Finding the right balance between breathability and durability is a constant struggle for designers. Using a weak fabric leads to structural failure, while too dense a material sacrifices comfort. Imagine the frustration of a performance line launching only for the seams to fray and the ventilation to fail under tension; this vulnerability damages brand reputation and wastes massive R&D budgets. tricot mesh fabric provides the definitive solution through warp-knit engineering that balances industrial strength with aesthetic finesse.

1. What Is Tricot Mesh Fabric?

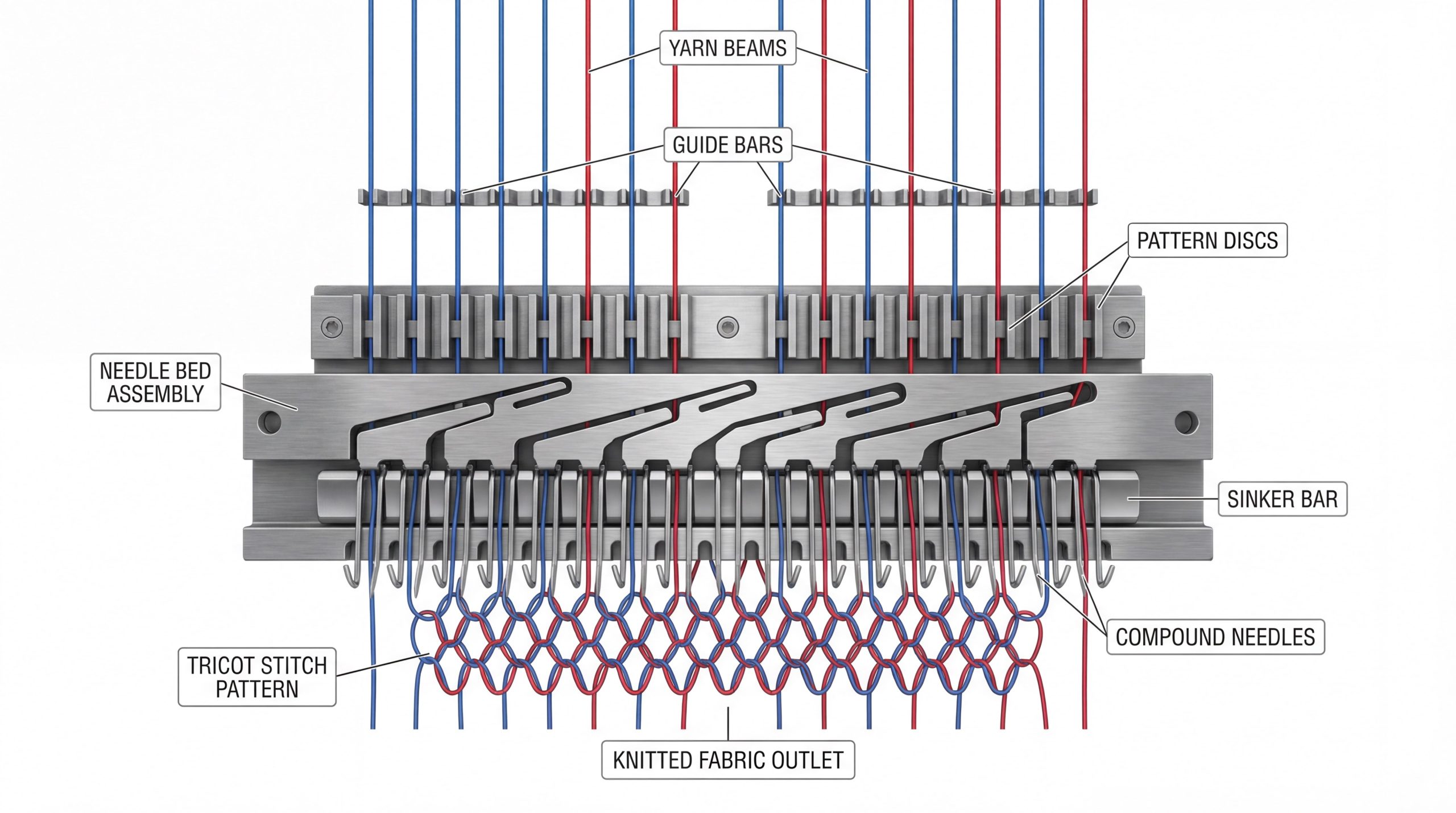

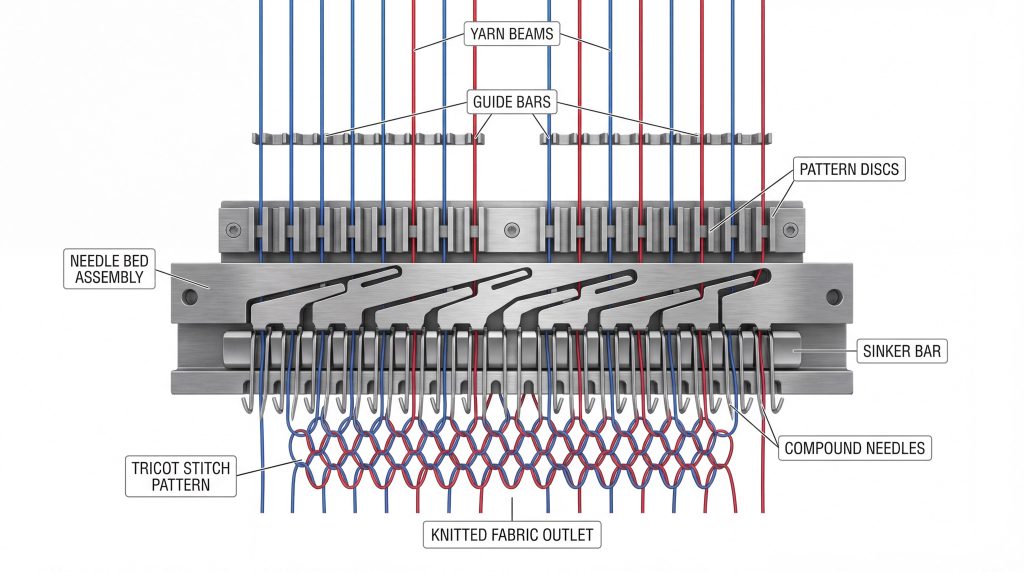

Understanding the core structure of tricot mesh fabric is the first step toward optimizing your product line. Unlike standard knits, this material is formed by a complex “warp” process where yarns run lengthwise, creating a ladder-resistant grid.

Why is the tricot stitch unique?

You might be wondering…

- Run-Resistance: The interlocking zig-zag pattern prevents a single broken thread from unravelling the entire piece.

- Dimensional Stability: It maintains its shape under tension better than weft-knit fabrics.

