It is incredibly frustrating when a garment traps heat and sweat, ruining a workout or a summer day. You spend hours designing or sourcing the perfect activewear piece, only to find the material feels like a plastic bag against the skin. But here is the deal: The right textile choice eliminates this discomfort entirely. By utilizing high-quality polyester mesh fabric , you can create garments that offer superior breathability, durability, and moisture management without sacrificing structure or style. Polyester mesh fabric is a synthetic textile knitted or woven with an open-hole structure that creates a net-like appearance.

1. Understanding Polyester Mesh Fabric

Polyester mesh fabric is defined by its specific chemical makeup and unique construction method. It relies on the inherent strength of durable polyester textiles to maintain its shape even with an open-knit structure. You might be wondering why this specific synthetic is preferred over others for netting. The answer lies in the polymer’s ability to resist degradation while providing a flexible framework for airflow.

What defines the mesh construction structure?

The “mesh” aspect refers to the intentional spaces between the yarns. Unlike standard knits, these fabrics are engineered with regular holes that reduce weight and increase ventilation. This structural design is what separates standard polyester from performance mesh.

The relationship between PET fibers and open-knit designs

PET (polyethylene terephthalate) fibers provide the necessary rigidity to keep the mesh open. Without this stiffness, the holes would collapse, reducing breathability. Think about it: The chemical bond of the fiber directly supports the physical architecture of the fabric.

Is polyester mesh the right choice for your project?

If your application requires high tensile strength combined with air permeability, this material is likely your best option. It serves as an excellent liner for sportswear or a sturdy base for industrial filters. Evaluating the specific environmental conditions the fabric will face is crucial.

2. The Power of Polyester Mesh Fabric

The inherent properties of polyester mesh fabric make it a powerhouse in the textile industry. It combines the chemical resilience of polymers with the physical benefits of a net-like weave. Here is why that matters: This combination creates a material that performs exceptionally well under physical stress and environmental exposure.

Breathability and airflow in open-weave fabrics

The most obvious benefit of this fabric is its ability to let air circulate freely against the skin. This “chimney effect” allows heat to escape rapidly, preventing the wearer from overheating. It creates a microclimate that remains cooler than the surrounding environment.

