Selecting the ideal textile for laundry applications is a high-stakes decision for manufacturers and designers. A single snagged thread or a pilled silk garment can result in costly returns and damaged brand reputations. While the purpose of a laundry bag is to protect, using the wrong mesh density can actually hinder the cleaning process or fail to provide a sufficient barrier.

Think about it: Engineering the perfect laundry solution requires a precise balance between hydraulic permeability and physical protection. This guide breaks down the technical differences between fine and coarse fabrics to help you optimize your production line and ensure garment longevity.

Key Takeaways

- Fine Mesh is essential for protecting ultra-delicate fibers like silk and lace from friction.

- Coarse Mesh allows for maximum water agitation, making it ideal for sturdier items like denim or sneakers.

- Material Choice impacts the heat resistance and longevity of the bag in industrial dryers.

- Structural Integrity depends on the GSM (Grams per Square Meter) and the specific weave pattern used during manufacturing.

1. What is the primary function of Laundry Bag Mesh ?

Protecting Delicates from Agitation

The primary role of the mesh is to create a physical buffer between sensitive garments and the mechanical action of the washing machine. By containing the item, the fabric prevents the stretching and twisting that often leads to permanent distortion.

Preventing Lost Items in the Wash

Beyond protection, these bags act as organizational tools that keep small accessories together during the cycle. This is particularly vital for infant clothing, socks, and intimate apparel that might otherwise disappear into the machine’s drainage system.

Manufacturer’s Note: Effective mesh must balance barrier protection with hydraulic permeability to ensure detergent reaches the fibers.

