Breathable mesh fabric is the definitive textile solution for any application requiring high-level ventilation and moisture management. Imagine the discomfort of a long shift or an intense workout where your clothing traps heat, causing sweat to cling to your skin and body temperature to spike. This persistent dampness not only agitates the skin but actively ruins your productivity and focus throughout the day. By integrating breathable mesh fabric into your designs, you effectively solve these thermal issues, ensuring a cool and dry experience for the end-user.

Why is breathable mesh fabric so popular today?

This material is favored because its openwork structure facilitates an unrestricted flow of air that traditional knits simply cannot match. When you evaluate breathable mesh fabric , you see how the evolution of synthetic fibers like polyester and nylon has allowed for lighter, more durable textiles.

The evolution of openwork textiles

The transition from heavy natural fibers to high-tech synthetics has redefined comfort in the textile industry. Modern manufacturing allows for precise hole sizing to balance opacity with airflow.

Look:

- Lightweight synthetic base.

- Enhanced moisture-wicking properties.

- High resistance to UV fading.

How does the knit structure work?

The knit creates a series of interlocking loops that leave consistent gaps throughout the surface of the material. This physical geometry is what allows heat to escape the body instantly during physical exertion.

Wait, there is more.

- Open-cell architecture.

- Structural integrity under tension.

- Rapid drying capabilities.

Key Takeaway: The popularity of this fabric stems from its ability to provide structural integrity while remaining almost weightless and highly ventilated.

| Feature | Description | |

|---|---|---|

| Material Base | Polyester or Nylon | |

| Airflow Level | High (Open-cell) | |

| Weight | Ultralight |

Use this data to determine if a lightweight synthetic base meets your project’s thermal requirements.

What are the main types of breathable mesh fabric?

There are several variations ranging from rigid tulle to highly elastic power mesh used in various apparel sectors. You must select a breathable mesh fabric based on the specific mechanical requirements of your final product, such as stretch or abrasion resistance.

Polyester vs. nylon mesh options

Polyester is typically preferred for its colorfastness and durability in outdoor or athletic settings. Nylon, conversely, offers a softer hand-feel and slightly better elasticity for intimate apparel.

Simply put:

- Polyester: Best for sublimated graphics.

- Nylon: Superior for skin-contact items.

- Both: Excellent moisture management.

Stretch vs. rigid mesh variations

Rigid mesh provides a stable structure for linings or industrial filters where shape retention is paramount. Stretch mesh incorporates elastane to provide the compression needed for athletic gear and shapewear.

The best part?

- High recovery rates in stretch types.

- Zero-sag performance in rigid types.

- Versatile application across industries.

Key Takeaway: Understanding the chemical and physical differences between polyester and nylon is the first step in successful material selection.

| Mesh Type | Elasticity | Durability | Best For | |

|---|---|---|---|---|

| Power Mesh | High | Medium | Lingerie/Shapewear | |

| Birdseye | Low | High | Sports Jerseys |

Compare these types to align your fabric’s elasticity with the wearer’s range of motion needs.