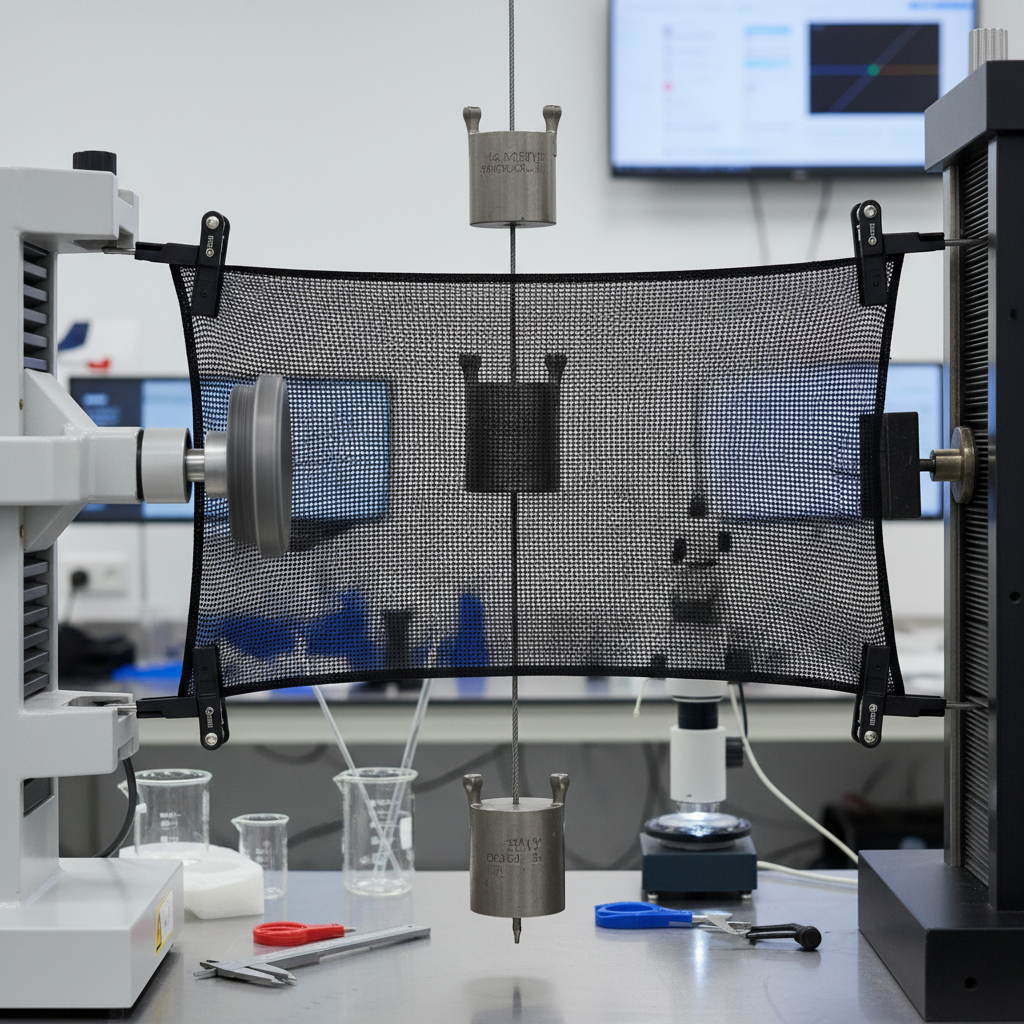

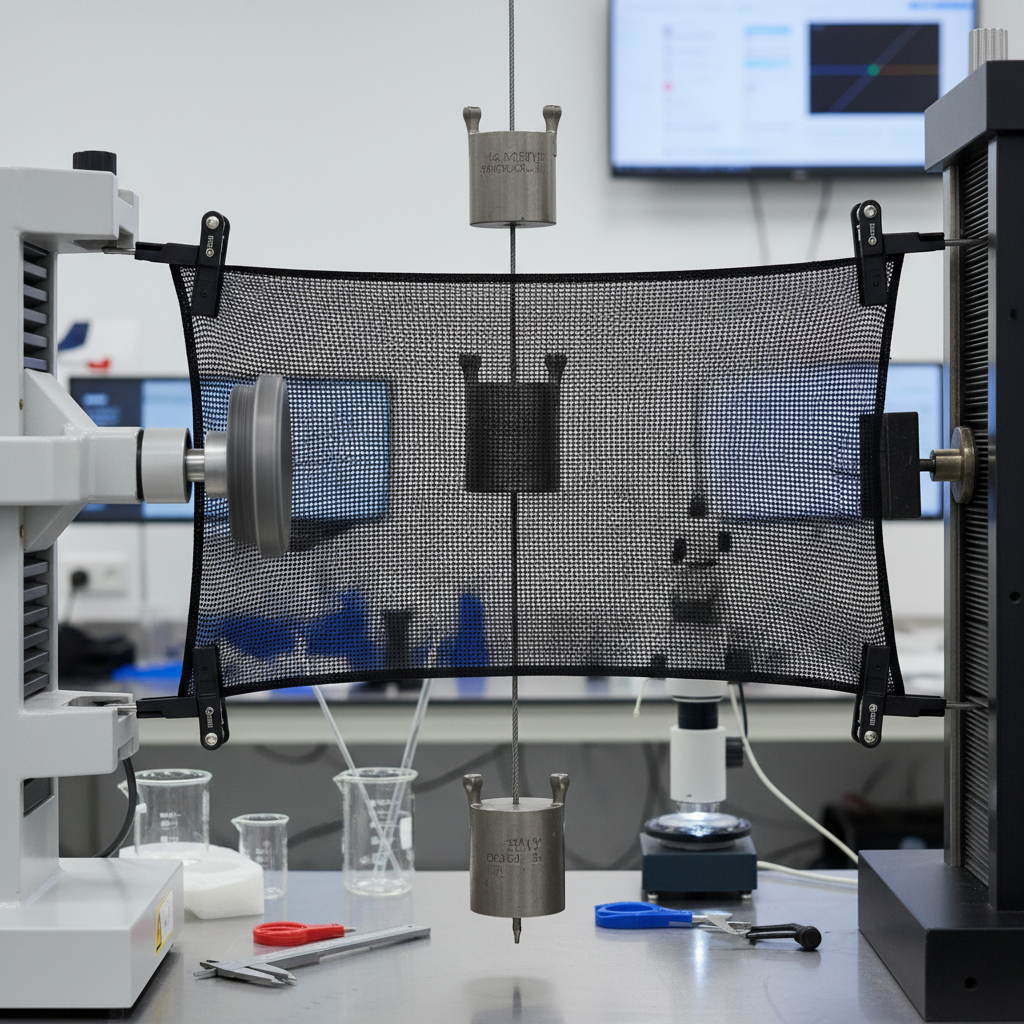

High tensile strength and tear resistance

Despite its lightweight appearance, polyester mesh is incredibly tough. The interlocking knit pattern distributes stress across the fabric, preventing rips from spreading. This makes it ideal for gear that undergoes rough handling, like laundry bags or camping equipment.

