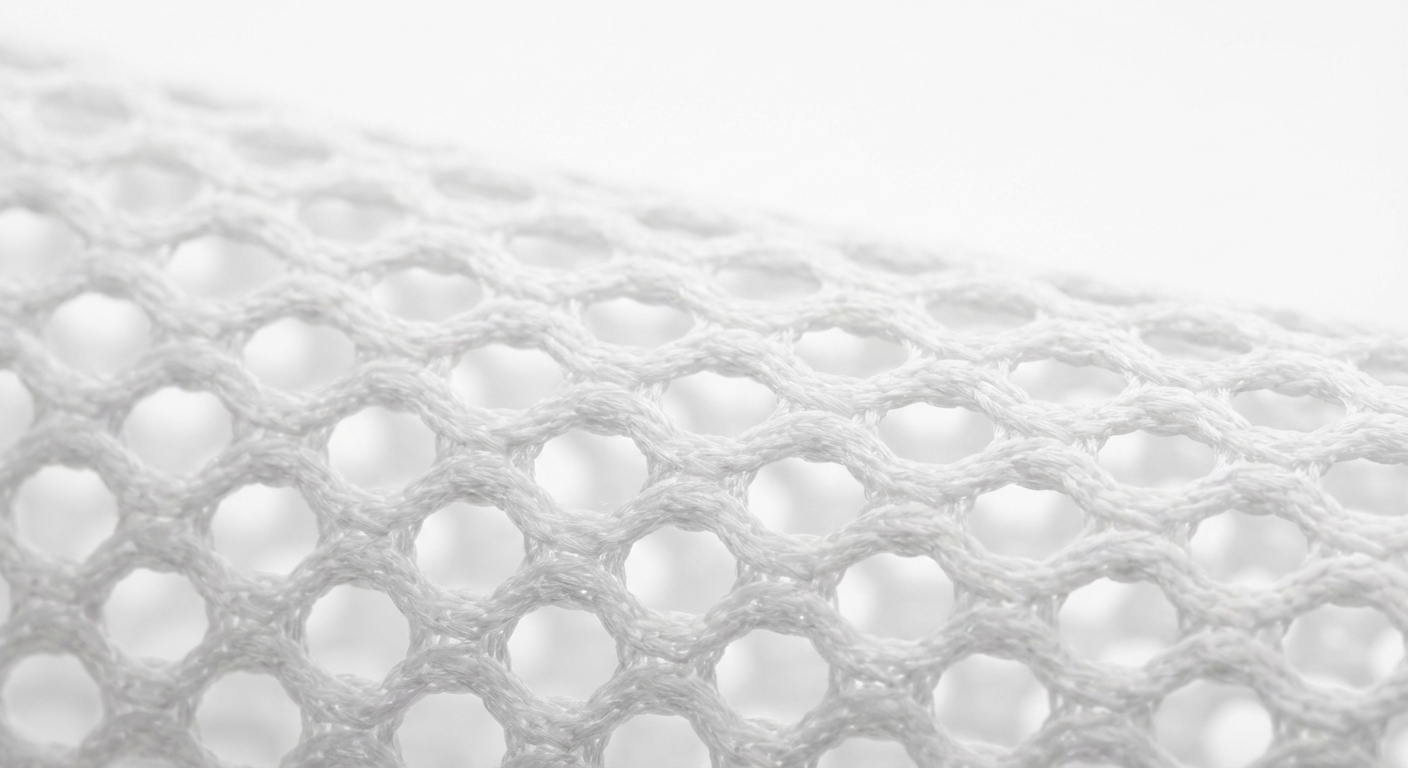

Mesh fabric is a textile characterized by its open-weave structure, creating a net-like appearance with breathable “voids” between the yarns. Many designers and manufacturers struggle with traditional textiles that trap heat and moisture, leading to wearer discomfort and reduced product lifespan in high-performance environments. This stagnation in material utility can stifle innovation and limit the functional appeal of your collections. To overcome these barriers, high-performance fabric mesh material provides the necessary ventilation and structural integrity required for modern industrial and fashion applications.

