Tulle is a fine, lightweight netting fabric characterized by its hexagonal mesh structure, typically made from fibers such as silk, nylon, polyester, or rayon to achieve varying degrees of stiffness and transparency. When you are sourcing materials for high-end fashion or industrial applications, understanding the technical nuances of what fabric is tulle is essential for maintaining quality standards.

Navigating the global textile market often presents significant challenges for professional designers and manufacturers. You likely struggle with inconsistent mesh density and high markups from retail suppliers that drain your project margins. A single shipment of poor-quality netting can lead to structural failure in a couture gown or compromised performance in technical apparel.

By sourcing directly from advanced warp-knitting facilities, you can eliminate middleman complexities and secure specialized textiles tailored to your exact specifications. This guide breaks down the essential categories and technical properties of modern tulle to empower your procurement decisions.

Exactly what fabric is tulle in textile terms?

In technical textile terms, what fabric is tulle is defined as a sheer, fine-gauge netting with a distinctive hexagonal or diamond-shaped hole structure produced on specialized warp-knitting machines. Unlike woven fabrics that rely on interlacing threads, this material uses a series of loops that prevent the fabric from fraying when cut.

You will find that the gauge of the machine and the denier of the yarn directly influence the fabric’s weight and hand-feel. This unique construction allows the material to maintain significant tensile strength despite its airy and transparent appearance.

How does the mesh structure affect your design?

