Tulle is a lightweight, very fine, stiff netting typically made of silk, nylon, or polyester fibers. You may have struggled with garments that require significant volume but end up feeling heavy and restrictive. This lack of structural “loft” often ruins the ethereal aesthetic required for high-fashion designs and bridal wear. Understanding what is tulle fabric made of provides the ultimate solution for creators seeking transparency without sacrificing durability.

What is tulle fabric and what is tulle fabric made of?

In the professional textile world, the specific origins of what is tulle fabric made of date back to 18th-century France. The material was originally handcrafted in the city of Tulle, where bobbin lace makers developed a unique hexagonal mesh. This early version was a true luxury good reserved for the aristocracy and high-ranking clergy.

What are the historical origins of this mesh?

The city of Tulle was a renowned center for silk production long before the industrial revolution. Skilled artisans used bobbins to twist fine threads into a stable, open-work pattern. These early manual techniques required immense precision and time.

Believe it or not…

- Tulle was originally a subset of the lace-making tradition.

- Early iterations were exclusively produced using premium silk.

- The fabric’s name is a geographical marker of its heritage.

- Royal patronage helped establish it as a status symbol.

How did mechanized production change the industry?

The invention of the bobbinet machine in the early 1800s transformed the market entirely. This allowed manufacturers to produce larger quantities of the mesh at a fraction of the cost. Consequently, the fabric transitioned from an elite luxury to a staple in European fashion.

Key Takeaway: The evolution of tulle from a handcrafted lace to a mechanized textile allowed for its widespread adoption in bridal and evening wear. Modern professionals still value this heritage when selecting premium materials for couture projects.

| Era | Key Milestone | Market Impact | |

|---|---|---|---|

| 1700s | Hand-spun silk production | High-end luxury status | |

| 1808 | Bobbinet machine invention | Industrial scaling possible | |

| 1840 | Queen Victoria’s wedding | Global bridal trend set | |

| 1950s | Synthetic fiber introduction | Drastic cost reduction |

The following analysis explores the specific chemical compositions that define modern varieties of this mesh.

How does the history explain what is tulle fabric made of?

When examining what is tulle fabric made of, you must look at how fiber technology has evolved over three centuries. The transition from natural filaments to high-performance synthetics has changed the fabric’s physical behavior. Today, the choice of material determines whether a garment floats softly or stands with rigid structural integrity.

Why was silk the original choice for production?

Silk offered the highest tensile strength among natural fibers available to early French weavers. Its long, continuous filaments were perfect for creating the intricate twists required for a stable hexagonal mesh. Even today, silk versions remain the gold standard for luxury “liquid” drapes in haute couture.

You might be wondering…

- Silk filaments are naturally hypoallergenic and soft.

- The protein structure provides a unique sheen.

- Natural silk takes dyes with incredible depth.

- It remains the most expensive fiber choice for mesh.

What role did the industrial revolution play?

The industrial era introduced metallic and cotton-blend nettings to satisfy growing demand. While these lacked the delicacy of silk, they paved the way for more diverse applications. Machines could finally replicate the complex “twist and turn” of manual bobbinet weaving.

Key Takeaway: Historical fiber choices were dictated by the limitations of hand-weaving, whereas modern selections focus on specialized performance and cost-efficiency. Understanding this shift helps you select the right grade for your specific design needs.

| Fiber Class | Historical Usage | Modern Equivalent | |

|---|---|---|---|

| Protein | Luxury Silk | High-end Couture | |

| Cellulose | Cotton Blends | Vintage Style Net | |

| Polymer | None | Modern Nylon/Polyester | |

| Metallic | Gold/Silver threads | Lurex Mesh |

To understand the current market, we must investigate the chemical engineering behind today’s most common variants.

Exactly what is tulle fabric made of in the modern industry?

Determining what is tulle fabric made of in a contemporary factory usually leads to one of two polymers: nylon or polyester. These synthetic materials are engineered to provide specific levels of stiffness, weight, and elasticity. By manipulating the chemical structure, manufacturers can create anything from an invisible “illusion” net to a stiff structural support.

Why is nylon the preferred choice for softness?

