Tulle fabric represents a fine hexagonal mesh textile primarily utilized for creating airy volume or delicate overlays in professional garment manufacturing today. Many procurement teams face significant delays when sourcing consistent netting because local suppliers frequently provide inconsistent weights or poor dye lots. These supply chain failures lead to missed delivery windows plus unhappy retail partners who demand perfection across every single bulk order. Our premium mesh solutions solve these sourcing headaches by providing high-quality materials so your business maintains peak production efficiency what is tulle fabric used for throughout the year. Professional textile selection directly correlates with increased product longevity plus higher market valuations for finished garments.

# 1. What is tulle fabric used for in modern fashion?

Fashion houses employ this mesh for building structural volume without adding excessive weight within seasonal collections sold throughout many global markets today. Many procurement officers wonder what is tulle fabric used for when they manage complex textile supply chains during busy production cycles for new apparel. This fine netting offers incredible versatility by providing sheer coverage plus structural volume within sophisticated garment architectures across global wholesale markets without increasing overhead costs. Manufacturers often choose these specific synthetic fibers because they resist wrinkling while maintaining crisp edges during intense sewing operations in busy modern garment factories.

Textile Selection For Volume

Choosing a stiff hex-mesh allows garments to maintain rigid shapes through multiple wearings during long runway shows or high-pressure retail sales events. Here is the deal. Buying premium materials ensures your brand avoids defects while maximizing customer satisfaction through durable products that withstand frequent cleaning processes without losing shape. Supply chain managers often select synthetic variants due to their superior elasticity plus strength during high-speed industrial stitching processes in many large manufacturing plants. These professionals understand that quality netting reduces waste while increasing overall profit margins on luxury apparel lines sold globally to discerning corporate clients. Selecting premium netting ensures your manufacturing facility operates at peak capacity while minimizing fabric waste during precision cutting stages for every bulk production order. Quality control officers prefer these textiles because they offer uniform tensile strength across every roll of material purchased for intensive garment manufacturing cycles. Reliable sourcing partners provide these high-grade meshes so brands create luxury items that satisfy demanding consumer expectations in competitive international retail environments today. Investing in top-tier textiles reduces long-term costs by preventing production errors plus maintaining high quality standards throughout your entire apparel catalog without failure.

| Category | Feature | Benefit | |

|---|---|---|---|

| Design | Weightless Volume | Elevated Aesthetics | |

| Production | Tear Resistance | Lower Waste Rates | |

| Logistics | High Compressibility | Reduced Shipping Fees |

Key Takeaways:

- Nylon and polyester variants dominate the high-fashion sector due to durability.

- Hexagonal weave patterns provide optimal tension during industrial sewing.

- Volume-to-weight ratios make tulle superior to solid woven fabrics for skirts.

Analysis: Professional mesh selection directly correlates with increased product longevity plus higher market valuations for finished garments.

# 2. Exactly what is tulle fabric used for in bridal wear?

Bridal designers utilize these fine materials for crafting ethereal veils plus voluminous skirt layers that define traditional wedding aesthetics across the international bridal industry. Manufacturers often ask what is tulle fabric used for when they develop high-margin wedding gowns requiring delicate textures plus significant structural support for heavy embellishments. This specific netting provides a transparent canvas for intricate lace applications or hand-sewn beadwork while remaining comfortable for brides during long wedding ceremonies. Premium bridal illusion variants offer superior clarity plus softness so designers achieve a sophisticated look that justifies luxury price points in high-end boutiques.