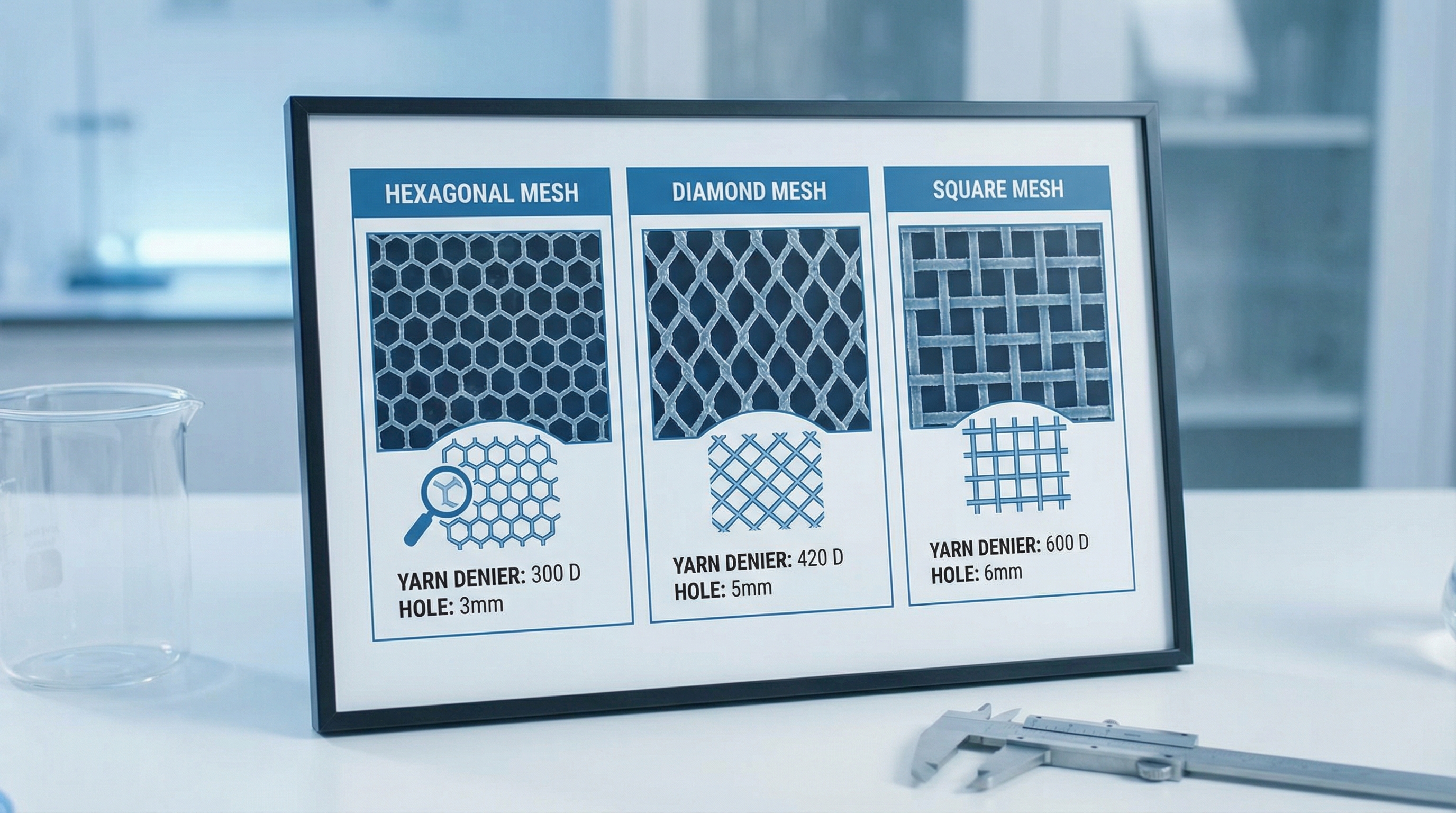

The geometry of the holes determines how the fabric catches the light and interacts with other layers. Hexagonal structures are traditional for bridal wear, while diamond meshes are often preferred for their mechanical stretch in apparel.

Think about it.

- Hexagonal Mesh: Best for traditional volume and light diffusion.

- Diamond Mesh: Offers superior flexibility and drape.

- Square Mesh: Typically reserved for industrial or utility applications.

Key Takeaway: Choosing the correct hole geometry is the first step in ensuring your garment achieves the intended silhouette and movement.

| Mesh Structure | Common Application | Visual Profile | |

|---|---|---|---|

| Hexagonal | Bridal Veils | Soft & Traditional | |

| Diamond | Fashion Overlays | Modern & Sleek | |

| Fine Gauge | Illusion Details | Near-Invisible |

This comparison identifies how specific hole geometries dictate the final aesthetic and functional performance of the textile.

What fabric is tulle when made from silk?

When crafted from silk, what fabric is tulle becomes the most luxurious and delicate version available, characterized by an exceptionally soft drape and high breathability. Silk variants are the gold standard for couture houses due to their weightless quality and sophisticated matte finish.

You must handle these fabrics with extreme care as the natural protein fibers are far more fragile than their synthetic counterparts. Despite its high price point, silk remains irreplaceable for designers who prioritize a fluid, cloud-like movement in their garments.

Is silk the right choice for your luxury collection?

Silk offers a tactile experience that synthetic fibers cannot replicate, making it ideal for high-end bridal veils and evening wear. It reacts beautifully to movement, creating a subtle, elegant shimmer rather than a plastic-like shine.

But here is the catch:

- Extreme Fragility: Silk snags easily on jewelry or rough surfaces.

- High Maintenance: Requires professional dry cleaning to maintain integrity.

- Premium Cost: Significantly higher investment compared to nylon.

Key Takeaway: Reserve silk for garments where weightlessness and a prestigious hand-feel are the primary design requirements.

| Property | Silk Tulle | Synthetic Tulle | |

|---|---|---|---|

| Hand-feel | Ultra-Soft | Ranges from Soft to Stiff | |

| Luster | Subtle Matte | Glossy to Semi-Matte | |

| Durability | Low | High |

Analyzing fiber properties helps you balance the need for luxury with the practicalities of garment longevity.

What fabric is tulle for high-volume bridal gowns?

For high-volume bridal gowns, what fabric is tulle serves as the foundational material used to build architectural layers and ethereal silhouettes without adding significant weight. Designers often stack twenty or more layers of fine mesh to create the iconic “cloud” effect seen in ballgowns.