Nylon is a polyamide that offers exceptional elasticity and a soft hand-feel. When used in mesh, it creates a textile that feels gentle against the skin and drapes with natural grace. It is the primary choice for high-quality wedding veils and intimate apparel.

But wait, there’s more…

- Nylon can be heat-set to maintain its shape memory.

- It possesses a natural luster that mimics silk.

- The fibers are highly resistant to abrasion.

- Nylon mesh has a higher moisture regain than polyester.

How does polyester provide structural support?

Polyester is a more rigid polymer that excels in holding volume without sagging over time. It is significantly more heat-resistant than nylon, making it easier to pleat and shape. If you need a tutu or a tiered skirt to maintain its “poof,” polyester is the technical answer.

Key Takeaway: Most commercial tulle today relies on polyester for structure and nylon for softness. Selecting between them requires a balance of budget, skin comfort, and the desired silhouette of the finished piece.

| Property | Nylon Tulle | Polyester Tulle | |

|---|---|---|---|

| Hand Feel | Silky and soft | Crisp and textured | |

| Elasticity | High mechanical stretch | Low stretch, high stability | |

| Heat Resistance | Low (melts easily) | High (can be pleated) | |

| Cost | Moderate to High | Low and affordable |

Physical characteristics are just as important as the chemical makeup when evaluating these textiles.

What characteristics define what is tulle fabric made of?

The physical properties of what is tulle fabric made of are defined by the “denier” of the yarn and the density of the knit. Unlike woven fabrics, this mesh does not have a traditional grain line, allowing it to be cut in any direction. This unique construction provides a “raw edge” that will not fray, which is a massive advantage for complex designs.

Why is the hexagonal structure so important?

The hexagon is nature’s most stable geometric shape, and in tulle, it prevents the mesh from deforming under tension. This geometry allows the fabric to be mostly air, yet strong enough to support heavy embroidery or beadwork. The size of these holes determines the “illusion” factor of the material.

Think about this…

- Smaller holes create a sheer, matte appearance.

- Larger holes result in a more traditional “net” look.

- The structure allows for excellent airflow and breathability.

- Hexagonal cells distribute weight evenly across the surface.

How does weight and denier affect transparency?

Weight is typically measured in GSM (grams per square meter) or denier. A lower GSM indicates a finer, more transparent mesh that is ideal for overlays. Higher GSM fabrics are denser and provide more opacity, which is useful for structural layers under heavy gowns.

Key Takeaway: The combination of hexagonal stability and low weight makes this fabric unique among all textiles. It provides maximum visual impact with minimum physical weight, which is essential for performance and bridal wear.

| Characteristic | Measurement | Designer Benefit | |

|---|---|---|---|

| Hole Shape | Hexagonal | Prevents distortion/tearing | |

| Weight | 10 – 50 GSM | Extremely lightweight loft | |

| Transparency | Sheer to Semi-Opaque | Ideal for layering effects | |

| Edge Quality | Non-fraying | Easy to leave raw or laser-cut |

The manufacturing process itself is a marvel of textile engineering that deserves closer inspection.

