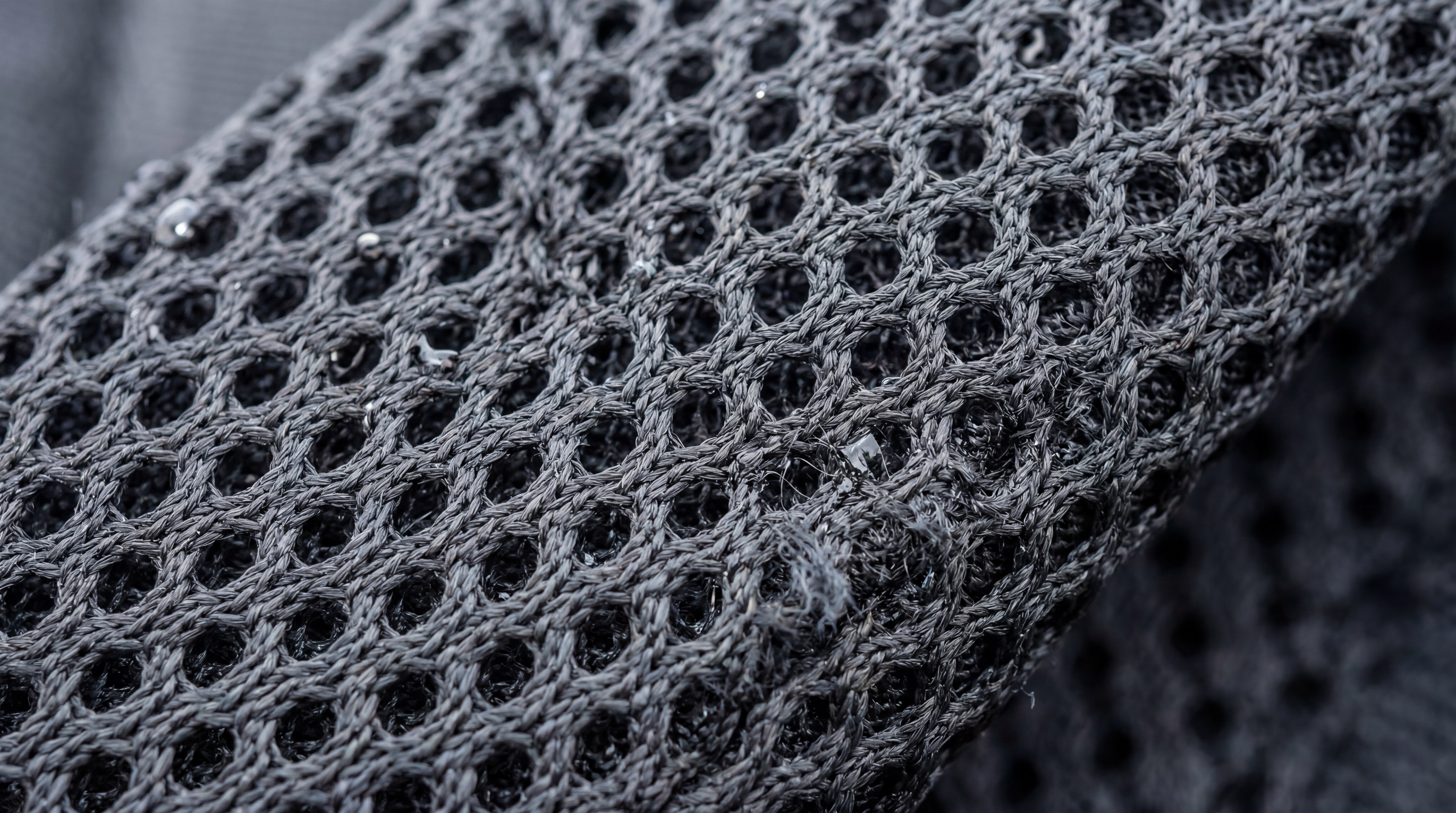

Mesh fabric is a versatile textile characterized by its open-weave structure and lightweight breathability. You likely face the challenge of selecting a material that balances aesthetic transparency with structural integrity for your B2B production needs. Choosing the wrong substrate can lead to manufacturing delays or product failures that damage your brand’s reputation and bottom line. By understanding the diverse mesh fabric types , you can optimize your supply chain and deliver superior final products that meet modern performance and fashion standards.

