Imagine yourself in a high-end design atelier, surrounded by sketches of ethereal gowns, yet the prototype on the mannequin looks flat and lifeless. You’ve invested hours into a garment only to find the fabric lacks the necessary “poof,” drooping sadly under its own weight rather than defying gravity. Tulle fabric is a lightweight, fine netting made from various fibers that provides the structural integrity and airy volume required for high-fashion silhouettes. If you are struggling to identify the right textile for your project, you are likely asking what is tutu material called so you can source the exact weight and stiffness needed to transform a limp garment into a professional masterpiece.

What Is Tutu Material Called Exactly?

Tutu material is most accurately called tulle, a term derived from a French city known for its lace and netting production. When designers and manufacturers discuss what is tutu material called, they are usually referring to a broad category of hexagonal mesh textiles that range from soft bridal veiling to rigid ballet net. Understanding these distinctions is vital for B2B procurement and large-scale manufacturing.

Defining the Primary Netting Terminology

The textile industry classifies these materials under “netting,” though “tulle” is the standard term for the finer varieties. You will find that these fabrics are categorized by their hole size and the fiber used during the knitting process.

Most commercial tulle is knitted on Raschel machines, which create a stable, non-raveling mesh. This allows you to cut the fabric in any direction without the edges fraying.

The Real Difference Between Net and Tulle

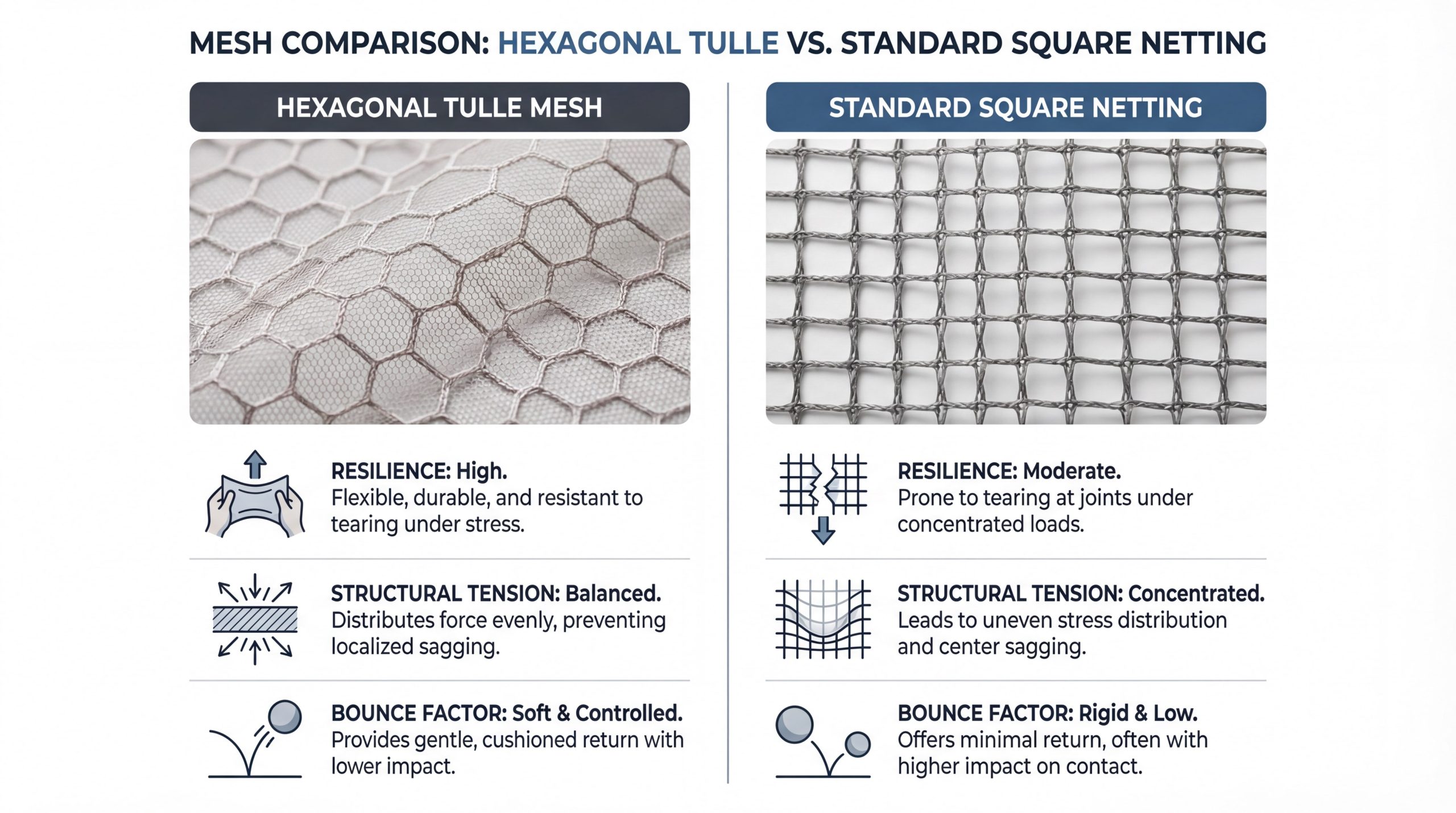

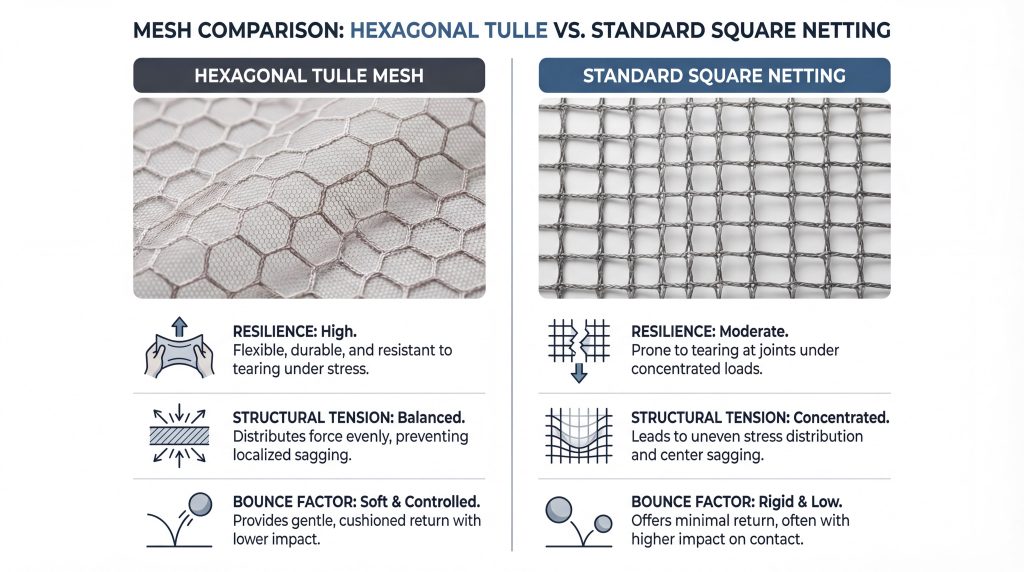

Netting is generally coarser and features larger, square-shaped holes compared to the fine hexagonal weave of tulle. While both provide volume, netting is often too abrasive for garments intended for skin contact.

- Hole Size: Tulle has microscopic holes; netting has visible gaps.

- Feel: Tulle is smoother; netting is scratchy and industrial.

- Drape: Tulle flows with movement; netting holds a static shape.

Let’s dive deeper.

Key TakeawayAlways specify “tulle” for fashion applications and “netting” for industrial or heavy structural needs to ensure the correct hand-feel.

Core Terminology Summary

| Term | Description | Primary Usage | |

|---|---|---|---|

| Tulle | Fine, hexagonal mesh | Fashion, veils, tutus | |

| Netting | Coarse, large mesh | Industrial, rigid base | |

| Bobbinet | Luxury hexagonal net | Bridal, high-end couture |

Standard tulle remains the most versatile option for achieving both volume and a soft aesthetic in professional garment construction.

