Tulle fabric is a fine, lightweight netting with a hexagonal mesh structure commonly used in fashion, upholstery, and industrial applications. Finding the right balance between structural rigidity and delicate aesthetics often frustrates high-volume manufacturers who require consistency. Low-quality mesh can tear during high-speed production, leading to wasted materials and increased overhead costs for your business. Implementing premium polyester tulle fabric ensures consistent durability and a professional finish for any commercial or creative project.

What exactly is the origin of polyester tulle fabric?

The origin of this material traces back to the French town of Tulle, where lace-makers first developed the signature hexagonal weave in the 18th century. Modern polyester tulle fabric evolved as a synthetic alternative to delicate silk to provide better mechanical strength and affordability for mass production. This transition allowed the textile to move from exclusive royal garments to versatile industrial and decorative uses.

The Evolution of Synthetic Warp-Knitting

The reality is: The shift from handmade lace to machine-made mesh revolutionized the textile industry. Modern machines now produce thousands of meters of consistent netting that remains true to the original French design.

- Hexagonal Weave: The classic geometry that prevents unraveling.

- Synthetic Fibers: Polyester offers superior tensile strength compared to silk.

- Warp-Knitting: The specialized process used to create a stable, non-fraying edge.

Key TakeawayPolyester variants maintain the historical aesthetic of traditional tulle while offering the durability required for modern manufacturing.

| Feature | Historical Silk Tulle | Modern Polyester Tulle | |

|---|---|---|---|

| Production | Handmade / Slow | Machine-made / Fast | |

| Durability | Fragile | High Strength | |

| Cost | Premium Luxury | Cost-Effective |

The technological leap from natural to synthetic fibers has enabled the widespread adoption of tulle in diverse global markets.

