Mesh is a textile characterized by its open-weave, net-like structure that facilitates maximum airflow. Designers often struggle to find fabrics that provide high ventilation while maintaining structural integrity for professional projects. Without proper airflow, garments trap heat and moisture, leading to wearer discomfort and skin irritation in high-performance environments. Learning what fabric is mesh is the solution to creating breathable, durable products that stand the test of time.

What is the basic definition of what fabric is mesh?

Mesh fabric is a unique textile defined by a porous, net-like structure where yarns are knitted or woven to create closely spaced holes. This construction allows air to circulate freely, making it a staple in performance and industrial sectors. You will find it primarily made from synthetic fibers like polyester, nylon, or spandex to ensure it maintains its shape under stress.

What are the core materials used?

Synthetic fibers are the preferred choice for manufacturing because they offer the necessary tensile strength and moisture resistance. While cotton can be used for softer, lifestyle applications, polyester and nylon dominate the wholesale market.

- Polyester: Known for being hydrophobic and durable.

- Nylon: Offers superior abrasion resistance and strength.

- Spandex: Integrated for elasticity and recovery.

- Cotton: Used in pique knits for a softer hand feel.

But that’s not all. The material choice directly dictates how the fabric will perform in different environments.

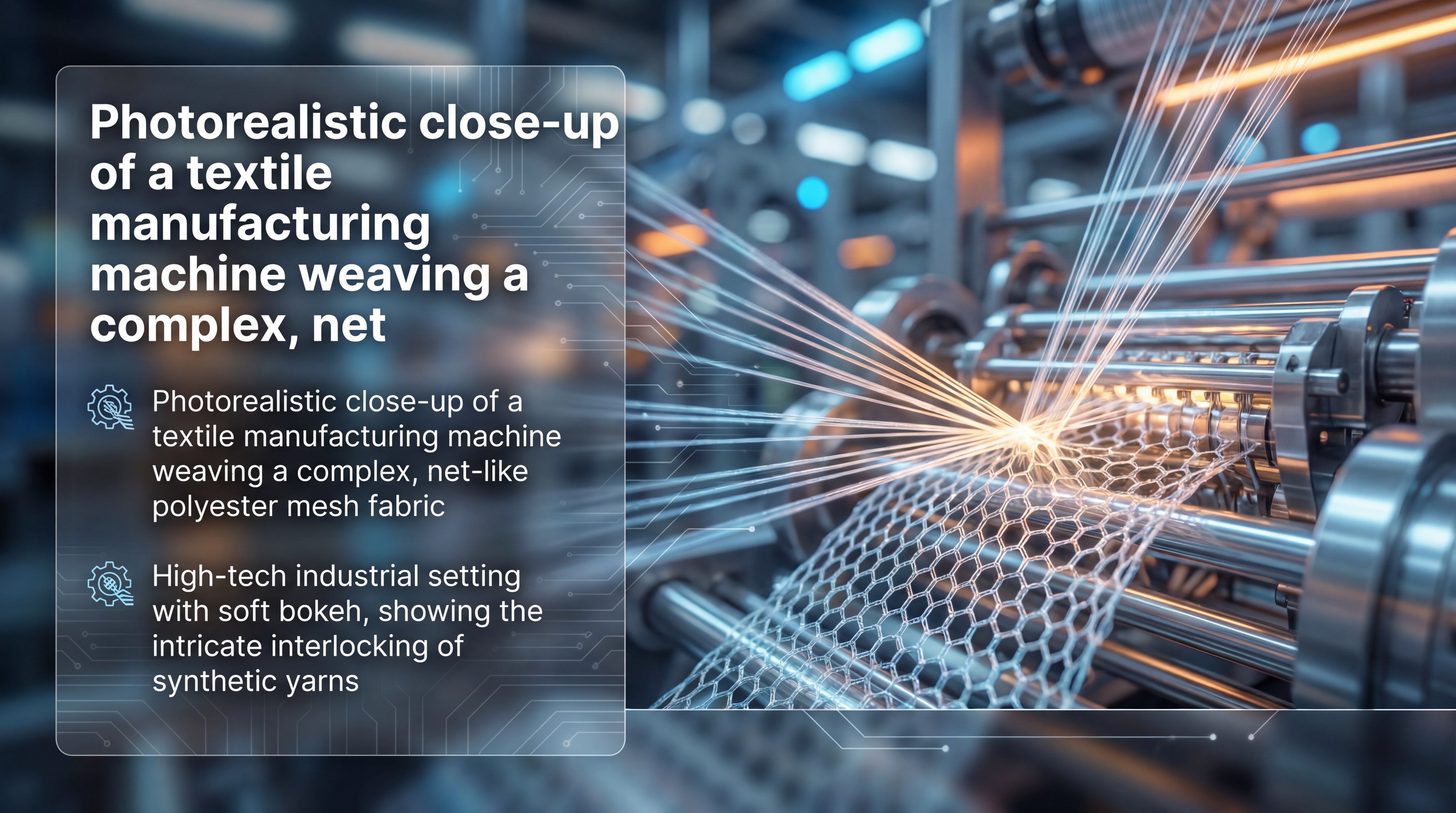

How does the manufacturing process work?

The process involves specialized knitting or weaving techniques that lock yarns into a grid-like pattern to prevent unraveling. High-speed machines create thousands of precise apertures that define the fabric’s weight and transparency.

Think about this. The density of these holes determines whether the fabric is a fine tulle or a heavy-duty industrial screen.

Key Takeaway: Understanding the technical composition of mesh allows you to select the right fiber for your specific production needs, ensuring longevity and performance.

| Feature | Description | |

|---|---|---|

| Structure | Open-weave, net-like porous surface | |

| Primary Materials | Polyester, Nylon, Spandex, Cotton | |

