Glitter tulle sheds because the decorative particles are typically applied with a topical adhesive that breaks under the mechanical stress of handling and needle penetration. You know the feeling: you start a project with a vision of high-fashion glamour, only to find your sewing room, your clothes, and your machine covered in a fine layer of inescapable dust. This glitter tulle shedding is not just a nuisance; it can actually compromise the integrity of your seams and the longevity of your garment. By understanding the bond between the glitter and the mesh, you can implement strategies to keep the sparkle on the glitter tulle shedding and out of your morning coffee.

Why is the glitter bond so fragile?

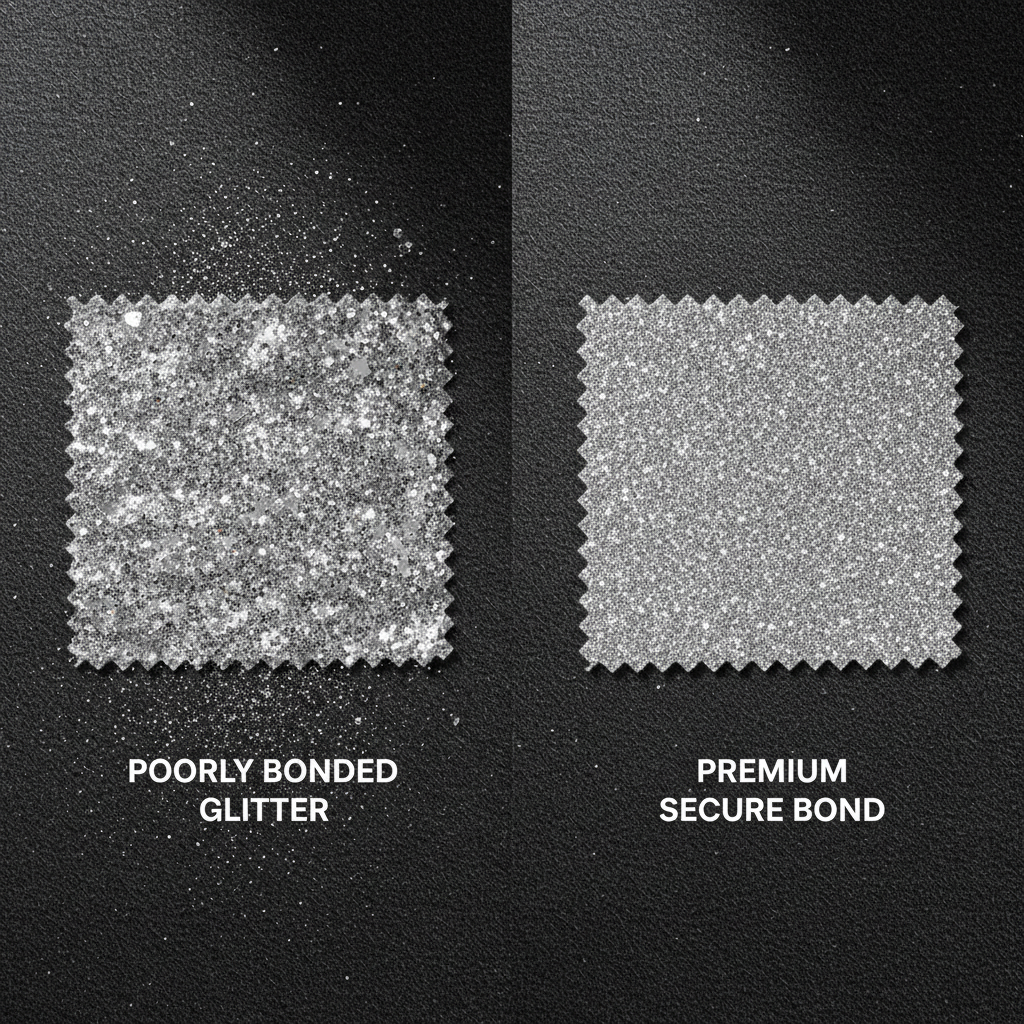

The primary reason for glitter tulle shedding is the topical nature of the application process. Unlike metallic threads that are woven into the structure, glitter is an additive component glued onto a polyester or nylon base. This surface-level bond is inherently prone to detachment when the fabric is manipulated.