Crafting Elegant Bridal Veils

Creating a perfect bridal veil requires ultra-fine netting that drapes beautifully without snagging on delicate jewelry or sequined bodices during a wedding ceremony. What is the real story? Specialized production facilities focus on weaving these meshes with extreme precision so every yard meets the stringent clarity requirements of the bridal market. Supply chain experts prioritize these materials because they offer consistent dyeability for matching various shades of white or ivory across different textile components. Using high-clarity netting enhances the overall presentation of a bridal ensemble while ensuring the veil remains a timeless accessory for many future generations. Quality bridal netting serves as a foundational element for building high-value wedding collections that stand out in a crowded global fashion marketplace. Professional buyers should look for materials that offer a balance between softness plus strength so finished gowns survive the rigors of shipping and fitting. Selecting the right mesh weight ensures that every design maintains its intended silhouette without requiring excessive internal support structures or heavy boning materials. Consistency in textile sourcing remains the primary driver for maintaining high production standards within the luxury bridal sector over long periods of time. Reliable textile specifications allow bridal manufacturers to maintain tight production schedules while delivering flawless garments to high-end retail partners.

| Bridal Component | Mesh Requirement | Desired Outcome | |

|---|---|---|---|

| Long Veils | Ultra-Soft Handfeel | Graceful Fluid Draping | |

| Skirt Support | Medium Stiffness | Durable Consistent Volume | |

| Bodice Overlays | High Clarity | Intricate Detail Visibility |

Key Takeaways:

- Bridal illusion tulle requires a higher hole-per-inch count for transparency.

- Silk tulle remains the gold standard for luxury heritage bridal brands.

- Layering different stiffness levels creates depth in ballgown silhouettes.

Analysis: High-clarity netting serves as an essential substrate for intricate lace applique work in couture bridal design.

# 3. In ballet, what is tulle fabric used for specifically?

Costume designers primarily use this netting for building traditional ballet tutus that require extreme stiffness plus durability during rigorous stage performances across the world. Professional choreographers often inquire what is tulle fabric used for when they seek lightweight solutions for high-energy dance routines involving complex leaps or rapid turns. This material provides the necessary lift for pancake tutus while allowing air to circulate freely around the athlete during intense physical activity. Using specialized stiffened meshes ensures that costumes retain their professional appearance through multiple shows without drooping or losing their characteristic stage-ready silhouette.

Engineering High-Performance Tutus

Building a professional tutu involves layering multiple tiers of varying mesh weights to create a self-supporting structure that resists gravity during athletic movements. Think about it. Dance apparel companies rely on these specialized textiles because they offer a unique combination of extreme lightness plus remarkable structural integrity under pressure. Choosing the correct stiffness level prevents the garment from collapsing while also ensuring the fabric does not irritate the skin of the performer. Superior manufacturing processes produce netting that holds its shape even after repeated use in professional ballet companies or competitive dance studios. Specialized dance textiles represent a significant investment for costume departments that require consistent performance standards for their elite professional athletes. Sourcing high-grade netting ensures that every tutu maintains its crisp horizontal line during every single performance on stage throughout the long theater season. Manufacturers must prioritize materials that resist fraying or tearing during the intense sewing processes required to assemble complex multi-layered dance garments for professionals. Achieving the perfect balance of rigidity plus weight allows dancers to focus on their technique without being hindered by heavy or cumbersome clothing. Consistent material quality enables dance apparel brands to build a strong reputation for excellence among world-class ballet companies plus theater productions.

| Performance Metric | Textile Feature | Resulting Benefit | |

|---|---|---|---|

| Aerodynamics | Low Air Resistance | Faster Performer Movement | |

| Durability | High Tensile Strength | Extended Costume Lifespan | |

| Aesthetics | Stage Light Reflection | Enhanced Visual Impact |

Key Takeaways:

- Rigid starched tulle is vital for the classical pancake tutu profile.

- Nylon 6,6 fibers provide superior memory for costume shape retention.

- Multi-tier construction utilizes up to twelve layers of varied mesh density.

Analysis: Engineering professional tutus requires specialized stiffened netting that maintains structural integrity against gravity during athletic performance.

# 4. For events, what is tulle fabric used for most?

Event planners frequently utilize these versatile meshes for transforming large venues into elegant spaces through sophisticated ceiling draping plus table ornamentation at gala events. Decorators often ask what is tulle fabric used for when they need to cover large surface areas quickly while maintaining a high-end visual appeal. This netting offers a cost-effective way to hide architectural flaws or create intimate atmospheres within cavernous convention centers or hotel ballrooms globally. Selecting fire-retardant mesh variants ensures that commercial installations meet safety regulations while providing a beautiful backdrop for corporate celebrations or high-profile charity auctions.