Why Is Tulle the Gold Standard for Tutus?

Tulle is considered the gold standard because its hexagonal mesh structure provides a unique balance of tensile strength and “bounce” that other weaves cannot replicate. When you are sourcing what is tutu material called for professional dancewear, the spring-back capability of the hexagonal cells ensures the tutu maintains its iconic horizontal “pancake” shape even after hours of rehearsal.

The Science of the Hexagonal Mesh

The hexagonal weave distributes tension across six sides rather than four, preventing the fabric from sagging in the center. This geometry allows the fabric to support its own weight over large surface areas without collapsing.

Think about it. This structural efficiency means you can use fewer layers to achieve significant volume, reducing the overall weight of the costume for the performer.

Sheerness and Color Blending Secrets

Because tulle is semi-opaque, it allows for incredible depth when you layer different shades on top of one another. Designers often use this “optical mixing” to create custom colors that appear to change as the dancer moves.

- Layering blue over yellow creates a vibrant teal with a shimmering finish.

- Using a flesh-toned base layer under bright colors increases the “pop” on stage.

- Graduated shades can create an ombre effect without the need for fabric dyes.

But that’s not all…

Key TakeawayThe hexagonal structure is the secret to “bounce,” making tulle the only viable choice for high-performance ballet tutus.

Tulle Structural Benefits

| Property | Benefit | Impact on Tutu | |

|---|---|---|---|

| Lightweight | High volume, low mass | Improves dancer mobility | |

| Airy Texture | High breathability | Regulates body temperature | |

| Resilience | High “spring-back” | Maintains the “poof” factor |

The resilience of the hexagonal weave ensures that the fabric retains its aesthetic value throughout the life of the garment.

How Does Nylon Tulle Differ from Other Types?

Nylon tulle is distinguished by its superior elasticity and durability compared to polyester or natural fiber alternatives. In the context of what is tutu material called, nylon is the industry standard for high-traffic environments because it resists wrinkling and can withstand the rigors of frequent laundering.

Affordability for Large-Scale Production

Nylon is highly accessible and cost-effective, making it the preferred choice for wholesale orders. You will find it in a vast array of finishes, from matte to high-gloss, allowing for extreme design flexibility.

It is also exceptionally easy to dye, which means manufacturers can offer a virtually unlimited color palette to match specific branding or production themes.

Stretch and Recovery Factors

Unlike polyester, which can be brittle, nylon has a natural “memory” that allows it to be stretched and return to its original state. This is crucial for waistbands and bodices that must move with a dancer’s body.

- Resistance: Highly resistant to tearing and abrasion.

- Maintenance: Can often be hand-washed without losing stiffness.

- Longevity: Does not degrade or become brittle over time.

But wait, there’s more.

Key TakeawaySelect nylon tulle for any project requiring high durability and a wide color selection at a competitive price point.

Nylon Tulle Characteristics

| Feature | Nylon Tulle | Benefit | |

|---|---|---|---|

| Finish | Matte or Shiny | Aesthetic versatility | |

| Durability | Exceptional | Resists tearing during use | |

| Care | Hand wash/Air dry | Long-term shape retention |

Nylon’s inherent resilience makes it the most practical fiber for garments that require both beauty and heavy-duty performance.

When Should You Use Luxurious Silk Tulle?

Silk tulle should be reserved for high-end bridal wear and couture pieces where the drape and skin-feel are the primary priorities. While investigating what is tutu material called , you must recognize that silk is the “soft” version of this fabric, offering a fluid movement that synthetic fibers cannot emulate.

Creating the Perfect Bridal Silhouette

Silk tulle is remarkably delicate and is often used for veils that need to “float” behind a bride. Its natural fibers catch the light in a subtle, sophisticated way, avoiding the plastic-like sheen of some synthetics.

For professional designers, silk is the ultimate choice for editorial pieces where the camera needs to capture the softest possible texture.