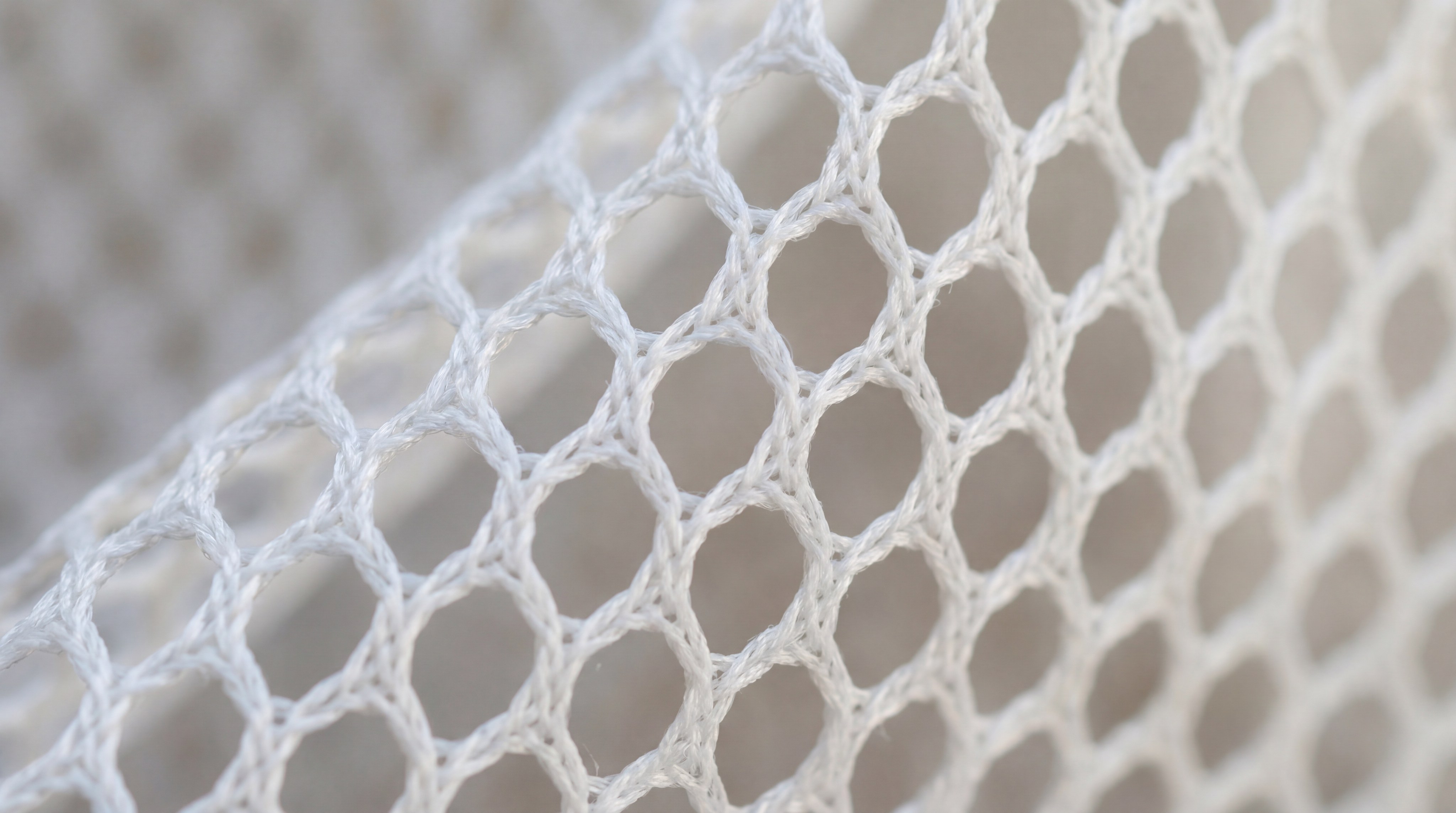

- Smooth Texture: One side is typically smooth while the other features a distinct rib or mesh pattern.

How does warp knitting differ from weft?

Think about it.

- Vertical Feed: Warp knitting feeds yarn vertically from beams, rather than horizontally from a single cone.

- Speed: Warp knitting machines operate at significantly higher RPMs than circular machines.

- Consistency: The automated vertical feed ensures a perfectly uniform grid without the “cloudy” imperfections found in manual knits.

Is it different from standard tulle?

Let’s get into the details.

- Utility Focus: While tulle is designed for volume and aesthetics, tricot mesh is engineered for load-bearing and airflow.

- Stretch Profile: Tricot mesh often integrates elastomers for recovery, whereas basic tulle is usually rigid.

- Hole Density: Mesh patterns are generally more open and structured than the fine hexagonal holes of bridal tulle.

| Feature | Tricot Mesh | Standard Tulle | |

|---|---|---|---|

| Primary Use | Performance & Utility | Decoration & Volume | |

| Durability | High (Run-Resistant) | Moderate (Delicate) | |

| Construction | Warp Knit | Warp Knit (Fine) |

Key Takeaway: Tricot mesh is a high-performance textile defined by its vertical interlocking loops and structural stability.

The inherent run-resistance of the tricot stitch makes it the superior choice for high-stress environments where fabric integrity cannot be compromised.

2. How Is Tricot Mesh Fabric Manufactured?

Manufacturing errors result in uneven hole sizes and inconsistent elasticity that can stall a production line for weeks. We utilise over 80 German KARL MAYER machines to ensure precision in every millimetre of our tricot mesh fabric.

