Problem: Standard textile materials frequently fail in high-pressure industrial environments, leading to tears and safety risks. Traditional solid fabrics often lack the necessary breathability required for heavy-duty applications.

Agitate: A single material failure in a cargo net or medical sling can result in catastrophic equipment damage or serious personal injury. Without the right balance of tensile strength and environmental resistance, your projects face constant, costly replacements.

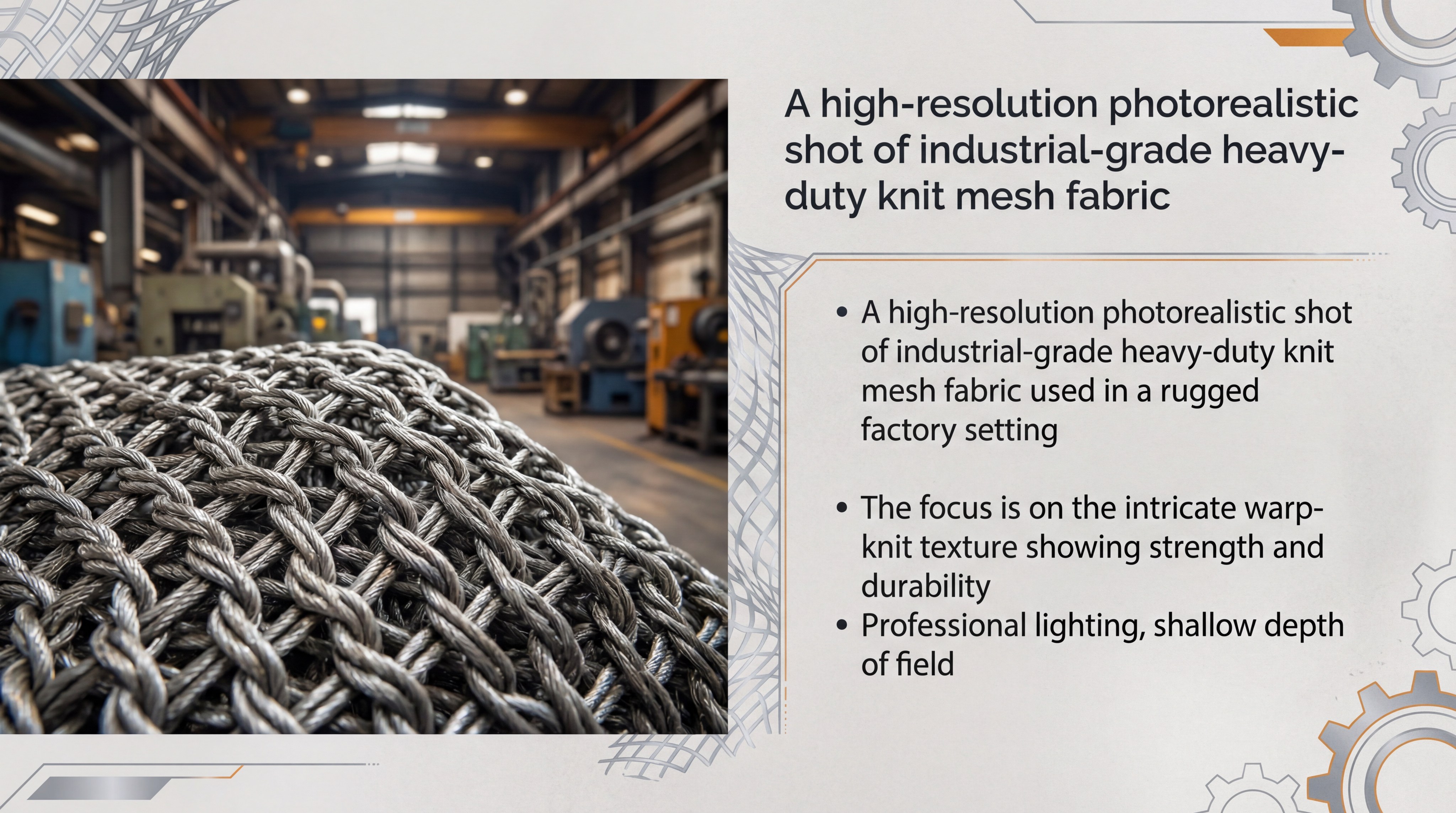

Solution: High-tenacity durable mesh fabric engineered from nylon and polyester provides the ultimate rugged solution. These materials feature a warp-knit structure designed for dimensional stability and specialized resistance to chemicals and weather.

Why use a durable mesh fabric for industrial jobs?

Industrial-grade mesh is engineered to withstand extreme mechanical stress without compromising structural integrity. This high-performance material is essential for environments where failure simply is not an option.

The open-knit structure ensures maximum airflow for moisture management and cooling. It effectively prevents heat buildup in safety equipment and outdoor gear.

The bottom line?

- High tensile strength prevents tearing under heavy loads.