Is the adhesive type to blame?

Low-quality adhesives often become brittle over time, losing their ability to grip the smooth fibers of the netting. When the glue dries too hard, it cannot flex with the movement of the tulle, leading to massive fallout.

But wait, there is more.

- Craft-grade glues lack polymer flexibility.

- Topical applications sit on the surface rather than penetrating the fiber.

- Environmental factors like low humidity can make these glues even more prone to cracking.

Does the mesh structure affect grip?

The open hex-mesh of tulle provides very little surface area for an adhesive to “anchor” itself. Because there is more air than fabric, the glitter particles are essentially hanging on by a thread.

Here is the kicker:

- Wider holes in the mesh provide fewer contact points for the glue.

- Smooth synthetic fibers offer less “tooth” for mechanical adhesion.

- High-density glitter layers create particle-on-particle friction that breaks the base bond.

Key Takeaway: The structural lack of surface area in tulle makes it nearly impossible for any adhesive to remain 100% permanent under stress.

| Factor | Impact on Shedding | Stability Level | |

|---|---|---|---|

| Fiber Texture | Smooth nylon leads to higher detachment rates. | Low | |

| Glue Flexibility | Brittle glues shatter during handling. | Very Low | |

| Mesh Density | Fine mesh holds glitter better than wide netting. | Moderate |

Understanding these physical limitations allows you to choose fabrics with finer mesh to improve glitter retention.

How does handling increase the fallout?

Every time you fold, pin, or shift your project, you are applying mechanical pressure that accelerates glitter tulle shedding . This constant manipulation acts like sandpaper, grinding the particles against each other and the table surface.

Does hand oil weaken the bond?

Natural oils from your skin can react with certain inexpensive adhesives, softening the bond and making the glitter easier to rub off. If you notice a “sparkle trail” following your fingertips, your skin chemistry may be accelerating the process.

Think about it this way:

- Sebum can act as a mild solvent for water-based glues.

- Friction from your palms creates heat that further destabilizes the adhesive.

- Frequent repositioning increases the total number of friction cycles.

Is movement the primary trigger?

Tulle is designed to be voluminous and airy, meaning it moves significantly more than a stable woven fabric. This kinetic energy is transferred to the rigid glitter flakes, which eventually “pop” off the flexible strands.

The truth is:

- Draping the fabric over a dress form causes gravity-induced friction.

- Folding the material for storage creates sharp creases that shatter the glue.

- Transporting the project in a bag leads to internal abrasion between layers.

Key Takeaway: Minimize the physical handling of your project to keep the glitter on the fabric and off your floor.

| Action | Risk of Shedding | Prevention Strategy | |

|---|---|---|---|

| Folding | High | Roll the fabric on a cardboard tube. | |

| Pinning | Medium | Use sewing clips to avoid puncturing. | |

| Draping | High | Support the weight with a flat surface. |

Reducing the number of times you touch the fabric directly correlates to a cleaner sewing environment.

Can mechanical stress shatter the glue?

High-frequency vibrations from your machine act as a physical disruptor that increases glitter tulle shedding. As the needle moves at hundreds of stitches per minute, it creates a “shatter zone” around every entry point, causing particles to detach.

What happens at high speeds?

Sewing at maximum speed increases the intensity of the vibration felt by the fabric. This energy travels through the mesh, vibrating loose any particles that were already tenuously attached to the fibers.

But wait, there is more.

- High-speed sewing generates friction heat at the needle site.

- Vibrations travel horizontally through the fabric layers.

- Rapid movement increases the “jerk” action of the feed dogs.

Does needle friction play a role?

The needle must physically push aside glitter flakes to enter the mesh structure. If the needle is dull, it crushes the particles instead of piercing them, causing the surrounding adhesive to fail immediately.

Here is the kicker:

- Blunt tips create a larger impact radius on the glue bond.