What are the most common mesh fabric types?

The most common mesh fabric types include polyester mesh, nylon mesh, and power mesh, each serving distinct functional purposes in the textile industry. These materials are defined by their knit patterns and the synthetic fibers used during the extrusion process.

Is polyester mesh best for sports?

Polyester is the primary fiber used for athletic uniforms and activewear due to its moisture-wicking properties. It remains durable under physical stress and resists shrinking or stretching during heavy use.

- High breathability for temperature regulation.

- Resistance to UV damage and chemicals.

- Quick-drying capabilities for outdoor use.

Think about this: polyester mesh is the backbone of the modern sports industry.

What defines nylon mesh?

Nylon mesh is known for its exceptional strength and elasticity compared to polyester alternatives. It is frequently utilized in industrial applications and delicate evening wear where a soft touch is required.

- Superior abrasion resistance for long-term wear.

- High tensile strength for structural loads.

- Silky texture suitable for skin-contact layers.

The best part? It combines resilience with a premium hand-feel.

How does power mesh function?

Power mesh is a specialized fabric with high spandex content, designed for compression and support. It is the standard choice for shapewear, lingerie, and the supportive elements of high-performance athletic gear.

- Four-way stretch for maximum mobility.

- Contouring effects for silhouette enhancement.

- Recovery strength to maintain shape over time.

Key Takeaway: Selecting the right common mesh depends on balancing the need for stretch, strength, and moisture management.

| Mesh Type | Primary Benefit | Common Application | |

|---|---|---|---|

| Polyester | Moisture Wicking | Athletic Jerseys | |

| Nylon | Durability | Industrial Filters | |

| Power Mesh | Compression | Shapewear |

This data indicates that material selection must align strictly with the mechanical requirements of the end-use product.

Why choose specific mesh fabric types for apparel?

Specific mesh fabric types are chosen for apparel because they offer a unique combination of ventilation, transparency, and weight reduction that solid textiles cannot provide. Designers leverage these properties to create garments that are both functional and visually layered.

Does mesh improve activewear performance?

In activewear, mesh panels are strategically placed to maximize airflow in high-heat zones of the body. This targeted ventilation prevents overheating and improves the overall comfort of the wearer during intense activity.

- Enhanced airflow through porous knit structures.

- Reduced garment weight for better agility.

- Flexible movement without fabric bunching.

But wait, there is more: mesh also allows for faster evaporation of sweat.

How is mesh used in high fashion?

High-fashion designers use mesh to create architectural shapes and illusions of transparency without sacrificing the garment’s structure. It serves as an excellent base for embroidery, beadwork, and intricate lace appliqués.

- Visual depth through layered textures.

- Structural support for voluminous silhouettes.

- Foundation for luxury embellishments.

You might be wondering, how does it stay so light while holding heavy beads?

Key Takeaway: Apparel mesh serves as both a functional cooling system and a creative canvas for modern fashion aesthetics.

| Apparel Use | Function | Fabric Choice | |

|---|---|---|---|

| Performance | Cooling | Polyester Mesh | |

| Couture | Structure | Rigid Tulle | |

| Lingerie | Comfort | Soft Nylon Mesh |

The integration of mesh into apparel highlights a shift toward materials that support biological cooling while enabling complex design.

Which mesh fabric types offer the most durability?

Industrial-grade mesh fabric types offer the highest durability, specifically those constructed from high-tenacity nylon or reinforced polyester. These fabrics are engineered to withstand extreme environmental conditions and mechanical stress.