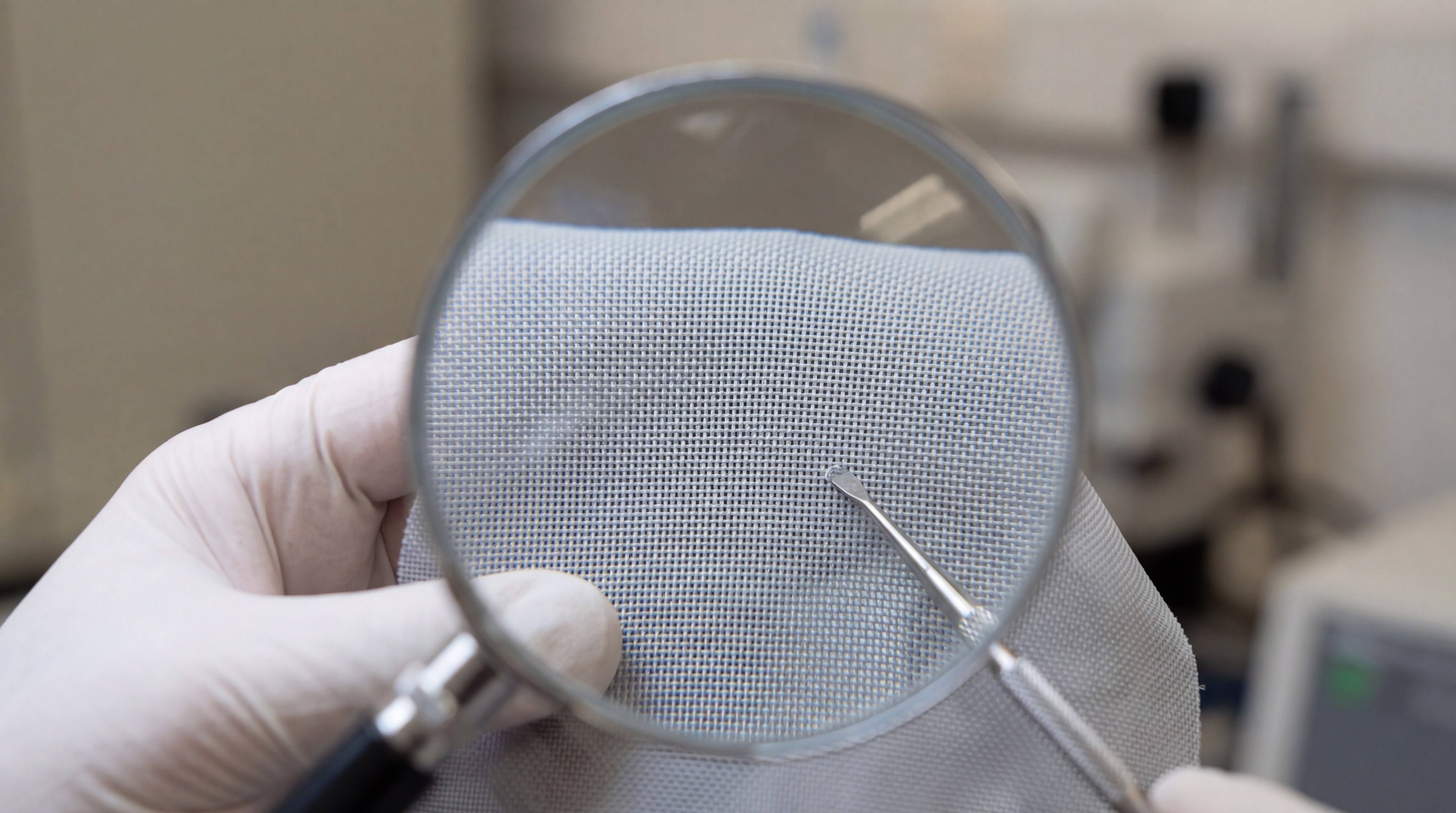

How do you identify quality breathable mesh fabric?

Quality is identified by the consistency of the hole pattern and the material’s ability to recover its shape after stretching. When sourcing breathable mesh fabric , you should inspect the edges for fraying and the surface for any snagged loops.

Checking the hole density and size

The density of the holes determines both the transparency and the airflow volume of the garment. You should ensure the pattern remains uniform across the entire width of the fabric roll.

Think about it:

- Consistent aperture size.

- Uniform light transmission.

- Predictable air permeability.

Testing for tear resistance and snagging

High-quality mesh should resist “runs” even when a single fiber is compromised or stressed. You can test this by applying tension diagonally across the grain to check for structural failure.

The result?

- Longer garment lifespan.

- Reduced manufacturing waste.

- Improved customer satisfaction.

Key Takeaway: High-quality mesh should maintain its shape after stretching and feature consistent hole dimensions throughout the roll.

| Quality Metric | High Quality | Low Quality | |

|---|---|---|---|

| Edge Finish | Clean, no fraying | Uneven threads | |

| Hole Symmetry | Consistent | Irregular spacing |

Evaluate the edge finish to predict how the fabric will behave during high-speed sewing processes.

Where is breathable mesh fabric used in fashion?

Fashion designers use this material to create depth, texture, and technical aesthetics in modern streetwear and high-fashion collections. Modern breathable mesh fabric is no longer restricted to gym wear; it is now a staple for layered jackets and avant-garde overlays.

Designing airy summer apparel

Incorporating mesh panels into summer shirts allows for natural cooling in urban environments. You can use large-hole mesh for statement pieces or fine mesh for subtle, breathable inserts.

It gets better:

- Modern “naked” visual effects.

- Lightweight layering possibilities.

- Unique textural contrasts.

