Glitter fabrics are specialized decorative textiles designed with reflective particles bonded to a base material to produce a shimmering visual effect. Many designers struggle with low-grade materials that shed glitter excessively, ruining the garment’s longevity and the wearer’s experience. This shedding not only diminishes the aesthetic over time but can also lead to significant returns and brand dissatisfaction in the luxury market. By sourcing high-quality glitter tulle fabric , professionals can achieve a permanent, high-impact sparkle that remains intact through production and wear.

Why choose glitter tulle fabric for luxury designs?

Glitter tulle fabric provides an unmatched combination of lightweight structure and intense luminosity for high-end fashion. This material allows designers to create voluminous shapes that appear to glow from within.

What makes the shimmer unique?

The shimmer in these fabrics comes from micro-cut particles that catch light from every angle. This creates a multidimensional depth that flat fabrics cannot replicate.

Think about it:

- Reflective particles are often diamond-cut for maximum refraction.

- The mesh base allows light to pass through, enhancing the glow.

- Modern bonding agents ensure the glitter remains soft to the touch.

How does it impact garment drape?

Unlike heavy beaded fabrics, this material maintains the airy, fluid movement essential for evening gowns. It adds visual weight without physical burden.

The best part?

- It supports structured silhouettes like ball gowns.

- The fabric remains breathable despite the glitter application.

- Layering multiple colors creates a custom holographic effect.

Key Takeaway: Choosing this fabric ensures your luxury designs remain lightweight while delivering maximum visual impact for the runway.

| Feature | Performance | Benefit | |

|---|---|---|---|

| Weight | Ultra-light | High Comfort | |

| Brilliance | High Refraction | Luxury Aesthetic | |

| Flexibility | High | Versatile Design |

Explore the technical nuances of how light interaction defines the value of your textile selection.

How do you source wholesale glitter tulle fabric?

Sourcing glitter tulle fabric at a B2B level requires identifying suppliers who utilize heat-pressed bonding for superior durability. Quality control is paramount when purchasing in bulk to ensure consistency across bolts.

