticity and mechanical stretch

Standard bridal tulle has almost zero mechanical stretch, especially in the vertical direction. If you try to use it for a form-fitting garment, it will likely tear or restrict the wearer’s movement significantly.

- Power mesh offers 4-way stretch for dynamic fit.

- Tulle provides “stiff” structure for silhouettes.

- Mesh has a soft, flowing hand-feel compared to tulle’s crispness.

The bottom line is this. If you need a garment to hug the body, you must use mesh. If you need it to stand away from the body, use tulle.

Exploring the use of soft tulle

In some cases, you might find that soft tulle offers a middle ground for certain fashion applications. Soft tulle is more pliable than standard bridal versions but still lacks the high-compression recovery found in technical power mesh.

- Soft tulle is ideal for ethereal, multi-layered skirts.

- It provides a romantic, hazy aesthetic without the “grid” look of mesh.

- However, it does not offer the support needed for shapewear.

Think of it this way: use soft tulle for the “look” and power mesh for the “function.”

Volume vs. Compression

Designers often layer these materials to get the best of both worlds. For example, a wedding gown might have an internal layer of power mesh for tummy control and multiple outer layers of tulle for dramatic volume.

- Mesh provides the structural foundation for the body.

- Tulle provides the external visual architecture.

- Both use a hexagonal knit but with different fiber thicknesses.

Key TakeawayThe primary difference lies in functionality: power mesh is built for stretch and support, while tulle is built for volume and aesthetics.

| Property | Power Mesh | Bridal Tulle | |

|---|---|---|---|

| Stretch | High 4-way stretch | Low to zero stretch | |

| Feel | Soft and smooth | Stiff or “crunchy” | |

| Purpose | Compression/Support | Volume/Decoration |

Choosing between these two depends entirely on whether your design needs to expand with the wearer or hold a static shape.

How does power mesh improve modern activewear?

In the rapidly evolving athleisure market, power mesh has become an indispensable tool for enhancing both the performance and the style of athletic garments. It allows for targeted ventilation in high-heat zones like the back, underarms, and behind the knees. Furthermore, its slimming effect makes it a popular choice for high-waisted leggings and supportive sports bras.

Strategic ventilation for thermal regulation

High-intensity exercise generates significant body heat, which must be managed to prevent fatigue. By integrating mesh panels into key areas, you can significantly increase the comfort of the wearer.

- Mesh panels under the arms allow for maximum airflow.

- Back panels dissipate heat during endurance activities.

- Legging inserts provide cooling during leg-heavy workouts.

Here is why this matters. A cooler athlete can perform longer, making your apparel more attractive to the serious fitness community.

Creating the “illusion” aesthetic

Modern activewear often uses sheer mesh panels to create flattering lines and visual interest. This allows designers to show a bit of skin while still providing the coverage and support required for public gym environments.

- Curvy mesh inserts can visually slim the legs.

- Translucent panels on the chest add a touch of high-fashion.

- Layering sheer mesh over solid colors creates a dynamic, multi-dimensional look.

The result? You end up with a product that looks just as good at a brunch table as it does on a treadmill.

Enhancing structural support in sports bras

The high recovery of power mesh makes it the perfect lining for sports bras. It provides the necessary “hold” to minimize bounce without the bulk of thick foam padding or heavy elastic bands.

- Mesh linings offer firm compression for high-impact activities.

- The fabric remains breathable even when layered.

- It prevents the bra from stretching out over months of heavy use.

Key TakeawayPower mesh improves activewear by providing strategic cooling, aesthetic versatility, and high-performance structural support.

| Activewear Use | Feature | Consumer Benefit | |

|---|---|---|---|

| Ventilation Panels | Open-knit structure | Keeps the athlete cool and dry | |

| Waistband Lining | High compression | Provides tummy control and stay-up grip | |

| Sheer Inserts | Translucency | Enhances fashion appeal and slimming effect |

By utilizing mesh, you solve the dual problem of needing both extreme breathability and firm physical support.

What makes power mesh ideal for sheer aesthetics?

Sheer fashion is a perennial trend, and power mesh is the preferred material for achieving this look without the fragility of silk chiffon or lace. Its fine knit allows for varying degrees of transparency depending on the GSM weight. Whether used for a “naked dress” effect or a subtle sheer sleeve, it provides a modern, edgy aesthetic that is also incredibly durable.

Achieving the “naked dress” effect

The fashion industry often relies on skin-tone mesh to create the illusion of bare skin. This “illusion mesh” is strong enough to hold heavy beadwork or embroidery while remaining nearly invisible against the wearer’s body.

- Available in dozens of nude shades to match diverse skin tones.

- Strong enough to support the weight of thousands of sequins.

- Stretches to fit perfectly, preventing any unsightly wrinkles.

Think about this: without high-strength mesh, the most iconic red-carpet looks of the last decade simply wouldn’t be possible.

Layering for depth and texture

Because it is sheer, power mesh is the perfect candidate for layering over other fabrics. This technique allows designers to play with color and light in ways that solid fabrics cannot match.

