Working with delicate, high-stretch materials often leads to frustration when seams pucker or threads snap under tension. You might find that standard sewing techniques leave your “invisible” necklines looking bulky or amateurish. This agitation is common for designers moving into high-end bridal or performance athletic wear. By understanding the technical properties of 4-Way Stretch Mesh, you can create seamless, durable, and professional-grade garments that defy gravity and movement.

What makes 4-Way Stretch Mesh unique?

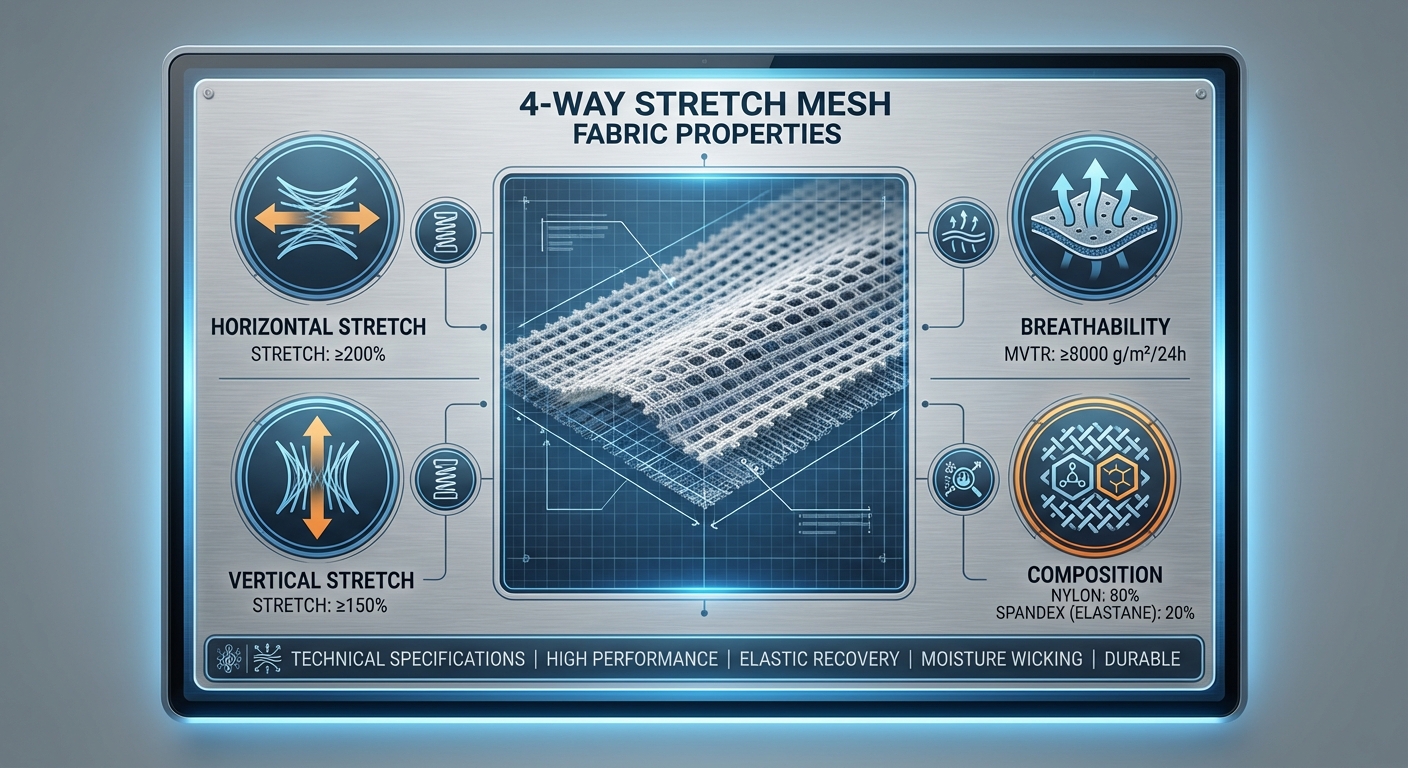

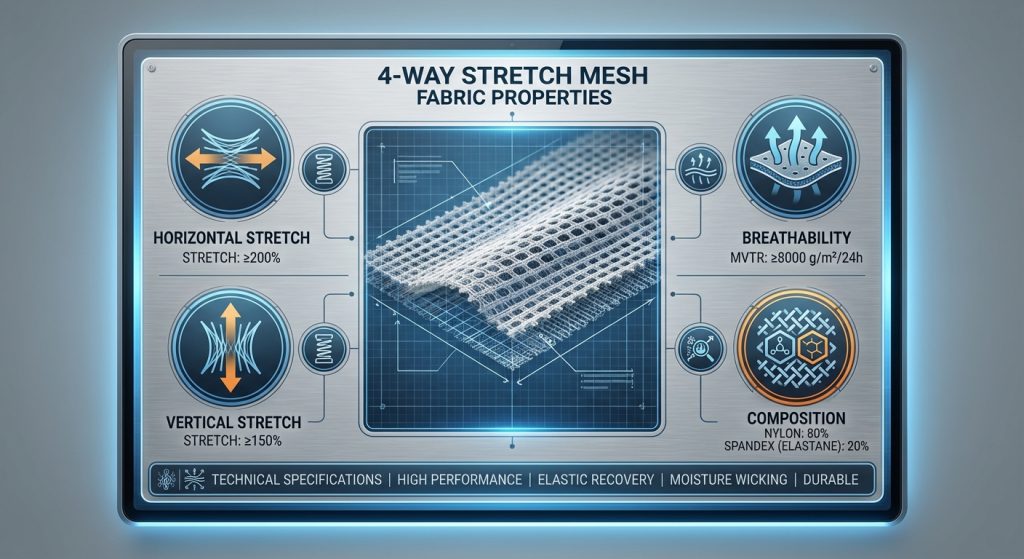

4-Way Stretch Mesh is a warp-knit fabric that offers significant elasticity in both the horizontal and vertical directions. This multi-directional movement allows the fabric to contour perfectly to the body without restricting range of motion. Unlike standard tulle, this mesh incorporates spandex or elastane to ensure it snaps back to its original shape. It is the gold standard for creating the “naked” look in modern couture.

The bottom line is this:

- It provides 360-degree flexibility for the wearer.

- The knit structure is run-resistant and breathable.

- High spandex content ensures excellent recovery.

- It is significantly more durable than Supporting Decorative Tulle .

Key Takeaway: The defining characteristic of this mesh is its ability to expand and recover in all directions, making it essential for form-fitting apparel.

| Feature | Property | |

|---|---|---|

| Stretch Direction | 4-Way (Vertical & Horizontal) | |

| Material Base | Nylon/Spandex Blend | |

| Common Use | Illusion necklines, dancewear | |

| Durability | High run-resistance |

How do you choose the right 4-Way Stretch Mesh weight?