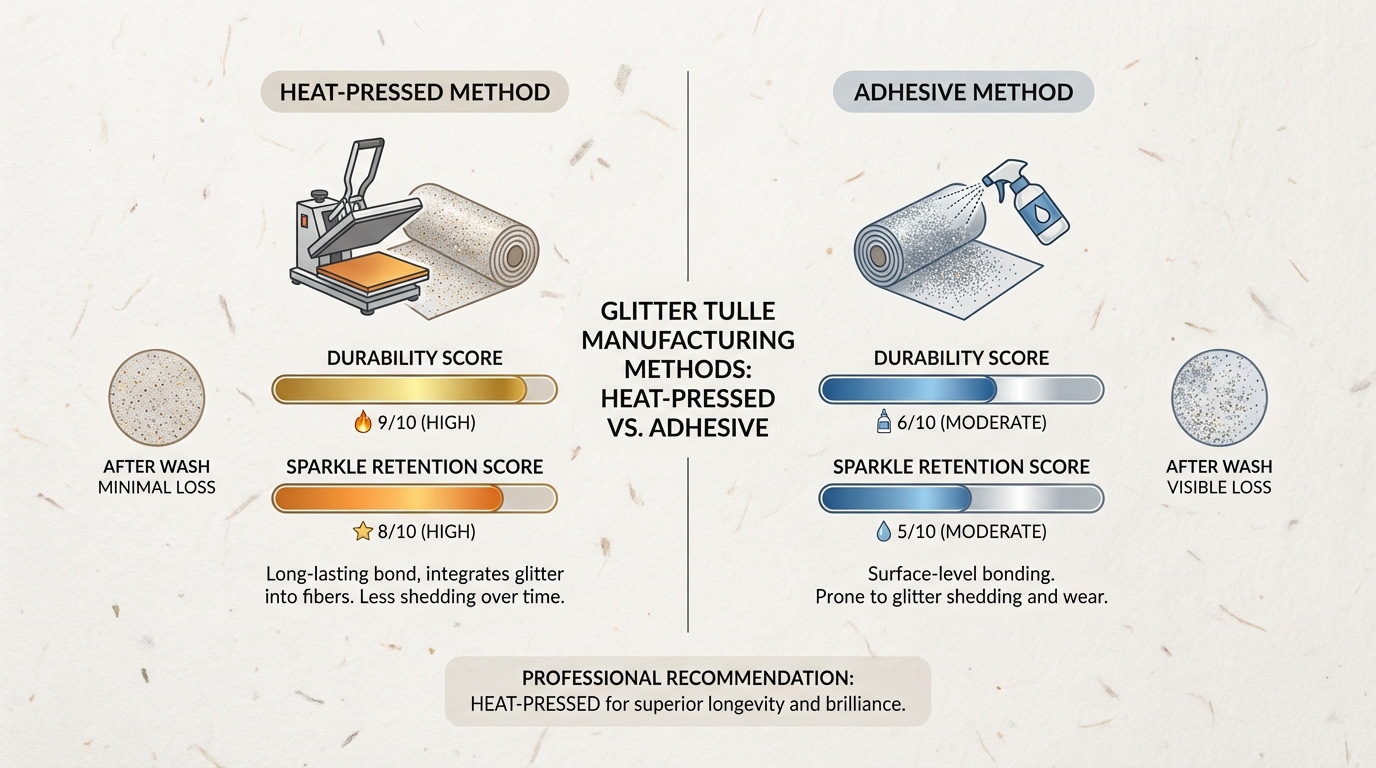

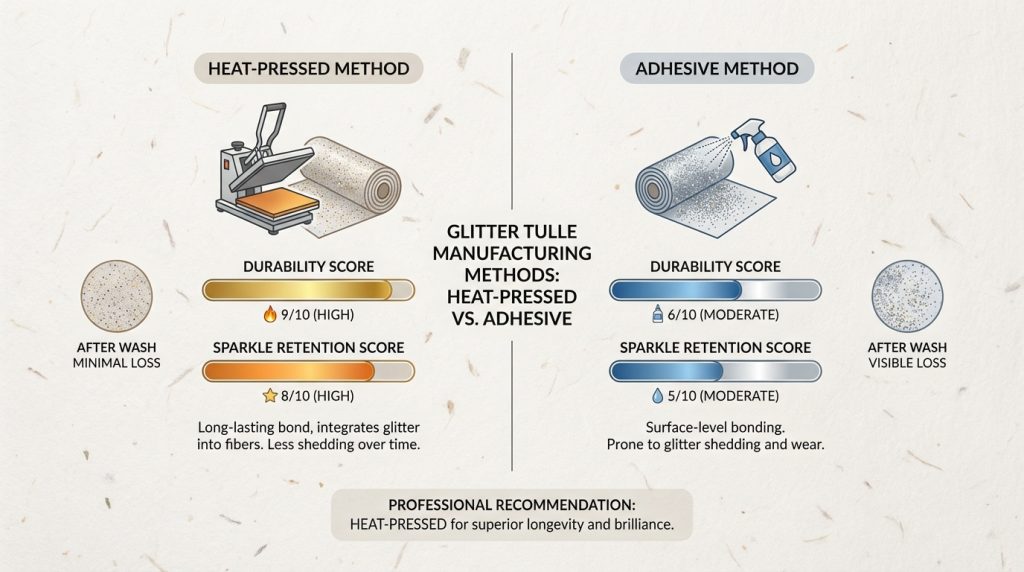

What are the primary production methods?

Most manufacturers use either adhesive sprays or heat-transfer films to apply glitter to the mesh. Heat-pressed methods are generally superior for long-term sparkle retention.

Here is the kicker:

- Adhesive sprays are cheaper but prone to high shedding rates.

- Heat-pressing integrates the glitter deeper into the polyester fibers.

- Solvent-free bonds are safer for skin contact and environmental standards.

Why is bulk quality control necessary?

In wholesale procurement, variations in glitter density can occur between different production batches. Inspecting samples from each lot prevents color mismatches in large-scale manufacturing.

Let’s be honest:

- Minor shifts in dye lots can alter the glitter’s undertone.

- Edge-to-edge glitter coverage must be verified for wide-width rolls.

- Tension testing ensures the mesh won’t tear under the weight of the finish.

Key Takeaway: Prioritize heat-pressed manufacturing to minimize product returns and ensure a consistent professional finish across your entire inventory.

| Criteria | Adhesive Method | Heat-Pressed | |

|---|---|---|---|

| Shedding | High | Minimal | |

| Cost | Lower | Premium | |

| Durability | Moderate | Exceptional |

Review the manufacturing process to understand the long-term ROI of premium fabric investments.