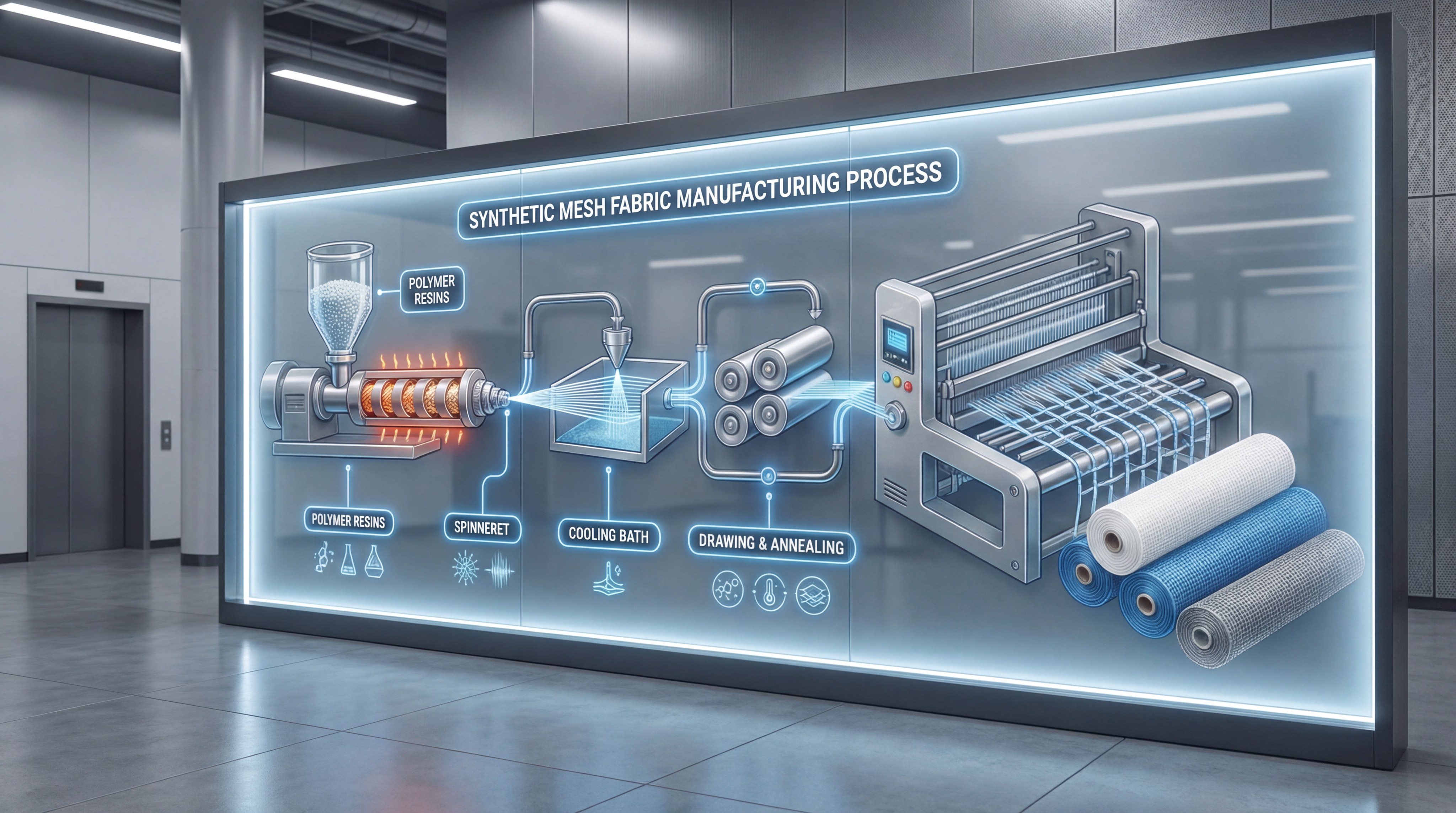

What is the manufacturing process?

The manufacturing process involves polymer extrusion and precise warp knitting to ensure the mesh does not unravel when cut. Advanced coatings can be added to enhance resistance to chemicals, fire, or moisture.

- Polymer melting and fiber spinning.

- Warp knitting for interlocking loops.

- Heat setting to stabilize the mesh dimensions.

The result is a fabric that holds its shape under immense pressure.

Is vinyl-coated mesh stronger?

Vinyl-coated polyester mesh is a top-tier choice for heavy-duty outdoor applications like truck covers and pool fences. The coating provides a barrier against UV rays and physical tearing.

- Weatherproof properties for outdoor storage.

- Extreme tear resistance for safety barriers.

- Easy to clean and maintain over years.

Believe it or not, this material can last over a decade in harsh sun.