1. What defines high-quality fabric mesh material?

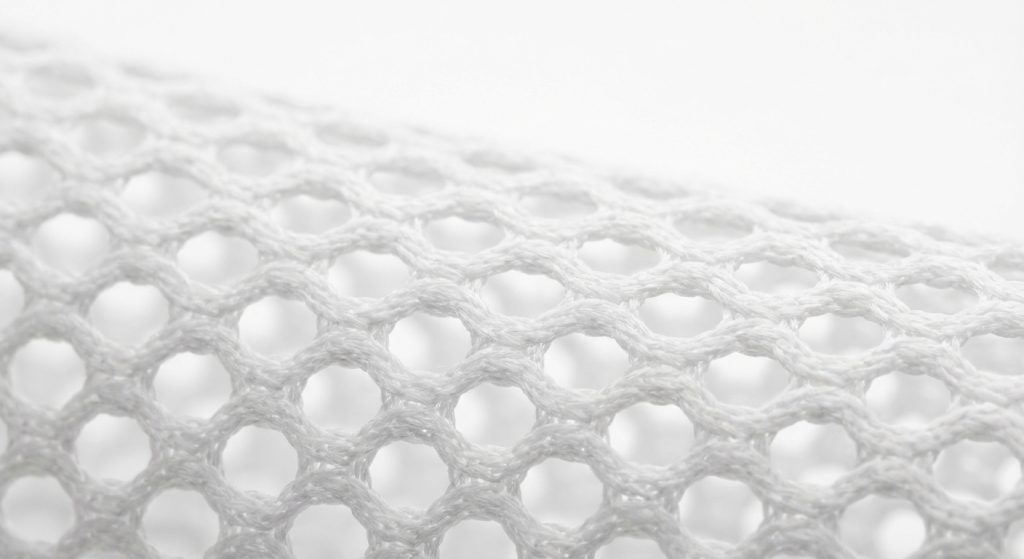

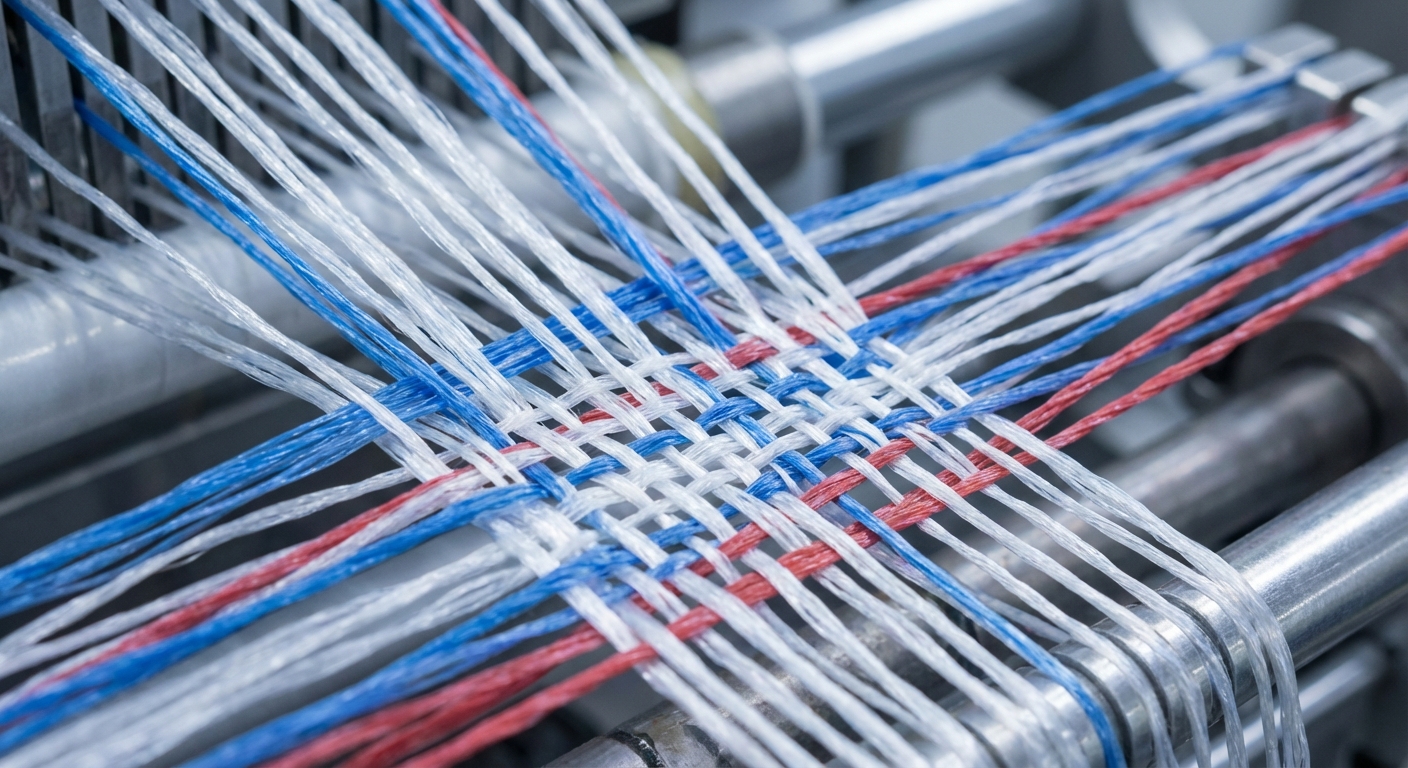

High-quality fabric mesh material is primarily defined by its knit consistency and the tensile strength of the individual synthetic filaments used. The manufacturing process ensures that the “pores” are uniform in size, which prevents structural failures under mechanical stress.

How does the weave density affect durability?

The density of the weave determines how well the fabric resists tearing and abrasion during heavy use. When you select a higher-density knit, you ensure the material can withstand significant tension without losing its shape.

But wait, there’s more…

- Knit Pattern: Warp-knitted structures are less likely to run or unravel.

- Yarn Quality: High-tenacity polyester or nylon increases life expectancy.

- Finish: Heat-set finishes ensure dimensional stability.

Key Takeaway: Quality is a measure of structural memory and the precision of the knit pattern, ensuring long-term performance.

| Quality Factor | Performance Impact | B2B Priority | |

|---|---|---|---|

| Pore Uniformity | Consistent airflow | High | |

| Tensile Strength | Resistance to tearing | Critical | |

| Color Fastness | Longevity of aesthetic | Medium |

Analysis: A focus on technical specifications like pore uniformity is essential for ensuring that the mesh meets rigorous industrial standards.

2. What kind of fabric mesh material is best for gear?

Selecting the right fabric mesh material for technical gear depends on the specific environmental stressors the product will encounter. For heavy-duty equipment, manufacturers typically prioritize high-denier polyester for its UV resistance and hydrophobic properties.

Is polyester or nylon better for industrial gear?

Nylon is often chosen for its superior abrasion resistance and softer hand-feel, whereas polyester excels in outdoor settings due to its dimensional stability. You may find that integrating power mesh is necessary when your gear requires high-recovery elasticity and compression.