- Warp-knit design ensures the fabric won’t unravel if cut.

- Open apertures promote rapid drainage and ventilation.

| Feature | Industrial Benefit | |

|---|---|---|

| Tensile Strength | High resistance to weight-based tearing | |

| Warp-Knit Design | Prevents structural unraveling | |

| Ventilation | Enhances cooling and moisture release |

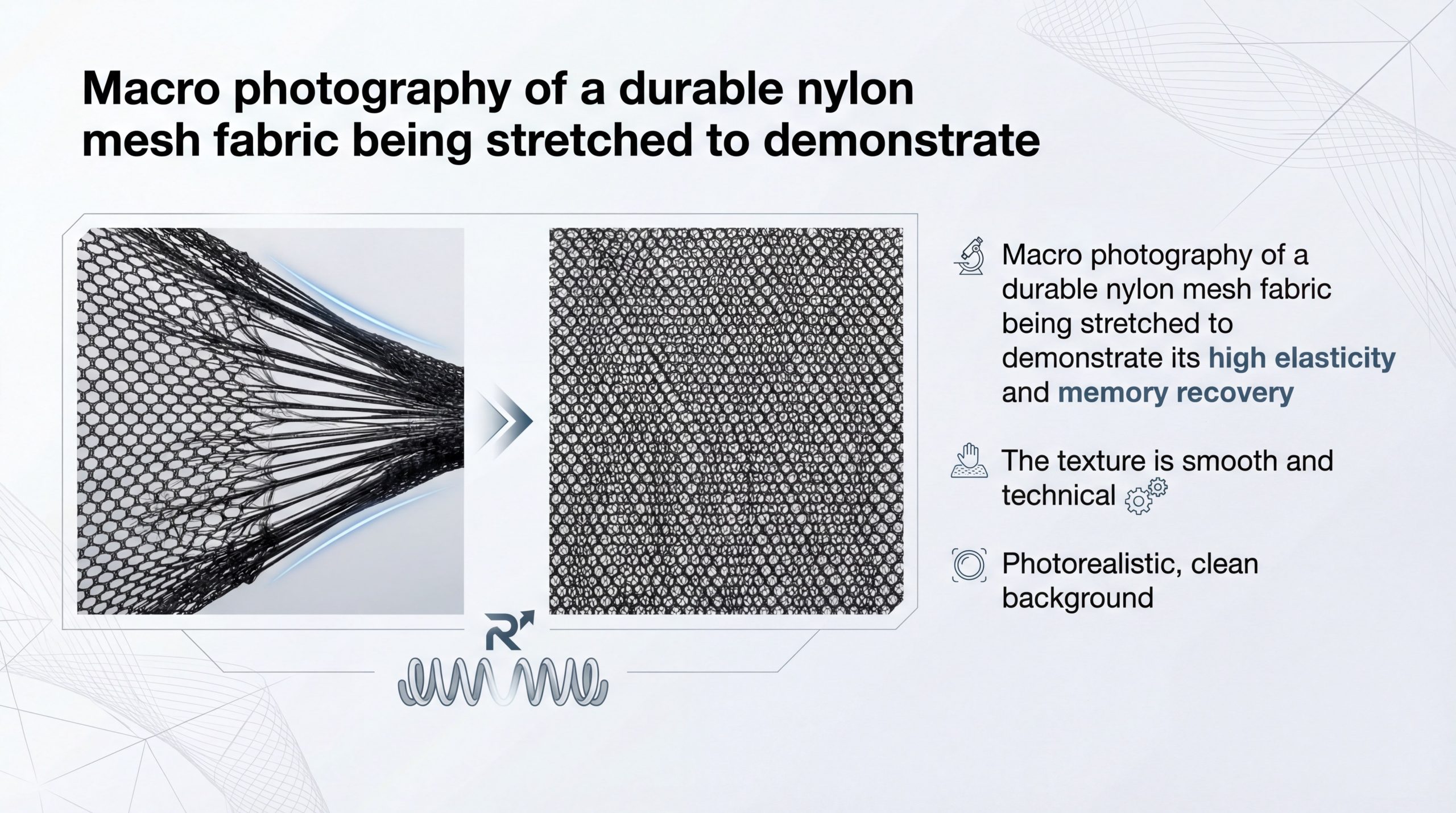

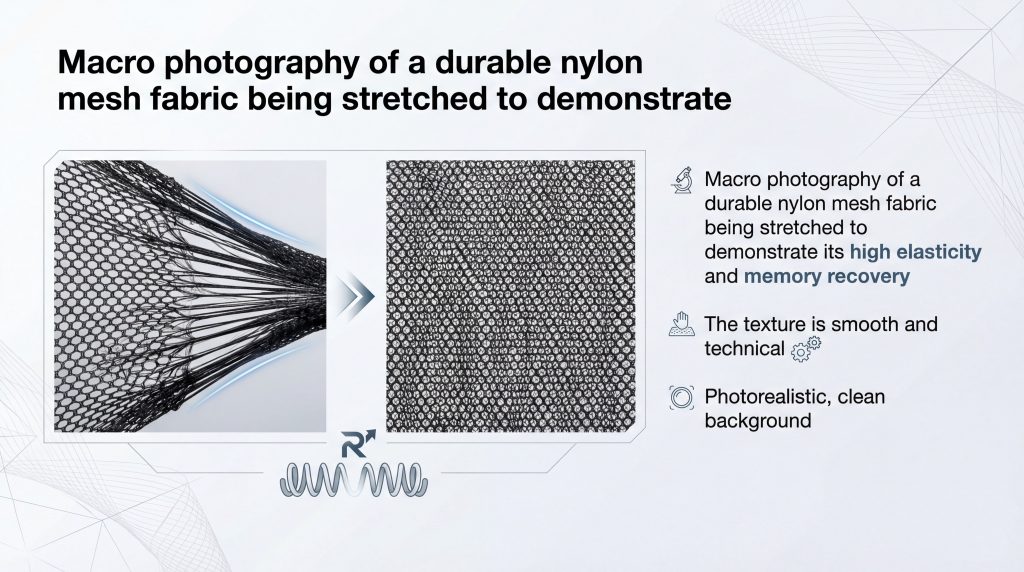

Is nylon the best durable mesh fabric for elasticity?

Nylon is a polyamide known for its remarkable ability to stretch and return to its original form. This makes it the premier durable mesh fabric choice for applications requiring high flexibility and memory.

Despite its immense strength, nylon remains lightweight and soft to the touch. It is frequently utilized in specialized textile solutions for both comfort and utility.

Think about this:

- Polyamide fibers offer exceptional bending capabilities.

- The material is highly resistant to alkalis and solvents.

- Lightweight construction reduces the overall weight of gear.

