Stiff tulle is a lightweight, open-weave mesh fabric characterized by a firm finish, typically achieved through specialized resin coatings or dense synthetic fibers like nylon and polyester. Many high-volume designs—like ballgowns and tutus—fail because the fabric lacks the structural integrity to hold a silhouette. Soft fabrics drape beautifully but collapse under their own weight, leading to garments that look flat and unprofessional within hours. stiff tulle fabric acts as the hidden architectural foundation for the fashion industry, providing the necessary lift and durability for high-impact designs.

What exactly is stiff tulle fabric?

Stiff tulle is a variety of hexagonal mesh characterized by a rigid finish that resists draping, used primarily for structural support in apparel. This specialized version of stiff tulle fabric is engineered to maintain its shape even when under the pressure of heavy top-layers.

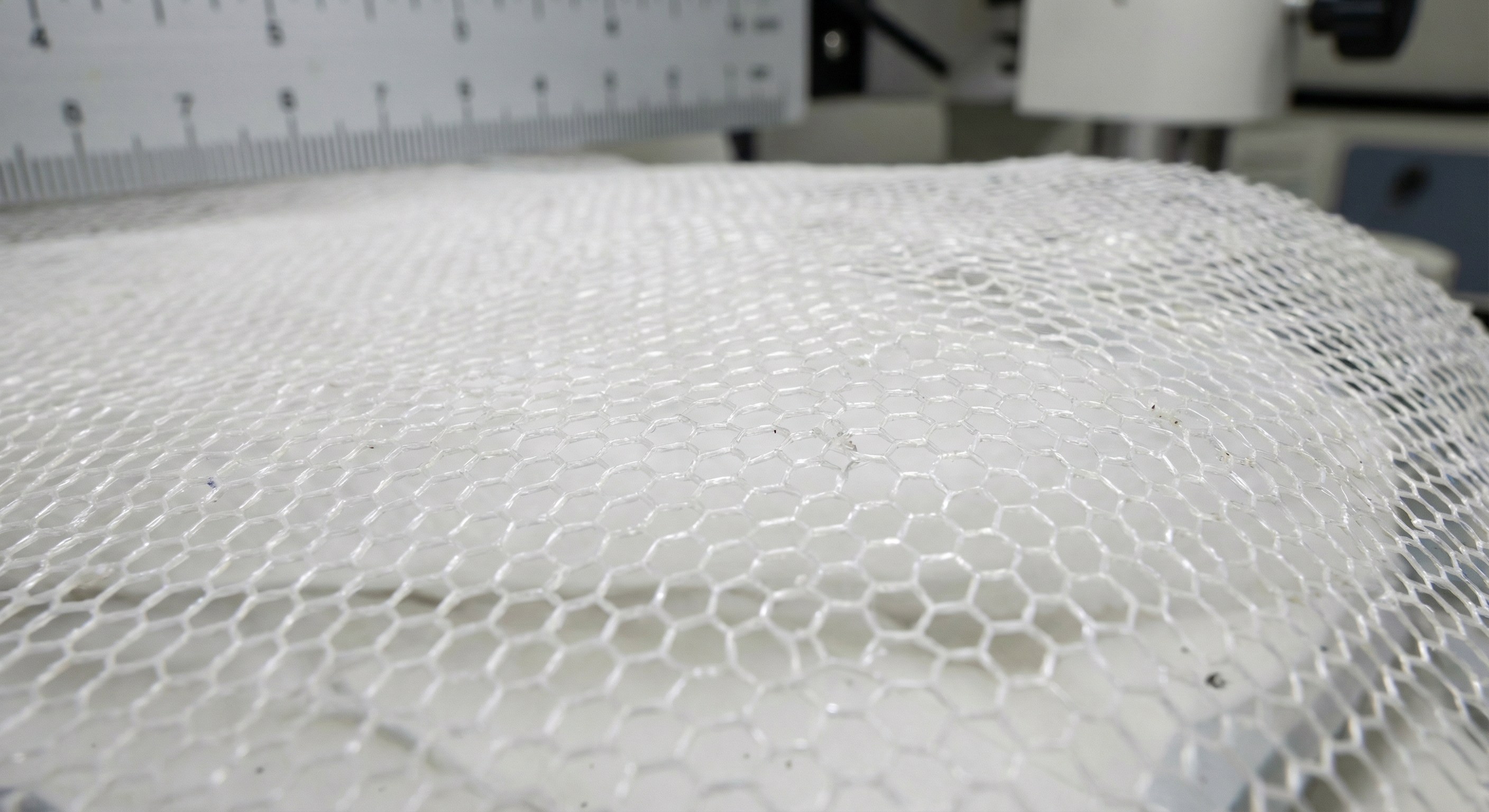

Understanding the hexagonal mesh structure

Think about it:

- The hexagonal grid provides inherent stability to the textile.

- Small cell sizes increase the density and support capability.

- Uniform holes ensure that the tension is distributed evenly across the garment.

How is the stiffness achieved?

It gets better:

- Synthetic fibers are treated with a starch or resin-based coating.

- High-heat setting processes lock the fibers into a permanent rigid state.

- Some variations use thicker denier threads to create a mechanical stiffness.

Key Takeaway: The structural integrity of stiff tulle relies on the combination of a tight hexagonal weave and specialized chemical finishing.

| Feature | Description | |

|---|---|---|