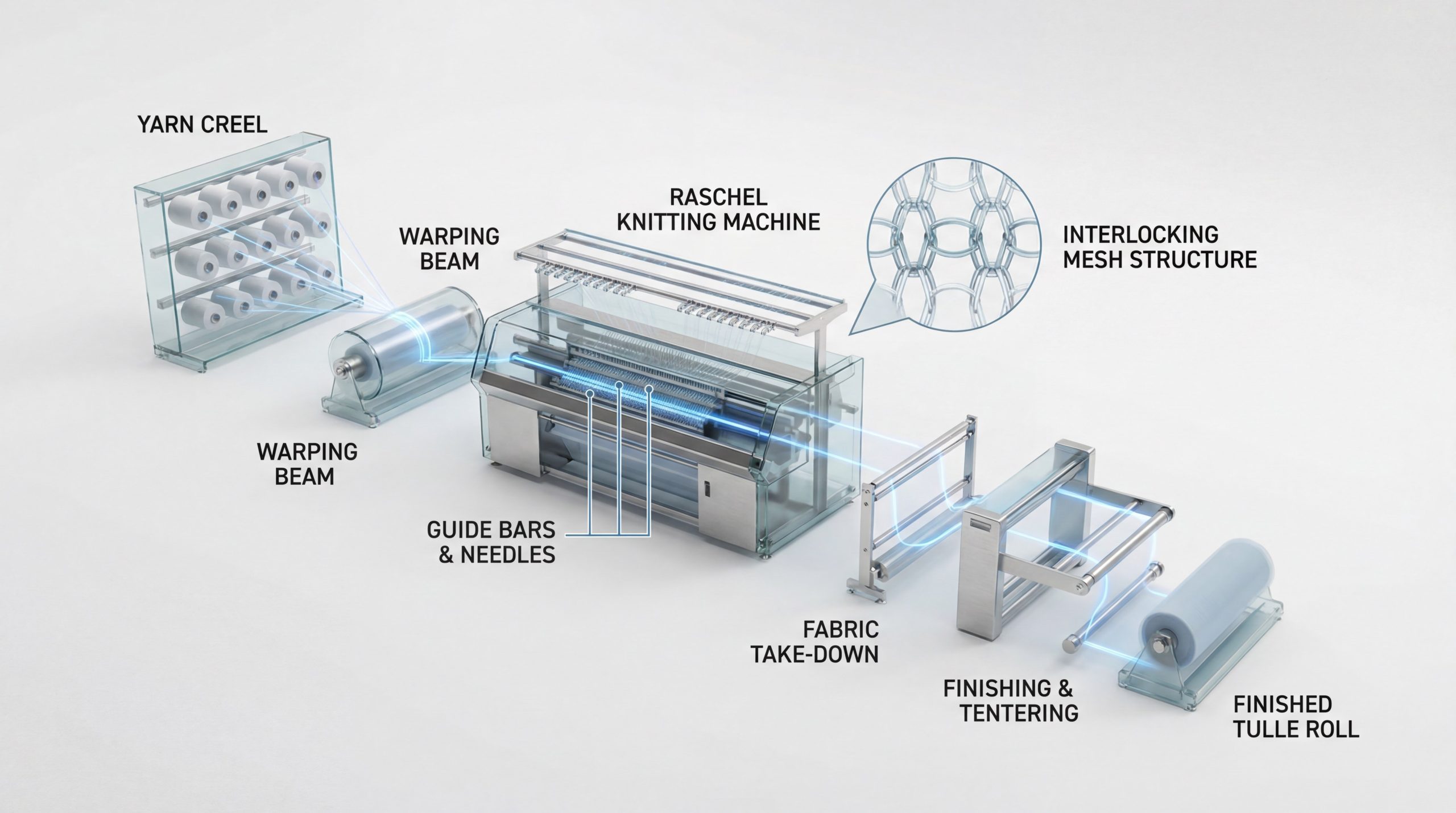

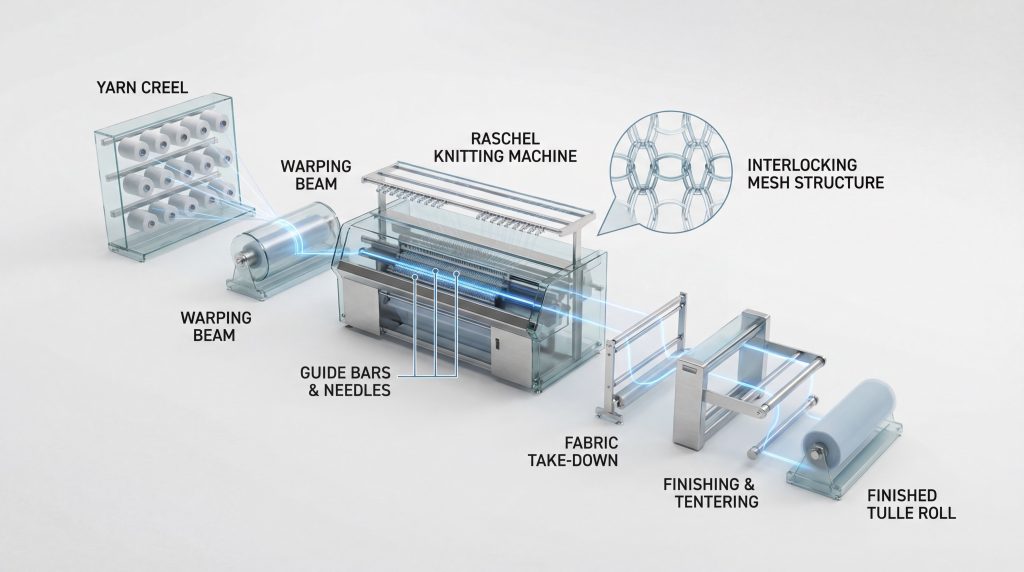

How is the process of what is tulle fabric made of executed?

To understand what is tulle fabric made of , you must examine the warp-knitting process. Most modern tulle is produced on Raschel machines, which use thousands of needles to loop yarns together simultaneously. This is a far cry from the single-thread bobbin methods of the past.

What is the Raschel knitting method?

Raschel knitting is a form of warp knitting that produces open-work fabrics with high dimensional stability. The machine creates vertical rows of loops that are interconnected in a zig-zag pattern. This technique allows for the creation of complex mesh patterns at extremely high speeds.

It gets even better…

- Raschel machines can handle very fine synthetic yarns.

- The process allows for “in-lay” yarns to add patterns.

- It produces a fabric that is ladder-resistant.

- Automation ensures consistent hole size across thousands of yards.

How does heat setting lock in the shape?

Once the mesh is knitted, it passes through a “stenter” frame where high heat is applied. This process permanently sets the thermoplastic fibers (like polyester or nylon) into their final shape. This is the stage where the manufacturer determines if the tulle will be “soft” or “stiff.”

Key Takeaway: Modern tulle is a product of high-speed warp knitting followed by precision thermal processing. This controlled environment ensures that every roll of fabric meets specific standards for stiffness and transparency.

| Process Stage | Action Taken | Final Result | |

|---|---|---|---|

| Warping | Aligning yarns on beams | Preparation for knitting | |

| Knitting | Interlooping on Raschel machines | Creation of the mesh grid | |

| Dyeing | Pressure or jet dyeing | Uniform color saturation | |

| Heat Setting | Thermal treatment | Fixed stiffness/memory |

