Lingerie fabrics are high-performance textiles engineered to balance delicate aesthetics with structural integrity for intimate apparel. Many designers face the struggle of garments losing shape or irritating the skin after just a few washes. This lack of resilience agitates customers and hurts your brand’s reputation for quality. By integrating 4-Way Stretch Mesh into your collections, you provide the technical foundation needed for lasting comfort and luxury.

Why use 4-Way Stretch Mesh for intimates?

Using 4-Way Stretch Mesh ensures that your garments provide maximum mobility without losing their original form. This material is specifically designed to expand and contract both horizontally and vertically. It is the gold standard for modern B2B lingerie production.

Does it offer superior comfort?

You will notice a significant difference when your designs utilize this fabric against the skin. It feels remarkably lightweight while maintaining a high level of breathability for the wearer.

- Wicks moisture effectively.

- Reduces skin friction.

- Offers a sheer, modern look.

Here is the kicker: the ventilation properties are unmatched. You can create pieces that feel invisible under clothes.

Is the recovery rate high enough?

High recovery rates mean the fabric returns to its original shape after being stretched to its limit. This prevents the “bagging” effect often seen in cheaper synthetic alternatives.

- Maintains elasticity over time.

- Resists permanent deformation.

- Supports repeated laundering.

But that’s not all. You will find that this recovery ensures a consistent fit for every body type.

Key Takeaway: High recovery and breathability make this mesh a staple for luxury intimates.

| Feature | 4-Way Stretch Mesh Benefit | |

|---|---|---|

| Movement | Total 360-degree flexibility | |

| Longevity | Maintains shape after 50+ washes | |

| Feel | Ultra-soft nylon/spandex blend |

Choosing materials with high recovery rates ensures your brand delivers a premium experience that lasts.

Can 4-Way Stretch Mesh improve garment fit?

Yes, because 4-Way Stretch Mesh accommodates the body’s natural curves and fluctuations throughout the day. It provides a dynamic fit that static fabrics simply cannot match. This flexibility is essential for creating high-end bras and bodysuits.

Does it solve the issue of gaping?

You can eliminate the common problem of cup gaping by using fabrics that contour to the wearer. The multidirectional stretch fills the gaps that traditional wovens leave behind.

- Contours to various breast shapes.

- Flexes with movement.

- Provides a smooth silhouette.

Believe it or not, this fabric acts like a second skin. You will see higher customer satisfaction rates as a result.

How does it help with sizing?

The adaptability of this mesh allows a single garment size to fit a broader range of measurements comfortably. This reduces the complexity of your inventory management and sizing charts.

- Overlaps between standard sizes.

- Accommodates monthly body changes.

- Reduces returns for fit issues.

Think about it: less stock complexity means higher profit margins for your business.

Key Takeaway: Dynamic contouring reduces fit complaints and streamlines your production sizing.

| Fit Factor | Impact of 4-Way Mesh | |

|---|---|---|

| Contouring | Eliminates dead space and gaping | |

| Versatility | Fits varied proportions within one size | |

| Profile | Creates a seamless, bulk-free look |

Implementing adaptive fabrics allows your designs to cater to a more diverse range of customers effortlessly.

Is 4-Way Stretch Mesh durable for daily wear?

Absolutely, as 4-Way Stretch Mesh is engineered with high-tenacity nylon and spandex fibers that resist tearing. It maintains its structural integrity even under constant tension from the body. This makes it an ideal choice for everyday essentials.

What is the pill resistance?

You can expect a smooth surface even after months of friction against outer clothing. The tight knit structure prevents the fibers from breaking and forming unsightly pills.

- Resists abrasion.

- Stays smooth over time.

- High-quality finish.

Check this out: your garments will look brand new for much longer than those made with cotton knits. You are investing in long-term brand loyalty.

Can it withstand machine washing?

Modern mesh is built to handle the rigors of frequent laundering without losing its stretch properties. While delicate bags are recommended, the fabric itself is quite resilient.

- Colorfast after many cycles.

- Quick-drying material.

- Maintains fiber strength.

The bottom line is this: durability in lingerie is a non-negotiable requirement for repeat buyers.