Key Takeaway: Durability in mesh is a product of both the base fiber strength and the specialized coatings applied during finishing.

| Durability Factor | Nylon Mesh | Coated Polyester | |

|---|---|---|---|

| Tensile Strength | High | Very High | |

| UV Resistance | Moderate | Excellent | |

| Chemical Stability | High | Superior |

Analysis of these specifications shows that coated meshes are indispensable for long-term industrial and outdoor reliability.

How are synthetic mesh fabric types produced?

Synthetic mesh fabric types are produced through a process of extrusion and knitting, where raw polymers are transformed into continuous filaments. These filaments are then fed into specialized machines that create the characteristic hole-filled structure.

What role does extrusion play?

Extrusion is the first step where plastic pellets like polyester or nylon are melted and forced through a spinneret. This determines the thickness and cross-sectional shape of the individual fibers.

- Precision control of fiber diameter.

- Ability to infuse color dyes during melting.

- Creation of monofilament or multifilament yarns.

It sounds technical, but this is where the fabric’s strength begins.

How does the knitting process work?

Most mesh is made using warp knitting machines, specifically Raschel or Tricot machines, which create zigzagging loops. Unlike traditional weaving, this prevents the fabric from running or fraying if a single thread breaks.

- Raschel knitting for complex hole patterns.

- Tricot knitting for smooth, thin apparel mesh.

- Interlocking loops for structural integrity.

The best part? This process is incredibly fast and efficient for mass production.

Key Takeaway: The production of mesh is a highly controlled mechanical process that ensures consistency and snag-resistance.

| Production Stage | Purpose | Outcome | |

|---|---|---|---|

| Extrusion | Fiber Creation | Consistent Yarns | |

| Warp Knitting | Structure Formation | Non-fray Fabric | |

| Heat Setting | Dimension Control | Stable Shape |

The efficiency of warp knitting allows manufacturers to produce vast quantities of high-performance mesh at competitive prices.

Do decorative mesh fabric types stay functional?

Decorative mesh fabric types remain highly functional by providing a lightweight structure that supports aesthetic additions like glitter, sequins, or flocking. While they prioritize appearance, the underlying mesh must still provide enough tensile strength to hold these heavy decorations.

Is glitter mesh difficult to use?

Glitter mesh requires specific handling during the cutting and sewing stages to ensure the decorative elements do not shed excessively. High-quality versions use heat-bonding or specialized resins to keep the glitter attached to the fibers.

- Bonded glitter for reduced shedding.

- Consistent hole size for even sparkle.

- Soft finish to prevent skin irritation.

You might be surprised at how well it holds up in a garment.

How does flocking affect mesh?

Flocking involves applying tiny fibers to the mesh surface to create a velvet-like texture or pattern. This adds a tactile dimension and visual richness while maintaining the fabric’s breathability and lightness.

- Velvety texture for luxury applications.

- Raised patterns for visual interest.

- Lightweight alternative to heavy velvet fabrics.

But wait, there is more: flocking can be applied in custom logos or intricate floral designs.

Key Takeaway: Decorative mesh blends high-end aesthetics with the practical benefits of a breathable, lightweight substrate.

| Decoration Type | Application Method | Best Use | |

|---|---|---|---|

| Glitter | Resin Bonding | Evening Gowns | |

| Flocking | Adhesive Fibers | Luxury Packaging | |

| Sequins | Machine Sewing | Dancewear |

This table demonstrates that decorative enhancements do not negate the fundamental utility of the mesh base.

What defines high-quality mesh fabric types?

High-quality mesh fabric types are defined by their uniformity, colorfastness, and resistance to snagging or “pilling” over time. In B2B sourcing, the consistency of the hole size and the strength of the knit are the primary indicators of a premium product.

How do you test for mesh quality?

Quality testing involves checking the fabric’s recovery after stretching and ensuring that the holes do not distort under tension. A premium mesh will return to its original shape immediately without leaving “ghost” impressions.

- Stretch recovery tests for elasticity.

- Colorfastness testing for wash cycles.

- Abrasion resistance for longevity.

The truth is, not all mesh is created equal.

Why does “hand-feel” matter?

For apparel applications, the softness of the mesh—often referred to as its “hand”—is crucial for wearer comfort. High-quality mesh uses finer filaments to ensure that the fabric does not feel scratchy or stiff against the skin.