| Texture | Rigid, crisp, and scratchy | |

| Material | Usually 100% Nylon or Polyester | |

| Primary Use | Underskirts, tutus, and craft structure |

The mechanical properties of this mesh allow designers to manipulate space and volume without adding significant weight to the final product.

Why use stiff tulle fabric in bridal wear?

In bridal design, stiff tulle fabric is the engine behind the “A-line” and “Ballgown” shapes, providing lift without adding excessive weight. This material is indispensable for designers who need to manage the transition from a slim waist to a voluminous floor-length skirt.

Supporting heavy satin and lace overlays

Check this out:

- Stiff mesh prevents heavy luxury fabrics from clinging to the legs.

- It provides a buffer that keeps the silhouette consistent during movement.

- Multiple layers can be tiered to create custom levels of “poof.”

Creating the iconic Cinderella silhouette

The best part?

- Achieving extreme volume is impossible with soft nylon mesh fabric alone.

- Stiff layers act as a skeleton for the lighter fashion fabrics on top.

- Designers can sculpt specific angles that remain crisp throughout the wedding event.

Key Takeaway: Stiff tulle is usually hidden between the lining and the fashion fabric to provide invisible support for high-drama bridal silhouettes.

| Bridal Application | Role of Stiff Tulle | |

|---|---|---|

| Petticoats | Provides maximum lift and floor clearance | |

| Veil Edging | Helps horsehair braids maintain shape | |

| Bodice Support | Adds minor rigidity to textured appliqués |

By using this fabric as a foundation, bridal houses can guarantee that their gowns look as intended from the first photo to the last dance.