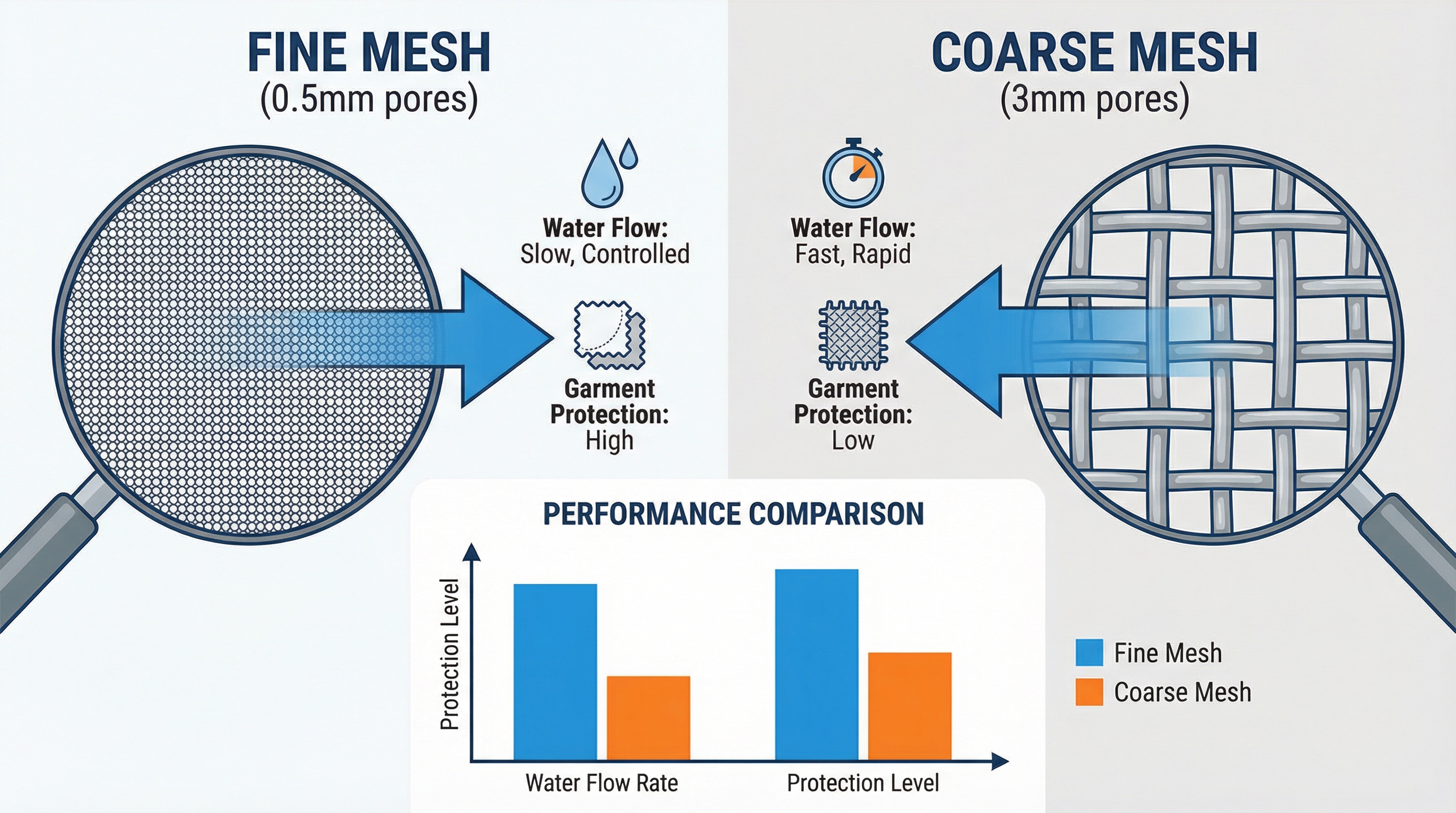

2. How does Fine Laundry Bag Mesh differ from coarse options?

The Science of Pore Size

Fine mesh features a tight weave with microscopic openings that prevent even the smallest hooks or sequins from poking through. This density is the gold standard for high-end lingerie and heirloom textiles where surface abrasion must be zero.

When Smoothness Matters Most

A smooth surface texture reduces the “sandpaper effect” during the spin cycle. For manufacturers looking to provide the highest level of care, using a soft tulle fabric provides the gentle touch necessary for luxury silk protection.

Here’s the thing: While fine mesh offers superior protection, it requires a more calculated approach to detergent concentration to ensure complete rinsing.

3. Which Laundry Bag Mesh offers the best durability for heavy loads?

Tensile Strength and Fabric Weight

For industrial or heavy-duty use, a higher GSM is required to withstand the weight of water-logged fabrics. Coarse mesh, often utilized in outdoor mesh applications , provides the ruggedness needed for washing sneakers or heavy denim without tearing.

Resilience Against Industrial Cycles

Heavy-duty mesh must maintain its shape through hundreds of high-heat cycles. Choosing a reinforced weave ensures that the bag does not lose its structural integrity when subjected to the high-speed centrifugal forces of commercial extractors.

Durability Checklist:

- High burst strength to prevent seam failure.

- Resistance to chemical degradation from bleach.

- Low shrinkage rates in high-temperature dryers.

- Abrasion-resistant fibers for longevity.

4. Can Power Mesh be used as a Laundry Bag Mesh ?

Benefits of 4-Way Stretch

Power mesh is unique due to its elastane content, providing a 4-way stretch that allows the bag to expand and contract. This flexibility is perfect for form-fitting bags that prevent internal movement of the garment.

Form-Fitting Protection for Delicates

By utilizing power mesh , manufacturers can create bags that “hug” the item, drastically reducing internal friction. This is an innovative solution for structured bras or athletic wear that requires specific shape retention during the wash.

But here is the kicker: The recovery of the fabric is just as important as the stretch. High-quality power mesh ensures the bag returns to its original dimensions, preventing the “sagging” common in low-grade laundry bags.

5. Why is drainage crucial in Laundry Bag Mesh design?

Balancing Water Flow and Barrier Protection

If the mesh is too dense, it may trap air or repel water, leading to “buoyancy” where the bag floats on top of the wash. Engineering the correct porosity ensures that soapy water flows in and dirty water flows out efficiently.

Avoiding Soap Scum Buildup

Poorly designed mesh can trap detergent particles, leading to white streaks on dark clothing. A well-calculated pore size ensures a thorough rinse, which is critical for users with sensitive skin or allergies to residual chemicals.