- Fine denier yarns for a silky touch.

- Chemical softening agents in finishing.

- Smooth knotting to prevent irritation.

The best part? You can feel the quality difference instantly.

Key Takeaway: Quality mesh is an investment in product longevity and user satisfaction, defined by physical resilience and tactile comfort.

| Quality Indicator | Premium Mesh | Economy Mesh | |

|---|---|---|---|

| Recovery | Instant | Permanent Stretch | |

| Softness | High (Silky) | Low (Abrasive) | |

| Hole Uniformity | Exact | Variable |

Choosing premium materials significantly reduces the rate of consumer returns and manufacturing defects.

Which mesh fabric types work for heavy luggage?

Heavy-duty mesh fabric types for luggage are typically made from “Sandwich” mesh or thick-denier nylon. These fabrics provide the necessary ventilation for items like gym bags while being strong enough to support the weight of heavy gear.

What is sandwich mesh?

Sandwich mesh, also known as 3D air mesh, consists of two layers of mesh separated by a vertical spacer fiber. This creates a cushioned effect that is perfect for backpack straps and back panels.

- Shock absorption for heavy loads.

- Maximum air circulation to prevent sweat.

- Cushioned feel without excessive bulk.

Think about this: it is like a suspension system for your shoulders.

Is ballistic nylon mesh necessary?

For the highest stress areas, manufacturers use mesh reinforced with ballistic-grade fibers. This ensures that pockets and dividers do not rip when sharp-edged items or heavy equipment are stored inside.

- Extreme puncture resistance.

- Heavy-duty knit for weight bearing.

- Resilience against rough handling.

But wait, there is more: it also resists mold and mildew in damp environments.

Key Takeaway: Luggage mesh must provide a balance of structural support, protection, and airflow to be effective in travel environments.

| Luggage Part | Recommended Mesh | Reason | |

|---|---|---|---|

| Straps | 3D Air Mesh | Cushioning | |

| Side Pockets | Heavy Nylon Mesh | Visibility & Air | |

| Interior Dividers | Lightweight Polyester | Weight Savings |

The use of multi-layered mesh in luggage design ensures both user comfort and the protection of internal contents.

Can bridal mesh fabric types support embroidery?

Bridal mesh fabric types are specifically engineered with a fine, stable hexagonal lattice that can support heavy embroidery and intricate beadwork. This specialized tulle provides the necessary tension to hold thousands of stitches without tearing or distorting the overall shape of the gown.

Why is hexagonal mesh preferred?

The hexagonal or “honeycomb” structure of high-quality tulle distributes weight more evenly than square mesh. This makes it the superior choice for haute couture pieces that feature dense floral embroidery or heavy crystal embellishments.

- Even weight distribution across the lattice.

- Minimal distortion under the weight of beads.

- Clear transparency for a “floating” effect.

You might wonder, how does something so thin hold so much weight?

Is soft tulle durable enough?

While soft tulle is prized for its drape and “hand,” it must still undergo rigorous quality checks to ensure the threads do not snap during machine embroidery. Modern bridal mesh uses high-strength nylon filaments to achieve this balance.

- Durable filaments for high-speed sewing.

- Soft finish for comfort against the skin.

- Stable structure to prevent puckering.

The best part? It remains ethereal while being functionally strong.

Key Takeaway: Bridal mesh is a high-performance material disguised as a delicate textile, capable of supporting significant decorative weight.

| Bridal Mesh Type | Best Use | Decoration | |

|---|---|---|---|

| Hard Tulle | Veils & Petticoats | Minimal | |

| Soft Tulle | Skirts & Overlays | Heavy Embroidery | |

| Illusion Mesh | Necklines & Sleeves | Crystals |

The structural integrity of bridal tulle is essential for maintaining the silhouette of luxury garments under the weight of artistry.

How do specialty mesh fabric types vary?

Specialty mesh fabric types vary based on their technical finishes, such as antimicrobial coatings, flame retardants, or metallic laminates. These variations allow the mesh to perform in niche markets like medical textiles, safety gear, and theatrical costuming.

What is antimicrobial mesh?