Because it is so lightweight, you can achieve massive volume that remains comfortable for the wearer throughout a long event. The sheer nature of the material also allows for beautiful color play when different shades are layered together.

Why is layering essential for your bridal silhouettes?

Layering allows you to control the opacity and structural “bounce” of a skirt. By alternating between different mesh densities, you can create a garment that is stiff at the base and soft at the surface.

Let’s face it.

- Volume Control: More layers equal more dramatic “lift.”

- Color Depth: Layering shades creates multidimensional tones.

- Light Diffusion: Multiple layers soften the glow of the gown.

Key Takeaway: Mastering the art of layering different tulle weights is critical for achieving a professional bridal finish.

| Layer Type | Purpose | Result | |

|---|---|---|---|

| Inner Support | Structural Lift | Voluminous Shape | |

| Middle Layers | Color Blending | Depth & Opacity | |

| Outer Layer | Finishing | Soft Texture |

This layering strategy provides a roadmap for constructing complex, high-volume skirts that maintain their shape.

What fabric is tulle when used in sportswear?

In the context of performance apparel, what fabric is tulle refers to power mesh variants engineered with spandex for maximum stretch and recovery. These textiles are designed to provide targeted compression and ventilation in high-intensity gear.

You will find power mesh used in everything from leggings to sports bra inserts, where moisture-wicking and airflow are non-negotiable. The open-knit structure allows the skin to breathe while the elastic fibers ensure the garment moves with the athlete.

Can performance mesh enhance your activewear line?

The integration of performance-grade mesh adds both functional and aesthetic value to sportswear. It provides the necessary ventilation in “hot zones” like the back or underarms while maintaining a sleek, modern look.

You see where this is going.

- Four-Way Stretch: Essential for unrestricted athletic movement.

- High Recovery: Ensures the fabric doesn’t sag after repeated use.

- Moisture Management: Keeps the wearer dry during intense training.

Key Takeaway: Always specify the spandex percentage to ensure the mesh provides the correct level of compression for your specific sport.

| Performance Metric | Standard Netting | Power Mesh | |

|---|---|---|---|

| Elasticity | Low to None | High (4-Way) | |

| Recovery Rate | Poor | >90% | |

| Breathability | High | Exceptional |

Technical specifications confirm that power mesh is the superior choice for functional activewear applications.

What fabric is tulle for near-invisible necklines?

To create near-invisible necklines, what fabric is tulle is manufactured as “illusion net,” featuring an ultra-fine mesh that blends seamlessly with various skin tones. This specialized textile allows lace appliques and beadwork to appear as if they are floating directly on the body.

The key to a successful illusion detail is a matte finish and a thread count so fine that the camera cannot detect the mesh structure. You must source these materials from suppliers who offer a diverse range of nude palettes to accommodate all skin tones.

How do you select the correct illusion shade?

Choosing a shade that is too light or too dark will break the “floating” effect and make the garment look unfinished. It is vital to test samples against natural skin under various lighting conditions before bulk production.

It gets better.

- Matte Coating: Prevents the mesh from reflecting flash photography.

- Skin-Tone Matching: Essential for the “naked” dress aesthetic.

- Soft Edge: Prevents skin irritation on delicate neck areas.

Key Takeaway: The success of an illusion neckline depends entirely on the transparency and color accuracy of the mesh.

| Shade Category | Skin Tone Match | Visual Effect | |

|---|---|---|---|

| Porcelain | Fair/Cool | Seamless | |

| Honey | Medium/Warm | Invisible | |

| Mocha | Deep/Rich | Disappearing |

This selection guide ensures your illusion details remain undetected, providing a high-end couture finish.

What fabric is tulle for structural gown support?

For providing structural support in heavy ballgowns, what fabric is tulle is produced in a “stiff” or “hard” finish to resist collapsing under pressure. These variants are often treated with sizing agents or resins during the manufacturing process to lock the fibers in place.