| Property | Nylon Mesh Performance | |

|---|---|---|

| Elasticity | Superior (Excellent memory recovery) | |

| Texture | Soft and smooth against surfaces | |

| Chemical Resistance | Resists alkalis and organic solvents |

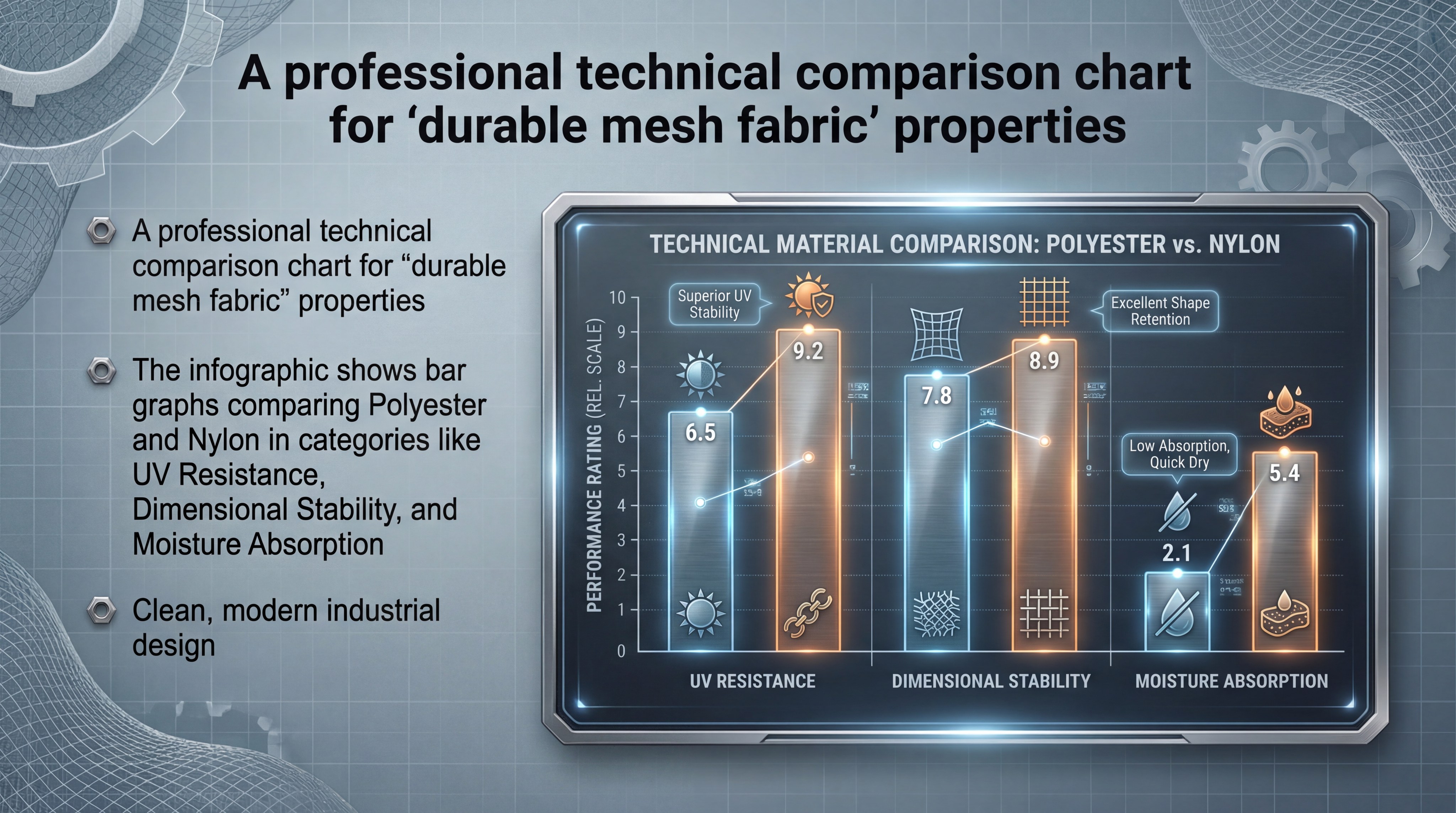