Antimicrobial mesh is treated with silver ions or other agents to prevent the growth of bacteria and fungi. This is critical for medical slings, shoe linings, and athletic gear where moisture and heat are present.

- Odors reduction in high-use products.

- Prevention of skin infections for patients.

- Long-lasting protection through many washes.

Believe it or not, this technology is now standard in premium footwear.

How does metallic mesh work?

Metallic mesh is created by laminating a thin foil layer onto the synthetic base or using metal-coated fibers. It provides a striking visual effect for stage costumes and high-end fashion accessories.

- Reflective surface for lighting effects.

- Unique texture compared to standard dyes.

- Available in gold, silver, and iridescent finishes.

But wait, there is more: it still retains the breathability of standard mesh.

Key Takeaway: Specialty meshes extend the utility of the fabric into technical and highly aesthetic domains by adding chemical or physical properties.

| Specialty Type | Key Feature | Market | |

|---|---|---|---|

| Antimicrobial | Bacteria Resistant | Healthcare | |

| Flame Retardant | Fire Resistant | Event Decor | |

| Metallic | High Shine | Theatre |

Innovation in specialty finishes continues to open new possibilities for mesh applications across diverse industries.

How do you maintain different mesh fabric types?

Maintaining different mesh fabric types requires careful attention to washing temperatures and the use of protective bags to prevent snagging. Because mesh is an open-weave material, it is more susceptible to damage from zippers and hooks during the cleaning process.

Is machine washing safe?

Machine washing is generally safe for polyester and nylon mesh, provided you use a delicate cycle and a cold water setting. Using a mesh laundry bag is the most effective way to protect the fabric from abrasion.

- Cold water to prevent fiber shrinkage.

- Mild detergents to preserve color.

- Protective bags to prevent snags.

The truth is, heat is the biggest enemy of synthetic mesh.

Should you ever iron mesh?

Ironing mesh is risky because the synthetic fibers can melt easily under direct heat. If wrinkles must be removed, using a handheld steamer from a safe distance is the recommended professional approach.

- Steam for gentle wrinkle removal.

- Low heat if an iron must be used.

- Pressing cloth as a protective barrier.

The best part? Most mesh is naturally wrinkle-resistant.

Key Takeaway: Proper maintenance extends the lifespan of mesh products by protecting the delicate knit structure from mechanical and thermal stress.

| Care Step | Recommended Action | Risk if Ignored | |

|---|---|---|---|

| Washing | Mesh Laundry Bag | Snagging & Tearing | |

| Drying | Air Dry / Low Heat | Fiber Melting | |

| Storage | Folded Flat | Stretching |

Adhering to these maintenance protocols ensures that mesh garments and industrial products retain their structural integrity for years.

Conclusion

Understanding the various mesh fabric types is the first step toward creating high-quality, durable, and aesthetically pleasing products. From the high-performance needs of activewear to the delicate requirements of bridal couture and the rugged demands of industrial luggage, there is a specific mesh engineered for every challenge. We have explored how material choice, manufacturing precision, and proper maintenance solve the problems of durability and functionality in the B2B sector.

Our commitment to excellence ensures that you receive only the most reliable and innovative textile solutions tailored to your unique specifications. We invite you to explore our comprehensive catalog and find the perfect material for your next project. To discuss your specific manufacturing needs or to request samples, contact us today and let our experts guide your selection.

FAQ

Can I use polyester mesh for heavy-duty industrial filters?Yes, because polyester is naturally resistant to many chemicals and UV degradation, making it ideal for harsh filtration environments.

What’s the best way to prevent glitter mesh from shedding?The best way is to choose a mesh where the glitter is resin-bonded or heat-sealed, as these professional finishes significantly increase the adhesion of the decorative particles.

How do I know if a mesh is high-quality without a lab test?Check for “recovery” by stretching a sample; a high-quality mesh will immediately snap back to its original shape without any distortion in the hole pattern.

Can I dye synthetic mesh fabrics at home for custom projects?No, because synthetic fibers like nylon and polyester require high-pressure, high-temperature industrial dyes and specific chemical carriers to achieve a permanent and even color.

What’s the best mesh for a garment that needs to be both breathable and supportive?The best choice is power mesh, as its high spandex content provides the necessary compression and support while the open-knit structure ensures maximum airflow.