- Layering black mesh over neon colors creates a “muted” vibrant effect.

- Combining mesh with lace adds a contemporary twist to traditional designs.

- Multiple layers of mesh can create a pleated or ruffled look with great depth.

The possibilities are endless. You can transform a simple silhouette into a complex piece of art just by varying the opacity of your mesh layers.

Transparency levels by GSM weight

The weight of the fabric directly correlates to how much skin is visible through it. When sourcing for a collection, you must choose the weight that aligns with the intended level of modesty or drama.

- 40-60 GSM is highly transparent, perfect for overlays and “see-through” styles.

- 80-120 GSM is semi-sheer, offering a balanced “shadow” effect.

- 150+ GSM provides significant coverage while still maintaining a mesh texture.

Key TakeawayThe sheer nature of power mesh allows for advanced illusion designs, creative layering, and customizable transparency.

| Transparency Level | Visual Effect | Typical Design Use | |

|---|---|---|---|

| High | Nearly invisible | Illusion necklines and “naked” dresses | |

| Medium | “Shadow” effect | Sheer sleeves and back panels | |

| Low | Textured coverage | Modest activewear and skirt linings |

The durability of the hexagonal knit ensures that even the sheerest designs can withstand the rigors of a night out or a high-pressure performance.

Can you customize power mesh for specific projects?

Customization is the key to differentiating your brand in a crowded B2B marketplace, and power mesh is highly adaptable to custom manufacturing. From specific Pantone color matching to variable widths and specialized finishes, factory-direct sourcing allows you to create a proprietary textile that meets your exact needs. This level of control ensures that every component of your garment is aligned with your brand’s unique identity.

Custom Pantone color matching

For large-scale production, you are not limited to stock colors like black, white, and beige. You can provide a specific Pantone reference to ensure your mesh matches your primary fabrics perfectly.

- Ensures a seamless look between different fabric types.

- Allows for unique, trend-driven color palettes.

- Maintains consistent color across multiple production runs.

But here’s the kicker. Accurate color matching in mesh is notoriously difficult due to its transparency, so working with an expert manufacturer is essential.

Variable weights and width options

Standard mesh usually comes in a 150cm width, but custom orders can be adjusted to suit your specific markers and cutting equipment. Furthermore, the GSM can be tweaked to find the perfect balance between compression and breathability.

- Wider rolls can reduce fabric waste during the cutting process.

- Custom weights allow for “in-between” compression levels.

- Specific roll lengths can be requested to match your logistics setup.

In short, you don’t have to settle for “off-the-shelf” specs that don’t quite fit your design requirements.

Specialized finishes and treatments

Modern textile technology allows for the addition of functional finishes to the mesh after it is knitted. These treatments can add significant value to your end product, especially in the activewear and industrial sectors.

- Anti-microbial finishes to prevent odors in sportswear.

- Flame retardant treatments for industrial or theatrical safety.

- Moisture-wicking enhancements for superior climate control.

Key TakeawayB2B customization options for power mesh include color matching, variable dimensions, and functional chemical finishes.

| Customization Type | Requirement | Brand Benefit | |

|---|---|---|---|

| Color Matching | Pantone Reference | Professional, unified aesthetic | |

| GSM Adjustment | Weight Spec (40-250) | Targeted performance for specific garments | |

| Functional Finish | Performance Add-on | Increased product value and utility |

Customizing your mesh at the source allows you to build a product that is truly unique to your brand’s specifications.

Why do athletes prefer power mesh for costumes?

Rhythmic gymnasts, ice skaters, and dancers require costumes that can withstand extreme stretching and high-velocity movements without failing. For these professionals, power mesh is the gold standard because it provides the “give” needed for deep lunges and flips while staying securely in place. It is the only fabric that can reliably combine theatrical sparkle with Olympic-level durability.

Unrestricted range of motion

When an athlete is performing a split or a high jump, the last thing they want to worry about is their costume restricting their movement. Power mesh’s 4-way stretch ensures that the fabric expands in every direction simultaneously.

- Zero resistance during complex acrobatic maneuvers.

- Maintains its position on the body during fast rotations.

- Reduces the risk of seam failure during high-stress poses.

Believe it or not, the “lightness” of the fabric also helps athletes feel unencumbered, which can contribute to better performance scores.

Skin-contact comfort and non-abrasiveness

Performance costumes are often worn for hours at a time during competitions. Unlike some stiff decorative fabrics, high-quality mesh is soft to the touch and does not chafe the skin during repetitive movements.

- Smooth fiber surface prevents irritation during intense sweat.

- Lightweight construction reduces the overall weight of the costume.

- Soft-touch variants are available for sensitive skin areas.

The simple truth is that if an athlete is uncomfortable in their costume, their focus is compromised.

Durability under heavy embellishment

Costumes for skating and gymnastics are often covered in thousands of hand-applied crystals and sequins. The mesh must be strong enough to support this weight without sagging or tearing under the centrifugal force of a spin.

- The warp-knit structure provides a stable “net” for attaching decorations.