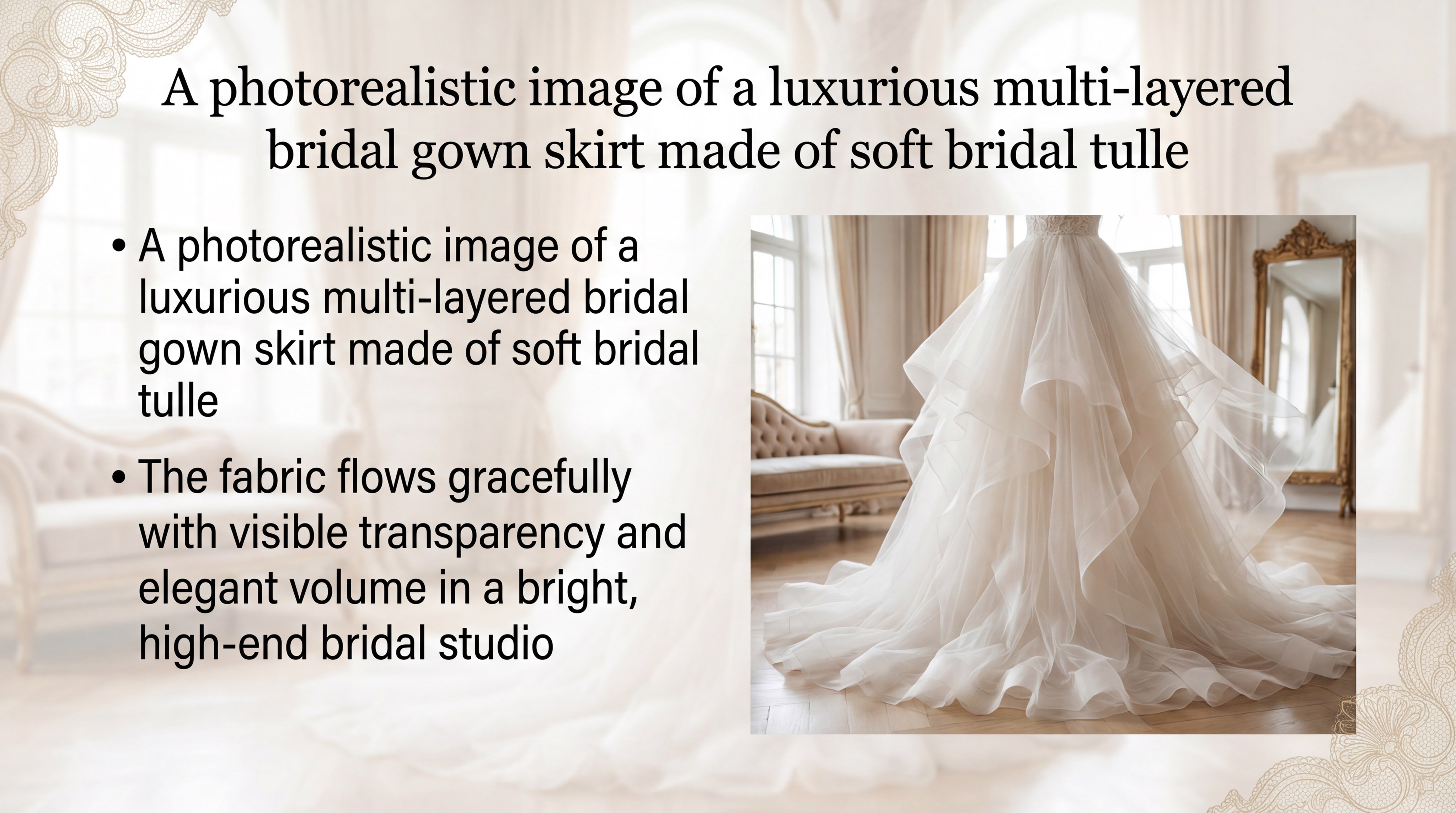

Why is polyester tulle fabric essential for bridal fashion?

Bridal designers rely on this textile for its unique ability to create ethereal volume and structured layers without adding significant weight to a garment. Incorporating polyester tulle fabric allows for the construction of dramatic ball gown skirts and delicate veils that maintain their shape throughout an entire wedding event. Its sheer nature provides a romantic aesthetic that remains a staple of high-end couture.

Secret to Elegant Wedding Veils

Here is the kicker: Weightless volume is the primary goal for every bridal designer seeking a “floating” effect. Without the structural integrity of synthetic mesh, large veils would collapse and lose their visual impact.

- Soft Finish: Provides a gentle drape against the skin.

- Illusion Necklines: Creates the appearance of floating lace or embroidery.

- Layering: Adds depth and opacity to skirts without heavy lining.

Key TakeawayThe versatility of synthetic mesh makes it the foundational material for creating both structural volume and delicate bridal accessories.

| Application | Tulle Type Preferred | Benefit | |

|---|---|---|---|

| Wedding Veils | Ultra-Soft Mesh | Elegant drape and clarity | |

| Gown Volumizing | Medium-Stiff Tulle | Holds shape under heavy lace | |

| Illusion Panels | Skin-Tone Fine Tulle | Discreet support for crystals |

Synthetic fibers provide the consistent tension needed for the intricate embroidery often found on premium bridal gowns.