Is glitter tulle fabric better than sequin alternatives?

Glitter tulle fabric offers a more seamless and subtle radiance compared to the heavy, textured appearance of sequined textiles. It is often the preferred choice for ethereal or romantic aesthetics.

Which offers better weight distribution?

Glitter particles are significantly lighter than plastic or metal sequins, making the fabric easier to wear for long periods. This weight reduction is crucial for intricate bridal designs.

Believe it or not:

- Glitter provides a “dusting” of light rather than a “shield” of shine.

- It prevents the garment from sagging under its own weight.

- Designers can use more yardage without compromising the wearer’s mobility.

How do material costs compare?

While high-quality glitter tulle is premium, it is often more cost-effective than hand-stitched or densely embroidered sequin fabrics. This allows for larger profit margins on finished pieces.

The bottom line:

- Production time is reduced since there is no need for beadwork alignment.

- Cutting and sewing are faster than working around individual sequins.

- Waste is minimized because the shine is uniform across the entire surface.

Key Takeaway: Use glitter-based mesh to achieve a high-end look with less physical weight and more efficient production costs.

| Metric | Sequined Fabric | Glitter Tulle | |

|---|---|---|---|

| Hand-feel | Textured/Scratchy | Smooth/Soft | |

| Production Speed | Slow | Fast | |

| Visual Style | Bold/Graphic | Ethereal/Glow |

Compare the tactile differences to determine which material suits your brand’s specific design language.

Can you order custom glitter tulle fabric designs?

Professional designers can commission custom glitter tulle fabric with specific patterns, such as ombré gradients or branded motifs. Customization allows for exclusive collections that stand out in the competitive bridal market.

What customization options exist?

You can adjust the density of the glitter, the base mesh color, and even the size of the glitter flakes. This level of detail ensures the fabric aligns perfectly with your vision.

Picture this:

- Custom motifs like stars or florals can be screen-printed in glitter.

- Gradient transitions provide a modern, high-fashion aesthetic.

- Specific hex colors for the base mesh can be dyed to match.

What are the typical lead times?

Custom production usually requires 4 to 8 weeks depending on the complexity of the design and the volume ordered. Planning ahead is essential for seasonal collection launches.

It gets better:

- Early prototypes allow for testing the bond strength before full production.

- Many suppliers offer lower minimum order quantities for custom mesh.

- Digital proofing helps narrow down the sparkle intensity quickly.

Key Takeaway: Customization transforms a standard textile into a proprietary asset that defines your brand’s unique signature style.

| Customization | Complexity | Production Time | |

|---|---|---|---|

| Color Dyeing | Low | 2-3 Weeks | |

| Pattern Printing | Medium | 4-6 Weeks | |

| Density Adjustment | Low | 3-4 Weeks |

Analyze your production calendar to integrate custom textile lead times into your design cycle.

How does glitter tulle fabric perform in bridal wear?

Glitter tulle fabric is a staple in the bridal industry, providing the “starry night” effect that modern brides increasingly demand. It works beautifully as an overlay or an inner layer for subtle luminosity.

Why is layered application effective?

Placing glitter mesh beneath a plain layer of silk organza creates a sophisticated “shimmer-from-within” look. This technique prevents the glitter from snagging on other fabrics.

Why does this matter?

- It creates a soft-focus effect in professional wedding photography.

- Layers add volume without the need for heavy crinolines.

- It protects the skin from potential irritation from the glitter particles.

Does it photograph well in natural light?

High-quality glitter is designed to reflect light without causing “hot spots” or lens flare in photos. It maintains its brilliance even in low-light reception settings.

The kicker:

- It enhances the movement of the skirt during the first dance.

- Natural sunlight brings out the rainbow-like diffraction of the particles.

- It looks equally stunning in both high-definition video and print.

Key Takeaway: In bridal contexts, this fabric acts as a versatile light-catcher that enhances the emotional impact of the gown.

| Application | Visual Result | Photography Tip | |

|---|---|---|---|

| Outer Overlay | Maximum Sparkle | Use soft diffusers | |

| Under-layer | Subtle Glow | Best in direct sun | |

| Veil Edging | Delicate Detail | Focus on the hem |

Evaluate how light sources in different venues will interact with the density of your fabric layers.