- High-tensile fibers resist the pulling force of heavy beadwork.

- The fabric maintains its compression even with the added weight.

Key TakeawayAthletes choose power mesh for its unrestricted 4-way movement, skin-friendly texture, and ability to support heavy decorative elements.

| Athletic Benefit | Technical Cause | Result | |

|---|---|---|---|

| Flexibility | 4-Way Warp Knit | Maximum range of motion | |

| Durability | High Spandex Density | Resists tearing under heavy decoration | |

| Comfort | Smooth Fiber Surface | No chafing or skin irritation |

The combination of stretch and strength makes this material the undisputed champion of the performance costume world.

How is industrial power mesh manufactured?

The production of high-grade power mesh is a high-tech process that utilizes precision German engineering. Warp knitting machines, specifically those from brands like Karl Mayer, are the industry standard for creating the consistent hexagonal structure required for B2B applications. This manufacturing process is far more complex than standard knitting, requiring constant monitoring to ensure that every roll of fabric meets global quality standards.

The precision of warp knitting machines

Unlike a standard loom, a warp knitting machine uses thousands of needles that work simultaneously to create a series of interlocking loops. This creates a fabric that is incredibly stable and resistant to unravelling.

- Allows for the creation of intricate hexagonal patterns.

- Enables the production of very wide rolls (up to 300cm+).

- Ensures consistent tension across the entire width of the fabric.

Now, consider this. The speed and precision of these machines are what allow manufacturers to keep MOQs low while maintaining high quality.

Quality control and OEKO-TEX certification

In the professional textile world, certifications are not optional. You need to ensure that the fabric you are putting next to your customers’ skin is free from harmful chemicals and produced under ethical conditions.

- 100% visual inspection identifies any minor flaws in the knit.

- Mechanical testing verifies the GSM and stretch recovery.

- OEKO-TEX® Standard 100 certification ensures chemical safety.

It gets better. When you source from a factory that prioritizes these standards, you protect your brand from future liability and quality complaints.

Selecting the best mesh for shapewear

When manufacturing for the compression market, choosing the right mesh fabric for shapewear is a matter of fine-tuning the spandex ratio and the GSM. Industrial-scale manufacturing allows for the creation of “zoned” mesh, where different areas of the fabric have different levels of power.

- High-compression zones for tummy and thigh control.

- Breathable zones for areas that require more airflow.

- Graduated compression to improve blood circulation.

Key TakeawayIndustrial power mesh manufacturing relies on precision warp-knitting technology, rigorous QC, and specialized engineering for compression garments.

| Manufacturing Stage | Key Component | Goal | |

|---|---|---|---|

| Knitting | Karl Mayer Warp Machines | Consistent hexagonal structure | |

| Dyeing | High-Pressure Vats | Color fastness and Pantone accuracy | |

| Inspection | 6-Person QC Team | 100% defect-free delivery |

The complexity of the manufacturing process is the reason why true power mesh provides performance that simple “stretch fabrics” cannot replicate.

Frequently Asked Questions

Can I use power mesh for industrial bag pockets?Yes, high-GSM power mesh (200-250g) is frequently used in the luggage and backpack industry for exterior pockets. Its 4-way stretch allows it to hold bulky items like water bottles securely, while the hexagonal knit ensures it won’t tear if snagged by a branch or sharp object.

What’s the best way to determine the right GSM for my project?The best approach is to request a sample swatch book. Generally, use 40-80 GSM for purely aesthetic sheer panels, 100-140 GSM for standard athletic wear, and 180+ GSM for serious shapewear or medical compression garments where maximum “hold” is required.

Can I wash garments made with power mesh in a standard machine?While power mesh is durable, it is best washed on a “delicate” cycle inside a mesh laundry bag to prevent the hexagonal structure from snagging on zippers or buttons of other garments. You should always air dry these pieces to preserve the elastic life of the spandex fibers.

What’s the best way to prevent the fabric from curling at the edges?High-quality warp-knit power mesh is designed to lay flat, but some lighter weights may curl slightly when cut. Using a temporary spray adhesive or stabilizing tape during the sewing process can keep the edges perfectly aligned for a clean seam.

Can I get custom colors for a small production run?Most professional manufacturers have a low MOQ (minimum order quantity) for stock colors, often around 100 meters. For custom Pantone dyeing, the MOQ may be higher, but it is the only way to ensure a 100% perfect match for a signature brand color.

Conclusion

Mastering the use of power mesh is a transformative step for any B2B apparel brand. By choosing a material with 88% recovery and high-precision warp-knit construction, you solve the chronic problem of garment sagging and poor support. Whether you are designing the next breakthrough in athleisure, a red-carpet illusion gown, or medical-grade shapewear, the right mesh provides the foundation for excellence.

Our vision is to empower designers with factory-direct access to the world’s most resilient and versatile technical textiles. We understand that your reputation is woven into every seam, which is why we prioritize OEKO-TEX certified quality and precision engineering in every roll. If you are ready to elevate your collection with superior stretch and support, contact us today to request samples and discuss your custom manufacturing needs.