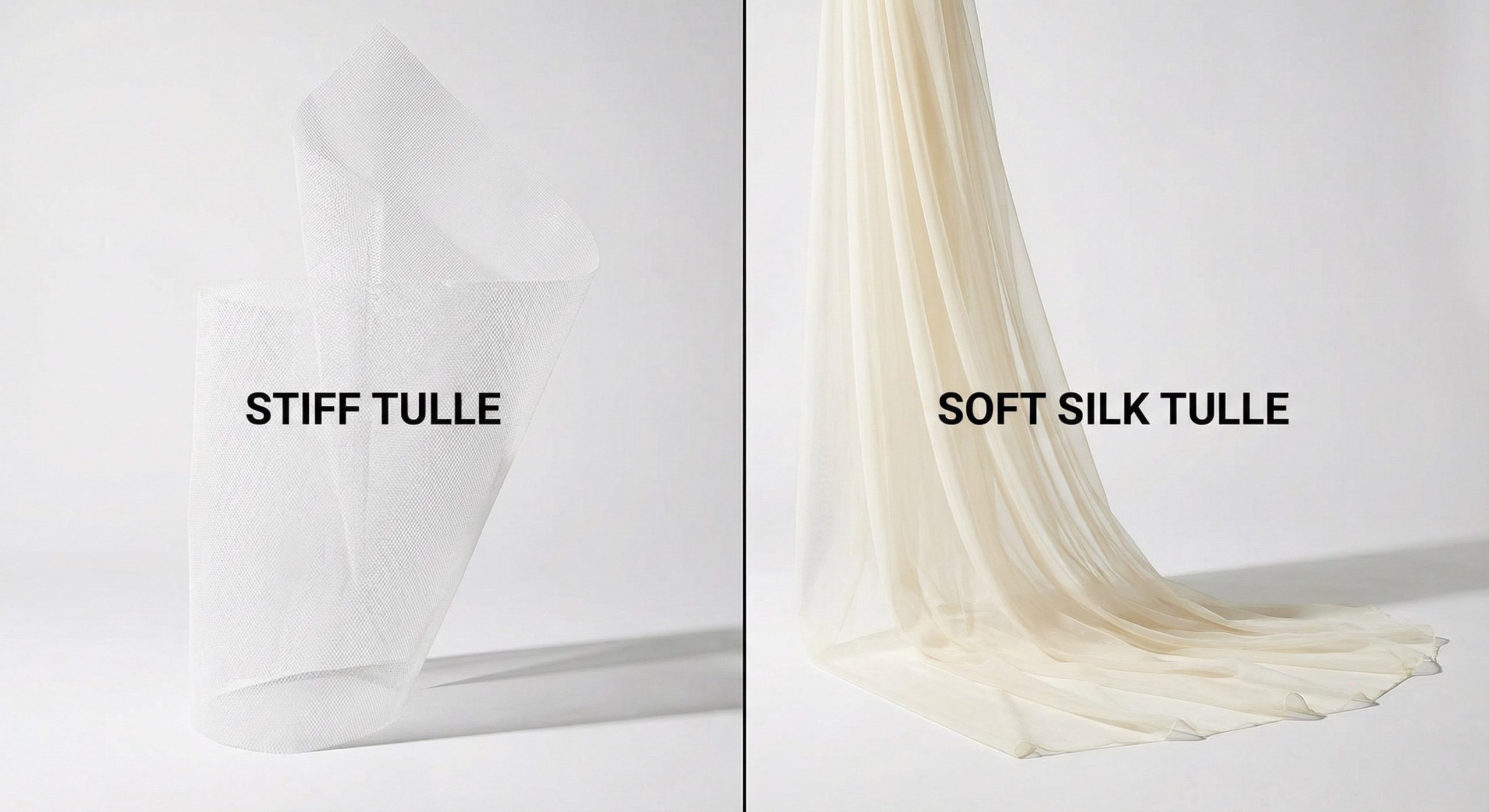

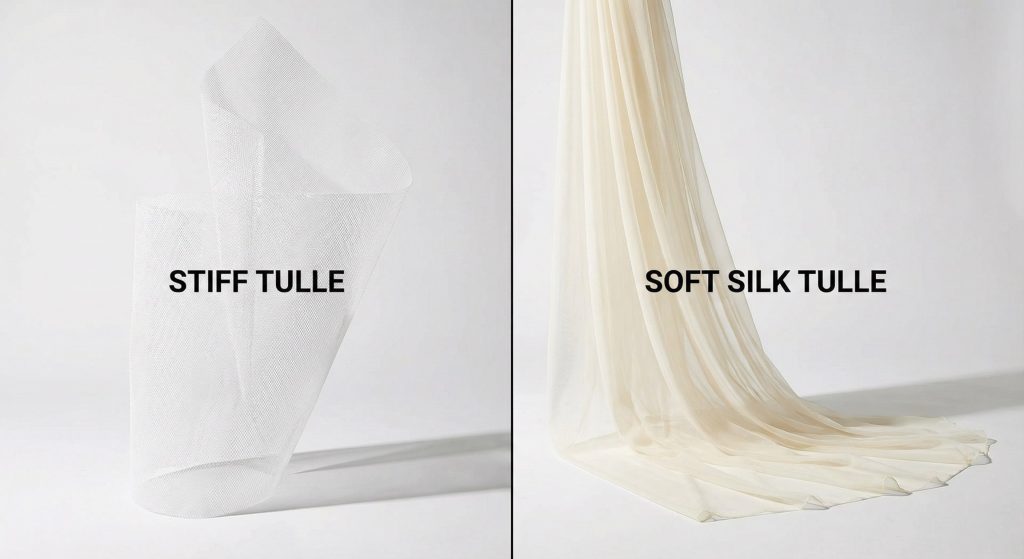

Is stiff tulle fabric better than soft tulle?

Neither is “better” in a vacuum; the choice of stiff tulle fabric depends entirely on whether your project requires structural volume or fluid movement. While soft tulle drapes like a dream, it lacks the “kick” required to hold out a heavy skirt.

Volume vs Fluidity: A comparison

Believe it or not:

- Stiff tulle stands away from the body to create architectural shapes.

- Soft tulle follows the body’s curves for a romantic, ethereal effect.

- Stiff versions are more durable for underlying support structures.

When should you combine both types?

The real secret?

- Professional gowns often use stiff tulle for the inner layers and soft tulle for the outer layers.

- This combination provides both the necessary height and a soft-to-the-touch finish.

- Hybrid layering hides the “scratchy” nature of the rigid mesh while retaining its benefits.

Key Takeaway: Successful garment construction often requires a tiered approach where stiff tulle provides the core and soft tulle provides the aesthetic.

| Characteristic | Stiff Tulle | Soft Tulle (Illusion) | |

|---|---|---|---|

| Drape | Stand-off / Rigid | Fluid / Hanging | |

| Skin Comfort | Can be abrasive | Very soft / Smooth | |

| Best For | Structural petticoats | Outer layers and veils |

Choosing the right stiffness level ensures the garment meets both the visual requirements and the wearer’s comfort expectations.

How to identify quality stiff tulle fabric?

High-quality stiff tulle fabric should have uniform hole sizes, a consistent dye lot, and a finish that doesn’t flake off. When sourcing for mass production, ensuring these quality markers are met is vital for maintaining brand standards and reducing waste.