Drainage Efficiency Comparison

| Mesh Type | Water Permeability | Best Use Case | Risk Level | |

|---|---|---|---|---|

| Ultra-Fine | Low | Silk, Lace | Potential soap residue | |

| Standard Fine | Medium | Lingerie, Hosiery | Minimal risk | |

| Coarse | High | Sweaters, Denim | No residue risk |

6. Is Stiff Tulle a viable option for Laundry Bag Mesh ?

Maintaining Bag Structure

Stiff tulle is often overlooked in laundry applications, but its rigidity is a benefit for “cage-style” bags. Using stiff tulle helps the bag maintain a 3D shape, preventing heavy items from crushing delicate contents.

Structural Integrity in High Heat

The heat-set nature of stiff tulle ensures it doesn’t wilt in the dryer. This makes it an excellent choice for the side panels of laundry hampers or bags designed to stand upright during the loading process.

Wait, there’s more: The rigidity of stiff tulle also aids in the sorting process, as the bags do not collapse when empty, making them easier to load in high-volume environments.

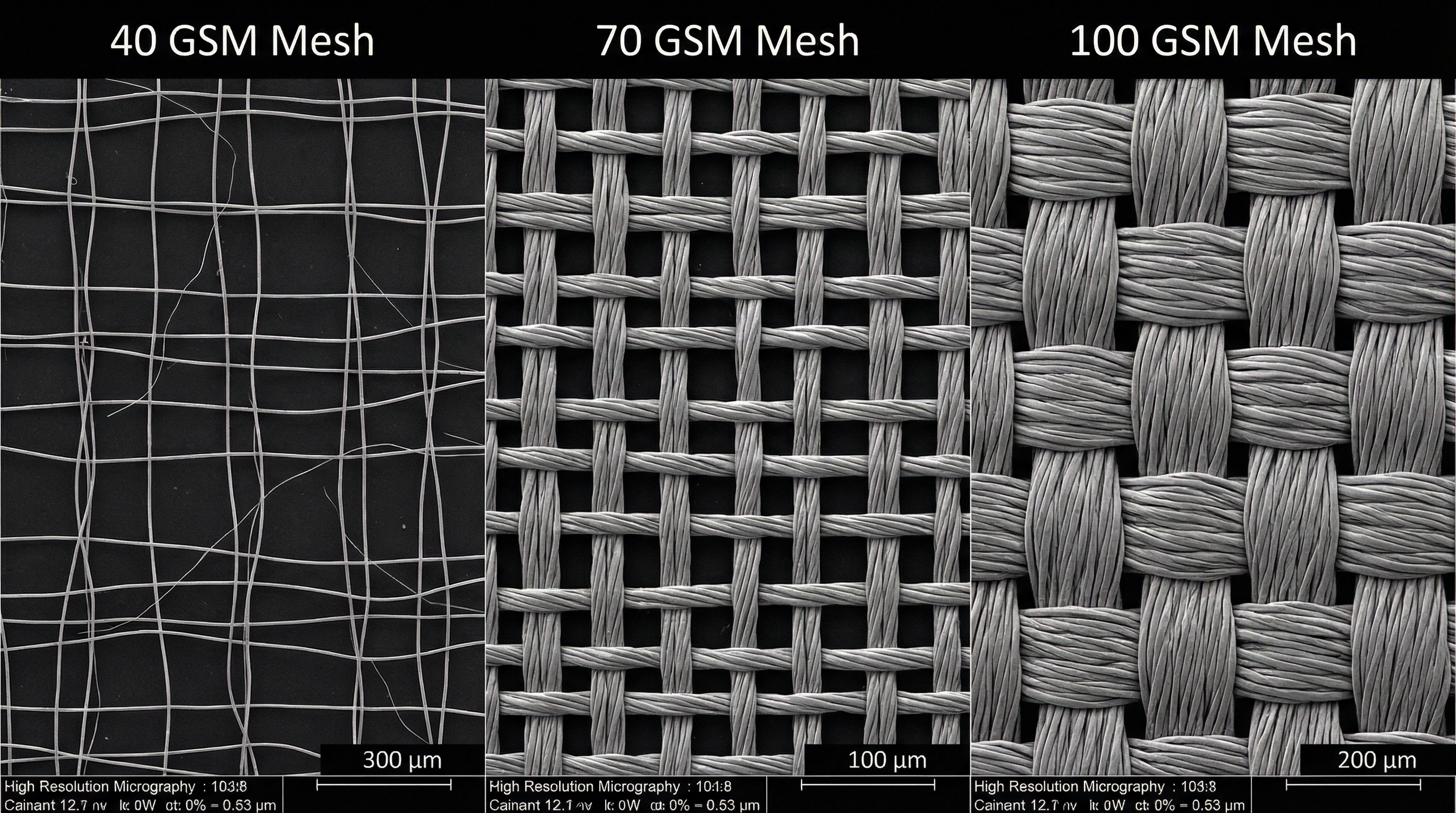

7. How do you select the right GSM for Laundry Bag Mesh ?

Decoding Grams Per Square Meter

GSM is the definitive measure of fabric density and weight. For laundry bags, a GSM between 40 and 70 is standard, providing a balance between lightweight handling and long-term durability.

Finding the Sweet Spot for Airflow

Higher GSM usually means a thicker fiber, which can provide better cushion but may reduce airflow. Manufacturers must test various weights to find the “sweet spot” where protection meets drying efficiency.

Key Performance Metrics:

- 40-50 GSM: Lightweight, fast-drying, ideal for travel bags.

- 60-80 GSM: Standard retail quality, durable for daily home use.

- 100+ GSM: Industrial grade, designed for hospitals and hotels.

8. What are the manufacturing standards for Laundry Bag Mesh ?

Choosing Between Nylon and Polyester

Polyester is the industry favorite for laundry bags because it resists stretching and dries quickly. Nylon offers superior strength but can yellow over time when exposed to high heat and certain detergents.

Heat Resistance and Shrinkage Factors

The fabric must be pre-shrunk during the manufacturing process. If the mesh shrinks more than 2-3%, zippers will ripple and the bag will become difficult to close, rendering it useless for the consumer. Precision in stitching and the choice of heat-resistant threads are non-negotiable for industrial-grade products.

9. How does Laundry Bag Mesh impact garment longevity?