The truth is:

- Polyester: Ideal for load-bearing vests and backpacks.

- Nylon: Perfect for hosiery, linings, and lightweight accessories.

- Blends: Used to balance cost, weight, and durability.

Key Takeaway: Material selection should align with the primary stress factor—either friction for nylon or UV/moisture for polyester.

| Material Type | Primary Benefit | Common Gear Use | |

|---|---|---|---|

| Polyester | UV & Weather Resistance | Tents, Bags, Vests | |

| Nylon | High Abrasion Resistance | Linings, Footwear | |

| Elastane Blends | Compression & Stretch | Compression Sleeves |

Analysis: The mechanical profile of the base polymer determines the suitability of the mesh for specific high-stress gear applications.

3. Which fabric mesh material suits specific industries?

The versatility of fabric mesh material allows it to bridge the gap between healthcare, sports, and aerospace. In each sector, the mesh serves a unique function, from moisture-wicking in athletics to biocompatible filtering in medical devices.

Why is breathability the standout feature?

Breathability is the core value proposition because it allows for instantaneous thermal regulation in high-intensity environments. When you utilize mesh, you are essentially engineering a ventilation system directly into the product’s surface.

Think about it:

- Sports: Maximizes airflow to prevent overheating.

- Medical: Provides lightweight support for orthotics.

- Industrial: Filters air and liquids while remaining durable.

Key Takeaway: The industry-specific value of mesh lies in its ability to facilitate fluid and air movement without sacrificing structural support.

| Industry | Primary Function | Mesh Characteristic | |

|---|---|---|---|

| Athletics | Cooling/Wicking | Large Pore Size | |

| Healthcare | Support/Sanitation | Hypoallergenic Fibers | |

| Manufacturing | Protection/Filtration | High Tensile Strength |

Analysis: Adapting mesh specifications to industry requirements ensures that functional benefits like cooling or filtration are maximized for the end user.

