Selecting the right mesh fabric material is the cornerstone of creating high-performance apparel and innovative industrial solutions. Many manufacturers and designers struggle to find textiles that offer both structural integrity and maximum ventilation. When projects lack the necessary airflow, the resulting products often lead to user discomfort, overheating, and eventual material fatigue. By mastering the technical specifications of mesh fabric material , you can ensure your designs meet the highest standards of durability and breathability.

1. What defines a high-quality mesh fabric material?

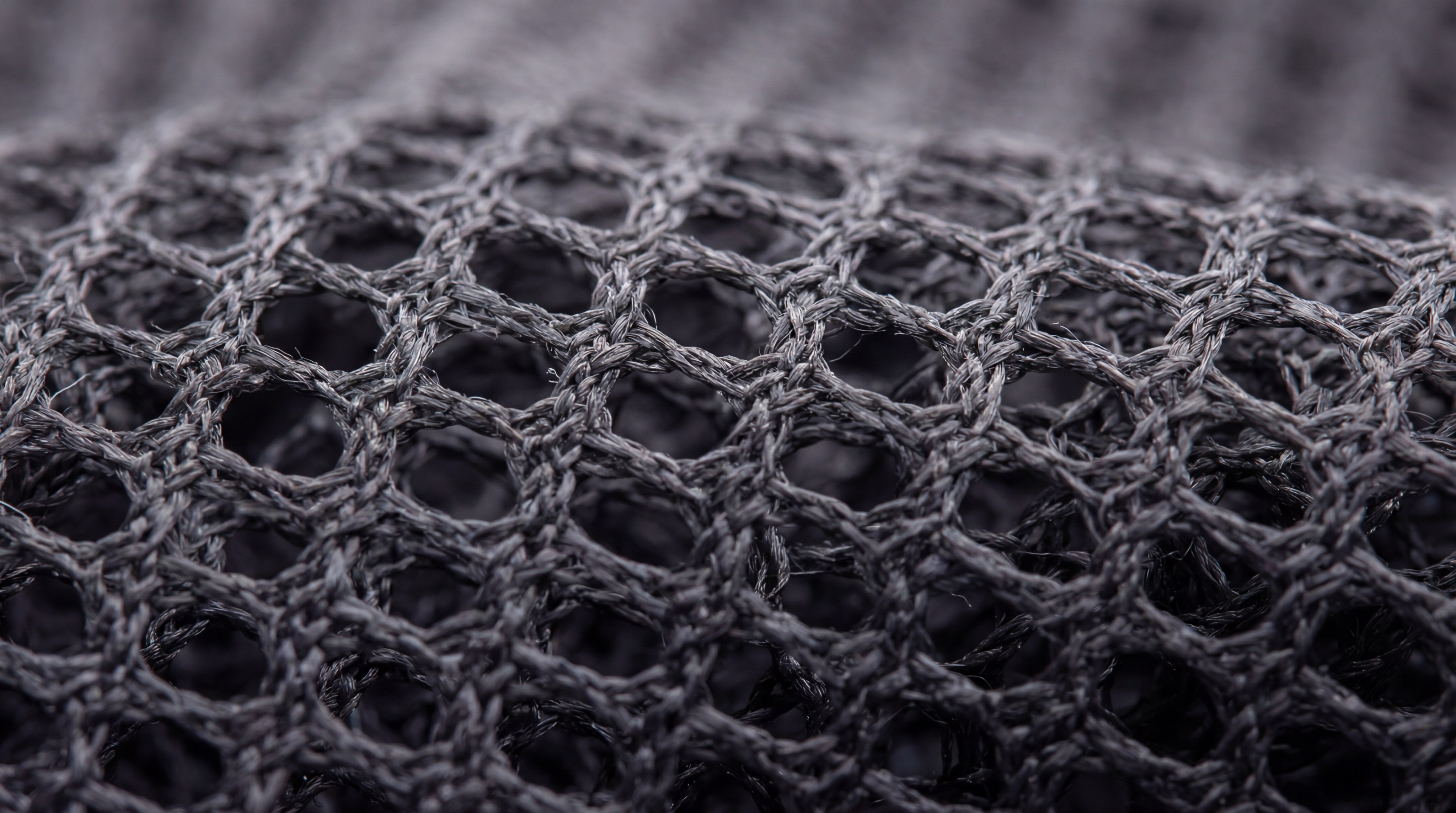

High-quality mesh is defined by its consistent open-weave structure and the tensile strength of the yarns used in its construction. This mesh fabric material relies on a net-like design where threads are knotted or looped at specific intervals to create uniform pores.

