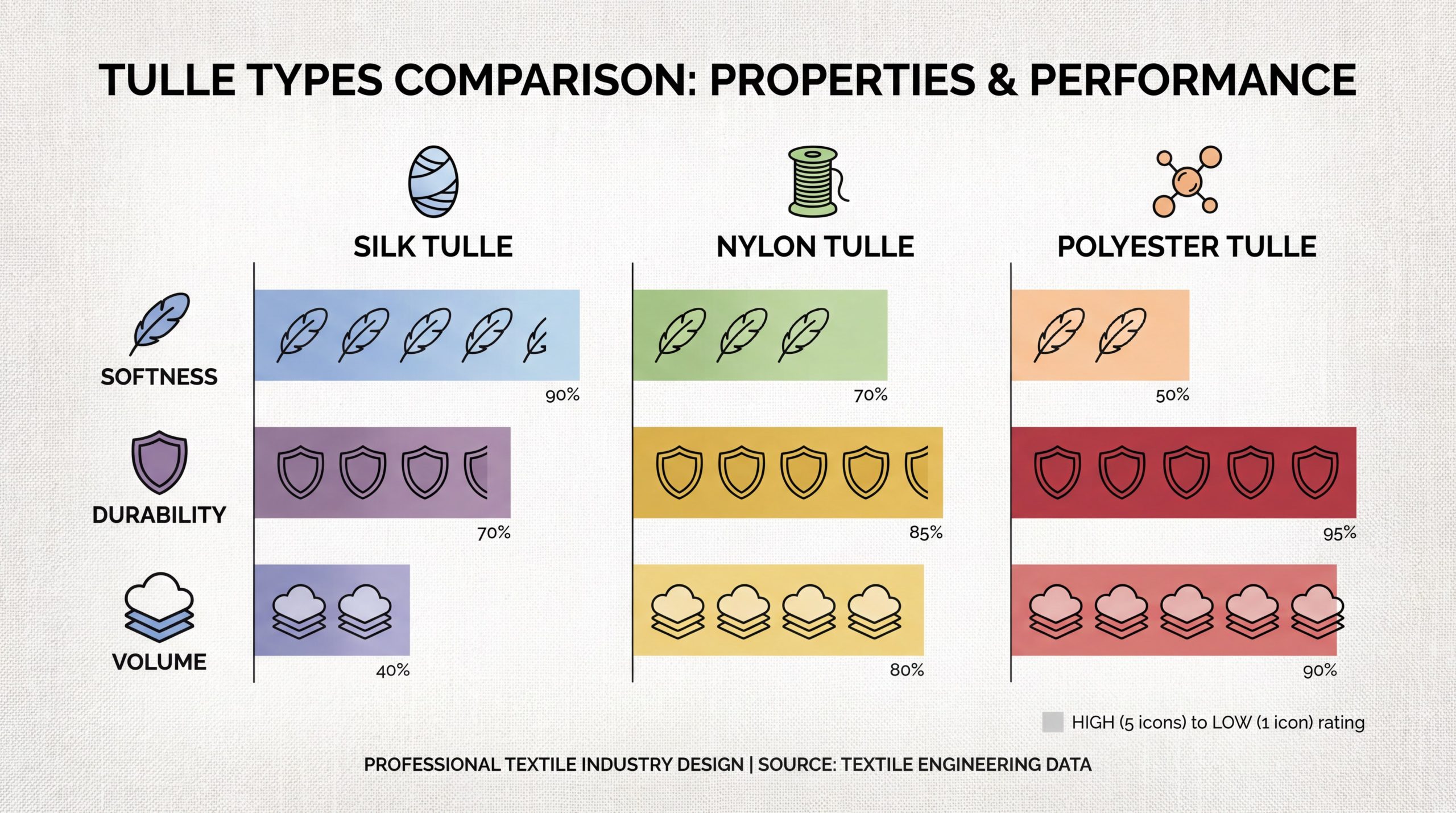

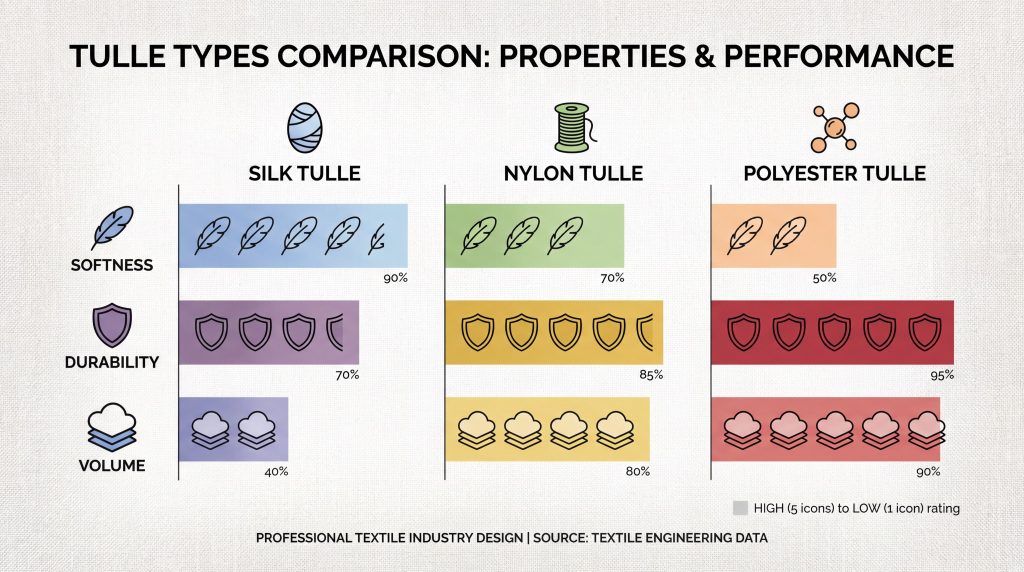

There are several types of tulle fabric, ranging from soft silk to stiff nylon, each serving distinct roles in fashion and decor. Imagine the heartbreak of spending weeks meticulously hand-sewing a bespoke ballroom gown, only to watch the skirt collapse into a shapeless heap during the final fitting because the mesh lacked structural integrity. Choosing the wrong tutu material name doesn’t just ruin the silhouette; it can lead to skin irritation, snagging, and a garment that feels like sandpaper against the wearer. By mastering the nuances of fiber composition and mesh density, you can transform your design from a frustrating failure into a professional-grade masterpiece that retains its ethereal volume and soft touch for years to come.

What is the most popular tutu material name today?

Nylon is widely considered the most popular tutu material name due to its incredible versatility and balance between softness and strength. This synthetic fiber allows for a fine hexagonal weave that maintains its shape even under the weight of heavy embellishments.

Why do synthetics dominate the market?

Nylon and polyester are favored for their high “spring back” quality and resistance to wrinkling. They provide the necessary volume for bridal and costume wear without the astronomical price point of natural silk.

- Superior shape retention compared to cotton.

- Resistance to fraying when cut with raw edges.

- Wide availability in hundreds of custom colors.

Here is the kicker: Most designers choose nylon because it offers the most professional “bounce” for every dollar spent.

Is it suitable for professional stage use?

Professional costume designers rely on high-denier nylon to ensure that garments survive the rigors of performance. This specific variety provides the structural “kick” needed for classical silhouettes while remaining lightweight.

- High tensile strength to prevent tearing during movement.

- Ability to hold starch or stiffening agents.

- Lightweight profile for dancer comfort.

You might be wondering: Does it hold up under stage lights? Synthetic nylon is often treated for flame retardancy, making it the safest choice for theatre.

| Property | Nylon Tulle | Market Popularity | |

|---|---|---|---|

| Material | 100% Polyamide | Very High | |

| Washability | Hand Wash Only | Standard | |

| Durability | Excellent | Industry Leader |

Key TakeawayNylon is the industry standard for tutus because it combines durability with the ability to hold a crisp, voluminous shape better than any other fiber.

How does Italian silk tulle compare to others?