You will typically use these stiff nets for petticoats, crinolines, and internal supports that are hidden from view. Without this structural foundation, heavy fabrics like satin or velvet would lose their dramatic shape within minutes of wear.

Does your project require stiff or soft netting?

Understanding when to use stiff versus soft netting is the difference between a gown that “pops” and one that falls flat. Soft tulle provides the aesthetic surface, while stiff tulle provides the engineering underneath.

The best part?

- Petticoat Base: Uses stiffest mesh for maximum lift.

- Sleeve Support: Prevents “puff” sleeves from sagging.

- Hem Reinforcement: Adds “kick” to the bottom of skirts.

Key Takeaway: Combine different stiffness levels to create a garment that is both architecturally sound and soft to the touch.

| Stiffness Level | Common Use | Material Finish | |

|---|---|---|---|

| Soft | Outer Layers | Untreated Nylon | |

| Medium | Everyday Tutus | Standard Resin | |

| Stiff | Bridal Petticoats | High-Resin Sizing |

Strategic use of various stiffness levels allows for the creation of complex silhouettes with lasting durability.

What fabric is tulle in industrial applications?

In industrial and outdoor sectors, what fabric is tulle is utilized for mosquito netting and utility screens due to its durability and airflow properties. These technical meshes are often treated with UV inhibitors and flame retardants to survive harsh environments.

You will find these materials in aerospace components, medical filters, and high-end camping equipment where weight savings are critical. The high burst strength of industrial-grade nylon makes it a reliable choice for long-term outdoor exposure.

Can utility mesh survive extreme outdoor conditions?

Outdoor utility mesh must withstand constant sun exposure and moisture without degrading. Manufacturers use high-denier polyester or nylon to ensure the mesh does not tear under tension from wind or impact.

Believe it or not.

- UV Resistance: Prevents the mesh from becoming brittle in the sun.

- Flame Retardancy: Essential for tent and indoor safety standards.

- Pest Protection: Fine mesh prevents even the smallest insects from entering.

Key Takeaway: Technical certifications are more important than hand-feel when sourcing mesh for industrial or outdoor use.

| Industry | Requirement | Treatment | |

|---|---|---|---|

| Camping | Lightweight | UV Resistant | |

| Medical | Biocompatible | Sterile Finish | |

| Safety | High-Visibility | Fluorescent Dye |

Technical data sheets should be the primary evaluation tool for any industrial mesh procurement.

What fabric is tulle for professional designers?

Professional designers recognize what fabric is tulle as a versatile medium that allows for intricate draping and complex surface embellishments. Its ability to hold shape while remaining transparent makes it a favorite for “mood board” prototyping and final garment construction.

You can use the material to “sculpt” with fabric, creating 3D textures like ruffles, rosettes, and pleated overlays. Because it does not fray, you are free to experiment with raw-edge designs that would be impossible with traditional woven textiles.

How do you optimize your draping process?

The secret to professional draping is choosing the right weight for the specific silhouette you want to achieve. Lightweight mesh flows with the body, while heavier gauges allow for more rigid, gravity-defying shapes.

Simply put.

- Raw Edges: Save time by skipping the hemming process.

- Volume Sculpting: Pin and pleat to create custom textures.

- Overlay Play: Add a sheer layer over solid fabrics for depth.

Key Takeaway: Use tulle as a design tool to add dimension and complexity to otherwise simple garments.

| Design Technique | Mesh Requirement | Visual Result | |

|---|---|---|---|

| Pleating | Medium Stiffness | Sharp Ridges | |

| Gathering | Soft Mesh | Cloud-Like Folds | |

| 3D Appliques | Stiff Netting | Architectural Detail |

Understanding these design techniques helps you translate creative visions into tangible, high-quality prototypes.

What fabric is tulle during quality inspection?

During the factory quality inspection process, what fabric is tulle is tested for color consistency, tensile strength, and uniformity across the entire roll. Inspectors look for “slubs” or irregular holes that could compromise the fabric’s appearance in a sheer garment.