Creating Immersive Event Atmospheres

Designing immersive environments for corporate clients requires textiles that can be manipulated into large-scale installations without requiring heavy support systems or expensive hardware. The best part? Large rolls of wide-width netting allow for seamless draping across massive distances while keeping the overall weight of the installation manageable for technicians. Professional decorators value these materials because they can be gathered or pleated to create depth plus texture that catches the light beautifully. Using a variety of mesh colors allows companies to align event aesthetics with brand identities while staying within budgetary constraints for temporary decor. Commercial decor projects demand reliable textile supplies that arrive on time plus match the specific color requirements of high-value corporate branding packages. Investing in high-quality netting ensures that decorative elements remain intact during the entire duration of the event without sagging or becoming damaged. Supply chain managers for event firms prioritize these materials because they offer high visual impact for a relatively low cost compared to solid fabrics. Building a portfolio of successful installations requires a consistent source of premium mesh that performs predictably under various lighting conditions plus installation methods. Strategic textile selection empowers event professionals to deliver stunning results that exceed client expectations while optimizing operational efficiency for large-scale projects.

| Decor Element | Application Method | Visual Result | |

|---|---|---|---|

| Ceiling Swags | Long Length Draping | Softened Room Height | |

| Chair Sashes | Simple Knot Tying | Unified Seating Aesthetic | |

| Photo Backdrops | Layered Mesh Panels | Sophisticated Depth Effect |

Key Takeaways:

- Fire-retardant certifications are non-negotiable for commercial venue decorations.

- Wide-width rolls minimize seams in large-scale ceiling draping projects.

- Tulle diffuses harsh LED lighting to create a soft ambient glow.

Analysis: Strategic use of wide-format netting allows decorators to transform massive industrial spaces into intimate high-end environments efficiently.

# 5. For interiors, what is tulle fabric used for today?

Interior designers incorporate these delicate meshes into residential projects for creating soft window treatments or romantic bed canopies that add texture to modern rooms. Many homeowners wonder what is tulle fabric used for when they seek ways to soften the hard lines of contemporary furniture or architectural features. This netting allows natural light to filter into a space while providing a basic level of privacy for inhabitants without blocking the view. Using layered mesh in window displays creates a sophisticated look that mimics the appearance of more expensive custom draperies at a fraction of the price.

Designing Modern Bed Canopies

Adding a mesh canopy to a bedroom suite creates a luxurious sanctuary feeling that appeals to high-end residential clients looking for comfort plus style. Now for the secret. Designers often layer different weights of netting to achieve the perfect balance of transparency plus privacy for a custom look in luxury homes. These lightweight installations do not require heavy ceiling mounts so they can be easily integrated into existing room layouts without major renovations. Choosing a mesh with a subtle sheen enhances the play of light within the room while providing a soft tactile element to the design. Integrating mesh textiles into interior design schemes offers a unique way to introduce volume plus texture without overwhelming the existing decor of a home. Professional designers should select materials that are easy to maintain so the finished installation remains beautiful for the homeowner over many years. Consistent sourcing of premium netting allows design firms to offer reliable products that meet the high expectations of their affluent residential clientele. Utilizing these versatile materials provides an affordable path to achieving high-end looks in various rooms while maintaining a cohesive aesthetic throughout the property. Thoughtful textile application in home interiors creates a sophisticated atmosphere that enhances the daily living experience for modern residents in urban environments.

| Interior Use | Material Requirement | Design Advantage | |

|---|---|---|---|

| Window Tiers | High Transparency | Maximized Natural Light | |

| Bed Canopies | Soft Fluid Draping | Enhanced Room Comfort | |

| Wall Hangings | Textured Mesh Layers | Modern Visual Interest |

Key Takeaways:

- Sheer mesh allows for 90% light transmission while obscuring direct views.