Different varieties of the fabric cater to specific niches within the global fashion market.

What different types show what is tulle fabric made of?

The variety of what is tulle fabric made of today allows you to choose a material that perfectly matches your project’s goals. From “English Net” to “Illusion Tulle,” the terminology can be confusing for new designers. Each type is defined by its specific blend of fiber, weight, and finishing chemicals.

When should you use soft bridal tulle?

Soft tulle, often referred to as “veil tulle,” is designed for maximum drape and skin comfort. It is usually made from nylon to ensure it doesn’t feel scratchy against the bride’s face or arms. Its fine mesh density makes it appear almost like a mist when layered.

Don’t miss this…

- Soft tulle is perfect for gathered skirts.

- It provides a romantic, flowing movement.

- High-quality versions are resistant to static.

- It is the standard for multi-layered ball gowns.

What makes “Illusion Tulle” so special?

Illusion tulle is an ultra-fine mesh used primarily for “naked” necklines and sleeves. It is designed to be virtually invisible against the skin, providing just enough support for lace appliqués or beads. This material requires a very high gauge machine to produce such tiny, consistent holes.

Key Takeaway: Selecting the right type of tulle is a balance between the desired volume and the level of transparency needed. Soft types are for comfort and drape, while specialized illusion types are for invisible support.

| Tulle Type | Primary Fiber | Common Use | |

|---|---|---|---|

| Soft / Bridal | Nylon | Veils and flowing skirts | |

| Stiff / Hex | Polyester | Tutus and petticoats | |

| Illusion | Fine Nylon | Invisible necklines | |

| Sparkle / Glitter | Coated Polyester | Event decor and costumes |

Practical applications for this material extend far beyond the runways of Paris and Milan.

How do you identify what is tulle fabric made of in professional settings?