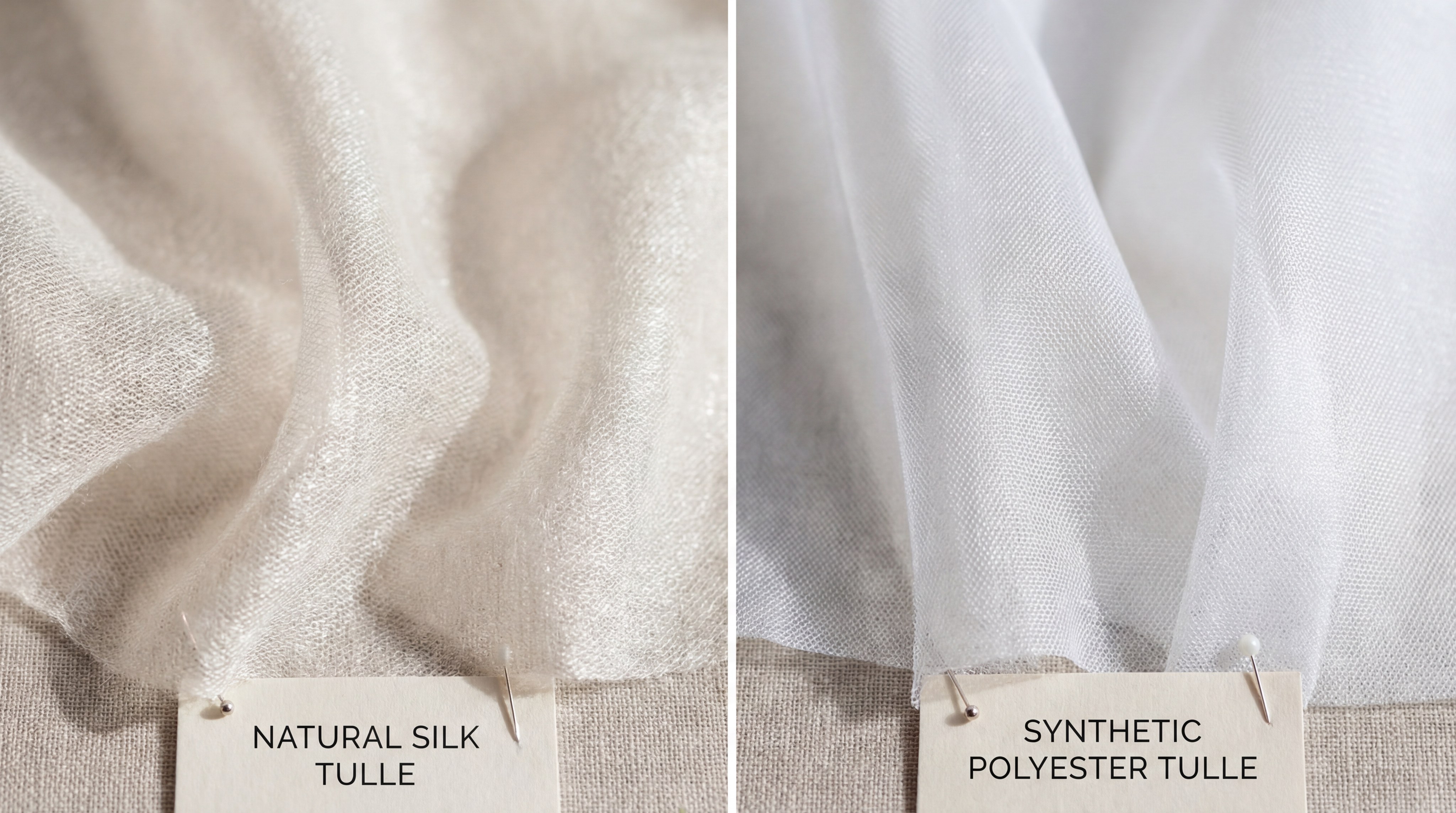

Italian silk tulle represents the absolute pinnacle of luxury in the textile world, offering a drape that is incomparable to synthetic variants. This tutu material name is prized for its ultra-fine weave and a matte finish that reflects light with a sophisticated, subtle glow.