How does polyester act as a durable mesh fabric?

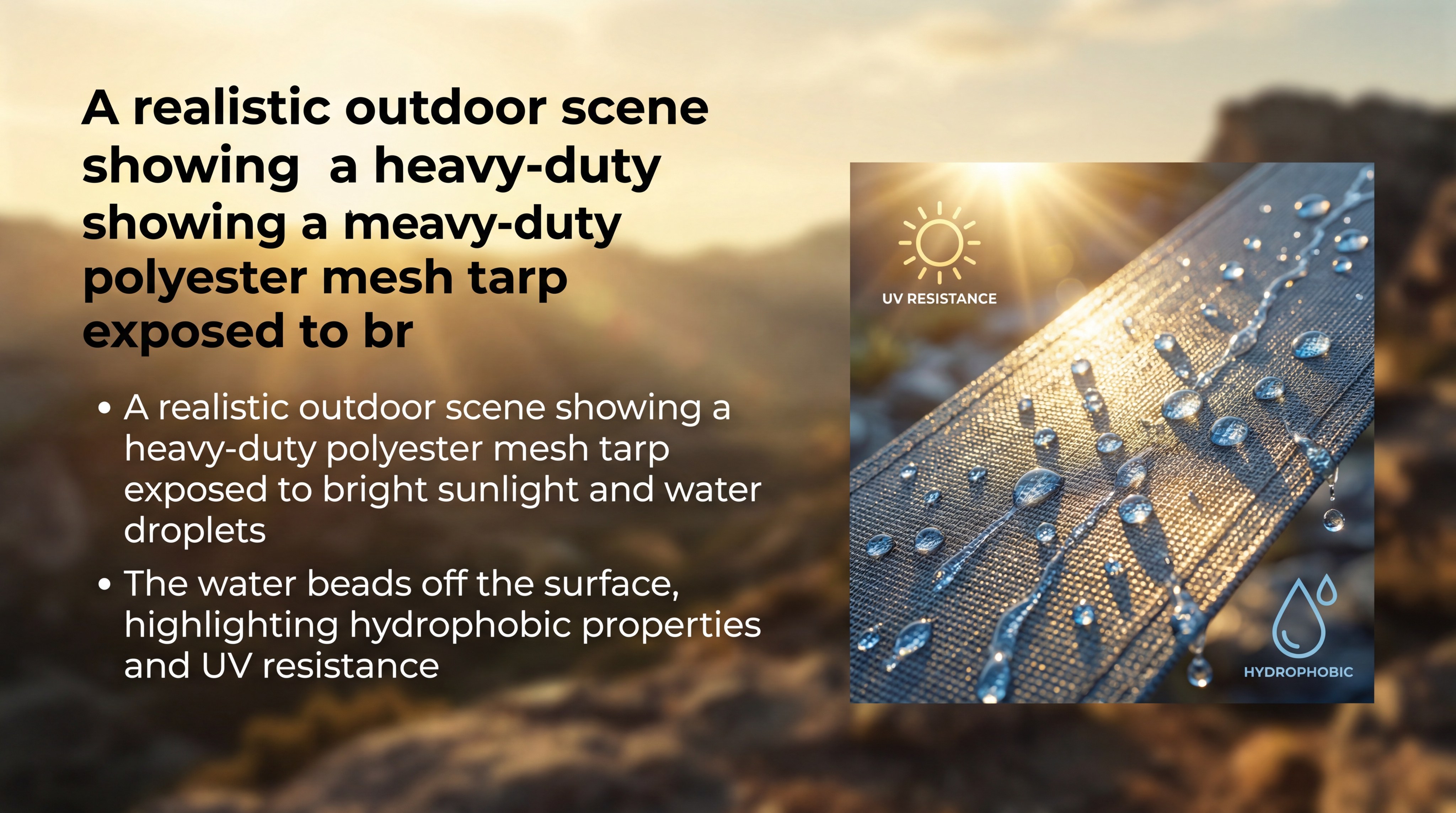

Polyester is a hydrophobic material that maintains its shape even when saturated with water. It resists stretching beyond its intended limits, providing a stable foundation for industrial structures.