Key Takeaway: Technical fiber blends provide the strength needed for high-frequency use.

| Durability Metric | Mesh Performance | |

|---|---|---|

| Pill Resistance | Excellent (Grade 4-5) | |

| Color Retention | High resistance to fading | |

| Tensile Strength | Maintains bond under pressure |

Durability directly correlates with perceived value in the competitive B2B intimate apparel market.

How does 4-Way Stretch Mesh compare to lace?

4-Way Stretch Mesh offers a more uniform support and a smoother profile compared to the textured surface of lace. While Stretch Lace is prized for its classic beauty, mesh provides a modern, sporty aesthetic. Both have critical roles in a well-rounded collection.

Which provides more support?

You will find that mesh generally offers a more consistent hold across the entire panel. Lace often has varied density in its pattern, which can lead to uneven tension.

- Consistent modulus levels.

- Distributed weight support.

- Reliable shaping power.

Let me explain: for structural components like bra wings, mesh is usually the superior technical choice. You get the stability your customers need.

Is mesh better for minimalist designs?

Lace is inherently decorative, whereas mesh allows you to create sleek, “naked” looks that are currently trending. It disappears under tight clothing better than textured lace does.

- Invisible under t-shirts.

- Clean, architectural lines.

- Versatile for layering.

The best part? You can layer mesh under lace to provide structure while keeping the aesthetic.

Key Takeaway: Mesh is for structure and invisibility, while lace is for decoration and romance.

| Attribute | 4-Way Stretch Mesh | Stretch Lace | |

|---|---|---|---|

| Texture | Smooth and flat | Raised and patterned | |

| Tension | Uniform distribution | Variable distribution | |

| Visibility | Low (Seamless look) | High (Decorative) |

Balancing these two materials allows you to target both the functional and decorative market segments.

What makes 4-Way Stretch Mesh ideal for lining?

4-Way Stretch Mesh is the perfect lining because it provides opacity and softness without adding bulk. It moves perfectly with the outer fabric, preventing the two layers from fighting each other. This creates a cohesive, high-quality garment.

Does it improve skin sensitivity?

You can use mesh linings to protect the wearer from scratchy embroidery or seams on the outer layer. It acts as a soft barrier that increases the overall comfort of the piece.

- Hypoallergenic options.

- Silky surface feel.

- Gentle on delicate areas.

You might be wondering if it adds too much heat, but the open-cell structure ensures air flows freely.

How does it affect the drape?

Because it is so thin, it does not distort the way the outer fabric sits on the body. It provides just enough “grip” to keep the garment in place without being restrictive.

- Lightweight profile.

- Enhances outer fabric stability.

- Prevents garment shifting.

Wait, there’s more: lining with mesh can actually help sheer outer fabrics look more expensive and finished.

Key Takeaway: Mesh linings provide professional finishing and skin protection without compromising breathability.

| Lining Benefit | Practical Application | |

|---|---|---|

| Skin Barrier | Covers rough seams or lace | |

| Opacity | Adds modesty to sheer panels | |

| Stability | Keeps delicate fabrics from over-stretching |

A well-lined garment signifies craftsmanship and attention to detail that B2B buyers expect.

Will 4-Way Stretch Mesh support larger sizes?