What defines the “Italian” quality?

Italy uses heritage weaving techniques and specialized machinery to produce a silk net that is significantly softer than standard tulle. The result is a fabric that feels like a second skin rather than a structured mesh.

- 100% natural silk fiber composition.

- Incredibly fine, almost microscopic hexagonal holes.

- Natural breathability and hypoallergenic properties.

Think about it: When a bride wants a “cloud-like” effect, Italian silk is the only material that truly delivers that weightless aesthetic.

Can you use it for high-volume skirts?

While beautiful, silk tulle lacks the inherent stiffness required for “pancake” tutus or structured ballgowns. It is best utilized for flowing romantic tutus or top-layer overlays that require graceful movement.

- Excellent fluidity for “drop” veils.

- Low structural memory (will not stand out horizontally).

- High sensitivity to humidity and heat.

But wait, there’s more: Silk tulle is significantly more expensive and fragile, requiring a master’s touch during the construction phase.

| Feature | Italian Silk Tulle | Synthetic Tulle | |

|---|---|---|---|

| Touch | Velvety/Soft | Crisp/Textured | |

| Drape | High Fluidity | High Structure | |

| Cost | Premium Luxury | Budget-Friendly |

Key TakeawayItalian silk tulle is the go-to for luxury bridal wear where drape and softness are prioritized over structural volume.

Why is nylon tulle preferred for bridal veils?

Nylon is the preferred tutu material name for bridal veils because it offers the perfect level of transparency and “poof” without being overly heavy. Unlike silk, nylon veils can be easily shaped to frame the face or create a dramatic train that doesn’t drag.

Does it hold embellishments well?

The strength of nylon fibers allows the mesh to support heavy lace appliqués, pearls, and crystals without sagging or tearing. This makes it the ideal canvas for the intricate handiwork found on cathedral-length veils.

- High weight-bearing capacity for beads.

- Stable mesh structure that prevents hole distortion.

- Easy to bond with textile adhesives or fine thread.

The best part? It remains virtually invisible in photography, allowing the decorative details to appear as if they are floating in mid-air.

Why is shape retention crucial for veils?

A veil must maintain its intended silhouette from the walk down the aisle through hours of photography. Nylon resists the “wilting” effect that often plagues natural fibers in humid outdoor settings.

- Memory-retention properties that withstand folding.

- Resistance to static cling when treated.

- Crisp edges that don’t roll or fray.

As it turns out: Nylon is the only material that provides that iconic “halo” effect without requiring constant adjustments.

| Requirement | Nylon Veil Tulle | Performance | |

|---|---|---|---|

| Transparency | Ultra-Sheer | Excellent | |

| Support | High Embellishment Load | Superior | |

| Stability | Resists Humidity | High |

Key TakeawayBridal designers choose nylon for veils because it is the most reliable material for supporting heavy decorations while remaining nearly invisible.

What makes polyester tulle the best for events?

Polyester tulle is the champion of the event industry because it is exceptionally cost-effective and naturally more resistant to heat than nylon. This tutu material name is the standard for ceiling drapes, table runners, and large-scale floral installations.

Is it safe for large-scale decor?

Polyester is frequently manufactured with fire-retardant chemicals integrated into the fiber itself, meeting strict venue safety codes. This makes it the go-to choice for draping over lighting or in high-traffic banquet halls.

- Naturally higher melting point than nylon.

- Often certified for industrial safety standards.

- Available in extra-wide bolts for seamless draping.

Believe it or not: You can buy polyester tulle in bulk for a fraction of the cost of apparel-grade mesh, making it perfect for one-time events.

How does it handle outdoor conditions?

Unlike nylon, which can yellow under UV exposure, polyester is highly resistant to sunlight and moisture. This durability ensures that outdoor wedding arches and tent decor look pristine from morning until night.

- UV-resistant properties for sun-drenched events.

- Hydrophobic fibers that don’t absorb rainwater.

- Easy to clean and reuse for multiple seasons.