You must ensure your supplier uses computerized monitoring to detect defects in real-time on the warp-knitting machines. Consistent quality is especially critical for large-scale production where multiple rolls must match perfectly in color and texture.

Why is roll-to-roll consistency critical for you?

Inconsistent dye lots or varying mesh densities can cause panels of the same dress to look different under stage or studio lighting. This can lead to expensive re-cuts and production delays that hurt your bottom line.

Think about the impact.

- Color Matching: Essential for multi-panel garments.

- Density Uniformity: Ensures the “sheerness” is consistent.

- Hole Integrity: Prevents “runs” or tears during sewing.

Key Takeaway: Only work with manufacturers who provide certified quality control reports for every batch.

| Inspection Point | Standard | Consequence of Failure | |

|---|---|---|---|

| Dye Lot | Delta E < 1.0 | Mismatched Panels | |

| Mesh Gauge | Exact Count | Uneven Drape | |

| Surface Flaws | Zero Slubs | Visible Defects |

Strict quality control protocols are the only way to guarantee that your materials meet professional standards.

What fabric is tulle for sustainable fashion?

For designers focused on sustainable fashion, what fabric is tulle is increasingly available in recycled polyester and GRS-certified variants. These eco-friendly options allow you to maintain the aesthetic benefits of sheer mesh while reducing your environmental footprint.

You can now source textiles made from post-consumer plastic waste that perform identically to virgin polyester. This shift towards circularity is becoming a requirement for brands looking to capture the growing market of conscious consumers.

Can eco-friendly mesh meet your quality standards?

Modern recycling technology has advanced to the point where the differences between recycled and virgin fibers are virtually undetectable. Recycled mesh maintains the same strength, colorfastness, and hand-feel you expect from premium textiles.

Here is the truth.

- Identical Performance: No sacrifice in drape or durability.

- Certification Matters: Look for GRS or OEKO-TEX labels.

- Market Appeal: Adds a compelling “green” story to your brand.

Key Takeaway: Switching to recycled tulle is an easy way to improve your brand’s sustainability without compromising design quality.

| Fiber Source | Environmental Impact | Performance Level | |

|---|---|---|---|

| Virgin Polyester | High Carbon | Standard | |

| Recycled (rPET) | Low Carbon | High-Performance | |

| Organic Cotton | Minimal | Soft/Natural |

Sustainable sourcing proves that high fashion can be both beautiful and environmentally responsible.

Selecting the right textile is a strategic decision that directly impacts the cost, performance, and aesthetic of your final product. By mastering the differences between silk, nylon, and performance meshes, you can solve common production hurdles and protect your margins. We are dedicated to providing the technical expertise and factory-direct sourcing you need to elevate your brand. If you have specific technical questions or require custom development, please contact us today for a consultation.

Frequently Asked Questions

Can I wash tulle in a standard washing machine?While synthetic variants are durable, the delicate mesh can easily snag on zippers or the machine’s agitator; you should always use a protective laundry bag and a cold, delicate cycle to prevent tearing.

What’s the best way to remove wrinkles from tulle layers?Direct ironing will likely melt the synthetic fibers; instead, use a handheld garment steamer or hang the item in a steamy bathroom to gently release creases without damaging the mesh.

How do I know if I need stiff or soft tulle?You should evaluate the desired silhouette; if you need dramatic “lift” for a petticoat, specify a stiff resin-treated mesh, whereas if you want a flowing, ethereal overlay, choose a soft nylon or silk variant.

Can I leave the edges of my tulle project raw?Yes, because it is a warp-knitted material rather than a woven one, it does not fray when cut; this allows you to create lightweight, clean edges without the bulk of a traditional hem.

Can I dye synthetic tulle at home?Nylon takes acid dyes very well, but polyester requires high-temperature disperse dyes; therefore, it is much more efficient to source custom-colored rolls directly from the factory for bulk needs.