- Polyester tulle resists yellowing from UV exposure better than cotton alternatives.

- Lightweight mesh installations reduce structural load on residential ceilings.

Analysis: Incorporating sheer mesh layers into modern interiors provides a soft acoustic dampening effect in glass-heavy contemporary spaces.

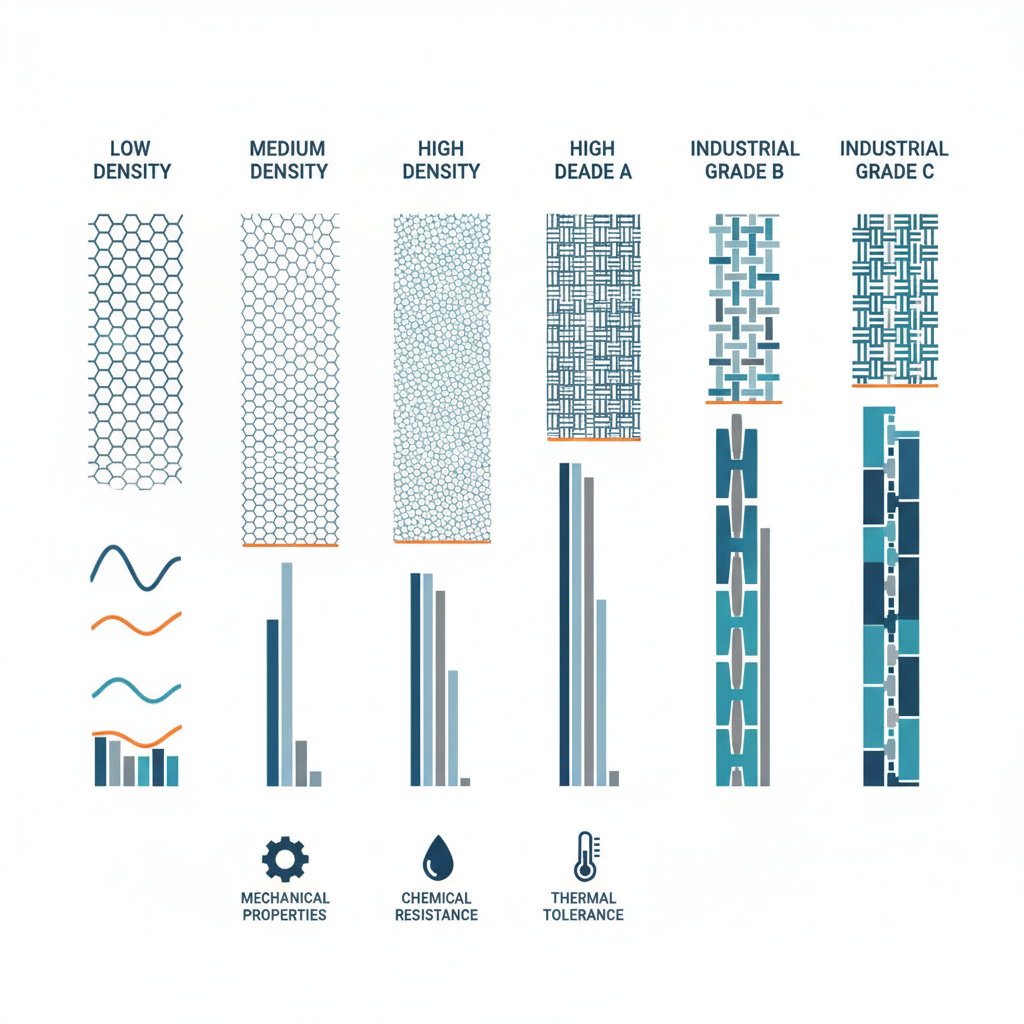

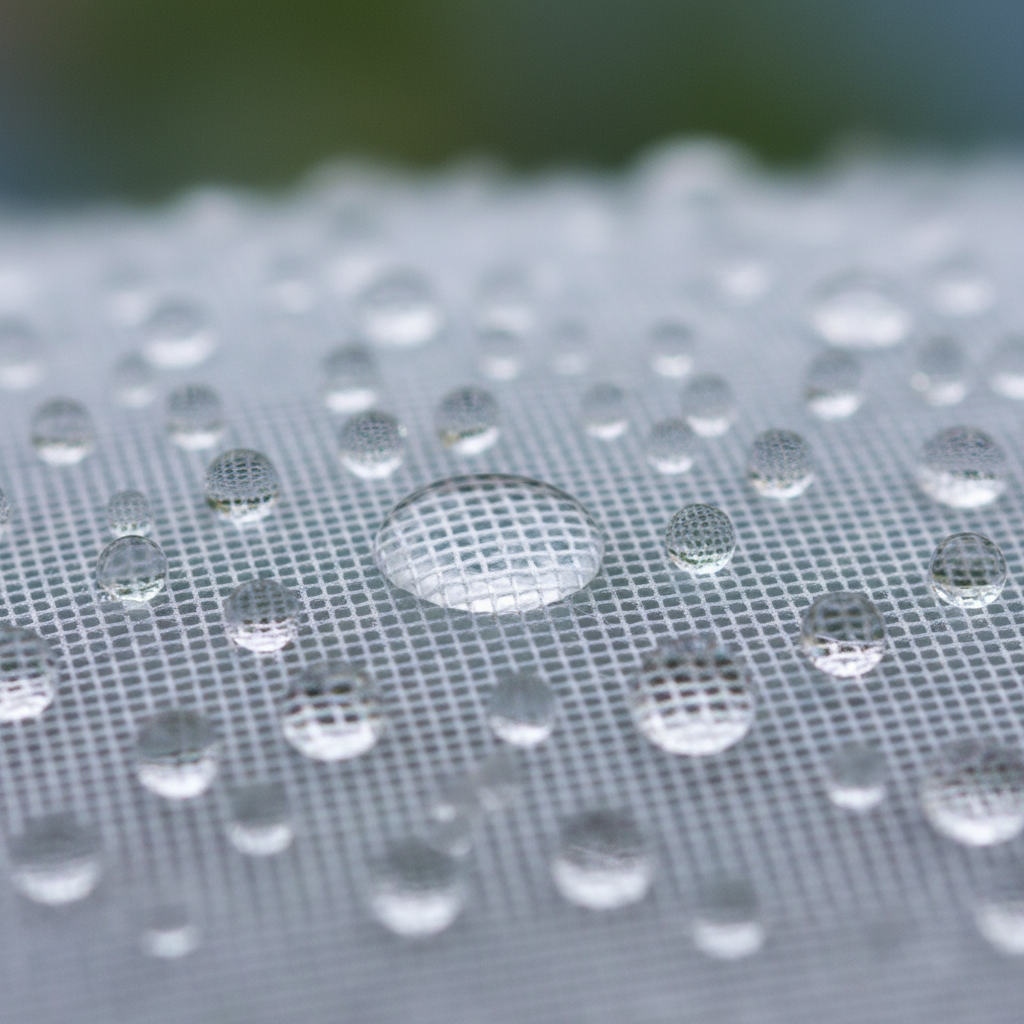

# 6. For filters, what is tulle fabric used for technically?

Industrial manufacturers utilize these precise hexagonal meshes for technical applications such as filtration systems or reinforcement layers in composite materials across several sectors. Engineering teams often ask what is tulle fabric used for when they need a lightweight substrate that offers high surface area plus consistent pore sizes. This netting serves as a reliable base for medical grade filters or protective screens that require a specific level of airflow plus durability. Selecting high-performance synthetic fibers ensures that these technical meshes withstand chemical exposure or mechanical stress while maintaining their structural integrity in demanding environments.