What role do KARL MAYER machines play?

Look at it this way.

- Precision Engineering: German technology ensures that needle bed synchronisation is maintained at ultra-high speeds.

- Uniformity: These machines eliminate the risk of “barre” or horizontal streaks in the mesh.

- Scalability: Advanced automation allows for massive yardage production with zero variance in quality between batches.

How are the hole patterns formed?

Ready to start?

- Guide Bar Control: Precision guide bars shift the warp yarns laterally to create specific apertures.

- Shape Variety: By adjusting the overlap and underlap, we can produce hexagonal, diamond, or square holes.

- Heat Setting: After knitting, the fabric is heat-set to lock the hole geometry permanently in place.

| Production Step | Purpose | Result | |

|---|---|---|---|

| Warping | Yarn Preparation | Uniform Tension | |

| Knitting | Loop Formation | Interlocked Structure | |

| Heat Setting | Stabilisation | Permanent Shape |

Key Takeaway: Premium tricot mesh requires advanced German machinery to achieve the technical precision demanded by global brands.

Modern warp knitting is a feat of engineering that transforms vertical yarn feeds into a highly stable and customisable porous surface.

3. What Are Typical Tricot Mesh Fabric Specifications?

Selecting tricot mesh fabric without knowing its technical specs is a gamble. If the GSM is too low, the fabric won’t hold; if it is too high, the garment becomes heavy and non-functional.

What are the standard weight ranges?

Best of all?

- Lightweight (20-60 GSM): Ideal for pocket linings, veil bases, and sheer apparel inserts.

- Mid-weight (70-130 GSM): The industry standard for athletic jerseys and footwear linings.

- Heavy-weight (140+ GSM): Engineered for industrial bags, tactical gear, and upholstery.

How is elasticity measured in mesh?

Here is the deal.

- Spandex Content: The percentage of elastane (usually 5% to 20%) dictates the “snap-back” force.

- Two-way vs Four-way: Warp knits can be engineered to stretch only horizontally or in all directions.

- Recovery Rate: Professional mesh must return to its original dimensions after being stretched to its limit.

| Specification | Range | Best For | |

|---|---|---|---|

| Weight | 20 – 250 GSM | Versatile Applications | |

| Hole Size | 0.5mm – 5.0mm | Filtration & Ventilation | |

| Material | Nylon or Polyester | Strength & Moisture Wicking |

Key Takeaway: Technical specifications must be precisely matched to the end-use to ensure the fabric performs under stress.

The relationship between GSM and hole diameter determines the “hand-feel” and structural integrity of the final product.

4. How Does Tricot Mesh Fabric Compare to Other Mesh Types?

Choosing between power mesh and standard tricot can be overwhelming. The wrong choice affects the compression and feel of the final product, potentially leading to customer dissatisfaction.

Why choose warp knit over circular knit?

But wait, there’s more.

- Edge Stability: Warp-knit mesh stays flat and stable on the cutting table, whereas circular knits curl.

- Run Prevention: Circular (weft) knits will run if a stitch is dropped; tricot mesh will not.

- Width Consistency: Warp machines produce wider rolls (up to 300cm) which reduces waste in large-scale manufacturing.

Does it offer better breathability?

You’ll love this.

- Open-Grid Design: The geometric precision of tricot allows for maximum cubic feet per minute (CFM) of airflow.

- Moisture Management: Unlike solid knits, the mesh structure facilitates rapid evaporation of sweat.

- Thermal Regulation: It creates a micro-climate between layers, essential for high-performance activewear.

| Mesh Type | Tricot (Warp) | Circular (Weft) | Raschel | |

|---|---|---|---|---|

| Curl Resistance | High | Low | Moderate | |

| Tear Strength | Superior | Moderate | High | |

| Production Speed | Very High | High | Moderate |

Key Takeaway: Tricot warp-knit mesh outperforms circular knits in stability, waste reduction, and long-term durability.

Analysing the mechanical differences between knitting methods reveals why warp knitting is the industrial gold standard for technical textiles.