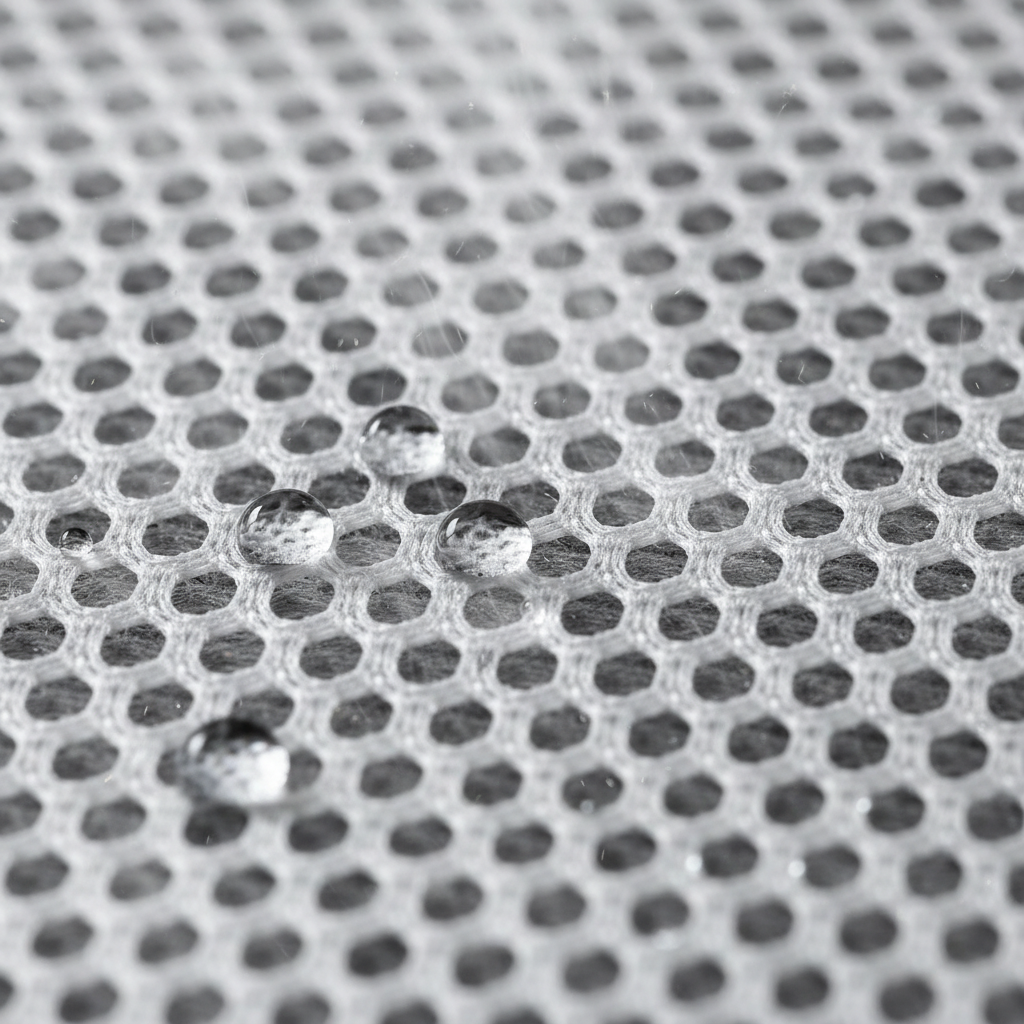

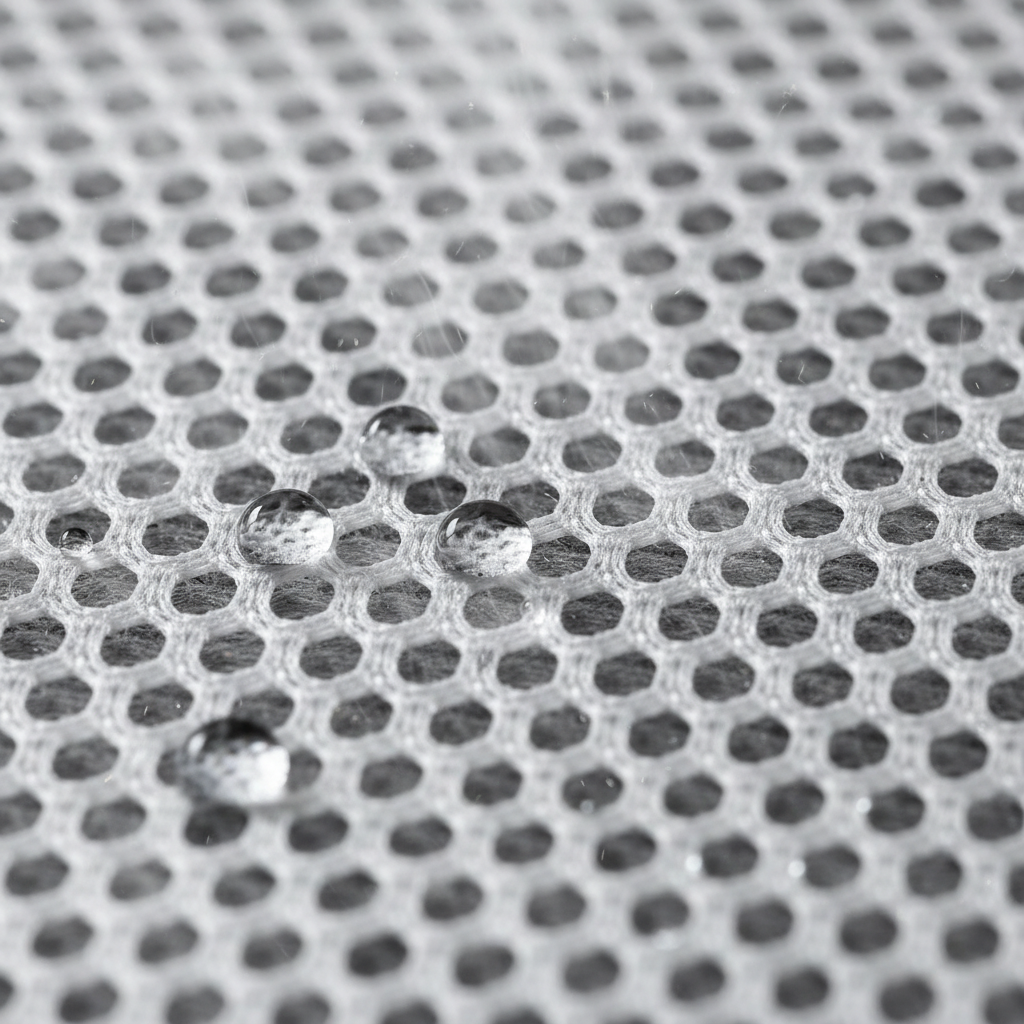

Inherent moisture-wicking properties

Polyester is hydrophobic, meaning it repels water rather than absorbing it. Moisture moves along the fiber surface to the outer layer of the fabric where it evaporates. This keeps the wearer dry even during intense physical exertion.

3. How Does Polyester Mesh Compare to Other Fabrics?

Choosing between polyester mesh fabric and alternatives like nylon or cotton often comes down to specific performance metrics. While natural fibers offer softness, synthetics generally win on durability and moisture management. Let’s look at the specific trade-offs involved in these material choices.