Is it defined by the net structure?

The primary characteristic of this textile is the intentional spacing between fibers. Unlike traditional weaves, the threads are stabilized to prevent the holes from shifting or closing under tension. This creates a predictable environment for air to pass through consistently.

Does the fiber source affect quality?

You should look for synthetic polymers like polyester or nylon to ensure the best performance. These materials provide the necessary resistance to moisture and environmental wear that natural fibers often lack.

Here is the kicker: High-quality mesh doesn’t just look breathable; it maintains its structural “pores” even when stretched to its limit.

Key Takeaways

- Mesh is defined by its intentional open-weave or “net” pattern.

- The material remains lightweight while offering significant durability.

- Pore density and yarn gauge determine the final application’s success.

| Feature | Quality Indicator | Benefit | |

|---|---|---|---|

| Pore Uniformity | Consistent hole size | Predictable ventilation | |

| Yarn Type | High-tenacity synthetic | Long-term durability | |

| Weight | Grams per square meter (GSM) | Balanced strength-to-weight |

The technical superiority of a mesh is found in its ability to balance transparency with ruggedness.

2. Which types of mesh fabric material exist?

There are several distinct categories of mesh ranging from high-compression power fabrics to decorative tulle. Understanding which mesh fabric material suits your specific project is vital for achieving the desired fit and finish.

Is power mesh different from standard tulle?

Power mesh is engineered for four-way stretch and compression, making it ideal for support garments. In contrast, tulle is a fine, often stiffer mesh used primarily for volume in bridal and evening wear.

What is the role of fishnet and lurex?

Fishnet provides a bold, wide-aperture look that is a staple in high-fashion and hosiery. When lurex is added, it introduces a metallic shimmer that elevates the material for luxury aesthetic applications.

But wait, there’s more: The variety in mesh allows you to choose between rigid support and fluid, elastic movement.

Key Takeaways

- Power mesh offers compression for activewear and lingerie.

- Tulle provides structural volume for formal attire.

- Specialized variants like fishnet cater to specific fashion statements.

| Mesh Type | Best For | Elasticity | |

|---|---|---|---|

| Power Mesh | Shapewear/Athletics | High | |

| Tulle | Bridal/Evening Wear | Low | |

| Fishnet | Layering/Hosiery | Moderate |

Choosing the right type depends entirely on whether your project requires structural support or aesthetic transparency.

3. How is this mesh fabric material produced?

Most modern mesh is produced using advanced warp-knitting techniques that prevent the fabric from unraveling. This production method ensures that the mesh fabric material remains stable even if a single thread is damaged during use.

Is it knitted or woven?

Warp knitting on Raschel or Tricot machines is the industry standard for creating durable mesh. This process creates a series of interlocking loops that are far more “run-resistant” than traditional woven textiles.

What roles do polyester and spandex play?

Polyester provides the base strength and ensures the fabric remains colorfast over time. Spandex is often integrated into the knit to provide the necessary “snap-back” recovery for form-fitting garments.

Think about this: Without the warp-knitting process, a single snag could ruin an entire garment.

Key Takeaways

- Warp knitting is the preferred method for stable mesh production.

- Polyester ensures the material is rugged and resistant to fading.

- Spandex integration allows for essential stretch and recovery.

| Component | Function | Result | |

|---|---|---|---|

| Warp Knit | Interlocking loops | Run-resistant structure | |

| Polyester | Core fiber | High tensile strength | |

| Heat Setting | Post-production | Dimensional stability |

The combination of mechanical knitting and synthetic chemistry creates a textile that is virtually indestructible.