This resilient material is ideal for harsh manufacturing environments due to its chemical stability. It offers long-term durability for outdoor and commercial projects.

Here is the deal:

- High dimensional stability prevents sagging or sagging.

- Naturally resistant to acids and petroleum substances.

- Low moisture absorption allows for rapid drying times.

| Property | Polyester Mesh Performance | |

|---|---|---|

| Dimensional Stability | Very High (Minimal stretch) | |

| Moisture Absorption | Very Low (Dries quickly) | |

| Longevity | Excellent for long-term outdoor use |

Which durable mesh fabric resists UV and water?

Polyester significantly outperforms other materials when exposed to prolonged sunlight and humidity. It is the most reliable durable mesh fabric for marine and agricultural applications.

The hydrophobic nature of polyester fibers makes the material naturally resistant to mold and mildew. It maintains its color and tensile strength better than nylon under UV radiation.

It gets better:

- UV-stabilized fibers prevent degradation from sunlight.

- Water-repellent properties ensure the mesh remains light.

- High resistance to rot makes it perfect for outdoor tarping.

| Factor | Polyester Mesh | Nylon Mesh | |

|---|---|---|---|

| UV Resistance | Superior | Moderate | |

| Water Response | Hydrophobic (Repels) | Hydrophilic (Absorbs) | |

| Mildew Risk | Naturally Resistant | Needs Treatment |

Can durable mesh fabric improve patient lift safety?

Heavy-duty mesh is a critical component in medical slings, capable of supporting over 1,500 lbs safely. This high-load capacity ensures healthcare workers can transfer patients without risk of fabric failure.

The open-knit structure prevents heat and moisture buildup against a patient’s skin. This reduces the risk of skin irritation and enhances overall comfort during use.

Why does this matter?

- High-tenacity fibers provide a reliable safety margin.

- Breathable knit patterns promote healthy skin ventilation.

- Materials are machine-washable for medical-grade hygiene.

| Metric | Medical Mesh Specification | |

|---|---|---|

| Weight Capacity | Supports up to 1,500+ lbs | |

| Skin Safety | Non-abrasive and highly breathable | |

| Maintenance | Rapid-dry and bleach-compatible |

Is durable mesh fabric effective for cargo securing?

Nylon and polyester cargo nets use their high tensile strength to absorb shocks during transit. Selecting a durable mesh fabric for transport prevents item mobility in truck beds or trailers.

Higher denier counts translate to thicker fibers and improved abrasion resistance for sharp-edged freight. This ensures the safety of the cargo and the vehicle operator.

Consider the facts:

- Cargo nets minimize movement and prevent load shifting.

- High-denier counts resist wear from friction and edges.

- Shock absorption properties protect delicate equipment.

| Application | Recommended Mesh Type | |

|---|---|---|

| Light Truck Beds | Standard Polyester Mesh | |

| Industrial Freight | High-Denier Heavy-Duty Mesh | |

| Safety Barriers | Coated High-Tenacity Netting |

What finishes enhance a durable mesh fabric’s life?