Polyester Mesh vs. Nylon Mesh: Durability and cost

Nylon is often softer and has higher stretch, but polyester is superior in UV resistance and cost-efficiency. But here is the kicker: Polyester retains its color better than nylon, which tends to fade in sunlight. For outdoor gear, polyester is often the smarter long-term investment.

Polyester Mesh vs. Cotton Netting: Moisture management

Cotton mesh absorbs moisture like a sponge, becoming heavy and wet during use. Polyester mesh transfers moisture away from the body, remaining light. For any athletic application, polyester is the clear winner over cotton.

Ultraviolet (UV) resistance comparisons

Polyester naturally reflects UV rays without degrading quickly. Other fibers may become brittle or yellow after prolonged sun exposure. This resistance makes polyester mesh the standard for outdoor safety vests and marine applications.

4. How Is Polyester Mesh Fabric Made?

The manufacturing of polyester mesh fabric involves precise chemical engineering and advanced knitting technologies. It begins with the creation of the polymer itself and ends with a structured textile. You can consult a comprehensive fabric dictionary to understand terms like “extrusion” and “spinneret” in more depth.

The extrusion of polyester yarns

The process starts by melting PET pellets and forcing them through a spinneret to create long filaments. These filaments are cooled and stretched to align their molecular structure. This alignment is what gives the final yarn its incredible strength.

Warp knitting vs. Weft knitting processes

Most durable meshes are created using warp knitting machines.

- Warp Knitting: Yarns run vertically in a zigzag pattern, creating a run-resistant fabric.

- Weft Knitting: Yarns run horizontally, producing a softer but less stable mesh.

Creating specific hole sizes and patterns

The machine settings determine the geometric shape and size of the mesh holes. Manufacturers can create anything from microscopic pinholes to large hexagonal patterns. It gets better: This versatility allows for infinite customization depending on the final product requirements.

5. Dyeing and Finishing Polyester Mesh Fabric

Raw polyester mesh fabric must undergo significant processing to become the finished product consumers recognize. These steps ensure the fabric is stable, colorful, and safe for use. Ready for the good part? This stage is where functional properties like fire retardancy are permanently added to the material.

Heat setting for dimensional stability

Polyester is thermoplastic, meaning it can be molded by heat. After knitting, the mesh is passed through a heat tenter frame to lock the fibers in place. This ensures the fabric will not shrink or warp during later washing or use.

Applying anti-microbial and fire-retardant finishes

Chemical baths can add invisible shields to the mesh fibers. Antimicrobial treatments prevent odor buildup in sportswear, while FR treatments are essential for industrial safety gear. These finishes add value without changing the look of the fabric.

Achieving vibrant colors in synthetic netting

Polyester requires disperse dyes and high heat to absorb color effectively. Once dyed, the color is chemically bonded to the fiber, resulting in excellent colorfastness. This prevents bleeding or fading, even after hundreds of wash cycles.

6. What Are the Different Types of Polyester Mesh?

Not all polyester mesh fabric is created equal; variations in weight and weave create distinct categories. From heavy-duty industrial nets to delicate linings, there is a specific type for every need. You can explore our premium mesh options to see the textural differences firsthand.

Standard PET Mesh

This is the versatile “all-rounder” used in laundry bags and basic apparel lining. It balances strength with cost and is widely available. It typically features a square or diamond hole pattern.

High-Tenacity Industrial Mesh

Designed for extreme conditions, this mesh uses thicker filaments.

- Uses: Cargo nets, safety barriers, and outdoor furniture.

- Strength: Can withstand significant load-bearing pressure.

Hexagonal vs. Square hole configurations

The shape of the hole dictates the fabric’s drape and stretch. Hexagonal meshes (like tulle) tend to have more structure and less stretch. Square hole meshes often have more flexibility and are used where movement is required.

7. What Is Polyester Mesh Fabric Used For?

The applications for polyester mesh fabric extend far beyond basic clothing. Its unique properties make it a staple in sectors ranging from civil engineering to high-performance athletics. Many designers utilize our performance activewear fabrics to create garments that withstand rigorous use.

Industrial filtration and screening

Because the holes in the mesh can be manufactured to exact sizes, it is perfect for filtration. It allows liquids to pass while capturing solids. Think about it: This makes it essential for everything from pool filters to medical devices.