The bottom line: If you are decorating a 500-person gala, polyester is the only fabric that won’t break your budget or fail safety inspections.

| Application | Polyester Tulle | Advantage | |

|---|---|---|---|

| Price | Low/Bulk Pricing | Budget Efficiency | |

| Safety | Flame Retardant | Venue Compliance | |

| Width | Up to 120 inches | Seamless Coverage |

Key TakeawayPolyester tulle is the most practical choice for event decor due to its low cost, safety ratings, and durability against environmental factors.

Is illusion tulle the right tutu material name?

Illusion tulle is technically a variant of the standard tutu material name , but it is specifically engineered for transparency and “naked” dress effects rather than volume. Its name comes from its ability to blend seamlessly with human skin tones.

Is it too soft for a classic tutu?

Illusion tulle is far too fine and limp to support the horizontal structure of a classical ballet tutu. If used for this purpose, the skirt would droop instantly, failing to provide the iconic silhouette.

- Extremely fine mesh count for invisibility.

- Silky hand-feel that minimizes skin chafing.

- Used primarily for necklines, sleeves, and back panels.

Here’s the deal: Using illusion tulle for a tutu is a common beginner mistake that leads to a “deflated” and disappointing garment.

Where does it excel in design?

This fabric is the secret weapon for creating “floating” lace motifs on couture gowns. It provides just enough tension to hold the dress in place while appearing as though the wearer is only covered by lace.

- Available in a wide range of nude/skin-tone shades.

- High stretch recovery for a snug, invisible fit.

- Ideal for “drop” veils that require zero volume.

You may be surprised: Even though it’s soft, high-quality illusion tulle is remarkably strong and can support intricate embroidery without tearing.

| Use Case | Illusion Tulle | Classic Tutu Net | |

|---|---|---|---|

| Visibility | Nearly Invisible | Clearly Defined Mesh | |

| Volume | None | High | |

| Purpose | Skin-blend Effects | Structural Foundation |

Key TakeawayIllusion tulle should be reserved for sheer panels and veils; it lacks the “body” required to create a successful, voluminous tutu.

How do you identify high-quality soft tulle?

Identifying high-quality soft tulle requires a combination of tactile testing and visual inspection of the mesh uniformity. This tutu material name should feel smooth to the touch, with a consistent hexagonal pattern that shows no signs of “knotting” or uneven holes.

What should you look for in the “hand” of the fabric?

A premium soft tulle will feel almost like a liquid when draped over the hand, without any scratchiness or stiffness. If the fabric catches on your skin or feels “plastic-y,” it is likely a lower-grade polyester blend.

- Silk-like smoothness that won’t irritate sensitive skin.

- Uniform color saturation across the entire bolt.

- High elasticity without permanent deformation.

It’s simpler than you think: Just scrunch a handful of the fabric; if it releases without deep wrinkles, you’re holding high-quality material.

Why does the machine origin matter?

High-end manufacturers use German-engineered Karl Mayer machines to ensure the weave is perfectly symmetrical. This precision prevents the fabric from leaning or twisting when cut into long panels for skirts.

- Perfectly aligned hexagonal cells.

- Consistent width and weight throughout the roll.

- Fewer structural defects like dropped stitches.

The reality is: Cheaper looms produce “wavy” mesh that can make your hemlines look crooked no matter how straight you cut.

| Quality Marker | Premium Soft Tulle | Budget Tulle | |

|---|---|---|---|

| Mesh Shape | Perfect Hexagon | Distorted Diamond | |

| Skin Feel | Soft/Gentle | Scratchy/Rough | |

| Recovery | Excellent | Poor (Creases) |

Key TakeawayHigh-quality soft tulle is defined by its silk-like feel and the precision of its machine-made hexagonal mesh.

What are the pros of using stretch tulle?

Stretch tulle is a specialized tutu material name that incorporates elastane (Spandex) into the knit, offering incredible flexibility for form-fitting garments. It is the backbone of modern dancewear, providing the “second skin” fit needed for leotards and bodysuits.

How does it improve garment comfort?

Traditional tulle can be restrictive, but stretch variants move with the body’s natural contours. This eliminates the “binding” feeling often found in tight sleeves or bodices made from rigid netting.