The rise of mesh in streetwear aesthetics

Streetwear brands utilize mesh to give garments a technical, utilitarian look that appeals to modern consumers. These designs often feature mesh pocket bags or ventilated back panels for functional style.

Look:

- Industrial aesthetic.

- Functional pocketing.

- Increased garment breathability.

Key Takeaway: Beyond sports, mesh has become a staple in fashion for adding texture and effects while ensuring the wearer stays cool.

| Fashion Use | Benefit | Impact | |

|---|---|---|---|

| Linings | Low friction | Smooth finish | |

| Overlays | Visual depth | Modern look |

Assess your design’s visual depth requirements to choose between fine or wide-hole mesh overlays.

Can breathable mesh fabric improve athletic performance?

Performance is significantly improved because the fabric prevents overheating and reduces the metabolic cost of thermoregulation. High-performance breathable mesh fabric effectively moves moisture away from the skin to the outer surface for evaporation.

Moisture-wicking properties for athletes

Synthetic mesh does not absorb water like cotton, which means it stays light even when the athlete is sweating heavily. This prevents the “heavy shirt” syndrome that can distract or slow down a competitor.

The bottom line:

- Reduced moisture retention.

- Faster evaporation rates.

- Consistent garment weight.

Why heat regulation matters in sportswear

Maintaining a stable core temperature allows an athlete to sustain high intensity for longer periods. You should place mesh panels in high-heat zones like the underarms and back to maximize this cooling effect.

Why does this matter?

- Extended endurance levels.

- Reduced risk of heat exhaustion.

- Superior comfort during peaks.

Key Takeaway: Strategic placement of mesh panels in high-sweat zones is scientifically proven to enhance athlete endurance.

| Performance Factor | Impact of Mesh | |

|---|---|---|

| Evaporation | Accelerated | |

| Body Temp | Maintained |

Analyze the heat zones of your specific sport to determine the optimal placement of ventilation panels.

What makes breathable mesh fabric ideal for shapewear?

The material provides a unique balance of high-tension compression and essential skin ventilation for all-day wear. Breathable mesh fabric in shapewear applications ensures that the wearer remains contoured without experiencing the suffocating heat of solid elastic fabrics.

Balancing compression and ventilation

Engineered power mesh uses a high spandex content to pull in the silhouette while the holes let the skin breathe. This combination is vital for medical-grade compression and everyday body-sculpting garments.

Look:

- High recovery stretch.

- Targeted compression zones.

- Minimal sweat buildup.