5. Is Tricot Mesh Fabric Suitable for High-Fashion and Apparel?

Designers often avoid mesh because they fear it looks too “industrial,” but this limits their creative palette for modern layering. When paired with soft tricot mesh fabric , the material adds a contemporary, edgy feel to high-end couture.

Can it be used for bridal wear?

You might be wondering…

- Beading Base: Sturdy tricot provides the structural foundation required for heavy pearls and sequins.

- Illusion Panels: Fine-gauge mesh creates a “naked” look that is stronger and more reliable than silk organza.

- Structural Support: It can be used as an internal layer to maintain the shape of voluminous skirts.

Is it comfortable against the skin?

It’s quite simple.

- Soft Finishing: Specialized chemical washes remove the “crunchy” feel of industrial mesh.

- Anti-Chafing: The smooth loops of the tricot stitch reduce friction during movement.

- Hypoallergenic Options: High-purity polyester and nylon ensure no skin irritation for intimate apparel.

| Apparel Use | Recommended GSM | Key Property | |

|---|---|---|---|

| Bridal Illusion | 20 – 40 GSM | Transparency & Strength | |

| Athletic Lining | 60 – 90 GSM | Softness & Wicking | |

| Fashion Outerwear | 100 – 150 GSM | Structure & Texture |

Key Takeaway: Modern finishing techniques have transformed tricot mesh into a soft, skin-friendly material suitable for the most delicate fashion applications.

The evolution of tricot mesh from a utility fabric to a couture staple highlights the importance of tactile finishing in textile development.

6. Can Tricot Mesh Fabric Withstand Industrial Use?

Industrial environments are harsh on textiles, leading to tears and abrasion that compromise safety and equipment. Using a standard apparel fabric in these settings is a recipe for failure, whereas our engineered mesh is built for high-tensile strength.

What makes it tear-resistant?

Think about it.

- Interlocking Loops: The vertical and diagonal yarn paths distribute stress across the entire fabric surface.

- High-Tenacity Yarns: We use industrial-grade polymers that resist breaking even under extreme loads.

- Abrasion Resistance: The smooth surface of the tricot knit prevents snagging against rough surfaces like rock or metal.

| Industrial Factor | Tricot Mesh Performance | |

|---|---|---|

| UV Resistance | High (with additives) | |

| Tensile Strength | 200N – 800N+ | |

| Chemical Stability | Resistant to most oils and acids |

Key Takeaway: Tricot mesh’s interlocking structure makes it an essential material for tactical, automotive, and luggage industries.

By distributing mechanical stress across a three-dimensional loop system, tricot mesh prevents localized punctures from becoming structural failures.

7. Why Is Tricot Mesh Fabric Essential for Modern Footwear?

Shoes take a beating, and the upper fabric is usually the first part to fail if the material choice is poor. Cheap mesh frays and loses its shape, ruining the aesthetic and fit, which is why tricot mesh fabric is the standard for high-performance sneakers.

How does mesh improve shoe ventilation?

Best of all?

- Engineered Vent Zones: We can vary the hole size within a single sheet to target high-heat areas of the foot.

- Moisture Transport: Hydrophobic yarns pull sweat away from the foot to the outer surface for evaporation.

- Lightweight Support: It provides the “cage” structure needed for stability without the weight of leather or rubber.

| Footwear Component | Mesh Requirement | |

|---|---|---|

| Vamp (Top) | High Breathability | |

| Quarter (Sides) | Structural Stability | |

| Tongue | Softness & Padding |

Key Takeaway: Footwear mesh combines targeted ventilation with extreme durability to support high-impact athletic movement.

The ability to engineer varying densities within the same warp-knit structure allows footwear brands to eliminate heavy overlays.

8. What Tricot Mesh Fabric Customization Options Are Available?

Generic colours and patterns make your brand look like everyone else, diluting your market impact. If you cannot match your brand’s specific palette or functional requirements, your product loses its unique identity.

Can we develop custom hole patterns?

You’ll love this.

- CAD Design: Our technical team can design bespoke apertures, from branding logos to complex geometric shapes.

- Sample Analysis: Send us a swatch, and our KARL MAYER machines can replicate the exact stitch count and density.