4. How do you maintain a fabric mesh material?

Maintaining the integrity of fabric mesh material requires specialized handling to prevent snagging and fiber degradation. Since mesh consists of open loops, it is more susceptible to mechanical damage during standard industrial cleaning processes.

What are the best washing practices for mesh?

You should always use a protective laundry bag to shield the mesh from abrasive contact with zippers or heavy buttons. Cold water settings are mandatory to prevent the synthetic fibers from shrinking or losing their elasticity over time.

Here is the kicker:

- Washing: Use delicate cycles and mild detergents.

- Drying: Avoid high-heat dryers; air drying is preferred.

- Storage: Store flat or rolled to prevent permanent creasing.

Key Takeaway: Longevity is directly tied to the reduction of thermal and mechanical stress during the maintenance cycle.

| Maintenance Step | Recommendation | Risk of Failure | |

|---|---|---|---|

| Washing | Cold Cycle / Mesh Bag | Fiber Snagging | |

| Drying | Air Dry / Low Heat | Melting / Shrinkage | |

| Ironing | Steaming Only | Surface Scorching |

Analysis: Proactive care protocols are essential for maintaining the aesthetic and functional properties of mesh products throughout their lifecycle.

5. How is fabric mesh material used in clothing design?

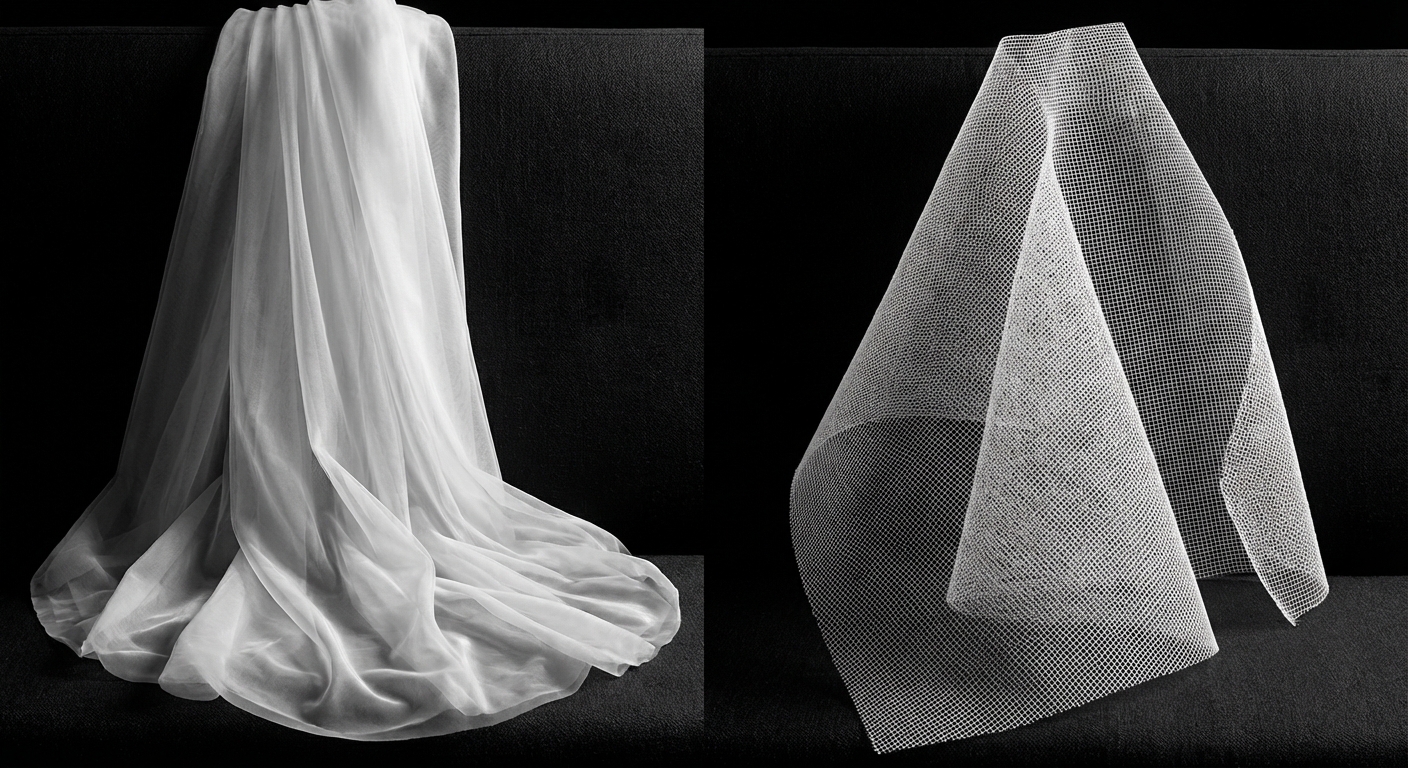

In contemporary fashion, fabric mesh material serves as both a structural foundation and a decorative overlay. Designers leverage its transparency to create depth, using materials like glitter tulle to add visual complexity without increasing the garment’s weight.

Where should mesh inserts be placed for airflow?

Strategic placement is critical; you should focus on high-perspiration zones such as the side panels, back, and underarms. This targeted approach improves the wearer’s comfort while maintaining a cohesive look for the overall garment design.

Simply put:

- Overlay: Adds volume and texture to gowns.

- Lining: Provides a soft, breathable barrier for the skin.

- Accents: Enhances visibility and modern aesthetic.

Key Takeaway: Effective clothing design integrates mesh to solve the dual challenge of visual appeal and thermal management.

| Design Use | Visual Result | Functional Result | |

|---|---|---|---|

| Panels | Modern/Athletic Look | Targeted Ventilation | |

| Overlays | Depth and Dimension | Lightweight Volume | |

| Full Mesh | Transparency | Maximum Airflow |

Analysis: Designers must balance the transparency of mesh with the functional needs of the garment to create a balanced product.