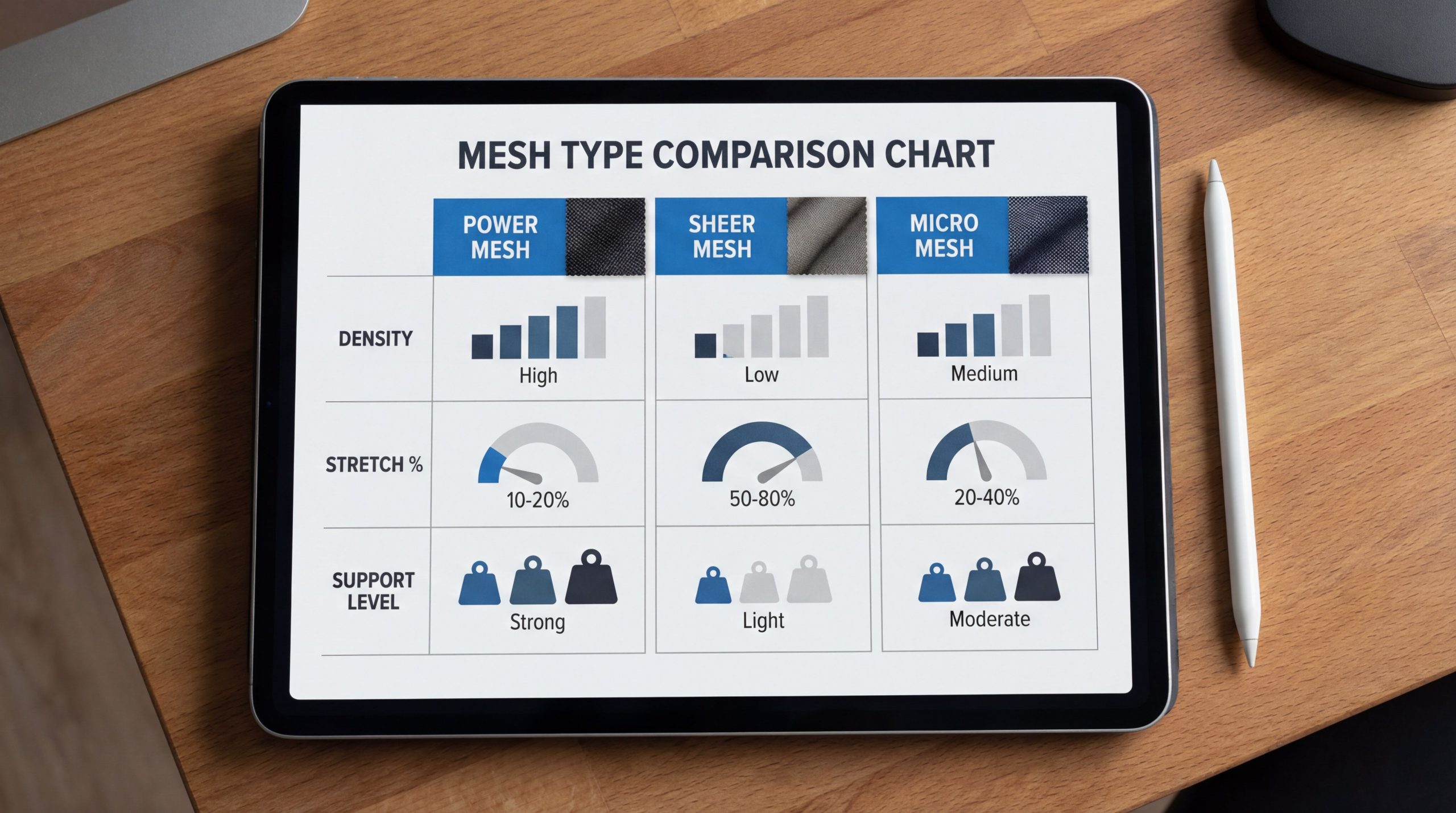

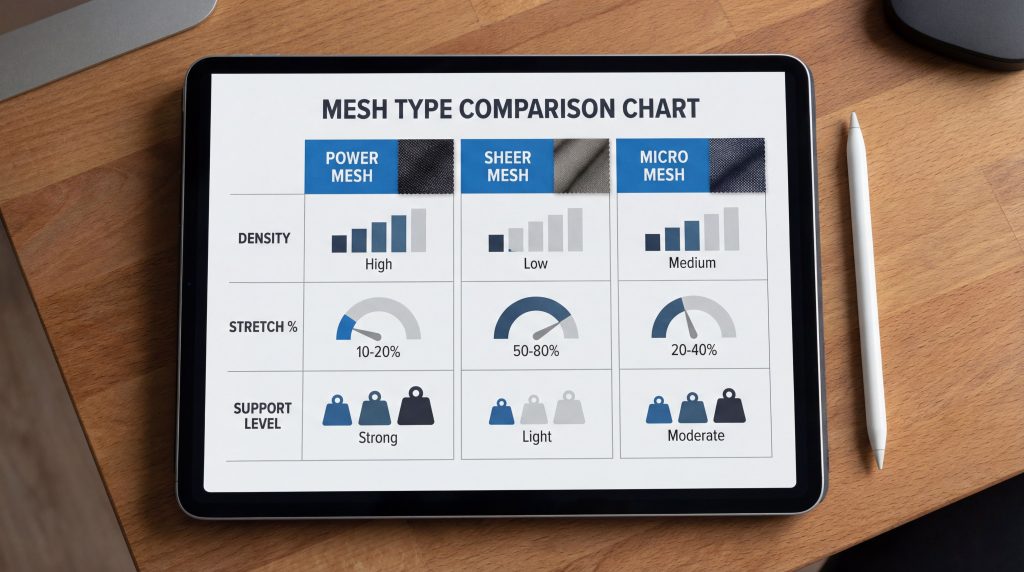

Yes, but for maximum support in larger sizes, it is often paired with a more rigid Power Mesh . The 4-way variety provides the comfort and fit, while the power version offers the lift and containment. This hybrid approach is common in high-end inclusive brands.