Softness for Sensitive Skin

Many synthetic nettings can cause redness or irritation, but silk is naturally hypoallergenic and smooth. This makes it ideal for the innermost layers of a gown that come into direct contact with the wearer’s skin.

- It provides a luxurious “liquid” drape.

- The fabric is highly breathable for summer weddings.

- It creates a timeless, heirloom-quality finish.

Here is the kicker…

Key TakeawaySilk tulle is an investment in comfort and elegance, best suited for bridal veils and couture where “stiffness” is not required.

Silk vs. Synthetic Comparison

| Feature | Silk Tulle | Synthetic (Nylon/Poly) | |

|---|---|---|---|

| Drape | Fluid and soft | Structured and stiff | |

| Price | Premium/Luxury | Economical/Wholesale | |

| Feel | Smooth and natural | Can be slightly abrasive |

The premium cost of silk is justified by its incomparable hand-feel and its status as a staple in luxury fashion.

Is Polyester Tulle Better for Cost-Effective Designs?

Polyester tulle is often better for event decor and budget-conscious projects because it provides a higher level of stiffness at a lower price point. When asking what is tutu material called in the world of event planning, polyester is the go-to for table skirts and chair sashes due to its extreme wrinkle resistance.

Stiffness and Shape Retention in Decor

Polyester fibers are naturally more rigid than nylon, which allows decorative elements like bows and ruffles to stay “perky” without the need for starch. You can use it to create large-scale installations that remain crisp throughout a multi-day conference.

It is also more flame-retardant than many natural fibers, which is a critical safety consideration for commercial event venues.

Fade Resistance for Stage Use

Stage lighting is incredibly intense and can fade lower-quality fabrics quickly. Polyester tulle is chemically treated to hold its pigments, ensuring that your vibrant reds and deep blues look just as good during the final performance as they did during dress rehearsal.

- UV Resistance: Better suited for outdoor events.

- Cost: Significantly lower per yard than silk or high-grade nylon.

- Maintenance: Resists water spots and moisture damage.

Believe it or not…

Key TakeawayChoose polyester for temporary decorations and high-volume event needs to maximize your ROI without sacrificing visual impact.

Polyester Utility Breakdown

| Application | Why Use Polyester? | Result | |

|---|---|---|---|

| Event Decor | Holds shape perfectly | Professional-grade displays | |

| Costumes | Vibrant, stable colors | Visual “pop” under stage lights | |

| Bulk Projects | Lowest price point | High ROI for large quantities |

Polyester’s rigidity and color stability make it the most efficient choice for high-impact, low-cost aesthetics.

What Makes Professional Tutu Materials Special?

Professional tutu materials are special because they utilize “ballet net,” a specific type of tulle that has been heavily “sized” (chemically stiffened) to support multiple layers of embellishment. When looking for what is tutu material called in a professional conservatory, you aren’t looking for fashion tulle; you are looking for technical mesh that can support the weight of jewels and heavy embroidery.

Secrets of Professional Construction

The construction of a professional tutu involves using different stiffness levels for different layers. The bottom layers are often the stiffest to provide a foundation, while the top layer is slightly softer to allow for a beautiful finish.

This “structural layering” is what allows a classical tutu to stand perfectly horizontal without the use of hoops or wires.

Standard vs. High-Performance Grades

Craft-grade tulle is designed for children’s play-wear and is typically very soft and limp. High-performance grades are significantly denser and have a much tighter weave to prevent the fabric from catching on the dancer’s shoes or partner’s costume.

- Ballet Net: Extremely stiff, used for base layers.

- English Net: Heavier and softer, used for romantic tutus.

- Diamond Net: Features a larger mesh for extreme rigidity.

But that’s not all…

Key TakeawayProfessional tutu building requires a mix of “stiffness” grades to achieve the perfect balance of structure and aesthetics.

Professional Material Grades

| Grade | Stiffness Level | Typical Application | |

|---|---|---|---|

| Craft Grade | Soft/Limp | DIY and play costumes | |

| Professional | High Stiffness | Elite ballet companies | |

| English Net | Medium/Heavy | High-fashion bridal gowns |

The distinction between craft and professional grades is immediately apparent in the garment’s ability to hold its shape over time.