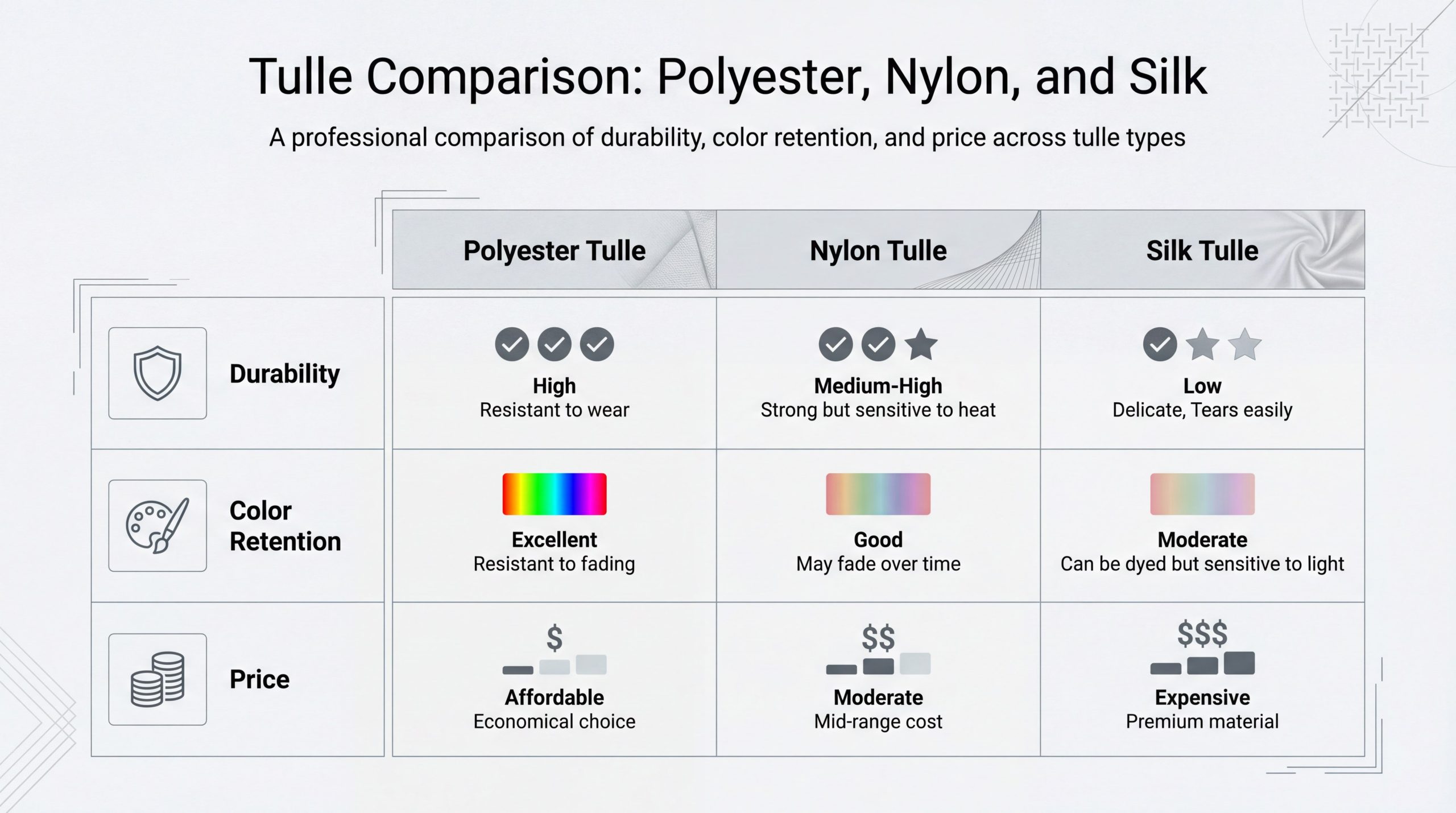

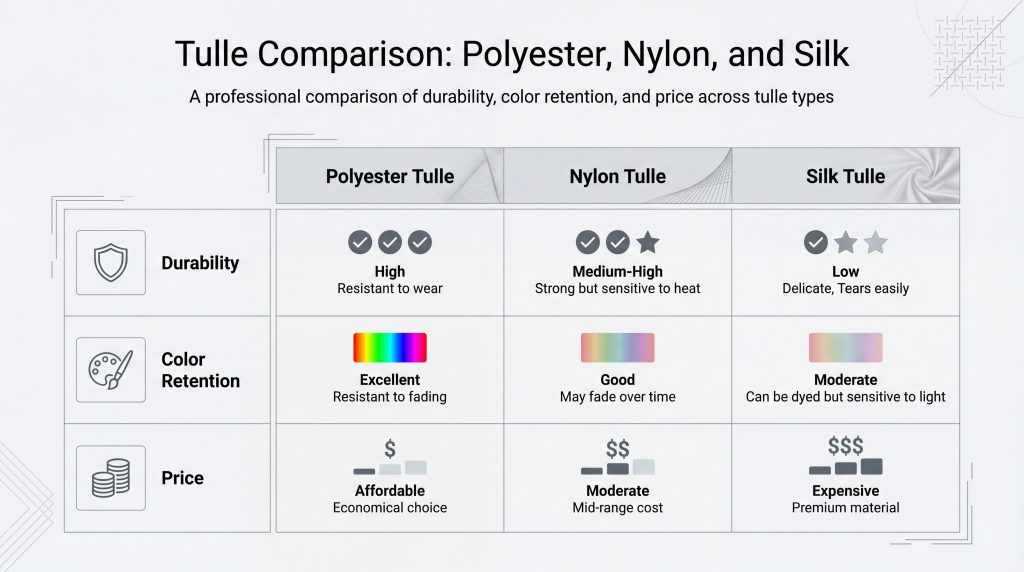

How does polyester tulle fabric compare to nylon tulle?

Polyester variants outperform nylon in heat resistance and colorfastness, making them the preferred choice for industrial-scale garment dyeing. While both are synthetics, polyester tulle fabric offers a crisp hand-feel that is more resilient to environmental humidity and UV exposure. This makes it a superior choice for products that require long-term color stability.

Choosing for Long-Term Vibrancy

But here is the truth: Nylon may feel slightly softer, but it suffers from yellowing and fiber degradation when exposed to sunlight over time. For B2B buyers, the longevity of polyester ensures fewer returns and higher customer satisfaction.

- UV Resistance: Polyester maintains its integrity in outdoor settings.

- Dye Absorption: Colors remain vibrant even after multiple washes.