Can you double-layer for more lift?

You can achieve a higher modulus by layering two pieces of mesh together. This increases the resistance without sacrificing the breathable nature of the fabric.

- Adjustable tension levels.

- Reinforced support panels.

- Maintains a light feel.

Here is the kicker: you can change the grain direction of the second layer to lock out stretch where needed. You are in total control of the mechanics.

Is it suitable for wide bra wings?

You will find that the flexibility of 4-way mesh prevents the “digging in” effect at the side of the body. It spreads the pressure evenly across a wider surface area for all-day wearability.

- Soft edge finishes.

- No-roll technology.

- High side-body comfort.

Think about it: a happy customer is one who forgets they are wearing a bra at all.

Key Takeaway: Layering and strategic placement make mesh effective for the full-bust market.

| Size Range | Suggested Mesh Usage | |

|---|---|---|

| XS – M | Single layer 4-way stretch | |

| L – XXL | Double layer or Power Mesh hybrid | |

| Support Need | High modulus for lift and control |

Engineering your garments with specific mesh densities ensures comfort across your entire size range.

Can 4-Way Stretch Mesh handle high-tension seams?

Yes, 4-Way Stretch Mesh is surprisingly strong and handles the stress of being pulled during wear without the seams popping. Its knit structure allows the needle to pass through without breaking the core yarns. This is vital for the longevity of tight-fitting intimates.

What thread should you use?

You need to use high-quality polyester or nylon thread that also possesses some degree of stretch. This ensures the seam expands along with the mesh fabric.

- Prevents thread breakage.

- Maintains seam elasticity.

- Soft against the body.

Check this out: using a wooly nylon thread in the looper of your serger creates the softest, strongest seam possible.

Does it fray during production?

One of the best features you will appreciate is that mesh does not unravel like woven fabrics. This makes it easier to handle during the cutting and sewing stages of manufacturing.

- Clean cut edges.

- Easy to manipulate.

- Low waste during production.

The bottom line is this: easy handling in the factory reduces your labor costs and increases efficiency.

Key Takeaway: Superior seam strength and fray resistance make it a production-friendly material.

| Production Factor | Mesh Advantage | |

|---|---|---|

| Cutting | Stable edges, no fraying | |

| Stitching | High needle-heat resistance | |

| Seam Strength | High burst-strength ratings |

Choosing factory-friendly fabrics helps you maintain high production standards and minimize errors.

How to sew 4-Way Stretch Mesh professionally?

Sewing 4-Way Stretch Mesh professionally requires using ballpoint needles and stretch stitches to maintain the fabric’s integrity. It is often used alongside Soft Tulle for a multi-textured finish. Using the right equipment prevents skipped stitches and fabric damage.

Should you use a walking foot?

You will find that a walking foot or a dual-feed system helps feed the slippery mesh layers evenly through the machine. This prevents one layer from stretching more than the other during the process.

- Prevents fabric rippling.

- Ensures even seam lengths.

- Maintains design symmetry.

Here is the kicker: a simple adjustment to your presser foot pressure can make a world of difference. You get a professional finish every time.

What is the best stitch for hems?

You should utilize a narrow zig-zag or a coverstitch for hems to allow the opening to expand when putting the garment on. A straight stitch will simply snap under the pressure of the stretch.

- High stretch retention.

- Flat, professional look.

- Durable construction.

But that’s not all. You can also use decorative elastics to finish edges while adding structural support.

Key Takeaway: Specialist needles and stretch-friendly stitches are essential for professional results.

| Tool | Recommended Specification | |

|---|---|---|

| Needle | Size 70/10 Ballpoint or Stretch | |

| Stitch | Zig-zag, Triple-stretch, or Serged | |

| Foot | Walking foot or Teflon foot |

Investing in the correct technical setup ensures your factory output meets luxury market standards.