Selecting the appropriate GSM (grams per square meter) is vital for the structural integrity of your garment. A lighter mesh is nearly invisible against the skin but may not support heavy embroidery or appliqués. If you are designing for daily wear, you might consider Apparel Mesh for its increased density. Always match the fabric weight to the specific stress points of the pattern.

Here is the secret:

- Lightweight mesh (30-50 GSM) is best for illusion effects.

- Mid-weight mesh (80-120 GSM) works well for sleeves and panels.

- Heavyweight mesh provides compression and muscle support.

- Testing the “drape” helps determine how the fabric will hang.

Key Takeaway: Weight determines both the transparency level and the amount of weight the fabric can support before sagging.

| Weight Category | GSM Range | Best Application | |

|---|---|---|---|

| Ultra-Light | 30 – 50 | Bridal Illusion | |

| Medium | 60 – 100 | Activewear Panels | |

| Heavy | 110+ | Support/Shaping |

Which needles work for 4-Way Stretch Mesh?

Using the wrong needle can cause irreversible damage to the delicate knit of 4-Way Stretch Mesh. You must use a stretch or ballpoint needle to ensure the tip slides between the fibers rather than piercing them. A sharp needle often creates “runs” or tiny holes that expand when the garment is worn. For the best results, stick to a size 70/10 or 75/11 to maintain a small entry point.

Believe it or not:

- Stretch needles prevent skipped stitches on elastic fabrics.

- Ballpoint tips are safer for the nylon knit loops.

- Frequent needle changes prevent snags from dull tips.

- High-quality polyester thread is stronger than Core Decorative Tulle fibers.