- The needle shaft rubs against the glitter during every cycle.

- Pushed particles can be driven into the bobbin race, causing mechanical clogs.

Key Takeaway: Slowing down your sewing speed reduces the vibration energy that shakes the glitter loose from the adhesive.

| Stress Factor | Effect on Fabric | Mitigation | |

|---|---|---|---|

| Vibration | Shakes loose weakly bonded flakes. | Reduce stitch speed. | |

| Impact | Cracks brittle glue at stitch points. | Use sharp needles. | |

| Friction | Sandpapers the surface finish. | Use tissue paper buffer. |

Managing the mechanical impact of your machine is the first step toward a cleaner workspace and better garment integrity.

Why do certain needles cause more mess?

The geometry of your needle determines how much damage it does to the surface treatment, directly influencing glitter tulle shedding . A needle that is too thick or the wrong shape will act like a hammer, shattering the delicate glitter bonds rather than passing through them.

Are ballpoint needles the worst choice?

Ballpoint needles are designed to push fibers aside rather than piercing them, which is ideal for knits but disastrous for glitter tulle. The rounded tip “plows” through the glitter, knocking off massive amounts of sparkle as it struggles to enter the mesh.

The truth is:

- Rounded tips cannot cleanly penetrate the plastic or foil glitter flakes.

- The “pushing” action creates a wider area of disturbance.

- Ballpoints often snag on the mesh, increasing mechanical tension.

How does needle heat impact glue?

During a long sewing session, your needle can become surprisingly hot. This heat can soften the topical adhesive, causing it to gum up your needle and pull more glitter off the fabric with every stroke.

Here is the kicker:

- Softened glue sticks to the needle eye, causing thread breaks.

- Heated adhesive loses its structural integrity and bond strength.

- The needle acts as a heat transfer tool, “melting” the bond locally.

Key Takeaway: A sharp, slim needle allows for clean entry with minimal displacement of the surrounding glitter particles.

| Needle Type | Penetration Style | Shedding Risk | |

|---|---|---|---|

| Ballpoint | Pushing/Displacing | Very High | |

| Universal | General Piercing | Moderate | |

| Microtex | Precision Sharp | Low |

Using the smallest possible sharp needle ensures that the fabric’s decorative finish remains intact during the construction process.

Can pre-treating the fabric save your sanity?

Stabilizing the fabric before you begin cutting can significantly reduce the glitter tulle shedding in your studio. Taking a few minutes to set the bond can make the difference between a successful project and a messy failure.

Is hairspray a viable solution?

A light mist of extra-hold, unscented hairspray can act as a temporary fixative for the loose particles. It provides an additional layer of “tack” that keeps the glitter in place while you manipulate the garment through your machine.

But wait, there is more.

- Hairspray is inexpensive and readily available for most sewists.

- It creates a thin, flexible film over the particles.

- Testing a scrap first is vital to ensure the drape isn’t ruined.

Should you use fabric stabilizers?

Professional spray-on stabilizers are designed to provide temporary stiffness and adhesion. These are often superior to hairspray because they are formulated to disappear over time without leaving a gummy residue on the fibers.

Here is the kicker:

- Water-soluble sprays provide a “shield” during construction.

- Stabilizers prevent the mesh from stretching and breaking the glue.

- They reduce the amount of static electricity generated by the fabric.

Key Takeaway: Pre-treating your fabric “locks” the glitter in place, providing a cleaner experience during the most intense handling phases.

| Treatment | Duration | Effectiveness | |

|---|---|---|---|

| Hairspray | Temporary | Moderate | |

| Fabric Sealant | Semi-Permanent | High | |

| Outdoor Shake | Instant | Low (removes loose only) |

Applying a fixative is a professional trick that keeps your workspace pristine and your machine running smoothly.

Is your sewing machine a glitter magnet?

Your sewing machine is designed to move fabric with precision, but that very movement creates friction that increases glitter tulle shedding . The metal components, particularly the feed dogs and presser foot, can act as abrasive surfaces that strip the glitter away.

Do feed dogs act as abrasives?