Is 4-Way Stretch Mesh eco-friendly for B2B?

Yes, many modern versions of 4-Way Stretch Mesh are now available in recycled nylon or polyester variations. This allows your brand to maintain high performance while meeting sustainability goals. B2B buyers are increasingly prioritizing these “green” textile solutions.

Are recycled meshes as strong?

You will find that recycled fibers undergo rigorous testing to ensure they match the performance of virgin materials. They provide the same stretch and recovery that your designs require.

- Equivalent tensile strength.

- Same soft hand-feel.

- Verified GRS certification.

Believe it or not, your customers will value the transparency and eco-conscious effort of your brand.

Does it reduce chemical waste?

Using high-quality, long-lasting mesh reduces the overall “fast fashion” cycle by creating garments that don’t need frequent replacement. Furthermore, modern dyeing processes for synthetics are becoming more water-efficient.

- Longer product lifecycle.

- Reduced landfill waste.

- Lower carbon footprint.

The bottom line is this: sustainability is a powerful selling point in the current fashion landscape.

Key Takeaway: Recycled mesh variants allow for sustainable growth without compromising on quality.

| Sustainability Goal | Mesh Solution | |

|---|---|---|

| Resource Saving | Use of pre/post-consumer waste | |

| Longevity | High durability stops frequent disposal | |

| Certification | Look for OEKO-TEX or GRS labels |

Transitioning to sustainable mesh options positions your company as an industry leader in responsible manufacturing.

Why is 4-Way Stretch Mesh essential for brands?

It is essential because it bridges the gap between high-fashion aesthetics and the technical demands of the human body. Pairing it with Embroidered Tulle creates the sophisticated look that consumers crave. Without this fabric, achieving a modern fit would be nearly impossible.

Can it improve your brand’s reputation?

You will build a reputation for reliability when your customers realize your garments don’t stretch out or tear. Quality materials lead to repeat purchases and positive word-of-mouth marketing.

- Increased customer trust.

- Lower return rates.

- Premium brand positioning.

Check this out: the most successful lingerie brands in the world all rely on high-spec mesh as a core material.

Is it cost-effective for mass production?

While the initial cost may be higher than basic cotton, the efficiency of production and the low return rate make it more profitable in the long run. You save money on quality control and customer service.

- Streamlined manufacturing.

- Higher perceived value.

- Better margin potential.

Wait, there’s more: its versatility means you can use one fabric across multiple styles in your collection.

Key Takeaway: Technical mesh is a strategic investment that pays off in brand equity and customer retention.

| Business Metric | Mesh Impact | |

|---|---|---|

| Brand Image | Modern, high-tech, and luxurious | |

| Customer Loyalty | High, due to superior fit and comfort | |

| ROI | Excellent, through reduced returns |

Incorporating premium mesh into your supply chain is a foundational step toward long-term market success.

Conclusion

Mastering the use of specialized lingerie fabrics is the key to creating intimates that empower the wearer. We have solved the common problems of poor fit and low durability by highlighting the technical advantages of modern mesh. Our brand stands for uncompromising quality and innovation in textile manufacturing. If you are ready to elevate your next collection with premium materials, contact us today to discuss your specific requirements.

FAQ

Can I use 4-Way Stretch Mesh for swimwear?Yes, provided the mesh is treated for chlorine and salt-water resistance. Most nylon-based meshes are naturally suitable for swim applications when paired with appropriate linings.

What’s the best way to prevent skip stitches on mesh?Skip stitches are usually solved by switching to a fresh stretch needle and reducing the sewing speed. Ensuring your machine’s timing is correctly set for fine knits is also a critical factor.

Can I dye 4-Way Stretch Mesh custom colors?Certainly, as nylon-based meshes take acid dyes extremely well, allowing for perfect color matching with your elastics and laces. Always perform a test batch to ensure the spandex core is not damaged by high heat.

What’s the best fabric for a bra’s power bridge?Non-stretch stable tricot or a stabilized mesh is best for the bridge to ensure the cups stay in place. While the wings need stretch, the center front must remain static for proper support.

Can I laser cut this fabric for seamless designs?Yes, synthetic mesh reacts well to laser cutting, which seals the edges and prevents any future fraying. This is a common technique for high-end, raw-edge “invisible” panties.