Checking for Memory in the mesh

Look at this:

- Quality stiff mesh should spring back to its original shape after being crushed.

- Permanent creases in a new bolt indicate a low-quality resin treatment.

- The fabric should feel resilient rather than brittle or paper-like.

Why does the hole size matter for sourcing?

Here’s the best part:

- Consistent hexagonal dimensions ensure that the wholesale tulle fabric reacts predictably to tension.

- Irregular holes are a sign of poor manufacturing and lead to uneven silhouettes.

- Larger holes generally provide more stiffness but less surface area for attaching details.

Key Takeaway: Reliability in stiff tulle comes from the consistency of its chemical finish and the uniformity of its mechanical weave.

| Quality Marker | What to Look For | |

|---|---|---|

| Uniformity | No jagged edges or irregular hexagons | |

| Resilience | Returns to shape after being crushed | |

| Colorfastness | No bleeding when exposed to steam |

Sourcing from reputable mills prevents the common issues of “shedding” resin or inconsistent rigidity across different color batches.

Which fibers make the best stiff tulle fabric?

Nylon is the industry gold standard for stiffness because it accepts resin treatments better and has higher heat resistance than polyester. Most premium manufacturers prefer nylon-based stiff tulle fabric for its superior “snap-back” quality and longevity.

Nylon vs Polyester: The stiffness debate

Think about it:

- Nylon fibers are naturally more elastic, allowing for better shape retention.

- Polyester is often more cost-effective but can feel more plastic-like.

- Professional bridal houses almost exclusively use nylon for high-end crinolines.

Are there eco-friendly stiff mesh options?

The best part?