The sharp teeth of the feed dogs are meant to grip the fabric, but on glitter tulle, they act like a grater. As they pull the fabric forward, they physically scrape the glitter off the underside of the mesh.

The truth is:

- Standard feed dogs have sharp metal ridges.

- Pressure is concentrated on a very small area of the fabric.

- Scraped glitter falls directly into the bobbin case.

How does the presser foot drag?

A standard metal presser foot applies downward force while the fabric moves beneath it. This “dragging” action creates a trail of friction that can leave a visible line of missing glitter along your seam line.

Think about it this way:

- Metal feet do not glide easily over plastic-based glitter.

- High presser foot tension increases the abrasive force.

- A non-stick or Teflon foot can reduce this surface drag.

Key Takeaway: Reducing presser foot pressure and using a non-stick foot will help prevent the machine from “sanding” the glitter off.

| Machine Part | Action | Consequence | |

|---|---|---|---|

| Feed Dogs | Gripping and Pulling | Scrapes bottom glitter. | |

| Presser Foot | Constant Downward Force | Drags across top glitter. | |

| Needle Plate | Friction Point | Collects static-charged dust. |

By modifying your machine settings and parts, you can turn a hostile environment into a glitter-friendly one.

Does fabric quality dictate the shed rate?

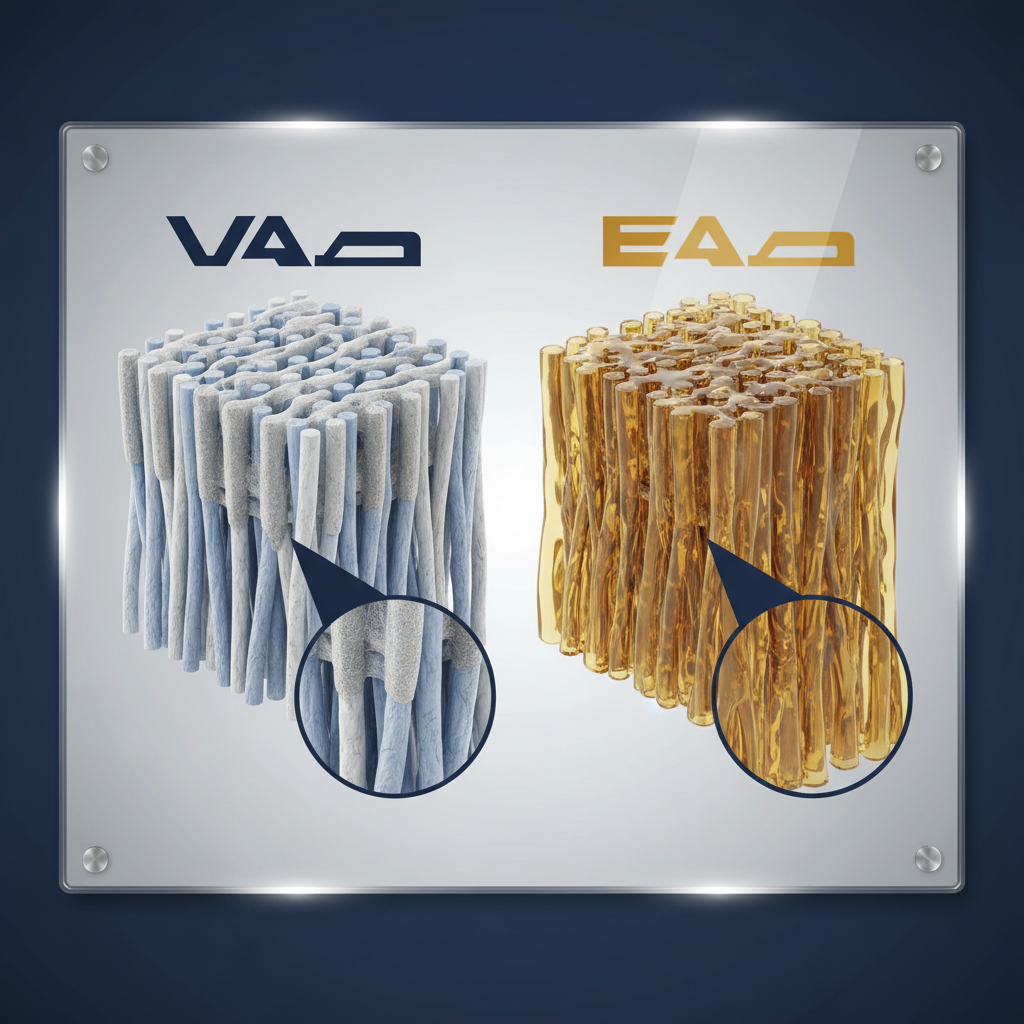

The chemical composition of the adhesive is the single most important factor in preventing glitter tulle shedding. Premium textiles use resin-based bonding agents that are engineered to survive the mechanical stresses of garment construction and wear.

Are resin bonds better than glue?

Polymer resins are more flexible and have higher “tack” than standard white glues. This allows the bond to stretch and move with the tulle rather than cracking and falling off at the first sign of tension.

But wait, there is more.

- Resins are often heat-cured for better durability.

- They resist moisture and hand oils more effectively.

- Higher-quality resins don’t become yellow or brittle over time.

Is heat-set glitter more durable?

Some high-end glitter fabrics use a thermo-transfer process where the glitter is essentially melted into a resin layer. This creates a much more permanent bond that can even withstand gentle laundering and frequent handling.

Here is the kicker:

- Heat-setting creates a “fused” layer rather than a “sitting” layer.

- The glitter is partially embedded in the fabric fibers.

- This method produces the lowest possible shed rate in the industry.