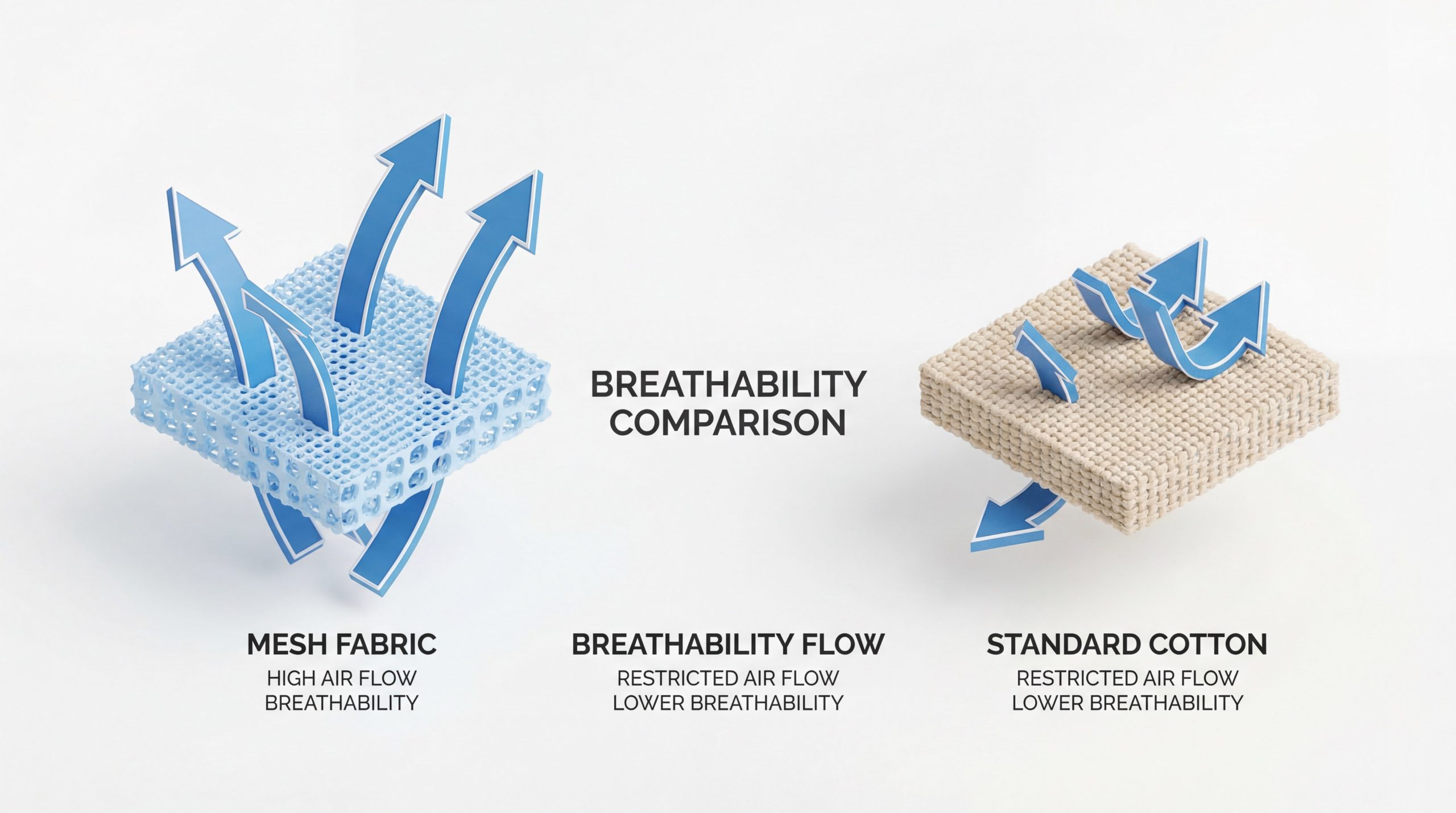

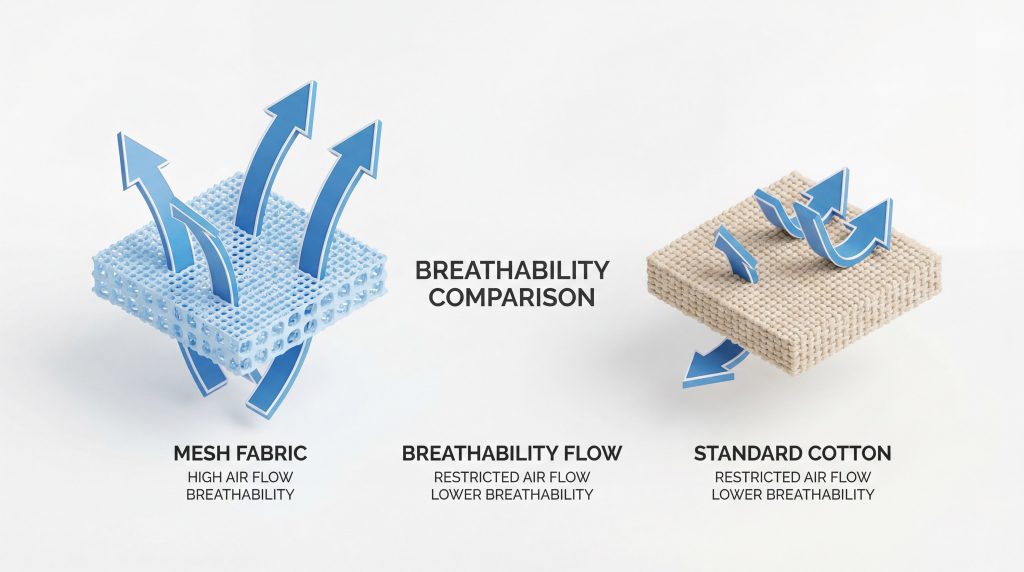

4. What makes mesh fabric material breathable?

The breathability of mesh is a result of its passive ventilation system, which allows air to move freely through the fabric. This mesh fabric material outperforms solid textiles by facilitating rapid heat dissipation and moisture evaporation.

How does the open-weave design work?

The physical holes in the mesh act as gateways for airflow, preventing the buildup of hot air against the skin. This design ensures that body temperature remains regulated even during high-intensity activities.

Does it offer moisture-wicking properties?

Synthetic mesh fibers do not absorb water, but rather push it toward the surface of the fabric. Once the moisture reaches the surface, the open airflow facilitates almost instantaneous evaporation.

You might be wondering: How can a fabric be so lightweight yet so effective at temperature control?

Key Takeaways

- Passive ventilation is the primary driver of cooling.

- Synthetic fibers prevent moisture absorption within the yarns.

- Air circulation speeds up the drying process significantly.

| Material | Airflow Rating | Moisture Retention | |

|---|---|---|---|

| Standard Mesh | Excellent | Very Low | |

| Solid Cotton | Poor | High | |

| Nylon Blend | Good | Moderate |

Comparing mesh to traditional solid weaves highlights its undeniable advantage in climate-controlled performance.

5. Where is mesh fabric material used in fashion?

In the fashion industry, mesh is used for everything from high-performance activewear to avant-garde evening gowns. This mesh fabric material provides a unique way to add texture and depth to a garment without adding significant weight or bulk.

Is it popular for activewear?

It is the standard choice for ventilation panels in leggings, jerseys, and footwear. Designers place mesh in high-heat zones to maximize cooling for athletes and fitness enthusiasts.

How are digital prints applied?

Modern printing technology allows for vivid designs to be transferred directly onto the mesh surface. This creates a “tattoo” effect where the print appears to float against the wearer’s skin.

And that’s not all: Mesh can be layered over solid colors to create a multidimensional look that changes with movement.

Key Takeaways

- Mesh is essential for cooling in modern sportswear.

- Digital printing enables high-detail aesthetics on sheer surfaces.