Engineering Precise Mesh Filters

Technical filtration requires a mesh with uniform openings that can reliably separate particles while allowing fluids to pass through at a constant rate. What is the real story? Production facilities use advanced computer-controlled looms to weave these materials with incredible accuracy so every square inch meets exact engineering specifications. These technical textiles are often treated with specialized coatings to enhance their resistance to moisture or bacterial growth in sensitive industrial applications. Manufacturers prioritize these high-spec materials because they ensure the reliability of the finished product while reducing the risk of system failure for the user. High-spec technical netting plays a vital role in the production of modern goods that require precision plus reliability across many different global industries. Engineers must select materials that offer consistent performance under various environmental conditions so their finished products meet all safety plus quality standards. Reliable textile suppliers provide the data needed to integrate these meshes into complex manufacturing processes while ensuring long-term product durability for the customer. Investing in premium technical textiles reduces the total cost of ownership by extending the life of filtration systems plus improving overall process efficiency. Precise textile engineering enables manufacturers to create innovative solutions for complex industrial challenges that demand high performance plus consistent material quality.

| Technical Metric | Mesh Property | Industrial Application | |

|---|---|---|---|

| Pore Size | Uniform Hexagonal | Liquid Gas Filtration | |

| Tensile Strength | High Polyamide Bond | Material Reinforcement | |

| Bio-Resistance | Treated Surface | Medical Device Components |

Key Takeaways:

- Micron-level precision in hexagonal openings ensures predictable fluid flow rates.

- Nylon mesh offers high resistance to alkalis in industrial cleaning systems.

- Heat-setting processes prevent dimensional changes during high-temperature filtration.

Analysis: Technical-grade hexagonal mesh serves as a cost-effective substrate for high-efficiency air and liquid filtration assemblies globally.

# 7. What is tulle fabric used for in layered clothing?

Fashion designers employ multiple layers of this netting to create depth plus color variation in high-end evening wear or artistic runway pieces. Many stylists ask what is tulle fabric used for when they want to achieve a three-dimensional effect that changes as the wearer moves. This material allows for the creation of ombré effects by stacking different shades of mesh together in a single garment construction for visual impact. Using layered netting provides a way to build structure into a dress while keeping the overall appearance soft plus feminine for the wearer.

Mastering The Layering Technique

Creating a successful layered look involves choosing complementary mesh weights so the finished garment has both the necessary volume plus a graceful movement. Ready for the good part? Designers can achieve complex color palettes by mixing primary colors of netting to create new hues through the optical blending of the layers. This technique allows for the creation of unique textures that cannot be achieved with solid fabrics alone in modern fashion design studios. Professional garment workers must handle these layers with care to ensure that the seams remain invisible while the volume stays consistent throughout the piece. Layered mesh constructions represent the pinnacle of haute couture craftsmanship by showcasing the ability to transform simple netting into complex wearable art. Brands that master this technique can command higher prices in the luxury market because of the high level of skill required for production. Consistent sourcing of high-quality mesh in a wide range of colors is essential for maintaining the creative freedom needed for these designs. Investing in premium materials ensures that the layered effect remains crisp plus vibrant throughout the life of the garment in a retail environment. Advanced layering techniques allow fashion brands to differentiate their products through unique visual narratives that capture the imagination of high-end consumers worldwide.

| Layering Goal | Technique Used | Aesthetic Outcome | |

|---|---|---|---|

| Color Depth | Multi-Shade Stacking | Complex Optical Hues | |

| Structural Lift | Graduated Stiffness | Defined Architectural Shape | |

| Visual Texture | Raw Edge Gathering | Modern Artistic Appeal |

Key Takeaways:

- Optical blending of colored mesh layers creates unique iridescent fashion effects.

- Graduated stiffness in layered skirts provides support without excessive bulk.

- Raw-edge layering techniques eliminate the need for heavy hems in couture.

Analysis: Mastering multi-layered mesh construction allows designers to create complex color narratives and structural depth in evening wear.

# 8. What is tulle fabric used for in millinery work?

Milliners utilize this fine netting for creating sculptural hat components or delicate face veils that add a touch of mystery to formal headwear. Hat makers often ask what is tulle fabric used for when they need a material that can be stiffened or pleated into complex shapes. This netting provides a lightweight way to add volume to a fascinator without making the accessory too heavy for the wearer to balance. Using high-quality mesh ensures that the structural elements of the hat remain crisp plus durable even when exposed to humidity or light rain.