Knowing exactly what is tulle fabric made of is the first step in applying it to high-stakes event design. You might see it used to transform a cavernous hall into a romantic wedding venue. Its ability to catch the light and create a soft glow makes it a favorite for decorators and florists worldwide.

Why is it a staple for event backdrops?

Tulle is sold in wide bolts, often up to 108 inches, making it ideal for covering large surface areas. When draped over LED fairy lights, the mesh diffuses the light, creating a professional “bokeh” effect. It is also lightweight enough to be hung from temporary ceiling structures without risk.

The best part is…

- Tulle is extremely cost-effective for large-scale decor.

- It can be tied into bows or swags without tools.

- The fabric comes in hundreds of colors for theme matching.

- It is easy to store and reuse for multiple events.

How does tulle function in interior design?

In the home, tulle is often used as a delicate window treatment or a bed canopy. It provides privacy by diffusing the view from outside while still allowing natural light to flood the room. Its non-fraying nature means you can create custom lengths with a simple pair of fabric shears.

Key Takeaway: Tulle’s versatility in decoration stems from its extreme width and light-diffusing properties. Whether for a wedding backdrop or home curtains, it provides an elegant texture that heavier fabrics cannot replicate.

| Decoration Use | Specific Application | Main Benefit | |

|---|---|---|---|

| Backdrops | Layering over lighting | Soft, diffused glow | |

| Table Design | Runners and skirts | Adds texture/dimension | |

| Floral Design | Bouquet wraps | Secures stems beautifully | |

| Gift Wrapping | High-end hampers | Premium presentation |

Professional buyers must also consider the quality markers and durability of their textile choices.

How can quality reveal what is tulle fabric made of?

To determine what is tulle fabric made of in terms of quality, you should perform a “touch and stretch” test. Premium tulle should feel smooth and fabric-like, not like a stiff plastic net. Inferior versions often have irregular hole sizes and a “crunchy” sound when handled.

How to spot irregularities in the mesh?

High-quality manufacturing ensures that every hexagonal cell is identical in shape and size. Hold the fabric up to the light; any “thick” spots or “snags” indicate a breakdown in the knitting process. Consistent tension is the hallmark of a professional-grade roll of tulle.

Here is a secret…

- Premium tulle will not “crack” when folded tightly.

- The dye should be perfectly even without streaks.

- Quality mesh recovers its shape immediately after being stretched.

- It should not have a chemical or plastic odor.

Why does the “hand-feel” matter for garments?

If you are designing a gown that will be worn for ten hours, the softness of the tulle is paramount. Stiff, low-quality polyester can cause skin irritation or “tulle burn.” Checking for a “silk-touch” finish is essential for high-end bridal garments.

Key Takeaway: Quality identification relies on visual consistency and tactile comfort. Investing in premium-grade mesh prevents manufacturing defects and ensures the comfort of the final wearer.

| Quality Marker | Premium Tulle | Low-Grade Tulle | |

|---|---|---|---|

| Texture | Silky and smooth | Scratchy and stiff | |

| Uniformity | Perfect hexagons | Distorted or elongated holes | |

| Recovery | Snaps back to shape | Stays stretched out | |

| Scent | Neutral | Often smells of chemicals |

Sustainability is a growing concern that affects the global supply chain for these materials.

Is the sustainability of what is tulle fabric made of high?

The question of what is tulle fabric made of is increasingly answered with “recycled materials.” As a synthetic-heavy industry, the production of virgin polyester and nylon has a significant carbon footprint. However, the rise of PET-recycled mesh is providing a more eco-friendly path for sustainable fashion brands.

Can synthetic mesh be eco-friendly?

Recycled polyester tulle is made from post-consumer plastic bottles, which reduces the need for petroleum extraction. These fibers maintain the same strength and clarity as virgin polymers. Many designers are now switching to these options to meet corporate social responsibility goals.

Consider the impact…

- Recycled mesh reduces landfill waste significantly.

- The manufacturing process uses less water and energy.

- It can be recycled again at the end of its life cycle.

- Many luxury brands are mandating recycled content.

Are there natural, biodegradable alternatives?