- Layering provides visual depth without the weight of heavy fabrics.

| Fashion Application | Common Mesh Type | Primary Benefit | |

|---|---|---|---|

| Activewear Panels | Power Mesh | Targeted cooling | |

| Formal Gowns | Soft Tulle | Voluminous silhouette | |

| Streetwear Tops | Printed Mesh | Unique visual texture |

The sheer versatility of mesh makes it a favorite for designers looking to push the boundaries of transparency.

6. Is mesh fabric material useful for industry?

Industrial applications rely on mesh for its incredible strength-to-weight ratio and resistance to environmental stress. Heavy-duty mesh fabric material is used in automotive interiors, cargo management, and specialized health equipment.

Can it be used for automotive interiors?

Industrial mesh is frequently found in car seat pockets and headliners to reduce vehicle weight while maintaining airflow. Its abrasion resistance makes it perfect for high-traffic areas inside a cabin.

Is it suitable for outdoor gear?

From tent windows to backpack side pockets, mesh is the go-to for rugged outdoor equipment. It provides visibility and drainage, ensuring that gear stays dry and organized in the field.

Here is the catch: Industrial mesh must meet much higher GSM standards than fashion-grade materials to ensure safety.

Key Takeaways

- Automotive mesh helps in weight reduction and ventilation.

- Outdoor gear utilizes mesh for its drainage and visibility properties.

- Durability is the most critical factor for industrial-grade textiles.

| Industry | Application | Key Requirement | |

|---|---|---|---|

| Automotive | Seat backing/storage | Abrasion resistance | |

| Outdoor/Camping | Tent netting | UV resistance | |

| Logistics | Cargo nets | High tensile strength |

Industrial mesh proves that transparency does not have to come at the expense of structural power.

7. How to maintain your mesh fabric material?

Maintaining mesh requires a delicate approach to prevent snagging and stretching during the cleaning process. Because this mesh fabric material has an open structure, it is more susceptible to damage from zippers and hooks than solid cloths.

Can you machine wash mesh?

Yes, you can machine wash most mesh, provided you use a protective laundry bag. This barrier prevents the fabric from getting caught on other garments or the machine’s internal components.

How to prevent snagging and tearing?

Using the “delicate” cycle and cold water is the best way to preserve the fibers’ elasticity. You should also avoid high-heat drying, as it can cause synthetic fibers to become brittle or warp.

But wait, there’s more: Air drying is the preferred method for ensuring your mesh garments retain their original shape.

Key Takeaways

- Protective laundry bags are essential for machine washing.

- Cold water and gentle cycles prevent fiber degradation.

- High heat is the enemy of synthetic mesh elasticity.

| Care Step | Action | Benefit | |

|---|---|---|---|

| Washing | Use mesh bag | Prevents snags/tears | |

| Drying | Air dry only | Maintains fabric shape | |

| Detergent | Mild/No bleach | Preserves color and stretch |

A small amount of extra care ensures that your high-performance mesh lasts for years of use.

8. Is mesh fabric material eco-friendly?

The environmental impact of mesh is evolving as more manufacturers shift toward recycled polymers. While traditional mesh fabric material is petroleum-based, new innovations are significantly reducing the carbon footprint of these textiles.

What are the impacts of synthetic fibers?

Standard polyester and nylon production is energy-intensive and involves non-renewable resources. However, the extreme durability of these materials means products stay in use longer, reducing overall waste.

Are there recycled mesh alternatives?

You might be wondering: Can high-performance mesh really be made from recycled plastic? The answer is a resounding yes. Many premium suppliers now offer rPET mesh, which is created by recycling post-consumer plastic bottles into high-quality yarns.

Key Takeaways

- Recycled polyester (rPET) is a growing segment of the mesh market.

- Long-lasting durability reduces the need for frequent replacements.

- Sustainable sourcing is becoming a priority for B2B manufacturers.

| Source | Environmental Impact | Durability | |

|---|---|---|---|

| Virgin Polyester | High carbon footprint | Excellent | |

| Recycled rPET | Lower carbon footprint | Excellent | |

| Bio-based Nylon | Renewable resources | Good |

Moving toward recycled options allows you to maintain performance while meeting sustainability goals.