Key Takeaway: Investing in premium resin-bonded glitter tulle will save you hours of cleanup and ensure a professional finished product.

| Adhesive Grade | Chemical Base | Durability | |

|---|---|---|---|

| Economy | Water-based Glue | Very Low | |

| Professional | Acrylic Resin | High | |

| Luxury | Heat-Set Polymer | Excellent |

Choosing your materials wisely is the most effective way to prevent the glitter storm before you even start your project.

What is the best way to manage cleanup?

Managing the fallout is just as important as the sewing itself to prevent glitter tulle shedding from damaging your equipment. If you allow glitter to accumulate, it can enter the internal workings of your machine and cause permanent damage to the motor.

Can you use compressed air?

Never use canned air to clean a machine covered in glitter particles. The force of the air will drive the tiny particles deeper into the bushings and gears, where they can act as an abrasive.

The truth is:

- Compressed air moves the problem rather than solving it.

- Particles can get stuck in the lubrication, creating a “grinding paste.”

- Static electricity keeps the glitter stuck to the plastic internals.

Should you clean your bobbin case daily?

When working with glitter tulle, you should clean your bobbin area every two hours. The fine dust settles in the bobbin race, causing tension issues and eventually seizing the hook assembly if left unchecked.

Think about it this way:

- A small micro-vacuum is the safest tool for glitter removal.

- A lint roller is essential for the table and your clothes.

- Static-reducing sprays can help the dust fall to the floor for sweeping.

Key Takeaway: Constant, proactive cleaning prevents glitter from migrating from your sewing table into the delicate internals of your machine.

| Tool | Purpose | Warning | |

|---|---|---|---|

| Micro-Vacuum | Bobbin and Hook | Avoid sucking up small screws. | |

| Lint Roller | Table and Clothes | Change sheets frequently. | |

| Microfiber Cloth | Fine Dust Removal | Don’t shake inside the house. |

A clean workspace isn’t just about aesthetics; it is about protecting your expensive sewing equipment from abrasive damage.

Which seam finishes trap loose particles?

The way you finish your seams can either contain the mess or let glitter tulle shedding continue indefinitely. By using enclosed seams, you can “lock” the raw, cut edges of the fabric where the shedding is most severe.

Are French seams worth the effort?

French seams are the gold standard for sheer fabrics because they completely enclose the raw edge. For glitter tulle, this means the most vulnerable part of the fabric is tucked away where it cannot shed onto the wearer.