Silk tulle remains the primary biodegradable option, as it is a natural protein fiber. While expensive, it offers the lowest environmental impact if sourced through organic sericulture. Some manufacturers are also experimenting with bio-based polymers like PLA (polylactic acid).

Key Takeaway: The industry is pivoting toward circularity by utilizing recycled plastics and bio-based fibers. While virgin synthetics still dominate, the availability of sustainable alternatives is growing rapidly.

| Sustainability Factor | Virgin Polyester | Recycled PET | Organic Silk | |

|---|---|---|---|---|

| Raw Material | Petroleum | Plastic Bottles | Silkworm Cocoons | |

| Biodegradability | None | None | High | |

| Energy Use | High | Moderate | Low | |

| Carbon Footprint | High | Reduced | Minimal |

Proper care and maintenance are required to ensure the longevity of these delicate structures.

How to care for garments and what is tulle fabric made of?

Maintaining garments depends entirely on what is tulle fabric made of. Because most tulle is synthetic, it is highly sensitive to heat and friction. You must treat these pieces with extreme care to avoid permanent damage like melting, snagging, or loss of volume.

What is the safest way to wash tulle?

Hand washing in cold water with a mild detergent is the only recommended method for high-quality tulle. Agitation in a washing machine will almost certainly cause the mesh to snag on other garments or the machine’s drum. Never wring the fabric, as this can distort the hexagonal structure.

Take note of this…

- Always wash tulle garments separately from zippers/hooks.

- Use a mesh laundry bag if machine washing is unavoidable.

- Air drying flat is the best way to prevent stretching.

- Avoid harsh bleaches which can weaken synthetic fibers.

How do you remove wrinkles without an iron?

An iron will melt synthetic tulle almost instantly upon contact. Instead, use a handheld steamer or hang the garment in a bathroom while a hot shower is running. The gentle steam will relax the fibers and allow gravity to pull out any creases.

Key Takeaway: Preservation of tulle requires avoiding heat and mechanical stress. Proper storage (folding vs. hanging) and gentle cleaning will keep the mesh looking new for years.

| Care Action | Recommended | Prohibited | |

|---|---|---|---|

| Cleaning | Cold hand wash | Hot water / Machine dry | |

| De-wrinkling | Steaming | Direct ironing | |

| Storage | Folded in acid-free paper | Hanging long-term | |

| Drying | Lay flat on towel | Tumble drying |

Frequently Asked Questions

Can I wash tulle in a washing machine?It is highly discouraged because the mesh can easily snag on the agitator or other clothing. If you must use a machine, place the garment in a delicate mesh bag and use the gentlest cold-water cycle available.

What’s the best way to cut tulle without it fraying?You can use standard sharp fabric shears or a rotary cutter. Because tulle is a knitted mesh, the edges will naturally stay clean and will not unravel or fray like woven fabrics.

Can I dye polyester tulle at home using standard dyes?No, polyester requires specialized disperse dyes and high heat to absorb color. Standard household dyes will usually wash right off synthetic mesh without leaving a permanent stain.

What’s the best way to restore volume to a flattened tutu?The most effective method is to use a garment steamer. The heat and moisture from the steam will reactivate the “shape memory” of the synthetic fibers, allowing you to fluff the layers back to their original state.

Can I use a sewing machine on fine illusion tulle?Yes, but you should use a very fine needle (size 60/8 or 70/10) and a zigzag or overlock stitch. Placing a piece of tissue paper under the fabric can help prevent the machine’s feed dogs from “eating” the delicate mesh.

Master the Art of Mesh

Selecting the right textile for your professional project requires more than just a passing glance at a swatch. By understanding the intricate details of what is tulle fabric made of, from its hexagonal geometry to its synthetic polymer base, you gain the power to create garments that are both structurally sound and visually stunning. Whether you are designing a high-fashion gown or planning an elaborate event, the right choice of mesh will elevate your work to a new level of elegance.

We invite you to explore our comprehensive range of high-performance textiles designed for the modern creator. From ultra-soft bridal veils to rigid structural supports, we provide the materials you need to bring your vision to life. Contact us today to request samples or consult with our experts on your next project.