- Moisture Management: Polyester does not absorb water, preventing sagging.

Key TakeawayPolyester is the more robust choice for manufacturers prioritizing durability and color consistency over extreme softness.

| Characteristic | Polyester Mesh | Nylon Mesh | |

|---|---|---|---|

| Heat Tolerance | High (Iron-safe) | Low (Melts easily) | |

| Longevity | Excellent | Moderate | |

| Feel | Crisp / Structural | Soft / Pliable |

Investing in polyester-based textiles reduces the risk of fabric warping during the post-production steaming process.

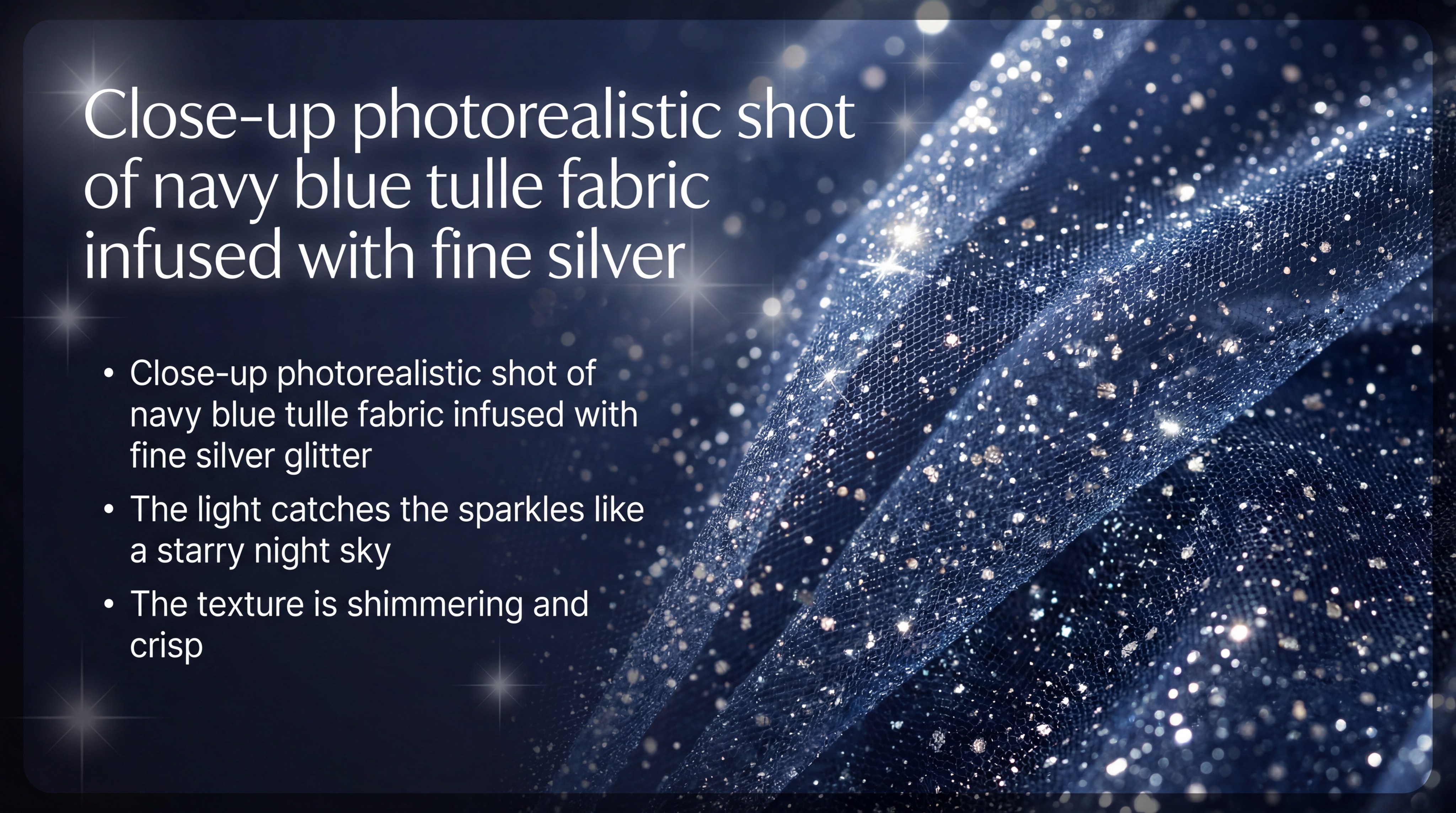

Can you achieve a sparkling look with polyester tulle fabric?