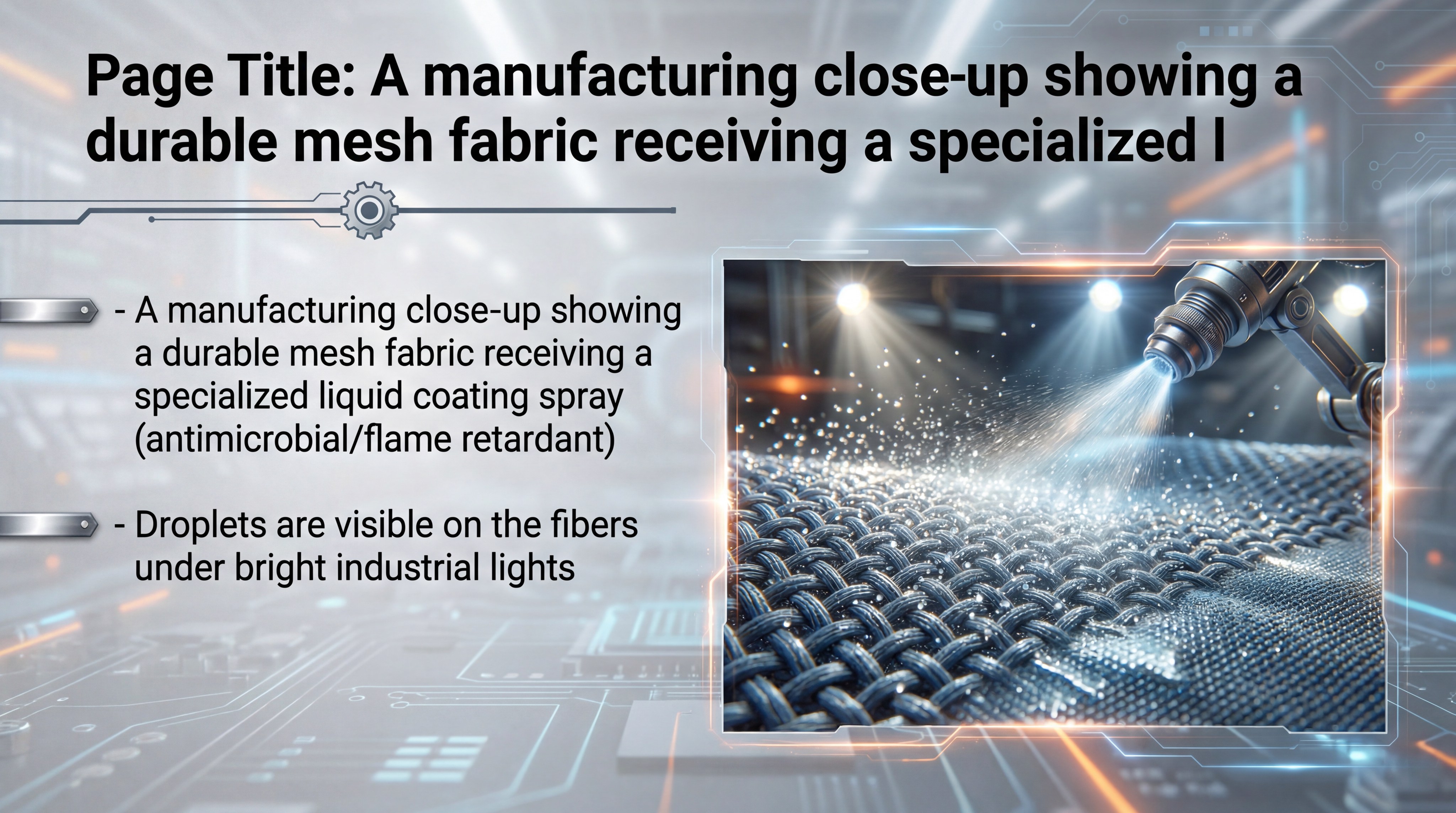

Applying specialized coatings can drastically extend the lifespan and utility of industrial mesh. Antimicrobial treatments using silver ions are particularly valuable for medical and athletic applications.

Flame retardant and water-repellent finishes allow these fabrics to meet strict commercial safety standards. These coatings ensure the material remains functional in hazardous or wet conditions.

What is the secret?

- Silver ion finishes prevent bacterial growth and odors.

- Flame retardant coatings meet essential fire safety codes.

- DWR finishes provide enhanced moisture shedding capabilities.

| Finish Type | Primary Purpose | |

|---|---|---|

| Antimicrobial | Hygiene and odor prevention | |

| Flame Retardant | Fire safety and code compliance | |

| Water Repellent | Enhanced moisture shedding |

How to select the weight for durable mesh fabric?