Where can you get glitter tulle fabric samples?

Acquiring glitter tulle fabric samples is a critical step in the procurement process to verify the “shake test” results. Samples allow you to evaluate the stiffness of the mesh and the true color under your studio lighting.

Why is the “shake test” important?

The shake test involves vigorously moving a sample to see how many particles fall off. A high-quality mesh should lose almost zero glitter during this process.

Think about it:

- Excessive shedding indicates a poor bonding agent or cheap adhesive.

- High loss rates will cause the fabric to look patchy after sewing.

- Clean samples lead to cleaner workrooms and happier end-users.

How many color swatches should you review?

You should always request a full color card because glitter can drastically change the appearance of the underlying mesh color. Champagne, silver, and iridescent are the most popular B2B choices.

Surprisingly:

- Gold glitter on white mesh looks different than gold on ivory mesh.

- Iridescent glitter can look pink or blue depending on the angle.

- Seeing the physical swatch prevents expensive ordering errors.

Key Takeaway: Physical samples are the only way to guarantee that the tactile and visual quality meets your luxury standards.

| Sample Type | Purpose | Recommendation | |

|---|---|---|---|

| Swatch Header | Color matching | Order for every project | |

| Yardage Sample | Drape testing | Use for prototyping | |

| Color Card | Inventory planning | Keep for reference |

Utilize physical swatches to eliminate guesswork and ensure your final product matches your digital designs.

What are the best uses for gold glitter tulle fabric?

Gold glitter tulle fabric is synonymous with opulence and is frequently used for holiday collections and gala event decor. Its warmth complements a wide range of skin tones and interior palettes.

How do you style large decor bows?

The inherent stiffness of the tulle mesh allows for large, architectural bows that hold their shape without wilting. These are perfect for grand entrances or chair accents.

Let’s be honest:

- Ribbon often lacks the volume that wide-width tulle provides.

- The glitter adds a festive touch that standard mesh lacks.

- It is durable enough to be used in outdoor event settings.

Is it suitable for table runners?

When used as a table runner, it adds a layer of texture and light to the event landscape. However, it should be layered over a solid cloth to prevent snagging on silverware.

The best part?

- It is inexpensive enough for high-volume event production.

- It catches the candlelight beautifully during evening receptions.

- You can easily cut it into custom widths without the edges fraying.

Key Takeaway: Gold variants offer a classic, high-value aesthetic that appeals to the most profitable sectors of the event industry.

| Use Case | Durability Requirement | Styling Tip | |

|---|---|---|---|

| Floral Accents | Low | Use as a wrap | |

| Structural Bows | High | Double-layer for stiffness | |

| Ceiling Draping | Medium | Use 108″ widths |

Assess the scale of your event to determine the total yardage needed for high-impact gold accents.

What is the proper care for glitter tulle fabric?

Maintaining glitter tulle fabric requires a “low-intervention” approach to preserve the delicate bond between the glitter and the mesh. Industrial laundering is generally avoided in favor of specialized gentle techniques.

Can you machine wash this material?

Machine washing is highly discouraged as the agitation can strip the glitter and damage the fine mesh. Hand washing in cool water is the industry-standard recommendation.

Here is the kicker:

- High heat in a dryer will melt the bonding agents.

- Detergents with harsh chemicals can dull the glitter’s finish.

- Air drying is mandatory to maintain the fabric’s structural integrity.

How should you store finished pieces?

Garments should be stored in breathable garment bags, ideally hanging rather than folded. This prevents permanent creases in the mesh and keeps the glitter from rubbing off.

Believe it or not:

- Plastic covers can trap moisture, which weakens the adhesive.

- Acid-free tissue paper should be used between folds if hanging isn’t possible.

- Storing pieces inside out protects the outer glitter layer from abrasion.

Key Takeaway: Educating your clients on proper care will extend the life of the garment and protect your reputation for quality.

| Care Step | Action | Why? | |

|---|---|---|---|

| Cleaning | Cool hand wash | Protects the bond | |

| Drying | Drip dry only | Prevents melting | |

| Pressing | Low steam | Avoids mesh distortion |

Develop a clear care label strategy to ensure your customers handle these delicate textiles with professional expertise.

How do you cut glitter tulle fabric without fraying?