6. Is fabric mesh material a sustainable design choice?

Fabric mesh material can be a highly sustainable option when manufactured using recycled polymers like rPET. These materials reduce the reliance on virgin petroleum products while offering the same performance characteristics required for industrial applications.

Are there recycled alternatives for polyester?

Yes, many suppliers now provide mesh made from post-consumer plastic waste, which you can use to meet your corporate sustainability goals. These recycled options maintain high tensile strength and color vibrancy, making them indistinguishable from standard versions.

Best of all:

- Resource Savings: Uses less energy to produce than virgin fiber.

- Waste Reduction: Keeps plastic bottles out of landfills.

- Durability: Long-lasting products reduce the need for replacement.

Key Takeaway: Moving toward recycled mesh allows brands to maintain high performance while significantly lowering their environmental footprint.

| Sustainability Metric | Recycled Mesh | Standard Mesh | |

|---|---|---|---|

| Carbon Footprint | Lower | Higher | |

| Water Usage | Reduced | Moderate | |

| End-of-Life | Recyclable | Limited |

Analysis: The adoption of recycled mesh is a strategic move for brands looking to align with global environmental standards without sacrificing quality.

7. What is the process for printing fabric mesh material?

Printing on fabric mesh material requires a deep understanding of the substrate’s transparency and open-weave nature. Standard ink applications may fail if the pores are clogged, which is why digital sublimation is the preferred method for high-detail designs.

Which printing techniques work best on mesh?

Sublimation printing is ideal because it dyes the fibers at a molecular level, ensuring that you don’t block the fabric’s essential air passages. This method preserves the breathability of the mesh while providing vibrant, permanent color that will not peel or crack.

It gets better:

- Digital Sublimation: Perfect for complex, multi-color patterns.

- Screen Printing: Best for simple, bold graphics on tight mesh.

- UV Printing: Useful for industrial-grade mesh used in signage.

Key Takeaway: Success in printing mesh depends on choosing a method that maintains the fabric’s permeability and tactile softness.

| Print Method | Clarity | Breathability Retention | |

|---|---|---|---|

| Sublimation | Excellent | 100% | |

| Screen Print | Good | 60-80% | |

| UV Digital | High | 40-70% |

Analysis: Sublimation remains the gold standard for mesh apparel printing due to its ability to preserve the primary functional benefit of airflow.