But wait, there is more.

- Enclosing the edge prevents “fringe shedding” from the mesh.

- The double layer of fabric provides extra stability for the stitches.

- It creates a clean, professional look on transparent garments.

Does lining the garment help?

Sandwiching a layer of glitter tulle between a lining and an outer layer of plain tulle can effectively trap the particles. This “capsule” method ensures that any loose glitter stays inside the garment rather than on the skin or furniture.

Here is the kicker:

- Silk organza makes an excellent stabilizing lining.

- Plain tulle “buffer layers” prevent the glitter from scratching.

- The friction is contained between the two layers of fabric.

Key Takeaway: Enclosing raw edges and using lining layers act as a physical barrier that prevents the glitter from escaping the garment.

| Seam Type | Effectiveness | Complexity | |

|---|---|---|---|

| Zig-Zag Edge | Low | Easy | |

| Serged/Overlock | Moderate | Moderate | |

| French Seam | High | Intermediate |

Strategic seam construction is the final line of defense against long-term shedding once the garment is in use.

Will the shedding ever actually stop?

The intensity of glitter tulle shedding follows a bell curve, peaking during construction and eventually plateauing. While it rarely stops 100%, a finished garment will lose significantly fewer particles once the loose “factory” layers are gone.

Does the first wash help?

A gentle hand wash in cold water can remove the majority of the particles that were loosened during the sewing process. This “initial purge” makes the garment much more wearable and less messy for the end-user in the long run.

The truth is:

- Never use a washing machine or dryer for glitter tulle.

- Agitating the fabric in a basin removes “clinging” dust.

- Air-drying keeps the remaining adhesive bond stable and intact.

How do professional skirts endure?

High-end theatrical and bridal skirts often undergo a “shake out” process before they ever leave the professional atelier. Professionals know that some shed is inevitable, so they manage the fallout before the client ever receives the final piece.

Here is the kicker:

- Static-reducing sprays help the fabric hang without attracting dust.

- Garment bags with soft linings prevent abrasion during transport.

- Once the “loose” layer is gone, the “set” layer remains stable.

Key Takeaway: While total prevention is impossible, a finished and cleaned garment will shed significantly less than raw yardage.

| Stage | Shedding Volume | Management | |

|---|---|---|---|

| Cutting | Maximum | Work over a cleanable floor. | |

| Sewing | High | Clean machine every 2 hours. | |

| Finished Wear | Low | Gentle hand wash only. |

By managing the lifecycle of the fabric, you can produce stunning garments that don’t leave a trail of chaos behind them.

Conclusion

Successfully navigating the challenges of specialty fabrics requires a blend of patience, the right tools, and a proactive cleanup strategy. By understanding that friction is the ultimate enemy of the adhesive bond, you can adjust your sewing speed and handling to preserve the sparkle. Enclosing seams and pre-treating the netting are essential steps for any professional-grade project. We envision an industry where brilliance doesn’t come at the cost of machine longevity or studio cleanliness. If you have further questions or need specific advice on your textile choice, please contact us today for expert guidance.

FAQ

Can I wash my glitter tulle in a washing machine?No, the mechanical agitation and heat will strip the adhesive and ruin both the fabric and your washer. Hand washing in a basin is the only safe method for preserving the glitter.

What’s the best needle for sewing with glitter?A sharp Microtex needle is the best choice because its slim profile and honed tip pierce the fabric without shattering the glue bond. This prevents the “shatter zone” that causes massive fallout.

How do I know if my glitter tulle is high quality?Perform a “rub test” on a small corner of the fabric. High-quality tulle uses resin bonds that will only release fine dust rather than large, visible flakes when handled.

Can I iron glitter tulle to remove wrinkles?No, direct heat will melt the adhesive and the synthetic mesh. Use a steamer from a distance or a very low-heat iron with a thick pressing cloth as a buffer.

What’s the best way to cut glitter tulle without a mess?Use a rotary cutter on a self-healing mat to minimize fabric shifting. This reduces the friction that occurs with traditional scissors, keeping the glitter attached to the mesh.