Sculpting Professional Headwear

Creating professional millinery requires a mesh that can hold its shape once it has been steamed or manipulated into a specific artistic form. The catch? Lower quality netting will collapse under its own weight or lose its shape quickly when worn outdoors during traditional horse racing events or weddings. Skilled artisans value premium netting because it offers a consistent reaction to stiffening agents while providing a smooth surface for adding further embellishments. Choosing the right mesh density allows the milliner to create either a soft romantic look or a bold avant-garde architectural statement for their clients. Premium millinery netting is a vital component for hat designers who wish to create high-value accessories that stand the test of time. Professional buyers should prioritize materials that offer a high degree of versatility so they can be used for a wide range of styles. Consistent material quality ensures that every hat in a collection meets the same high standards of craftsmanship plus durability for the customer. Utilizing specialized netting allows milliners to push the boundaries of traditional design while maintaining the functional requirements of luxury headwear for elite events. Expertly crafted headwear featuring high-quality mesh elements provides a significant competitive advantage for brands operating in the luxury accessory market.

| Millinery Task | Mesh Requirement | Functional Benefit | |

|---|---|---|---|

| Face Veiling | Open Hexagonal Weave | High Visibility Comfort | |

| Sculptural Bows | High Stiffened Finish | Permanent Shape Hold | |

| Brim Overlays | Fine Delicate Texture | Subtle Elegant Sheen |

Key Takeaways:

- Steam-shaping capabilities allow for custom avant-garde millinery silhouettes.

- Russian veiling variants offer a wider mesh pattern for retro aesthetic.

- Nylon millinery mesh accepts topical stiffeners better than polyester blends.

Analysis: High-tenacity mesh provides the necessary foundation for sculpting intricate lightweight structural elements in professional luxury headwear.

# 9. What is tulle fabric used for in eco-friendly textiles?

Sustainable manufacturers are developing new versions of this netting using recycled plastics or bio-based polymers to reduce the environmental impact of the textile industry. Eco-conscious brands often ask what is tulle fabric used for when they look for ways to integrate recycled materials into their high-fashion collections. These innovative meshes provide the same aesthetic benefits as traditional versions while supporting circular economy initiatives that appeal to modern consumers globally. Selecting recycled netting ensures that a brand stays ahead of environmental regulations while meeting the growing demand for ethically produced fashion items.

Innovating With Recycled Netting

Producing high-quality mesh from recycled sources requires advanced manufacturing techniques that maintain the clarity plus strength of the original virgin fibers. Let is face it. Moving toward a more sustainable production model is no longer optional for textile companies that want to remain relevant in a changing global marketplace. These new materials offer a story of innovation that adds value to a garment beyond its physical appearance or structural functionality for the user. Using bio-based or recycled netting helps to close the loop in the fashion supply chain while providing designers with the tools they need. Sustainable mesh solutions represent the future of the textile industry as brands look for ways to balance luxury aesthetics with environmental responsibility. Investing in these innovative materials allows companies to build a reputation for leadership in the growing field of circular fashion and green manufacturing. Consistent sourcing of high-quality recycled netting is becoming easier as more production facilities adopt green technologies to meet market demand for sustainable goods. Utilizing eco-friendly textiles provides a powerful marketing message that resonates with a new generation of shoppers who prioritize the planet in their purchasing. Strategic adoption of sustainable netting materials empowers fashion houses to lead the industry toward a more responsible plus profitable future for everyone.

| Sustainability Goal | Textile Innovation | Environmental Impact | |

|---|---|---|---|

| Waste Reduction | Recycled Fiber Use | Lower Landfill Volume | |

| Resource Savings | Bio-Based Polymers | Reduced Oil Dependency | |

| Clean Production | Non-Toxic Dyeing | Protected Water Systems |

Key Takeaways:

- Recycled PET (rPET) mesh matches virgin nylon in tensile performance standards.