- Recycled PET (polyester) is becoming a viable option for sustainable B2B sourcing.

- Bio-based resins are being developed to replace traditional chemical stiffeners.

- These innovations help brands meet their ESG goals without sacrificing structural performance.

Key Takeaway: While polyester is suitable for event decor, nylon remains the preferred choice for high-quality apparel and millinery.

| Fiber Type | Durability | Price Point | Best Use | |

|---|---|---|---|---|

| Nylon | High | Mid-High | Luxury Bridal | |

| Polyester | Moderate | Low | Event Decor / Tutus |

Understanding fiber chemistry allows buyers to select the most appropriate material based on the project’s budget and performance needs.

Can stiff tulle fabric hold its shape?

Yes, stiff tulle fabric is specifically engineered for “shape memory,” though it may require steaming to reset after long-term storage. This resilience is what makes it the preferred material for items that must endure heavy handling, such as dance tutus.

The impact of heat setting on durability

Check this out:

- Factory heat-setting ensures the mesh maintains its rigid structure for years.

- This process allows the fabric to be washed without losing its primary characteristic.

- Proper tulle definition in design involves leveraging this permanent stiffness.

How to manage creases during production

Look:

- Steam is the most effective tool for removing shipping creases without melting fibers.

- Never use a dry iron directly on the resin-coated surface.

- Hanging the finished garment allows the stiffness to “settle” into its final form.

Key Takeaway: Avoid ironing stiff tulle directly; the high heat can melt synthetic fibers and the specialized stiffening agent.

| Longevity Factor | Impact on Shape | |

|---|---|---|

| Storage | Hanging preserves loft; folding causes creases | |

| Cleaning | Hand wash only to preserve resin stiffness |

Managing the fabric’s memory effectively ensures that the final garment retains its retail-ready appearance through shipping and handling.

Where to buy wholesale stiff tulle fabric?

Direct-from-mill suppliers or specialized B2B distributors are the best sources for bulk quantities to ensure dye lot consistency. When purchasing stiff tulle fabric at scale, it is crucial to verify that the supplier can provide the same level of rigidity across all orders.

Evaluating North American suppliers

Check this out:

- Local distributors offer faster lead times for urgent production runs.

- Overseas mills provide the best pricing for high-volume manufacturing.

- Quality control is easier to manage when working with established fabric specialists.

What are the minimum order quantities (MOQs)?

The best part?

- Most wholesalers offer lower MOQs for standard colors like white and black.

- Custom colors or specific stiffness levels may require larger 100+ yard orders.

- Samples should always be requested to test the “hand” of the mesh before committing.

Key Takeaway: Sourcing directly from specialized manufacturers ensures a higher level of technical support and product consistency for B2B buyers.

| Sourcing Channel | Pros | Cons | |

|---|---|---|---|

| Direct Mill | Lowest price, high customization | High MOQs | |

| Distributor | Low MOQs, fast shipping | Higher per-yard cost |

Establishing a relationship with a dedicated tulle supplier allows for more predictable production schedules and better overall garment quality.

How to cut and sew stiff tulle fabric?

Use rotary cutters for clean edges and a longer stitch length on your machine to prevent the stiff tulle fabric from puckering. Because the material is quite abrasive, specialized tools and techniques are required to ensure a professional finish.

Best needles for stiff synthetic mesh

Think about it:

- A Microtex or Sharp needle is essential to pierce the resin-coated fibers cleanly.

- Ballpoint needles should be avoided as they can snag the hexagonal grid.

- Dull needles will cause the fabric to bounce rather than being sewn.

Why you should avoid standard pins?

The best part?

- Pins can leave permanent holes in the mesh or slip through the hexagonal gaps.

- Binder clips or Wonder Clips provide a secure hold without damaging the fibers.

- When comparing gossamer vs tulle , tulle’s structure requires more robust clamping.