Athletic apparel and jersey linings

This is the most visible use of polyester mesh. It forms the body of football jerseys and the lining of basketball shorts. The fabric keeps the athlete cool while holding up to the friction of contact sports.

Geotextiles and construction applications

Heavy-weight polyester mesh is used to stabilize soil in construction projects. It prevents erosion while allowing water to drain through the ground. This application highlights the material’s incredible resistance to rot and environmental degradation.

8. Why Choose Polyester Mesh Fabric for Safety Gear?

Safety equipment relies on materials that are dependable and highly visible. Polyester mesh fabric is the standard for high-visibility vests and industrial safety clothing. What’s the real story? It saves lives by combining visibility with the comfort needed for long shifts.

Meeting high-visibility standards

Polyester takes fluorescent dyes exceptionally well. Safety vests made from this mesh remain brightly colored (neon yellow or orange) longer than other fabrics. This ensures workers remain visible in hazardous environments.

Lightweight comfort for protective clothing

Workers often wear safety gear over other heavy clothing. Polyester mesh adds almost no weight and allows heat to escape. This prevents heat stroke and fatigue during physical labor in hot conditions.

Resistance to chemical degradation

Industrial environments often involve exposure to oils and mild chemicals. Polyester is inherently resistant to many of these substances. It maintains its structural integrity where natural fibers would dissolve or weaken.

9. How Sustainable Is Polyester Mesh Fabric?

The conversation around synthetic fabrics is shifting toward environmental responsibility. While traditional polyester is petroleum-based, new technologies are making polyester mesh fabric a greener choice. Brands are increasingly turning to eco-friendly fabric alternatives to reduce their carbon footprint.

