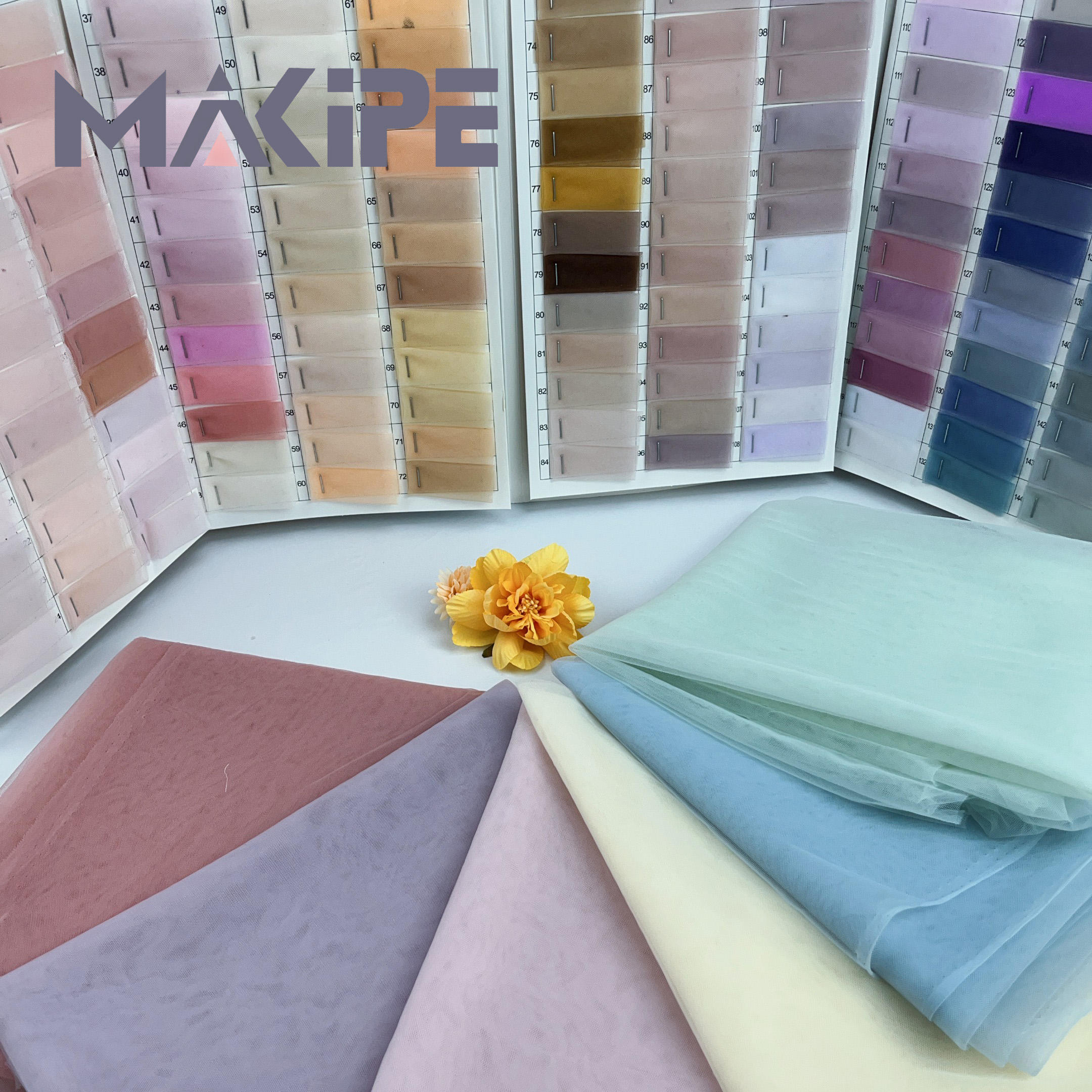

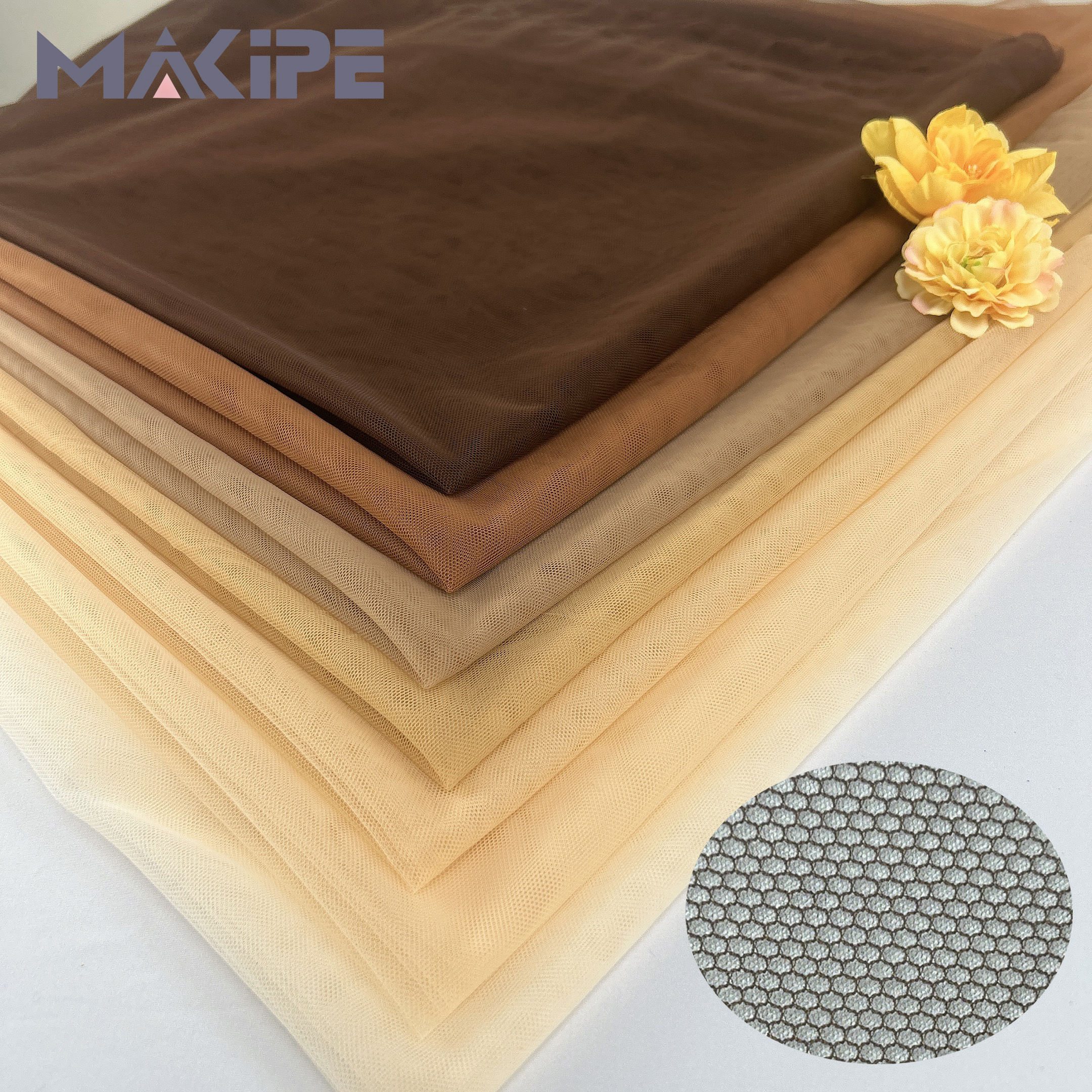

Soft Tulle Looks Simple

Until it touches skin, color runs out mid-production, or your reorder arrives looking nothing like the original.

The real challenge isn't finding soft tulle — it's finding soft tulle that performs consistently.

Who This Industry Is Really For

Different applications demand different priorities—but every segment needs fabric that delivers on its promise, order after order.