Key Takeaway: A 75/11 stretch needle is the industry standard for preventing fiber damage and ensuring stitch consistency.

| Tool | Specification | Purpose | |

|---|---|---|---|

| Needle Type | Stretch / Ballpoint | Protects nylon fibers | |

| Needle Size | 70/10 or 75/11 | Minimizes puncture holes | |

| Thread Type | Polyester / Nylon | Provides seam elasticity |

How do you stabilize 4-Way Stretch Mesh while sewing?

Stabilization is the most critical step to prevent the mesh from being “eaten” by your sewing machine’s feed dogs. You can place a strip of tissue paper or water-soluble stabilizer between the fabric and the throat plate. This provides the necessary friction for the machine to move the fabric forward evenly. Without this, your 4-Way Stretch Mesh will likely bunch up and jam the bobbin case.

Think about it:

- Tissue paper is a cost-effective, tear-away solution.

- Water-soluble stabilizers leave zero residue after washing.

- Spray adhesives can temporarily bond mesh to lining.

- It prevents the “tunneling” effect often seen in Stiff Tulle seams.

Key Takeaway: Temporary stabilizers provide the rigidity needed for clean, flat seams on slippery mesh surfaces.

| Method | Material | Removal | |

|---|---|---|---|

| Paper Method | Tissue Paper | Tear away | |

| Wash Method | Soluble Stabilizer | Rinse with water | |

| Spray Method | Temporary Adhesive | Evaporates/Washes out |

Why is recovery essential in 4-Way Stretch Mesh?

Recovery refers to how well the fabric returns to its original dimensions after being pulled. When you use 4-Way Stretch Mesh for activewear or dance, the fabric must withstand extreme movement without losing its shape. Poor recovery leads to baggy elbows, knees, and waistbands after just one use. High-quality Power Mesh is engineered specifically to maintain high tension over long periods.

Let’s dive in:

- High spandex percentage (above 15%) improves recovery.

- Heat exposure during washing can destroy recovery properties.

- Test recovery by stretching a 10cm sample to its limit.

- Good recovery ensures the “illusion” stays tight to the skin.

Key Takeaway: Superior recovery is the hallmark of professional-grade mesh, ensuring the garment retains its fit over time.

| Metric | High Quality | Low Quality | |

|---|---|---|---|

| Elasticity | Returns to 100% size | Stays slightly larger | |

| Spandex % | 12% – 25% | Below 10% | |

| Longevity | Maintains fit | Sags after wear |

What are the best hemming techniques for 4-Way Stretch Mesh?

Hemming 4-Way Stretch Mesh is often optional because the knit structure does not fray like woven fabrics. However, for a finished look, a narrow rolled hem or a serged edge is preferred. You should avoid standard folded hems, as they create a visible line that ruins the illusion effect. If you need a more decorative finish, consider using Glitter Tulle as a layered trim.

Wait, there is more:

- A raw edge provides the most “invisible” transition.

- Use woolly nylon thread in serger loopers for soft edges.

- Horsehair braid can be added for structural volume.

- It handles similarly to Soft Tulle during finishing.

Key Takeaway: While raw edges are most common for illusion pieces, rolled hems offer a polished, professional finish for sportswear.

| Hem Style | Appearance | Best For | |

|---|---|---|---|

| Raw Edge | Invisible | Necklines / Sleeves | |

| Rolled Hem | Delicate Line | Skirt Hems | |

| Serged Edge | Functional | Activewear Seams |

How should you cut 4-Way Stretch Mesh for accuracy?

Precision cutting is vital because even a slight shift can distort the 4-way stretch grainline. You should use a rotary cutter and a self-healing mat instead of traditional shears. Shears lift the fabric off the table, which causes the slippery 4-Way Stretch Mesh to slide and change shape. Using pattern weights instead of pins also prevents snagging the fine mesh holes.

It gets better:

- Single-layer cutting prevents the bottom layer from shifting.

- Marking with tailor’s chalk is difficult; use marking pens.

- Always align the greatest degree of stretch correctly.

- This technique is also ideal for cutting Bag Luggage Mesh .

Key Takeaway: Use a rotary cutter and weights on a flat surface to maintain the fabric’s geometric integrity during cutting.

| Cutting Tool | Performance | Advantage | |

|---|---|---|---|

| Rotary Cutter | Excellent | No fabric lifting | |

| Pattern Weights | Essential | Prevents shifting | |

| Fine Pins | Use Sparingly | Can cause snags |

What is the proper care routine for 4-Way Stretch Mesh?