8. What makes a fabric mesh material feel soft or stiff?

The hand-feel of fabric mesh material is determined by the fiber diameter and the specific finishing agents applied after the knitting process. Softness is often a result of using fine nylon filaments, while stiffness is achieved through coarse polyester and resin coatings.

When should you opt for a structured, rigid mesh?

You should choose a stiff tulle when your design requires architectural volume or structural support, such as in tutus or filtration frames. Conversely, soft tulle is much better suited for garments that need to drape gracefully over the body.

Look at it this way:

- Soft Mesh: Feels like silk; ideal for lingerie and skin-contact linings.

- Stiff Mesh: Feels crisp; holds its shape even under the weight of other fabrics.

- Medium Mesh: Balances structure and comfort for standard sportswear.

Key Takeaway: The “hand” of the mesh dictates the silhouette of the final product and the comfort level of the wearer.

| Mesh Type | Hand-Feel | Ideal Application | |

|---|---|---|---|

| Soft Tulle | Smooth/Pliable | Lingerie, Gowns | |

| Stiff Tulle | Rigid/Textured | Millinery, Tutus | |

| Industrial Mesh | Rough/Durable | Filters, Screens |

Analysis: Tactile selection is a crucial design decision that influences both the aesthetic volume and the user’s sensory experience.

9. Is fabric mesh material safe for protective use?

Safety-grade fabric mesh material is engineered to meet specific regulatory standards for fire resistance and high visibility. These specialized textiles undergo chemical treatments to ensure they can protect workers in hazardous environments without causing heat stress.

How does flame-retardant mesh function?

When you use flame retardant mesh , the fabric is designed to self-extinguish when removed from an ignition source, preventing the material from melting onto the skin. This is essential for safety vests and protective gear used in electrical or construction work.

Here is why:

- Certification: Ensures the material meets OSHA or EN standards.

- Visibility: Mesh often incorporates fluorescent dyes for high-viz gear.

- Airflow: Keeps workers cool under heavy protective layers.

Key Takeaway: Safety mesh is a life-saving technology that combines high-visibility standards with fire-suppression capabilities.

| Protection Type | Certification | Common Application | |

|---|---|---|---|

| Fire Resistant | NFPA 701 / EN 11612 | PPE, Uniforms | |

| High Visibility | ANSI/ISEA 107 | Construction Vests | |

| Anti-Static | EN 1149 | Electronics Assembly |

Analysis: For safety applications, the technical certification of the mesh is as important as the physical knit properties.