How Do Weight and GSM Affect Tutu Performance?

Fabric weight, measured in Grams per Square Meter (GSM), directly dictates how much “lift” and “air” a tutu will have. In the search for what is tutu material called, you must pay attention to GSM; a low GSM (12-15) creates a soft, romantic look, while a high GSM (30+) is necessary for the gravity-defying lift of a classical tutu.

Understanding Fabric Density

Higher GSM usually means a tighter weave or thicker fibers. If you choose a GSM that is too low for a classical tutu, you will end up with a sagging skirt that looks more like a petticoat than a performance garment.

Conversely, using a high GSM for a wedding veil will result in a stiff, unattractive piece that lacks the necessary grace and movement.

Selecting the Right Density

You must match the density to the specific style of the garment. For instance, a “Bell Tutu” requires a medium GSM to create that iconic rounded shape that isn’t quite horizontal but doesn’t hang straight down either.

- Low GSM: Best for veils and long, flowing skirts.

- Medium GSM: Ideal for tiered skirts and fashion overlays.

- High GSM: Mandatory for professional classical tutus.

Think about it.

Key TakeawayGSM is the most important technical spec to check when ordering tulle for structural garments.

Weight Selection Guide

| Style | Recommended GSM | Effect | |

|---|---|---|---|

| Classical | 30 – 45 (Stiff) | Horizontal “pancake” look | |

| Romantic | 15 – 20 (Soft) | Long, flowing, ethereal skirt | |

| Bell Tutu | 20 – 28 (Medium) | Rounded, sloped silhouette |

Precision in GSM selection ensures that the final product meets the specific performance requirements of the choreography.

Can You Use Mesh for Tutus and Performance Wear?

Yes, technical mesh is frequently used for the bodice and “panty” section of a tutu to provide the necessary stretch and breathability for the athlete. When sourcing what is tutu material called , don’t overlook athletic mesh fabrics, which offer the compression needed to keep the heavy tulle skirt securely in place during jumps and turns.

Incorporating Athletic Mesh Fabrics

Athletic mesh is much more durable than tulle and can withstand the constant tension of being pulled and stretched. It is typically used for the “yoke” of the skirt—the part that sits on the hips—to ensure a smooth, bulk-free fit.

Using mesh in high-perspiration areas like the underarms and back panels also increases the comfort of the performer during long shows.

The Benefit of Breathable Layers

Performance wear needs to be a “second skin.” Stretch mesh provides the flexibility required for extreme ranges of motion while allowing air to circulate, preventing the dancer from overheating under heavy stage lights.

- It offers 4-way stretch for maximum mobility.

- The moisture-wicking properties keep the skin dry.

- It is much easier to sew to spandex than standard tulle.

But it gets better…

Key TakeawayCombine tulle for the skirt and stretch mesh for the bodice to create a costume that is both beautiful and functional.

Mesh in Dancewear Applications

| Mesh Type | Function | Placement | |

|---|---|---|---|

| Athletic Mesh | Ventilation | Bodice and back panels | |

| Stretch Mesh | Flexibility | Sleeves and yokes | |

| Tulle | Volume | The skirt layers |

Integrating different mesh types allows you to engineer a garment that supports the athlete’s body while maintaining a high-fashion look.

What Other Fabrics Are Used for Tutu Foundations?

Tutu foundations often rely on Power Mesh and Coutil to provide the rigid support necessary to anchor dozens of layers of tulle. Even though you are primarily concerned with what is tutu material called, you must also understand the internal “scaffolding” that prevents the skirt from collapsing under its own weight.

Power Mesh and Lining Applications

Power Mesh is a heavy-duty stretch fabric used for compression. In tutu construction, it is used for the “panty” to ensure the skirt stays anchored to the dancer’s waist and hips, even during rigorous movement.

Lining mesh is a softer, finer version used to protect the dancer’s skin from the scratchy edges of the structural tulle.