- Bio-based polymers reduce the carbon footprint of high-volume garment production.

- Closed-loop manufacturing minimizes water waste during the mesh dyeing process.

Analysis: Transitioning to recycled mesh variants allows luxury brands to align with global sustainability mandates without compromising aesthetic quality.

# 10. What is tulle fabric used for in industrial netting?

Heavy-duty industrial sectors employ this robust mesh for a wide range of practical applications including safety netting plus protective barriers in harsh working environments. Logistics managers often ask what is tulle fabric used for when they need lightweight materials that can secure cargo or provide shade for temperature-sensitive goods. This netting offers a high strength-to-weight ratio that makes it ideal for use in aerospace or automotive sectors where every gram of weight is significant. Selecting a mesh with specialized UV or water-resistant coatings ensures that it performs reliably during long-term outdoor exposure in various climates across the globe.

Securing Industrial Supply Chains

Industrial-grade netting must withstand extreme mechanical stress while remaining flexible enough to be used in a variety of complex logistics or storage situations. What is the real story? Engineering firms rely on these high-performance meshes because they offer a cost-effective way to improve safety plus efficiency in large-scale industrial operations every day. These materials are often woven with reinforced edges to prevent tearing when under high tension during shipping or construction projects in the field. Choosing the right mesh size ensures that the material provides the necessary protection without blocking essential airflow or visibility in critical work areas. Industrial netting provides a foundation for safer plus more efficient operations across a wide range of demanding sectors that require reliable material performance. Professional procurement officers should look for meshes that meet specific international safety standards to ensure the protection of their personnel plus high-value assets. Reliable textile manufacturers provide the technical documentation needed to integrate these materials into complex industrial systems while ensuring long-term durability for the end user. Investing in high-grade industrial mesh reduces the risk of accidents plus improves the overall reliability of the supply chain in competitive global markets. High-performance industrial netting serves as a vital tool for modern companies looking to optimize their operations through durable plus lightweight material solutions.

| Industrial Need | Mesh Specification | Operational Benefit | |

|---|---|---|---|

| Cargo Security | High-Tensile Weave | Reduced Shipping Damage | |

| Worker Safety | Impact-Resistant Net | Improved Site Compliance | |

| Weather Shield | UV-Stabilized Fiber | Extended Product Lifespan |

Key Takeaways:

- High-tenacity polyester mesh resists moisture absorption in outdoor marine environments.

- UV-stabilized coatings extend the operational life of safety netting significantly.

- Reinforced selvage edges prevent mesh unraveling under extreme industrial tension.

Analysis: Utilizing specialized industrial-grade mesh enhances operational safety and efficiency across the global logistics and construction sectors.

FAQ

Q1: Can I wash this mesh in a standard machine?Professional textile handlers recommend hand washing or using a delicate cycle in cold water to prevent the fine mesh from snagging or losing its shape.

Q2: What is the best way to remove wrinkles from netting?Using a professional garment steamer at a safe distance is the preferred method for removing creases without risking heat damage to the delicate synthetic fibers.

Q3: How do I choose the right stiffness for my project?Selecting the correct weight depends on whether you need a soft fluid drape for veils or a rigid structure for tutus and architectural fashion pieces.

Q4: Why does some netting feel scratchier than others?The texture of the mesh is determined by the fiber type and finishing treatments used during production with nylon typically offering a softer handfeel than polyester.

Q5: When should I use recycled netting over traditional versions?Brands should prioritize recycled options when they want to align their product lines with modern sustainability standards while maintaining high-quality aesthetic results for consumers.

Tulle fabric remains a foundational material for diverse industries by offering a unique combination of lightness plus structural versatility for modern production needs. By understanding the specific characteristics of different mesh weights, businesses can optimize their manufacturing processes while delivering high-quality products that meet demanding market standards. Investing in premium textiles ensures long-term brand success through consistent quality plus improved operational efficiency across every single project. For more information on how to source the best materials for your next collection, please contact us today .