Maintaining the longevity of 4-Way Stretch Mesh requires protecting the elastic fibers from heat and abrasion. You should always wash mesh garments in a protective laundry bag on a gentle cycle. High heat in a dryer will cause the spandex to become brittle and snap, leading to a loss of stretch. For specialized items like Footwear Mesh , air drying is the only way to preserve the shape.

Keep this in mind:

- Cold water prevents color bleeding and fiber damage.

- Mild detergents protect the nylon’s soft hand-feel.

- Never use bleach, as it dissolves spandex fibers.

- Hanging can cause stretching; lay flat to dry.

Key Takeaway: Gentle washing and air drying are non-negotiable for preserving the elasticity and color of your mesh.

| Care Step | Recommendation | Reason | |

|---|---|---|---|

| Water Temp | Cold | Protects Spandex | |

| Drying | Air / Flat | Prevents sagging | |

| Protection | Mesh Bag | Prevents snags |

How do you manage skin tone matching with 4-Way Stretch Mesh?

The success of an illusion design depends entirely on how well the 4-Way Stretch Mesh matches the wearer’s skin. You should view fabric swatches under various lighting conditions, including natural sunlight and fluorescent stage lights. A mesh that looks perfect in a showroom might look orange or grey under camera flashes. If you cannot find a perfect match, you can layer the mesh over Bridal Dress Tulle to shift the undertone.

That’s not all:

- Matte finishes disappear better than shiny ones.

- Custom dyeing is possible for nylon-based mesh.

- Layering two different shades can create depth.

- Testing against the inner wrist provides the best match.

Key Takeaway: True illusion effects require a matte finish and a precise color match tested across multiple light sources.

| Light Source | Effect on Mesh | Matching Tip | |

|---|---|---|---|

| Daylight | Reveals undertones | Check for “orange” hues | |

| Stage Lights | flattens color | Use matte textures | |

| Flash Photo | Can cause “glow” | Avoid high-sheen nylon |

Can you use 4-Way Stretch Mesh for high-impact sportswear?

Despite its delicate appearance, high-quality 4-Way Stretch Mesh is incredibly resilient and suitable for performance gear. It is frequently used for ventilation panels in leggings and compression tops. When sewing for high-impact use, you must reinforce the seams with clear elastic. This prevents the mesh from tearing away from opaque fabrics like performance polyester or spandex knits.

In other words:

- It provides essential moisture-wicking and airflow.

- Reinforcing seams prevents “stress-tears” during movement.

- It is more flexible than traditional Stiff Tulle .

- Use a 4-thread overlock for maximum seam strength.

Key Takeaway: When properly reinforced at the seams, mesh is a durable and functional component of high-performance athletic apparel.

| Feature | Sportswear Benefit | Reinforcement Need | |

|---|---|---|---|

| Breathability | Temperature control | Low | |

| Stretch | Muscle compression | High | |

| Dry Time | Moisture management | Low |

FAQ

Can I sew 4-way stretch mesh with a standard straight stitch?No, a straight stitch has no “give.” When the fabric is stretched, the thread will snap immediately, so you must use a zigzag or stretch stitch.

Does 4-way stretch mesh fray?Because it is a knit, it generally does not fray. You can leave edges raw for a seamless look, though a rolled hem is more durable for high-wear areas.

What is the difference between power mesh and illusion mesh?Power mesh is denser and offers more compression, while illusion mesh is sheerer and designed to blend into the skin.

Can I iron 4-way stretch mesh?You should avoid direct ironing, as the high nylon content can melt. Use a garment steamer on a low setting if you must remove wrinkles.

How do I prevent skipped stitches?Use a fresh stretch or ballpoint needle. If problems persist, ensure you are using high-quality polyester thread and a stabilizer like tissue paper.

Conclusion

Mastering 4-Way Stretch Mesh opens up a world of creative possibilities for bridal, athletic, and fashion designers. By utilizing the correct needles, stabilization methods, and cutting techniques, you can overcome the challenges of this slippery, high-stretch material. Whether you are creating a gravity-defying bridal bodice or a breathable performance top, the quality of your materials and the precision of your technique are paramount. At TulleMesh, we are committed to providing the premium textiles you need to bring your most ambitious designs to life. For expert advice or to explore our full range of professional fabrics, contact us today .