Avoiding Puckering During Construction

Sewing these technical fabrics requires specialized knowledge. Because they are so “airy,” they tend to shift under the presser foot, leading to puckering or uneven seams.

- Tips: Use a ball-point needle to avoid snagging the mesh.

- Support: Use a stabilizer or tissue paper when sewing fine edges.

- Thread: Opt for high-quality polyester thread that has a slight “give.”

Let’s dive deeper.

Key TakeawayThe foundation is just as important as the tulle; use Power Mesh for security and lining mesh for comfort.

Foundation Materials Summary

| Fabric | Role | Key Benefit | |

|---|---|---|---|

| Power Mesh | Compression | Keeps the tutu anchored | |

| Lining Mesh | Comfort | Prevents skin irritation | |

| Coutil | Rigid Support | Used in high-end bodices |

A well-constructed foundation is the difference between a costume that lasts for years and one that falls apart after a single show.

How Do You Match Tutu Materials to Specific Uses?

Matching materials to their use requires a careful evaluation of the desired stiffness, durability, and cost for that specific project. To truly master what is tutu material called , you should keep a swatch book of various GSM weights and fiber types to feel the difference in “hand” before placing a wholesale order.

Tailoring Fabric to Your Project

If you are creating a one-time-use table skirt for a gala, polyester is your best friend. However, if you are designing a wedding gown that will be an heirloom, you must choose the elegance of silk or a high-grade nylon English net.

For high-performance ballet, only specialized ballet net with a high GSM will provide the structural integrity required for a professional stage appearance.

Summary of Best Practices

Always request samples before committing to a large yardage. Different manufacturers may have slightly different sizing processes, which can change the stiffness of the fabric even if the GSM is the same.

- Test the “bounce” by crumpling a small piece in your hand.

- Check for “flaking” on glitter tulle to ensure high-quality adhesion.

- Verify the flame-retardant status for all commercial event applications.

But that’s not all…

Key TakeawayAlways prioritize the end-use environment—stage, wedding, or event—when selecting your final tulle material.

Application Selection Guide

| Application | Best Material Name | Reasoning | |

|---|---|---|---|

| Play Tutus | Nylon Tulle | Durable, colorful, and cheap | |

| Wedding Gowns | Silk or English Net | Elegant drape and premium feel | |

| Stage Tutus | Ballet Net | Extreme stiffness and lift |

Choosing the right material ensures that your design not only looks perfect on the mannequin but performs flawlessly in the real world.

In conclusion, understanding the nuances between nylon, polyester, and silk tulle—along with technical specifications like GSM—is what separates a hobbyist from a professional designer. By matching the specific properties of these nettings to your project’s needs, you can ensure structural integrity, comfort, and aesthetic brilliance. Ready to transform your next design? To explore our full range of professional-grade textiles or to discuss your wholesale needs, contact us today .

Frequently Asked Questions

What is the stiffest tutu material called?The stiffest material is generally referred to as Ballet Net or Diamond Net. This is a heavy-duty nylon mesh that has been chemically treated with sizing to maintain a rigid, horizontal shape required for classical tutus.

Is tulle and organza the same thing?No, they are fundamentally different. Tulle is a knitted mesh (net) with a hexagonal structure, while organza is a plain-weave fabric that is more opaque and has a different type of stiffness.

Why is my tutu material so itchy?Itchiness is usually caused by using cheap, coarse nylon netting with large, rough holes. To prevent this, you should use a high-quality Lining Mesh or soft Silk Tulle for any layers that come into direct contact with the skin.

Can I wash a tutu made of polyester tulle?Yes, polyester is highly durable and resistant to water damage. However, you should always hand-wash tutus in cool water and air-dry them to prevent the heat of a dryer from melting the fine fibers or ruining the “bounce.”

How do I know if I need nylon or polyester tulle?Nylon is the best choice if you need elasticity, a wide color range, and a soft feel for clothing. Polyester is the superior choice for event decorations, table skirts, and budget projects where extreme stiffness and wrinkle resistance are the priorities.