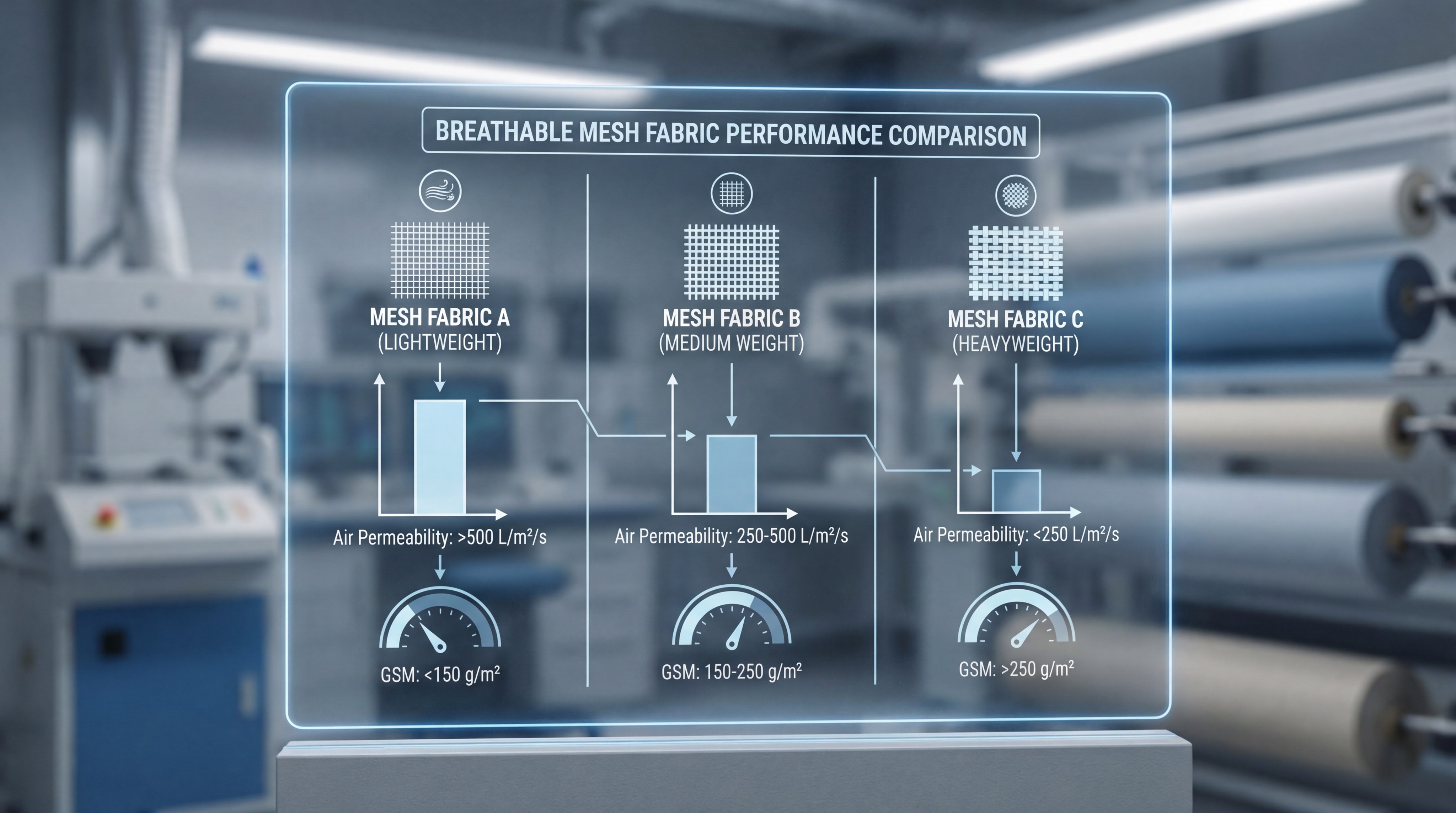

Which types offer the best support?

Higher GSM (grams per square meter) mesh provides more support and a firmer “hold” for abdominal or thigh contouring. You should choose a fine-gauge knit to ensure the fabric remains invisible under outer clothing.

The result?

- Smooth body lines.

- Invisible seams.

- All-day comfort.

Key Takeaway: Shapewear mesh utilizes a high density of elastic fibers to provide “sculpting” power while the holes allow the skin to breathe.

| Shapewear Goal | Required Mesh | |

|---|---|---|

| Contouring | High Spandex % | |

| Invisibility | Fine knit gauge |

Check the spandex percentage to ensure the mesh provides enough tension for effective body contouring.

How to sew with breathable mesh fabric effectively?

Sewing requires specialized needles and tension settings to prevent the delicate openwork from tearing or puckering. When you work with breathable mesh fabric , you must use a ballpoint needle to slide between the yarns rather than piercing them.

Choosing the right needle and thread

A size 70/10 or 80/12 jersey needle is ideal for maintaining the structural integrity of the mesh loops. You should pair this with high-quality polyester thread that matches the elasticity and strength of the synthetic base.

Wait, there is more.

- Ballpoint needle prevents runs.

- Polyester thread offers durability.

- Proper gauge avoids oversized holes.

Tips for preventing fabric puckering

Reducing your machine’s foot pressure and using a slight zigzag stitch will allow the seam to stretch with the fabric. You should also avoid pulling the material as it feeds through the machine to prevent permanent distortion.

In short:

- Use a walking foot.

- Match stitch to stretch.

- Maintain neutral tension.

Key Takeaway: Using a ballpoint needle is non-negotiable, as sharp needles can cut the delicate mesh fibers and cause holes to run.

| Tool | Recommendation | |

|---|---|---|

| Needle | Ballpoint (70/10) | |

| Stitch | Narrow Zigzag |

Select a ballpoint needle size based on the fineness of the mesh to prevent fiber damage.

Is breathable mesh fabric used in industrial settings?

Industrial applications utilize reinforced mesh for safety barriers, filtration systems, and heavy-duty cargo management. Breathable mesh fabric in these sectors is valued for its high tensile strength-to-weight ratio and resistance to environmental degradation.

Heavy-duty applications for mesh

Safety vests and architectural shading rely on the air permeability of mesh to protect workers and structures from wind load. You will find mesh in automotive seating where airflow prevents heat build-up against the leather.