Yes, the surface of synthetic mesh is ideal for bonding fine glitters and metallic foils to create high-impact evening wear. Utilizing polyester tulle fabric with a non-shedding finish ensures that the sparkle remains on the textile rather than transferring to other surfaces during handling. This is particularly vital for dancewear and theatrical costumes that undergo rigorous movement.

The Benefit of Non-Shedding Finishes

Look: Not all glittered fabrics are created equal, and shedding is a major quality concern for luxury retailers. High-quality bonding techniques ensure the metallic particles are embedded deeply into the hexagonal weave.

- Metallic Foils: Creates a liquid-like shine for modern designs.

- Fine Glitter: Offers a “starry night” effect for prom and gala dresses.

- Sequined Mesh: Adds weight and luxury to custom evening gowns.

Key TakeawayEnhanced polyester mesh provides a reliable substrate for decorative finishes that demand high durability and visual appeal.

| Finish Type | Best Use Case | Visual Effect | |

|---|---|---|---|

| Fine Glitter | Party Decor / Veils | Subtle Shimmer | |

| Metallic Foil | High-Fashion Skirts | Bold Reflection | |

| Beaded Tulle | Couture Gowns | Luxury Texture |

Advanced bonding agents have solved the historical problem of glitter fallout in synthetic textile manufacturing.