- Four-way stretch for maximum range of motion.

- Soft, non-abrasive edges that don’t bite into the skin.

- Breathable structure that allows for active airflow.

Think about it: If your design requires a dancer to move through full extensions, stretch tulle is the only way to prevent seam failure.

Is it durable enough for daily wear?

Despite its elasticity, high-quality stretch tulle is remarkably resilient to snagging and “runs.” The addition of Lycra fibers reinforces the mesh, making it more durable than standard bridal illusion.

- Resistant to “pilling” or fiber breakdown.

- Holds vibrant dyes better than pure nylon.

- Maintains its “snap” even after multiple washes.

But here is the catch: You must use a stretch needle (ballpoint) when sewing, or you risk popping the elastic fibers.

| Feature | Stretch Tulle | Rigid Tulle | |

|---|---|---|---|

| Flexibility | High (20-50% stretch) | None | |

| Fit | Body-conturing | Structured/Loose | |

| Application | Sleeves/Leotards | Skirts/Veils |

Key TakeawayStretch tulle is essential for athletic dancewear and form-fitting fashion where comfort and movement are the primary goals.

Can sparkling glitter tulle ruin your design?

While visually stunning, glitter tulle can be a double-edged sword for a designer if the quality is poor. This tutu material name often suffers from “glitter shed,” which can contaminate other fabrics and irritate the wearer’s skin.

How do you identify “shed-resistant” glitter?

Premium glitter tulle uses a heat-bonding process rather than simple glue to attach the sparkles to the mesh. When you rub the fabric together, only a few stray flakes should fall; if a cloud of glitter appears, the quality is too low for professional use.

- Heat-set glitter that stays on the fiber.

- Fine-milled sparkles that feel less abrasive.

- Even distribution across the hexagonal mesh.

Here is the deal: Cheap glitter tulle will leave a trail behind the wearer, effectively “ruining” carpets and other guests’ clothing at an event.

Does the glitter affect the fabric’s drape?

Heavy applications of glitter or sequins can make the tulle feel stiff and “crunchy,” losing the ethereal flow of the base mesh. High-quality variants manage to add sparkle without sacrificing the soft hand-feel of the fabric.

- Minimal impact on the fluidity of the drape.

- Compatible with steam for wrinkle removal.

- Available in “sparkle” (subtle) or “glitter” (bold) finishes.

You might be wondering: Can I wash it? Most glitter tulles are “spot clean only” because water can dissolve the bonding agents that hold the sparkles in place.

| Concern | Premium Sparkle Tulle | Low-Grade Glitter Tulle | |

|---|---|---|---|

| Shedding | Low/Minimal | Very High | |

| Skin Irritation | Low | High (Scratchy) | |

| Longevity | Multi-wear | Single-use |

Key TakeawaySparkling tulle adds glamour, but you must invest in heat-bonded varieties to avoid the mess and discomfort of excessive shedding.

Why choose stiff net for professional tutus?

Stiff net, often referred to as diamond mesh or tutu crinoline, is the structural tutu material name required for classical “pancake” silhouettes. Without this coarse, high-denier material, a ballet tutu would lack the tension needed to stand perpendicular to the dancer’s body.

Is it too scratchy for the wearer?

Stiff net is indeed abrasive, which is why it is never used for the layer touching the skin or the top decorative layer. It is hidden in the middle layers to act as a “shelf” for the softer tulles to sit upon.

- Provides the “structural lift” for the skirt.

- Higher denier (thickness) for maximum rigidity.

- Diamond-shaped holes for added tension.

Think about it: The scratchiness is a small price to pay for the gravity-defying shape that defines a professional prima ballerina.

How many layers are required for a professional look?

A standard classical tutu can require anywhere from 10 to 16 layers of stiff net, each cut at different lengths and “tacked” together with thread. This layering creates a solid, drum-like surface that supports the dancer’s arms during performance.

- Graduated lengths for a smooth “staircase” effect.

- Hand-tacking required for structural stability.

- Compatible with starching for extra crispness.