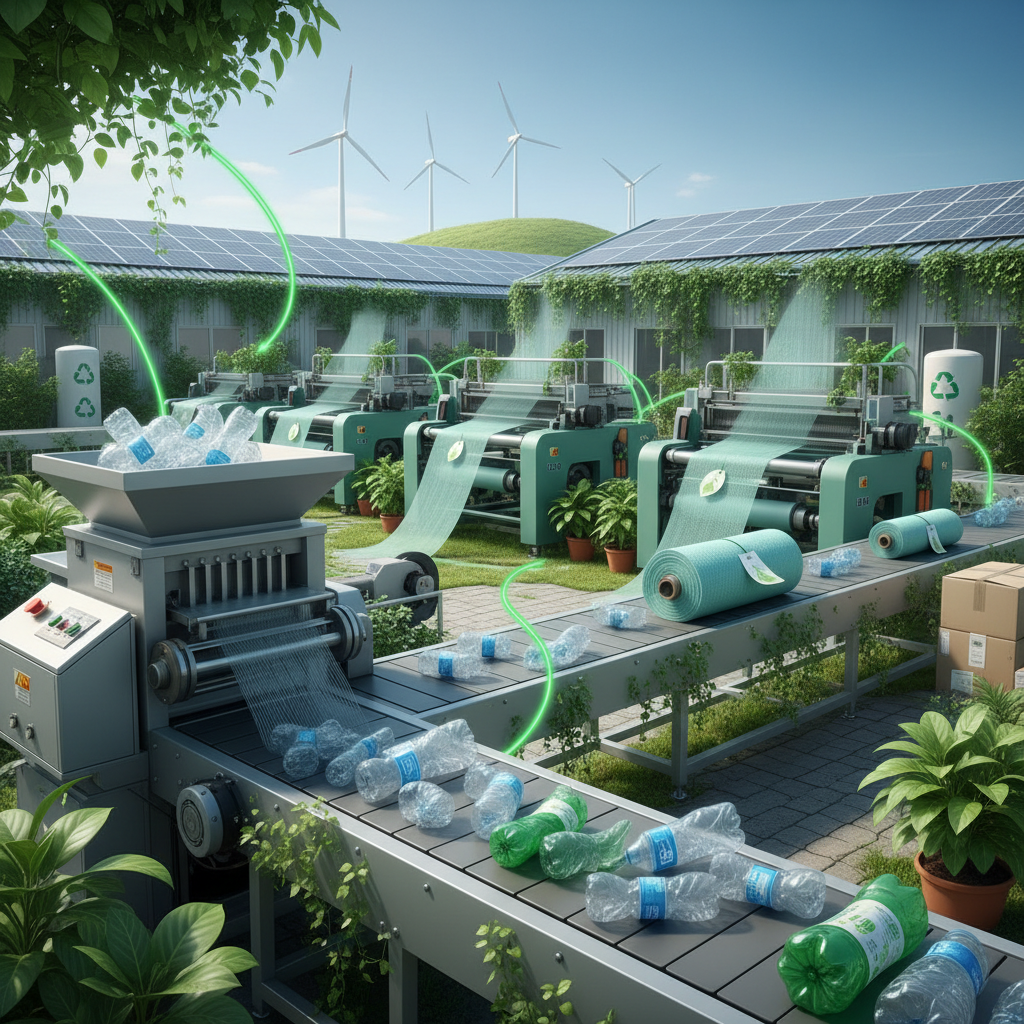

The rise of Recycled Polyester (rPET) mesh

Recycled polyester is created by melting down post-consumer plastic bottles.

- Process: Waste plastic is cleaned, chipped, and spun into new fiber.

- Impact: Reduces landfill waste and lowers energy consumption during manufacturing.

Recyclability of mono-material mesh products

Garments made 100% from polyester mesh are easier to recycle than blends. Because there is no need to separate different fiber types, the fabric can be melted down and reused. This promotes a circular economy in the textile industry.

Eco-friendly dyeing techniques

Modern dyeing methods for polyester use less water than traditional processes. Solution dyeing, where color is added to the molten polymer before extrusion, eliminates water waste almost entirely. This significantly lowers the environmental impact of the finishing process.

10. What Factors Influence the Cost of Polyester Mesh?

Understanding the pricing of polyester mesh fabric helps in budgeting for large-scale production or small projects. While generally affordable, specific features can drive up the price. This is where it gets interesting: The weight of the fabric often dictates the cost more than the yardage.

Raw material costs (Petroleum and Recycled inputs)

Since polyester is derived from petroleum, oil prices affect fabric costs. Interestingly, rPET (recycled) can sometimes be more expensive due to the complex processing required. However, as recycling technology improves, this gap is narrowing.

Complexity of the knit pattern and weight

Heavier meshes require more raw material, increasing the price per yard. Complex knits, such as 3D spacer meshes or intricate jacquards, require slower production speeds. These factors contribute to a higher final price point.

Impact of specialized coatings and treatments

Adding value through chemistry increases cost.

- Fire Retardant: Essential for safety but adds to the bill.

- Anti-Microbial: Adds longevity but requires expensive additives.

- UV Coating: Extends outdoor life at a premium.

Conclusion

Polyester mesh fabric is an indispensable material that bridges the gap between high-performance functionality and everyday comfort. From its chemically engineered durability to its diverse applications in activewear and industry, it offers solutions that natural fibers simply cannot match. Whether you are designing the next generation of athletic gear or sourcing reliable filtration media, understanding the specific properties of this textile is key to your success.

Ready to select the perfect mesh for your next project? Contact us today to explore our extensive catalog and find the exact specifications you need.

Frequently Asked Questions (FAQ)

Q1: Is polyester mesh fabric waterproof?No, the fiber itself is hydrophobic (repels water), but the open-hole structure allows water to pass through freely. It dries very quickly but does not block water unless coated with a specific waterproof backing.

Q2: Can I print on polyester mesh fabric?Yes, polyester is the ideal candidate for dye-sublimation printing. The heat transfer process bonds the ink directly to the fiber, creating vibrant, permanent images that do not fade or crack.

Q3: Does polyester mesh shrink in the wash?Generally, no. Polyester mesh is heat-set during manufacturing, making it highly resistant to shrinking. However, it should still be washed in cool or warm water to ensure maximum longevity.

Q4: Is polyester mesh comfortable against the skin?Yes, modern polyester mesh is designed to be soft and smooth. While some industrial grades are stiff, apparel-grade mesh is finished to prevent chafing and irritation, making it suitable for linings.

Q5: How do I sew polyester mesh fabric?Sewing mesh requires a ballpoint needle to avoid piercing the yarns. It is recommended to use a polyester thread for stretch and compatibility. Using a stabilizer or tissue paper can help prevent the mesh from getting caught in the machine’s feed dogs.