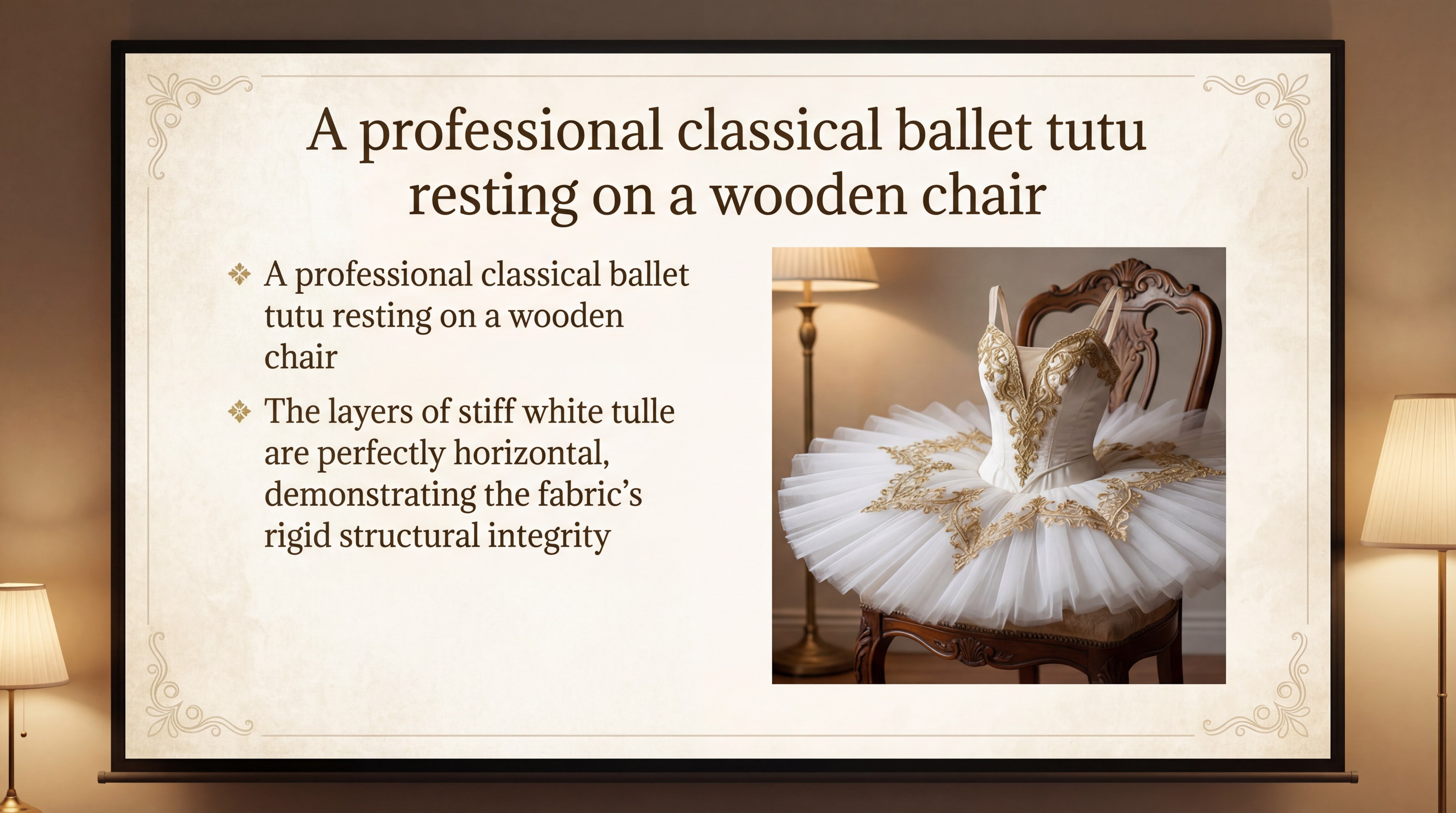

Is stiff polyester tulle fabric the best choice for tutus?

Stiff, high-denier mesh is the industry standard for classical ballet tutus because it provides the necessary horizontal support for the skirt. Manufacturers choose polyester tulle fabric specifically when they need a fabric that will not droop under its own weight or the weight of embellishments. This structural integrity is achieved through specialized chemical sizing treatments applied during the finishing stage.

Engineering Dance Costume Integrity

The bottom line is: A tutu that loses its “pancake” shape fails to meet professional performance standards. Stiffness is a technical requirement, not just an aesthetic choice, for classical dance apparel.

- Denier Count: Higher denier equals greater support and rigidity.

- Layering Potential: Multiple stiff layers create a self-supporting structure.

- Resilience: The fabric springs back to its original shape after compression.

Key TakeawayStiff polyester mesh is indispensable for performance-grade costumes that require permanent structural volume.

| Rigidity Level | Ideal Project | Structural Goal | |

|---|---|---|---|

| Extra Stiff | Classical Tutus | 90-degree horizontal projection | |

| Medium Stiff | Petticoats | Skirt “poof” and flare | |

| Soft | Overlays | Movement and flow |

Chemical sizing allows manufacturers to customize the level of stiffness to meet specific design requirements.

What are the industrial uses of polyester tulle fabric?

Beyond the fashion runway, this material is widely used in the manufacturing of luggage pockets, footwear ventilation panels, and safety screens. The high tensile strength of polyester tulle fabric makes it a reliable component for products that endure frequent friction and mechanical stress. Its breathable nature also makes it ideal for sports equipment where airflow is a primary functional requirement.

Technical Mesh in Modern Equipment

It gets better: Industrial designers favor mesh because it offers high visibility and breathability without sacrificing the containment of small items. It is the perfect balance of transparency and toughness.

- Footwear: Used in running shoes for moisture management.

- Luggage: Internal dividers and external bottle pockets.

- Automotive: Seat backing and storage nets for cabin interiors.

Key TakeawayThe industrial application of tulle proves that its utility extends far beyond decorative or aesthetic purposes.

| Industrial Sector | Mesh Use | Key Performance Metric | |

|---|---|---|---|

| Outdoor Gear | Tent Ventilation | Airflow & Bug Protection | |

| Footwear | Upper Panels | Breathability | |

| Logistics | Cargo Netting | Tensile Strength |

Warp-knit technology ensures that even if one thread breaks, the industrial mesh will not continue to run or unravel.

Why is polyester tulle fabric preferred for event decorations?

Event planners prefer this material for its wrinkle resistance and ability to drape elegantly over large surfaces like tables and backdrops. Using polyester tulle fabric in bulk allows for cost-effective transformations of venue spaces while maintaining a high-end, sophisticated aesthetic. Its resistance to fading makes it particularly useful for outdoor summer events and garden ceremonies.

Transforming Spaces with Bulk Mesh

The reality is: Decorating a large ballroom or outdoor pavilion requires hundreds of yards of material. Polyester’s low cost-per-yard makes it the only viable option for high-volume event styling.

- Table Skirts: Creates a soft, romantic perimeter for reception tables.

- Ceiling Draping: Covers large spans of overhead space effortlessly.

- Floral Accents: Adds texture to wreaths and bouquets without wilting.

Key TakeawayThe economic and aesthetic benefits of polyester mesh make it the go-to textile for professional event coordinators worldwide.

| Event Element | Tulle Usage | Visual Impact | |

|---|---|---|---|

| Chair Sashes | Tied Bows | Softens hard seating edges | |

| Backdrops | Layered Panels | Hides unsightly wall features | |

| Aisle Runners | Side Swags | Defines the ceremonial path |

Outdoor durability ensures that decorative elements remain pristine even in humid or breezy conditions.

How does stretch impact the performance of polyester tulle fabric?