The best part? Stiff net is incredibly durable and can be “revived” with a quick steam even after being crushed in a travel bag.

| Layer Type | Purpose | Material Weight | |

|---|---|---|---|

| Inner Layers | Structural Support | High-Denier Stiff Net | |

| Outer Layers | Aesthetic Finish | Soft Nylon Tulle | |

| Base Layer | Skin Protection | Cotton or Silk Tulle |

Key TakeawayStiff net is the non-negotiable foundation of any professional tutu that requires horizontal volume and structural longevity.

How do you care for delicate tulle fabrics?

Caring for any tutu material name requires a “no-heat” approach to prevent melting the synthetic fibers. Because tulle is essentially a fine plastic mesh, traditional ironing will instantly destroy the fabric, leaving behind a hole and a ruined garment.

What is the safest way to remove wrinkles?

Steam is the only acceptable method for smoothing tulle. A handheld steamer or hanging the garment in a hot, steamy bathroom will relax the fibers and allow gravity to pull out the creases without direct contact.

- Never let the steamer head touch the fabric.

- Steam from the inside out for better results.

- Allow the fabric to cool completely before wearing.

Believe it or not: A quick steam can restore the “poof” to a flattened tutu in under five minutes.

Can you wash tulle in a machine?

Machine washing is the fastest way to tear the delicate hexagonal mesh and lose the fabric’s crispness. Hand washing in cold water with a mild, residue-free detergent is the only way to preserve the integrity of the garment.

- Soak for 15 minutes; do not scrub or wring.

- Rinse by dipping in clean, cold water.

- Air dry flat on a clean, white towel.

As it turns out: Most high-end tulle garments only need “spot cleaning” or a quick refresh with a fabric-safe spray rather than a full wash.

| Care Task | Recommended Method | Risk of Failure | |

|---|---|---|---|

| Wrinkles | Hanging Steam | High (if using iron) | |

| Cleaning | Cold Hand Wash | High (if using machine) | |

| Drying | Air Dry Flat | Moderate (if hanging) |

Key TakeawayPreserving the life of tulle requires a strict “steam and hand-wash” regimen to avoid the irreversible damage caused by heat and agitation.

Mastering the Art of Tulle Selection

Navigating the vast world of mesh can feel overwhelming, but understanding the specific properties of nylon, silk, and polyester solves the “wrong fabric” problem once and for all. Whether you are building a gravity-defying classical tutu with stiff net or a whisper-light bridal veil with illusion tulle, choosing the correct fiber ensures your project moves from a sagging disappointment to a structured success. By matching the weight, stretch, and transparency to your design goals, you eliminate the risks of skin irritation and structural failure. If you are ready to source the perfect materials for your next collection, reach out to our team and let our experts guide you to the high-performance fabrics your designs deserve.

Frequently Asked Questions

Can I dye synthetic tulle at home?Synthetic tulle made from polyester or nylon requires specialized “disperse dyes” and high temperatures to bond with the plastic fibers. Home dyeing with standard cotton dyes will likely result in a patchy, uneven finish or no color absorption at all.

What’s the best way to cut tulle without it shifting?The best way to cut tulle is using a rotary cutter and a self-healing mat. Unlike scissors, which lift the fabric and cause the layers to slide, a rotary cutter applies downward pressure, keeping the fine mesh perfectly aligned for a straight, professional edge.

How do I know if a tulle is “bridal grade”?Bridal-grade tulle is identified by its “softness-to-strength” ratio. It should feel smooth against the skin (unlike craft netting) but still have enough “body” to hold its shape. Check for a very fine, uniform hexagonal weave without any visible knots or flaws.

Can I use a regular sewing needle for tulle?While you can, it is not recommended for fine varieties. A “Microtex” or “Sharp” needle in size 70/10 is best for preventing snags, while a ballpoint needle is necessary if you are working with stretch tulle to avoid cutting the elastic fibers.

How many yards of tulle do I need for a full adult tutu?For a standard, voluminous adult tutu, you typically need between 10 to 15 yards of 54-inch wide tulle. If you are aiming for a “pancake” style or a very dense romantic tutu, that number can easily climb to 25 yards or more depending on the number of layers.