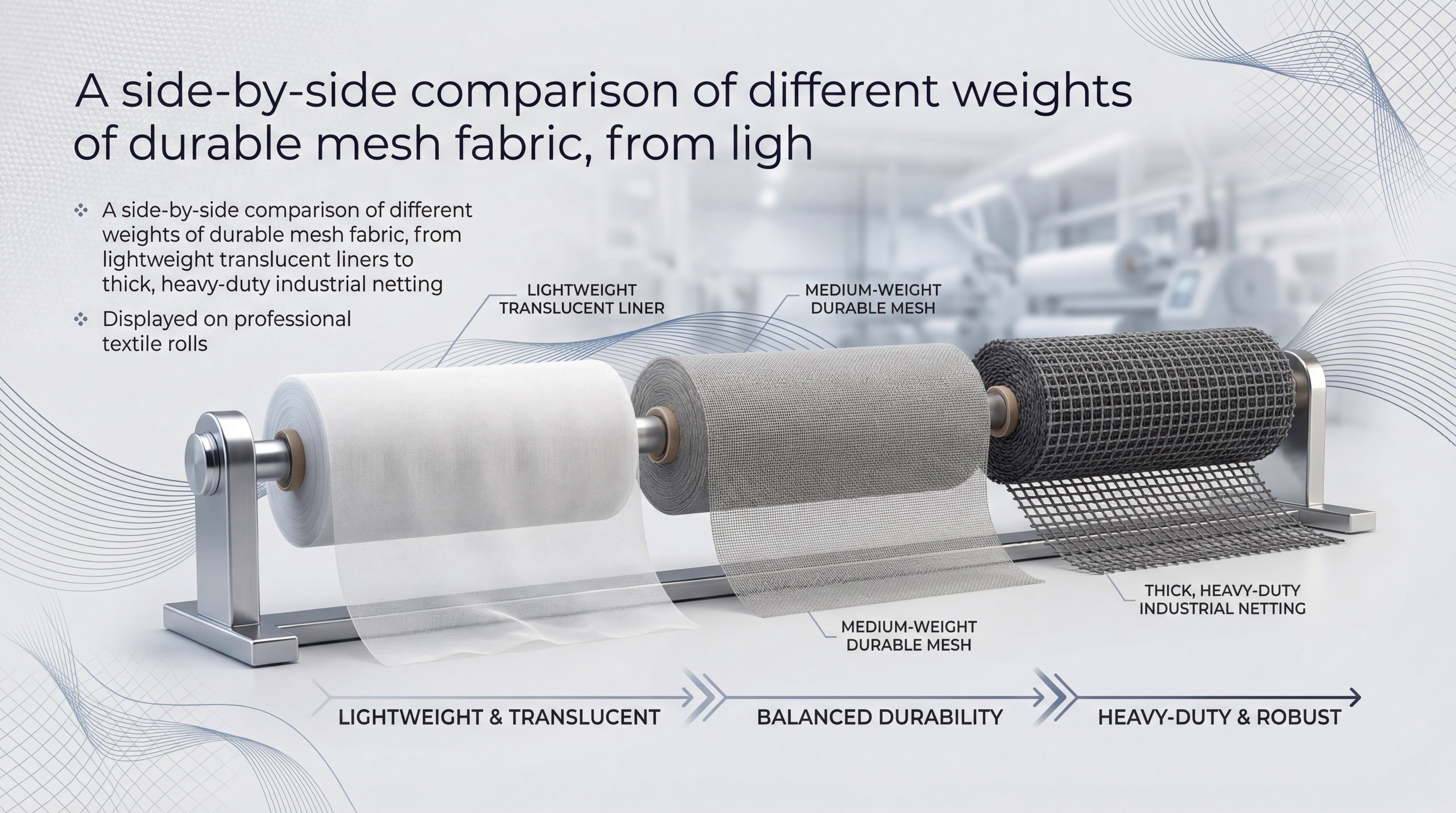

Fabric weight is typically measured in ounces per square yard and determines the load-bearing capacity. Choosing the correct durable mesh fabric weight is vital for balancing strength and portability.

Heavyweight meshes exceeding 15 oz are reserved for the most demanding industrial tasks. Lighter weights under 8 oz are often used for liners and protective apparel.

Don’t forget this:

- Lightweight mesh is ideal for liners and pockets.

- Medium weights suit sports bags and safety vests.

- Heavyweight mesh is required for cargo and slings.

| Weight Category | Weight (oz/sq yd) | Typical Use | |

|---|---|---|---|

| Lightweight | 2 – 6 oz | Apparel liners, laundry bags | |

| Medium | 7 – 12 oz | Sports bags, safety vests | |

| Heavyweight | 13 – 20+ oz | Cargo nets, patient slings |

Where is durable mesh fabric used in modern sports?

Modern sports equipment relies on heavy-duty mesh for its unique ability to absorb high-impact forces. From golf simulator screens to professional goal nets, these materials provide exceptional longevity.

The aesthetic versatility of industrial mesh also makes it a favorite for architectural displays. It combines modern design with the rugged durability required for public spaces.

Check this out:

- Impact screens require high energy absorption capabilities.

- Goal nets must resist weather and repeated mechanical stress.

- Architectural mesh serves as both a barrier and decoration.

| Sport Industry | Primary Usage | |

|---|---|---|

| Golf/Simulators | Impact screens and baffles | |

| Athletics | Professional goal and safety nets | |

| Outdoor Sports | Equipment bags and protective gear |

Why is knit structure key for durable mesh fabric?