The addition of spandex or elastane fibers creates power mesh, which provides the compression and breathability required for modern athletic wear. High-quality polyester tulle fabric with stretch capabilities allows for moisture-wicking and air circulation, preventing heat buildup during physical activity. This makes it an essential component for activewear brands focused on performance and comfort.

Engineering Breathable Athletic Gear

Think about it: Heat management is the difference between a good workout and an uncomfortable one. Strategic mesh panels provide targeted cooling in high-sweat zones like the back and knees.

- Four-Way Stretch: Ensures the fabric moves with the body.

- Compression: Provides support for muscles during high-impact sports.

- Recovery: The mesh returns to its original shape after being stretched.

Key TakeawayStretch-enhanced polyester mesh combines the aesthetic of tulle with the functional requirements of high-intensity athletics.

| Feature | Standard Tulle | Power Stretch Mesh | |

|---|---|---|---|

| Elasticity | Minimal | High (Spandex Blend) | |

| Primary Use | Fashion / Decor | Sportswear / Lingerie | |

| Structure | Rigid | Compression |

The integration of stretch fibers has expanded the use of mesh into the competitive world of performance apparel.

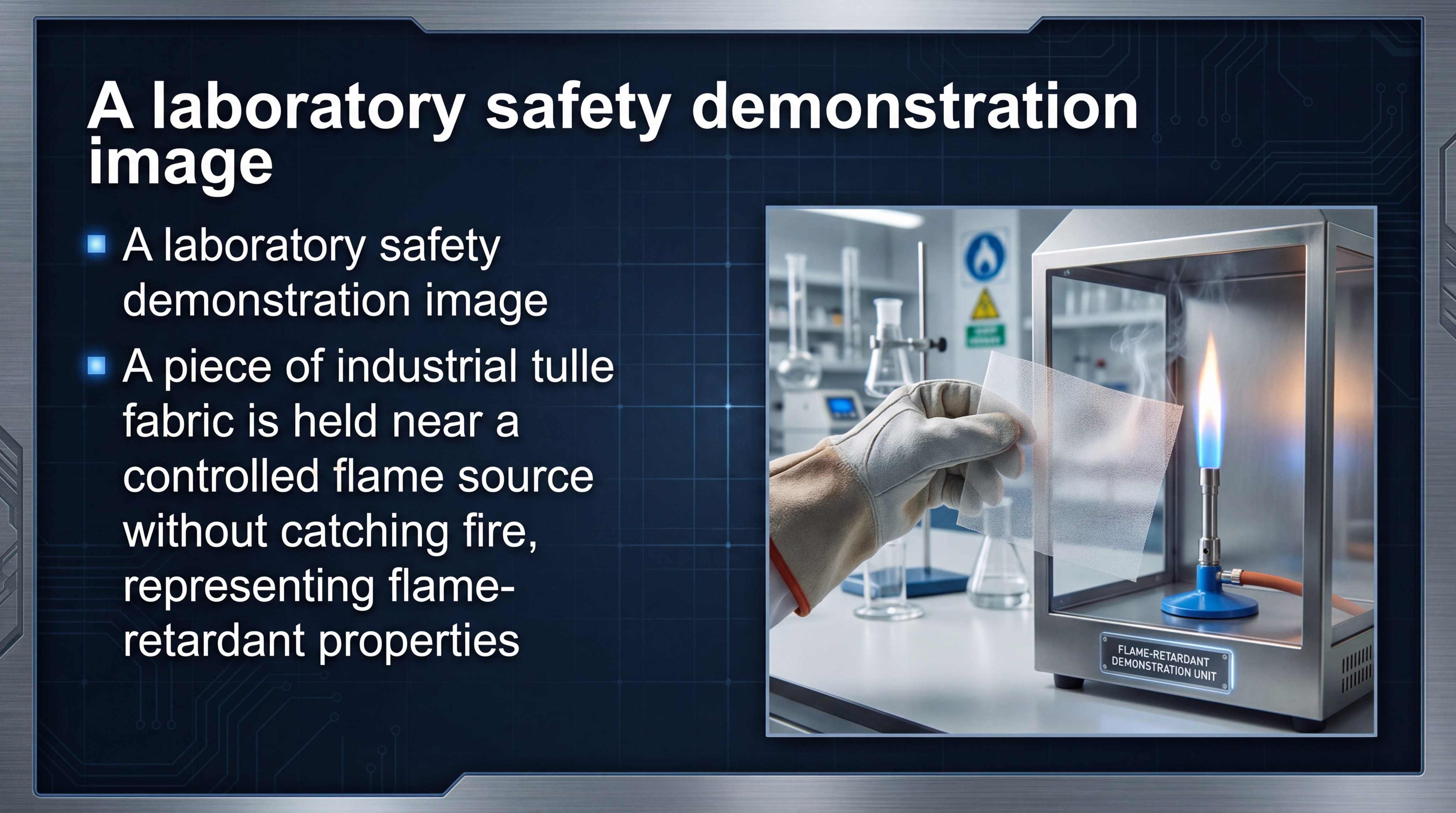

Is polyester tulle fabric safe for specialized applications?