Cutting glitter tulle fabric requires high-precision tools like rotary cutters to ensure a clean, professional edge. Because it is a knit mesh, it won’t fray like woven fabrics, but the glitter can create significant debris.

Is a rotary cutter better than scissors?

A rotary cutter provides a continuous, smooth slice that prevents the “jagged” look often caused by the opening and closing of scissors. This is especially important for long veil edges.

The bottom line:

- It allows for cutting through multiple layers with perfect alignment.

- A fresh blade slices through the glitter particles without dulling.

- It minimizes the amount of “glitter dust” released during the cut.

How do you manage the glitter mess?

Working on a self-healing mat makes it easier to sweep away the inevitable glitter fallout. Some professionals use a lint roller periodically during the cutting process.

Picture this:

- Static electricity can make glitter stick to everything in your shop.

- Using a dedicated “sparkle station” prevents cross-contamination of fabrics.

- Vacuuming the cutting area immediately after use is a best practice.

Key Takeaway: Precision cutting tools and a dedicated workspace are essential for maintaining a clean, high-efficiency production environment.

| Tool | Benefit | Best For | |

|---|---|---|---|

| Rotary Cutter | Cleanest edge | Straight lines/veils | |

| Micro-tip Scissors | High control | Appliques/Curves | |

| Weights | No pinning | Preserving mesh |

Optimize your cutting room setup to handle high-volume glitter production without sacrificing shop cleanliness.

Who provides the best glitter tulle fabric?

Identifying a top-tier provider of glitter tulle fabric means finding a partner that understands the specific needs of B2B manufacturing. Reliability in shipping and transparency in sourcing are the hallmarks of a great textile partner.

What defines a quality B2B partner?

A quality partner offers consistent stock levels, tiered wholesale pricing, and expert technical support for their products. They should act as an extension of your production team.

It gets better:

- Direct-to-factory relationships ensure the lowest possible pricing.

- Expert staff can recommend specific mesh weights for different designs.

- Fast shipping prevents bottlenecks in your manufacturing schedule.

Why does sourcing transparency matter?

Knowing where and how your fabric is made ensures that you are meeting ethical and safety standards. This is increasingly important for modern consumers who value sustainable practices.

The kicker:

- Transparent suppliers provide MSDS sheets for bonding agents.

- You can verify that the glitter is free from harmful heavy metals.

- Consistent sourcing leads to predictable results in every collection.

Key Takeaway: A strong relationship with a transparent supplier is the foundation of a successful, scalable fashion brand.

| Supplier Quality | Impact on Business | Priority | |

|---|---|---|---|

| Stock Stability | No production delays | High | |

| Technical Support | Reduced R&D time | Medium | |

| Tiered Pricing | Better profit margins | High |

Select a partner that offers both the technical specifications and the logistical reliability your business requires.

Conclusion

You have seen how the right choice in glitter fabrics can transform a standard design into a luxury masterpiece. By addressing the common pitfalls of shedding and weight through premium material selection, you protect your brand’s integrity and satisfy the most discerning clients. Our vision is to empower designers with textiles that never compromise on brilliance or durability. To elevate your next collection with the industry’s most resilient shimmer, contact us today for expert guidance and wholesale sourcing.

FAQ

Can I iron glitter tulle fabric?No, you should never use a direct hot iron on this material. The heat will melt the polyester mesh and the glitter’s adhesive bond; instead, use a handheld steamer from a safe distance of at least six inches.

How do I sew glitter tulle without breaking needles?Use a size 70/10 or 80/12 universal needle and change it frequently. Glitter particles are abrasive and will dull your needle quickly, which can lead to skipped stitches or snags in the delicate mesh.

Can I use glitter tulle for children’s clothing?Yes, but only if the glitter is high-quality and heat-pressed to prevent shedding. Ensure the fabric has been tested for skin safety and that the glitter particles are not sharp, as children’s skin is more sensitive to texture.

How do I prevent glitter from getting everywhere in my studio?Designate a specific area for cutting and sewing glitter fabrics and use a static-reducing spray on your work surfaces. Keep a high-quality vacuum and lint rollers nearby to clean the station immediately after each production session.

Can I dye glitter tulle fabric after it has been treated?No, it is highly recommended to buy the mesh in the desired color rather than attempting to dye it afterward. The dyeing process involves high heat and chemicals that will likely strip the glitter or ruin the reflective finish.