- Hybrid Patterns: We can mix different hole sizes to create aesthetic gradients.

Are eco-friendly options available?

Ready to start?

- Recycled Polyester (rPET): Sourced from post-consumer plastic bottles to meet ESG goals.

- Bio-based Nylon: Sustainable alternatives that maintain the strength of traditional polymers.

- Low-Impact Dyeing: Processes that reduce water consumption and eliminate toxic discharge.

| Customization Type | Options | |

|---|---|---|

| Color | Pantone Matching / Neon / Metallic | |

| Finishes | Anti-static / Flame Retardant / Antimicrobial | |

| Patterns | Hex / Square / Custom Branding |

Key Takeaway: Customizing tricot mesh allows brands to merge unique aesthetics with specific high-performance functional requirements.

Strategic customization transforms a commodity textile into a proprietary component that defines a brand’s technical edge.

9. How Should You Care for Tricot Mesh Fabric?

Improper washing can cause tricot mesh fabric to snag or lose its elasticity, leading to premature product disposal. One bad wash cycle can ruin an expensive garment or industrial filter.

Is it prone to snagging during use?

It’s quite simple.

- Velcro Awareness: Sharp hook-and-loop fasteners are the primary enemy of fine mesh.

- Laundry Bags: Always use a mesh bag to prevent the fabric from catching on zippers or buttons.

- Temperature Control: Excessive heat can damage the synthetic fibers and elastomers.

| Care Action | Recommendation | |

|---|---|---|

| Washing | Cold Cycle / Delicates | |

| Drying | Air Dry / Low Tumble | |

| Ironing | Low Heat / Steam Only |

Key Takeaway: Proper care protocols extend the lifespan of tricot mesh by preserving its loop structure and elastic memory.

Educating end-users on care is vital, as the open-grid nature of mesh requires protection from mechanical abrasion during cleaning.

10. Where Is the Best Place to Source Tricot Mesh Fabric?

Middlemen drive up costs and complicate communication, leading to shipping delays and inconsistent batches. Dealing directly with a factory is the only way to ensure quality and price transparency for your international supply chain.

Why choose a factory in Changle, Fuzhou?

Ready to start?

- Textile Hub: Fuzhou is the global epicentre for warp knitting, offering unmatched expertise.

- Direct Access: Bypass trading companies to get factory-direct pricing and technical support.

- Quality Control: On-site labs ensure every meter meets international export standards before it leaves the warehouse.

| Sourcing Factor | Tullemesh Advantage | |

|---|---|---|

| MOQ | Flexible 100m Options | |

| Machinery | 80+ German KARL MAYER | |

| Shipping | Global Logistics Expertise |

Key Takeaway: Sourcing directly from a specialized manufacturer in Fuzhou ensures the highest quality-to-cost ratio for technical mesh.

Eliminating the middleman allows for deeper technical collaboration, resulting in superior fabric performance and faster speed-to-market.

Choosing the right tricot mesh is a decision that defines your product’s durability, comfort, and brand value. From high-fashion layering to heavy-duty industrial applications, the warp-knit structure provides a reliable foundation that weft-knits simply cannot match. If you are looking to elevate your next collection with precision-engineered textiles, contact us today to request free samples and discuss your custom requirements.

Frequently Asked Questions

1. Is tricot mesh different from power mesh?Yes, while both are warp-knitted, power mesh usually contains a higher percentage of spandex to provide compression, whereas standard tricot mesh is used for lining, ventilation, and structure.

2. Can tricot mesh fabric be printed on?Absolutely. Its flat surface and synthetic composition make it excellent for sublimation printing, allowing for vibrant, permanent designs that won’t fade or peel.

3. Does this fabric fray when cut?No. One of the primary benefits of the warp-knit tricot stitch is that it is run-resistant and does not fray at the edges, making it much easier to work with during sewing.

4. What is the standard lead time for custom orders?For stock items, we can ship within 7-15 days. Custom development and large-scale production orders typically require 15-30 days depending on the complexity.

5. Are your mesh fabrics fire-retardant?We offer specialized fire-retardant coatings and treatments that meet international safety standards for industrial and protective gear applications.