Bridal & Formal Wear Factories

Wedding gowns and evening dresses require tulle that feels luxurious against skin during hours of wear. Repeat orders must match the original approval perfectly.

Independent Designer Brands

Emerging designers need access to quality soft tulle without committing to excessive minimums. Color variety enables creative freedom without inventory burden.

Dancewear & Children's Apparel

Performance costumes and kidswear demand exceptional softness for sensitive skin. Durability through washing and active movement is essential.

If you've faced skin complaints, color shortages, or batch inconsistencies — this page is for you.

The Real Problems Nobody Lists on Fabric Pages

These aren't specifications. These are the complaints we hear from buyers who've been let down before.

The sample felt fine, but the production batch scratches skin

Result: Fitting complaints, returns, brand reputation damage

First order was perfect, second order looked completely different

Result: Production delays, visible panel mismatch, customer complaints

Design was approved, but the MOQ killed our launch

Result: Dead stock risk, cash flow pressure, missed market timing

We needed dusty blue urgently, but it's always out of stock

Result: Design compromise, collection delays, lost sales opportunities

Why These Problems Keep Repeating

Most soft tulle suppliers focus on the wrong things. Here's why their "solutions" often create more problems.

Specifications Without Context

They quote mesh count and GSM, but never explain how yarn selection and finishing actually affect the hand-feel your customers will experience.

Stock Colors Without Planning

They advertise many colors in stock, but don't consider whether you can reorder the same shade six months later when your product sells well.

MOQ Promises Without Consistency

They offer low minimums to win orders, but don't maintain the batch-to-batch consistency that makes reordering worthwhile.

This is why many "soft tulle suppliers" still create production risk. Real solutions address the system, not just the specs.

What Actually Matters When Choosing Soft Tulle

Experienced buyers know that fabric specifications alone don't predict real-world performance. Here's how to separate marketing from substance.

Common Misconceptions

What Actually Matters

The difference between a successful product and a failed launch often comes down to these overlooked factors—not the numbers on a spec sheet.

System Thinking

Not just fabric selling

Our Soft Tulle Approach

We treat soft tulle as a system, not a commodity. Every recommendation starts with understanding how the fabric will be used, who will wear it, and what success looks like for your specific application.

Application-First Selection

We reverse-engineer from your end use—bodice vs. overlay vs. skirt all require different tulle characteristics.

Soft Tulle as a System

Yarn, mesh, weight, and finishing work together. We optimize the combination, not individual specs.

Scalable Entry Points

Whether you're sampling 50 meters or planning monthly production, we design pathways that make sense for your scale.

Why Skin-Friendly Tulle Fails in Real Garments

A fabric labeled "soft" doesn't guarantee comfort during actual wear. The disconnect between sample feel and production performance causes the most common complaints in bridal and direct-skin applications.

Low MOQ & Color Reality

Minimum order quantities aren't just about how much fabric you need—they determine your design freedom and business agility. High MOQs force compromises that affect your entire collection strategy.

Sampling

New Launches

Market Testing

MOQ isn't just a number—it's about decision freedom. The ability to test colors, validate designs, and scale gradually without inventory risk.

Batch Stability & Repeat Order Confidence

Inconsistent quality between orders is the hidden cost that B2B buyers rarely discuss openly. When your reorder doesn't match the original, the consequences cascade through your entire production and customer relationship.

A Quick Self-Check for Buyers

Before choosing a soft tulle supplier, consider whether any of these situations apply to your business.

If you checked any of these boxes, we should talk. These are exactly the challenges our soft tulle approach is designed to solve.

From Industry Problems to Real Cases

If these challenges sound familiar, here's how other brands solved them. Each case study documents a real purchasing decision and its outcome.

Skin-Friendly Cases

3 Case Studies

Low MOQ Cases

3 Case Studies

Batch Stability Cases

3 Case Studies

Your Next Step

Ready to explore whether our soft tulle approach fits your needs? Choose the option that works best for where you are in your process.