Key Takeaway: Use French seams to encapsulate raw edges, as the rigid fibers of stiff tulle can be uncomfortable against the skin.

| Sewing Task | Recommended Technique | |

|---|---|---|

| Seams | French seams to hide scratchy raw edges | |

| Hemming | Leave raw or use horsehair braid for lift |

Applying these technical standards during the sewing process reduces production errors and results in a more durable and comfortable garment.

Does stiff tulle fabric irritate the skin?

Yes, due to its rigid fibers and resin coating, stiff tulle is notoriously scratchy and should always be separated from the skin. Designers must strategically layer stiff tulle fabric between other materials to capitalize on its volume while maintaining wearer comfort.

Linings that pair well with stiff mesh

Look at this:

- Satin or high-count cotton linings create a smooth barrier against the skin.

- Silk habotai is an excellent choice for luxury garments requiring breathability.

- The lining should be cut slightly fuller than the tulle to prevent tension.

How to finish edges to prevent chafing

The real secret?

- Binding the hem with satin ribbon or bias tape protects the wearer’s legs.

- Ensure that the tulle layers are slightly shorter than the lining.

- When choosing organza vs tulle , remember that both can be abrasive without proper finishing.

Key Takeaway: A three-layer system—lining, stiff tulle, and fashion fabric—is the professional standard for high-volume skirts.

| Layering Order | Material | |

|---|---|---|

| Layer 1 (Skin) | Silk, Rayon, or Soft Polyester Lining | |

| Layer 2 (Middle) | Stiff Tulle for Volume | |

| Layer 3 (Outer) | Fashion Fabric (Satin, Lace, Soft Tulle) |

Prioritizing comfort in the construction phase ensures that high-impact designs remain wearable for the duration of an event.

What are the top uses for stiff tulle fabric?

While dominated by the bridal industry, stiff tulle fabric is also vital for theater costuming, millinery, and structural floral arrangements. Its ability to act as a lightweight “scaffold” makes it a favorite among creative professionals in multiple sectors.

Theater costuming and period dress

Think about it:

- Historical garments like panniers and bustles rely on stiff mesh foundations.

- It is much lighter and more flexible than traditional boning or wire frames.

- Costumes can be easily collapsed for transport and steamed back to life.

Creative uses in event decor and florals

The best part?

- Large-scale floral installations use stiff mesh to provide shape to soft petals.

- Oversized bows made from stiff tulle maintain their “perkiness” in outdoor settings.

- It is the ideal material for table runners that need to hold a specific sculpted form.

Key Takeaway: The versatility of stiff tulle extends far beyond the fashion runway, serving as a structural tool for any industry requiring volume.

| Industry | Specific Application | |

|---|---|---|

| Millinery | Foundation for fascinators and hat veils | |

| Dance | Professional-grade “pancake” tutus | |

| Decor | Chair sashes and table skirts with “poof” |

The architectural nature of this fabric allows for the creation of shapes that would be impossible with traditional woven textiles.

FAQ (Frequently Asked Questions)

- Is stiff tulle the same as crinoline?While often used interchangeably, crinoline refers to the finished underskirt garment, whereas stiff tulle is the specific fabric used to make it.

- Can I make stiff tulle fabric soft?Washing with fabric softener or soaking in vinegar can reduce stiffness, but it will also ruin the structural purpose of the fabric.

- Does stiff tulle fray?No, because it is a knit mesh, it does not fray like woven fabrics, allowing you to leave edges raw for a clean look.

- Can I dye polyester stiff tulle?Only with specialized disperse dyes at high temperatures; nylon is much easier to dye with standard acid dyes during production.

- How do I remove wrinkles from stiff tulle?Use a handheld garment steamer from a 6-inch distance to relax the fibers without melting the resin coating or synthetic threads.

Conclusion

At Tullemesh, we understand that the success of a garment lies in the materials you don’t see. Our stiff tulle options are engineered for the rigorous demands of professional manufacturing, solving common problems of skirt collapse and loss of silhouette. We believe in providing the architectural foundation that allows designers to dream bigger and build taller. Ready to elevate your next collection? Browse our full range of wholesale solutions and contact us today to find the perfect structural foundation for your designs.