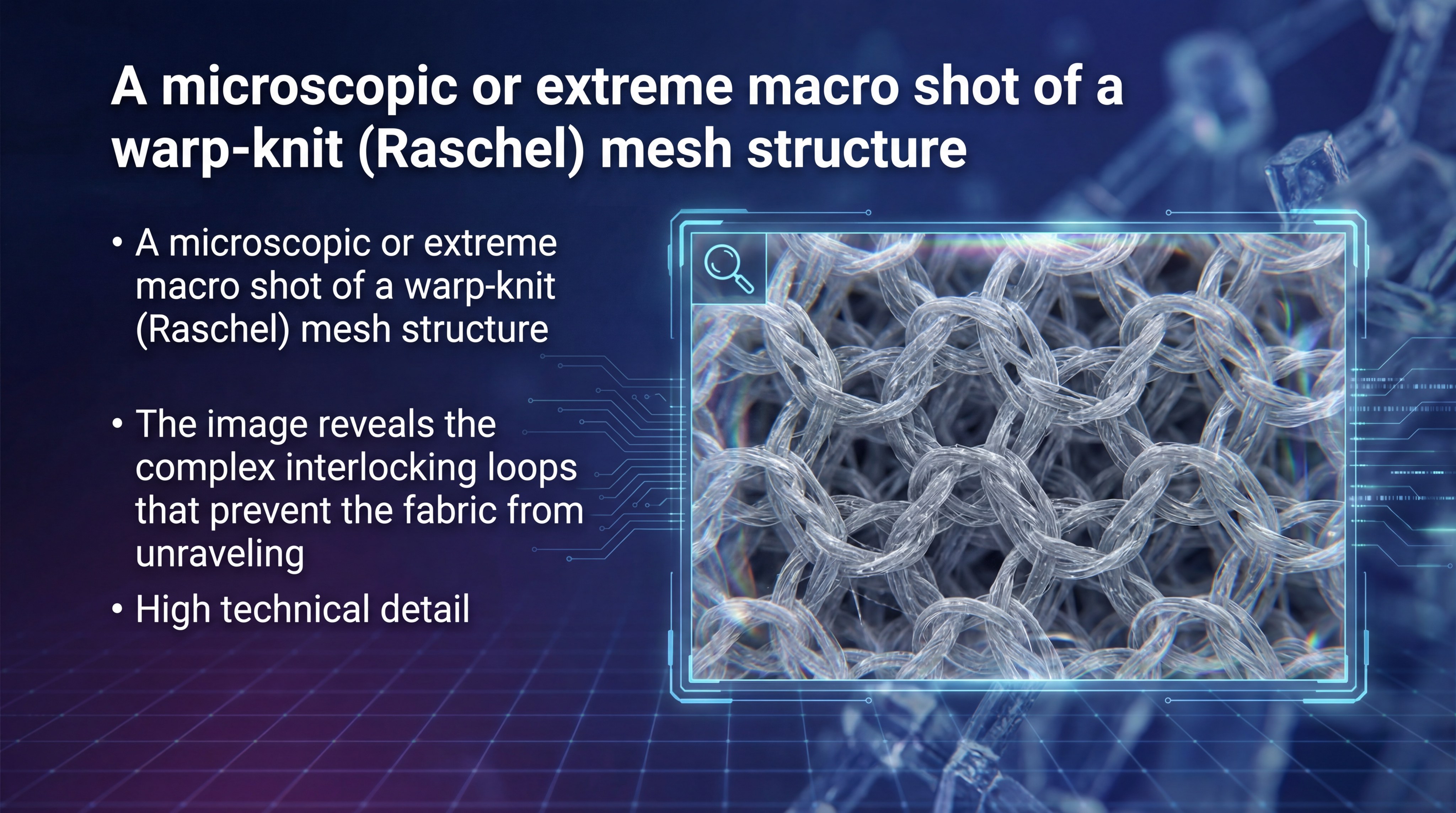

Warp knitting techniques like Raschel create a complex, interlocking loop system that exceeds standard weaves in strength. This specific construction ensures the durable mesh fabric maintains its shape under tension.

The primary benefit of a warp-knit mesh is its resistance to running or unraveling. Even if a single thread is compromised, the rest of the structure remains secure.

The final word:

- Warp-knit structures offer superior dimensional stability.

- Interlocking loops prevent the fabric from unravelling.

- Raschel machinery creates the strongest industrial patterns.

| Construction | Key Characteristic | |

|---|---|---|

| Warp Knit | Run-resistant and stable under load | |

| Raschel Knit | Best for intricate, high-strength patterns | |

| Tricot Knit | Ideal for fine and smooth surfaces |

Selecting the right heavy-duty material ensures safety and efficiency in your most demanding projects. For custom solutions or technical advice, please contact us today.

Frequently Asked Questions

Can I wash heavy-duty nylon mesh in a machine?Yes, most nylon mesh fabrics are machine washable. It is recommended to use cool or warm water and a mild detergent to maintain the fiber’s elasticity and structural integrity.

What’s the best way to cut durable mesh fabric safely?To prevent fraying and ensure a clean edge, use a hot knife or electric fabric cutter. This process cauterizes the edges of the synthetic fibers as they are cut, preventing future unraveling.

How long does polyester mesh last in direct sunlight?Polyester mesh is highly UV-resistant and typically lasts several years in direct sunlight before showing signs of degradation. Longevity depends on the intensity of exposure and the presence of UV inhibitors.

Are there specific heat limits for these mesh fabrics?Nylon typically has a melting point between 340°F and 400°F, while polyester can withstand slightly higher temperatures. Avoid direct contact with high-heat sources to prevent fiber damage.

Which fabric is softer against the skin for medical use?Nylon mesh is generally softer and more pliable than polyester. This makes it the preferred choice for medical patient slings or garments that come into direct contact with sensitive skin.