Simply put:

- High tensile strength.

- Low wind resistance.

- Chemical and UV stability.

The role of mesh in filtration and safety

Mesh acts as a precise filter for liquids and air in manufacturing plants, where the aperture size must be strictly controlled. These fabrics are often coated with specialized resins to enhance their rigidness and longevity.

Look:

- Controlled aperture size.

- Debris containment.

- Flame retardant options.

Key Takeaway: Industrial mesh prioritizes tensile strength and resistance to environmental factors over soft hand-feel.

| Industry | Primary Use | |

|---|---|---|

| Automotive | Seat backing | |

| Safety | High-vis vests |

Verify the tensile strength ratings if the mesh is intended for load-bearing or safety applications.

How should you care for breathable mesh fabric items?

Proper care involves cold water washes and avoiding high-heat dryers to maintain the elasticity of the synthetic fibers. When you maintain breathable mesh fabric , using a protective laundry bag is the most effective way to prevent mechanical damage.

Washing tips to prevent snags

The open structure of mesh makes it susceptible to catching on zippers or hooks from other garments in the same load. You should always close all fasteners and turn the garment inside out before starting the cycle.

Think about it:

- Use a laundry bag.

- Cold or lukewarm water.

- Mild detergents only.

Why you should avoid the tumble dryer

High temperatures can cause synthetic mesh to become brittle or lose its “snap-back” elasticity permanently. You should air dry mesh items, which usually takes less than thirty minutes due to the high airflow.

The bottom line:

- Heat damages elastane.

- Air drying is rapid.

- Flat drying prevents stretch.

Key Takeaway: Heat is the primary enemy of synthetic mesh; air drying preserves the elasticity and prevents fibers from becoming brittle.

| Action | Recommendation | |

|---|---|---|

| Water Temp | Max 40°C | |

| Drying | Air dry only |

Prioritize air drying to extend the life of any mesh garment containing stretch fibers.

How to select breathable mesh fabric for heavy duty?

Heavy-duty selection requires a focus on burst strength and GSM to ensure the fabric can withstand mechanical pressure. Breathable mesh fabric for industrial use often features a reinforced knit that prevents the holes from expanding under load.

Load-bearing capabilities of reinforced mesh

When selecting for industrial use, you must consider the denier of the yarn to determine the textile’s overall resistance to tearing. Heavy-duty mesh is often used in truck covers and pool safety nets where durability is the priority.

It gets better:

- Reinforced fiber cores.

- High denier counts.

- Resistance to abrasion.

What are the best coatings for outdoor mesh?

Outdoor mesh should be treated with UV inhibitors and antimicrobial coatings to prevent rot and fading in the sun. These treatments ensure that the mesh remains functional and aesthetically pleasing for years.

The best part?

- Weatherproof finishes.

- Antimicrobial properties.

- Long-term UV protection.

Key Takeaway: For heavy-duty use, always verify the technical data sheet for burst strength and UV resistance ratings.

| Spec | Importance | |

|---|---|---|

| GSM | Weight/Strength | |

| Aperture | Flow control |

Review the burst strength specifications to ensure the mesh can handle the intended mechanical stress.

Conclusion

Mesh fabric remains a cornerstone of functional design due to its unique combination of lightness and durability. Whether you are creating high-performance athletic gear, contoured shapewear, or industrial-grade safety equipment, the right breathable mesh fabric ensures your project meets the highest standards of ventilation and comfort. We are committed to providing only the most resilient and airy textiles to help your designs succeed in any environment. If you need assistance with bulk orders or technical specifications, please feel free to contact us today .

FAQ

- Can I wash breathable mesh fabric in a regular machine?Yes, but you should always use a mesh laundry bag and a gentle cycle to prevent the fabric from snagging on other items.

- What’s the best way to prevent mesh from fraying?Absolutely use a serger (overlock) or a narrow zigzag stitch, as these encapsulate the raw edges and prevent the knit from unraveling.

- How does mesh fabric compare to cotton for summer wear?Mesh is significantly better for active use because it doesn’t hold moisture and provides much higher air permeability than natural cotton.

- Is breathable mesh fabric environmentally friendly?Many varieties are now available in recycled polyester (rPET), making them a sustainable choice for brands focusing on eco-friendly production.

- Does mesh fabric lose its shape over time?No, provided you avoid high-heat drying and choose a mesh with a high quality elastane percentage that offers superior recovery.