9. How to choose the right mesh fabric material?

Choosing the right mesh involves balancing weight, stretch, and pore size to match your specific application. Testing the “recovery” of the mesh fabric material is the most important step for any designer working with form-fitting products.

Should you prioritize weight or stretch?

If you are designing bags or industrial covers, you should prioritize GSM and high-denier strength. For apparel like bodysuits, the percentage of spandex and the softness of the knit are the critical factors.

Does the pattern matter for functionality?

Flocked or embroidered patterns add aesthetic value but can sometimes restrict the natural stretch of the base mesh. You should always test how a pattern affects the breathability of the textile before finalizing a design.

Here is the kicker: A mesh that doesn’t snap back immediately after being stretched will quickly lose its shape and functionality.

Key Takeaways

- Match the fabric weight (GSM) to the intended load or use.

- Always verify the “stretch recovery” for apparel applications.

- Consider how decorative elements might impact air circulation.

| Project Type | Priority Metric | Recommended Feature | |

|---|---|---|---|

| Activewear | Stretch Recovery | 15% + Spandex | |

| Industrial Bag | GSM/Denier | High-tenacity Polyester | |

| Bridal Wear | Hand-feel/Softness | Fine Nylon Tulle |

Proper selection at the sampling stage prevents costly production errors and ensures user satisfaction.

10. Where can you source mesh fabric material?

Sourcing at the wholesale level is the most effective way for designers and manufacturers to maintain consistency and lower costs. A reliable supplier of mesh fabric material will provide detailed technical sheets and certifications for specialized use cases.

Is wholesale the best option for designers?

Purchasing in bulk ensures that you have the same dye lot and yarn quality across an entire production run. This consistency is vital for maintaining brand standards in the fashion and upholstery industries.

What should you look for in a supplier?

A top-tier supplier should offer transparency regarding fiber content, flame retardancy ratings, and ethical manufacturing certifications. You should always request sample swatches to verify the texture and stretch in person.

But wait, there’s more: Building a direct relationship with a supplier often gives you early access to new textile innovations.

Key Takeaways

- Wholesale sourcing guarantees batch consistency for production.

- Technical certifications are mandatory for specialized industrial mesh.

- Sampling is a non-negotiable step in the sourcing process.

| Sourcing Factor | Importance | Expert Tip | |

|---|---|---|---|

| Consistency | High | Always buy by the roll | |

| Lead Time | Critical | Account for seasonal demand | |

| Certifications | Essential | Verify FR and UV ratings |

Reliable sourcing is the final link in the chain that turns a great design into a successful commercial product.

Conclusion: Mastering Your Material Selection

The versatility of mesh fabric material makes it an indispensable asset across fashion, industrial, and domestic sectors. By selecting the appropriate knit structure and fiber blend, you can solve complex design problems related to heat, weight, and aesthetics. Whether you are developing the next line of elite activewear or looking for durable industrial solutions, the right mesh provides the balance of strength and permeability you need. To explore our full catalog and receive expert guidance on your next project, feel free to contact us today .

FAQ

1. Is mesh fabric material itchy against the skin?Not necessarily. While industrial variants can be stiff, apparel-grade power mesh and soft tulle are engineered with smooth synthetic fibers to ensure comfort for all-day wear.

2. Does mesh fabric material provide UV protection?Due to the open structure, standard mesh offers minimal protection. However, tightly knit versions treated with UV-resistant coatings are available for specialized outdoor applications.

3. Can I sew mesh on a regular home sewing machine?Yes, but you should use a ballpoint or stretch needle. A zigzag stitch is also recommended to allow the seam to stretch along with the fabric without snapping the thread.

4. What’s the best way to stop the edges of mesh from fraying?Most high-quality knitted mesh is naturally run-resistant and does not fray easily. For a professional finish, using a serger or binding the edges with a solid fabric is the best approach.

5. Will the colors in mesh fabric material fade over time?Polyester-based mesh is highly resistant to fading and holds digital prints exceptionally well, even after repeated exposure to sunlight and frequent washing.