10. How do you select the right fabric mesh material?

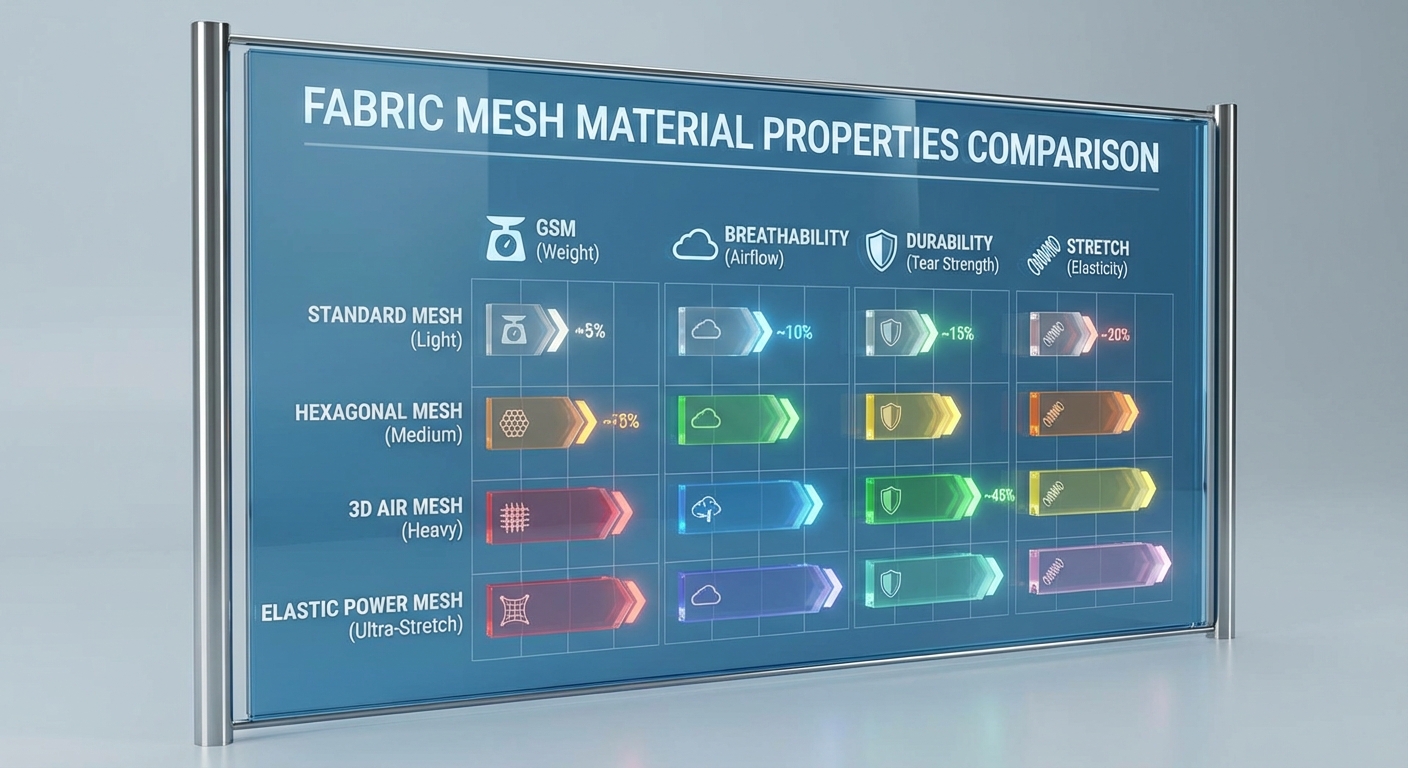

Choosing the correct fabric mesh material involves a technical assessment of weight (GSM), hole size, and fiber elasticity to match the intended end-use. Selecting an inappropriate mesh can lead to sagging, poor ventilation, or early product failure in the field.

What weight is appropriate for different projects?

For delicate apparel, you should look for lightweight mesh under 50 GSM, while heavy-duty bags and industrial filters often require weights exceeding 200 GSM. Understanding the relationship between weight and durability will help you optimize your material costs and product performance.

Look at it this way:

- Lightweight: Best for veils and decorative overlays.

- Midweight: Standard for basketball jerseys and athletic sneakers.

- Heavyweight: Required for load-bearing mesh and safety nets.

Key Takeaway: Weight and pore size must be balanced to achieve the desired levels of strength, opacity, and airflow.

| Project Type | Recommended GSM | Preferred Fiber | |

|---|---|---|---|

| Fashion Overlay | 15 – 40 | Fine Nylon | |

| Activewear | 80 – 150 | Polyester/Spandex | |

| Industrial Filter | 200+ | Coarse Polyester |

Analysis: A data-driven approach to material selection ensures that the final product meets both aesthetic expectations and performance requirements.

Conclusion

Mesh fabric is much more than just a material with holes; it is a sophisticated engineering solution for breathability and structural integrity. By addressing the common pain points of heat retention and moisture buildup, mesh has revolutionized industries from high-fashion to industrial safety. Our vision is to empower creators with high-performance textiles that push the boundaries of functional design. To explore our full range of premium solutions for your next project, contact us today .

Frequently Asked Questions

Can I use mesh for heavy-duty outdoor applications?Yes, provided you select high-tenacity polyester. Polyester is naturally hydrophobic and offers the UV resistance necessary to withstand prolonged sun exposure without degrading.

What’s the best way to print logos on mesh jerseys?Digital sublimation is the most effective method. It ensures the ink becomes part of the fiber, which maintains the fabric’s breathability and prevents the logo from cracking.

How do I know if my mesh is flame retardant?You must check for specific certifications such as NFPA 701. High-quality safety mesh will always be accompanied by technical documentation verifying its self-extinguishing properties.

Can mesh fabric be recycled?Yes, if it is made from 100% polyester. Pure polyester mesh can be mechanically or chemically recycled into new fibers, supporting a circular manufacturing economy.

What is the best mesh for compression wear?Power mesh is the ideal choice. It integrates high percentages of elastane to provide the necessary tension and recovery required for medical and athletic compression garments.