Reducing Friction and Pilling

Pilling occurs when fibers rub together and break. By encasing a garment in a high-quality mesh, you eliminate the friction caused by the garment rubbing against the metal drum or other abrasive fabrics.

Keeping Fasteners Under Control

Exposed zippers and hooks are the enemies of a clean wash. A secure mesh bag traps these fasteners, ensuring they don’t snag on other items or damage the internal seals of the washing machine.

Now, let’s look at the final details: The consistent use of protective mesh can extend the lifespan of high-performance and luxury apparel by up to 50%.

10. Where can you source high-quality Laundry Bag Mesh ?

Benefits of Bulk Bolt Purchasing

For large-scale manufacturing, sourcing fabric by the bolt is the only way to ensure color consistency and price stability. Buying in bulk allows for rigorous quality control across every production run and reduces the per-unit cost significantly.

Partnering with Premium Manufacturers

Success in the textile industry relies on reliable supply chains. To explore custom mesh options or request samples for your next production line, contact our specialists to discuss your specific technical requirements and sourcing needs.

The choice of mesh is more than a technicality; it is a commitment to the lifespan of the clothes your customers love.

FAQ: Common Questions on Laundry Bag Fabrics

Can I use any mesh for silk garments?No, you should only use ultra-fine mesh to prevent the delicate silk fibers from being pulled through the holes. A smooth, non-abrasive surface is mandatory to avoid “fuzzing” the fabric.

What’s the best mesh for industrial washers?Coarse polyester mesh with a high GSM (80+) is the best choice. It allows for maximum water throughput and can withstand the intense mechanical stress of commercial-grade machines.

Can I put mesh laundry bags in the dryer?Most polyester mesh bags are dryer-safe on low to medium heat. Always check the specific heat-resistance rating of the fabric, as nylon or low-quality plastics can melt or warp at high temperatures.

What’s the best way to clean the mesh itself?The mesh bag cleans itself during every wash cycle. However, you should periodically inspect the seams for lint buildup and air-dry the bags completely to prevent any mildew growth.

Can I mix different mesh types in one load?Yes, you can wash fine and coarse mesh bags together. Just ensure that the wash cycle is set to the most delicate item’s requirements to ensure total safety.