Specialized finishes can make the mesh flame-retardant and anti-static, qualifying it for use in high-risk environments and electronics protection. Many commercial sectors require polyester tulle fabric to meet strict safety certifications before it can be integrated into industrial equipment or protective clothing. These treatments do not compromise the lightweight nature of the mesh, maintaining its functional benefits.

Meeting Global Safety Standards

Make no mistake: In industrial settings, a fabric’s reaction to heat or static is a matter of life and safety. Using certified mesh reduces liability and protects personnel in sensitive work zones.

- Flame Retardancy: Prevents the rapid spread of fire in public spaces.

- Anti-Static: Essential for cleanrooms and electronics assembly.

- Chemical Resistance: Protects the mesh from degradation in harsh environments.

Key TakeawayTechnical treatments allow polyester mesh to serve as a critical safety component in specialized industrial fields.

| Certification | Application | Safety Benefit | |

|---|---|---|---|

| NFPA 701 | Stage Curtains | Fire Spread Prevention | |

| ESD Safe | Electronic Bags | Static Discharge Protection | |

| REACH/Oeko-Tex | Children’s Clothing | Non-Toxic Materials |

Safety-rated textiles are a prerequisite for many government and large-scale commercial contracts.

How do you care for items made from polyester tulle fabric?

Proper maintenance involves gentle steaming rather than direct ironing to preserve the integrity of the hexagonal synthetic structure. Because polyester tulle fabric is thermoplastic, high heat can melt the fibers instantly, so professional care guidelines always recommend low-temperature treatments. Storing these items in breathable garment bags prevents the mesh from snagging on other materials or zippers.

Preserving the Hexagonal Structure

Look at it this way: A single snag or burn mark can ruin an entire garment or decorative panel. Prevention through proper handling is always more cost-effective than attempting a repair.

- Steaming: The safest way to remove wrinkles from multiple layers.

- Cold Wash: Prevents the breakdown of chemical sizing or stiffeners.

- Air Dry: Synthetic fibers dry rapidly and do not require machine heat.

Key TakeawayCorrect maintenance procedures extend the life of polyester mesh products and maintain their professional appearance.

| Care Step | Recommended Method | Reason | |

|---|---|---|---|

| Cleaning | Hand Wash / Cold | Protects delicate weave | |

| Drying | Hang to Dry | Prevents heat damage | |

| Storage | Rolled or Padded | Avoids permanent creases |

Following these professional care standards ensures that your textile investments remain in pristine condition for years.

Conclusion and Strategic Vision

Selecting the appropriate tulle is a strategic decision that impacts the durability, safety, and aesthetic of your final product. As a leader in high-performance textiles, our vision is to provide innovative mesh solutions that meet the evolving demands of global industries. Whether you are scaling a bridal collection or sourcing technical mesh for industrial equipment, the quality of your raw materials is the ultimate determinant of success. We invite you to explore our comprehensive range of specialty fabrics and contact us today to discuss your specific manufacturing requirements.

Frequently Asked Questions

Can I use a household iron on polyester mesh?No, because the high heat of a standard iron will melt the synthetic fibers. You should always use a handheld steamer at a safe distance to remove wrinkles without direct contact.

How do I prevent the edges of the tulle from fraying?You don’t need to worry because the warp-knit structure of tulle is naturally resistant to unraveling. This allows you to leave edges raw for a clean, modern aesthetic in fashion and decor.

Can I wash glitter-infused tulle in a machine?No, because the mechanical agitation can cause the glitter to shed and damage the machine’s filter. Hand washing in cold water is the only way to preserve the sparkling finish.

How do I determine which stiffness level I need?Look at the intended use: if the fabric needs to stand away from the body, choose high-denier stiff tulle. If the goal is a soft, flowing drape, select a low-denier soft mesh.

Is polyester tulle suitable for outdoor mosquito netting?Yes, because polyester is highly resistant to UV rays and does not absorb moisture like cotton. It provides a durable barrier that maintains its structure in various weather conditions.