| Construction | Knitted or Woven | |

| Primary Benefit | Exceptional breathability and weight reduction |

The fundamental construction of mesh focuses on maximizing airflow while maintaining a lightweight profile across all material types.

What fabric is mesh and what are the main benefits?

When exploring what fabric is mesh , the primary focus is on how the porous structure facilitates moisture-wicking and heat dissipation. This material acts as a ventilation system for the body, allowing sweat to evaporate quickly during intense physical activity. It is the gold standard for any application where temperature regulation is a priority.

Why is breathability the top feature?

The thousands of tiny holes in the fabric create a path for air to move directly through the textile. This prevents the “greenhouse effect” common in tightly woven synthetics that trap heat against the skin.

- Moisture Management: Rapidly moves sweat away from the body.

- Cooling Effect: Constant airflow lowers surface temperature.

- Skin Health: Reduces the risk of rashes caused by trapped moisture.

- Comfort: Feels weightless even when layered.

Wait, there’s more. Beyond cooling, the structural integrity of the weave ensures the fabric doesn’t cling to the skin.

How does mesh offer strength and flexibility?

Interlocking yarns provide high tensile strength and abrasion resistance while allowing the material to adapt to the wearer’s movement. Even with its open structure, high-quality mesh resists pilling and tearing under significant stress.

Here is the kicker. Modern spandex blends allow mesh to stretch in four directions without losing its original shape.

Key Takeaway: The combination of extreme ventilation and mechanical durability makes mesh the most versatile choice for performance-driven design.

| Characteristic | Benefit to User | |

|---|---|---|

| Breathability | Reduces skin irritation and promotes cooling | |

| Durability | Resists pilling and tearing under stress | |

| Flexibility | Supports 4-way stretch in performance apparel | |

| Lightweight | Ideal for layering without adding bulk |

Mesh provides a unique balance of cooling properties and structural resilience that traditional solid textiles cannot match.

What are the common types of what fabric is mesh?

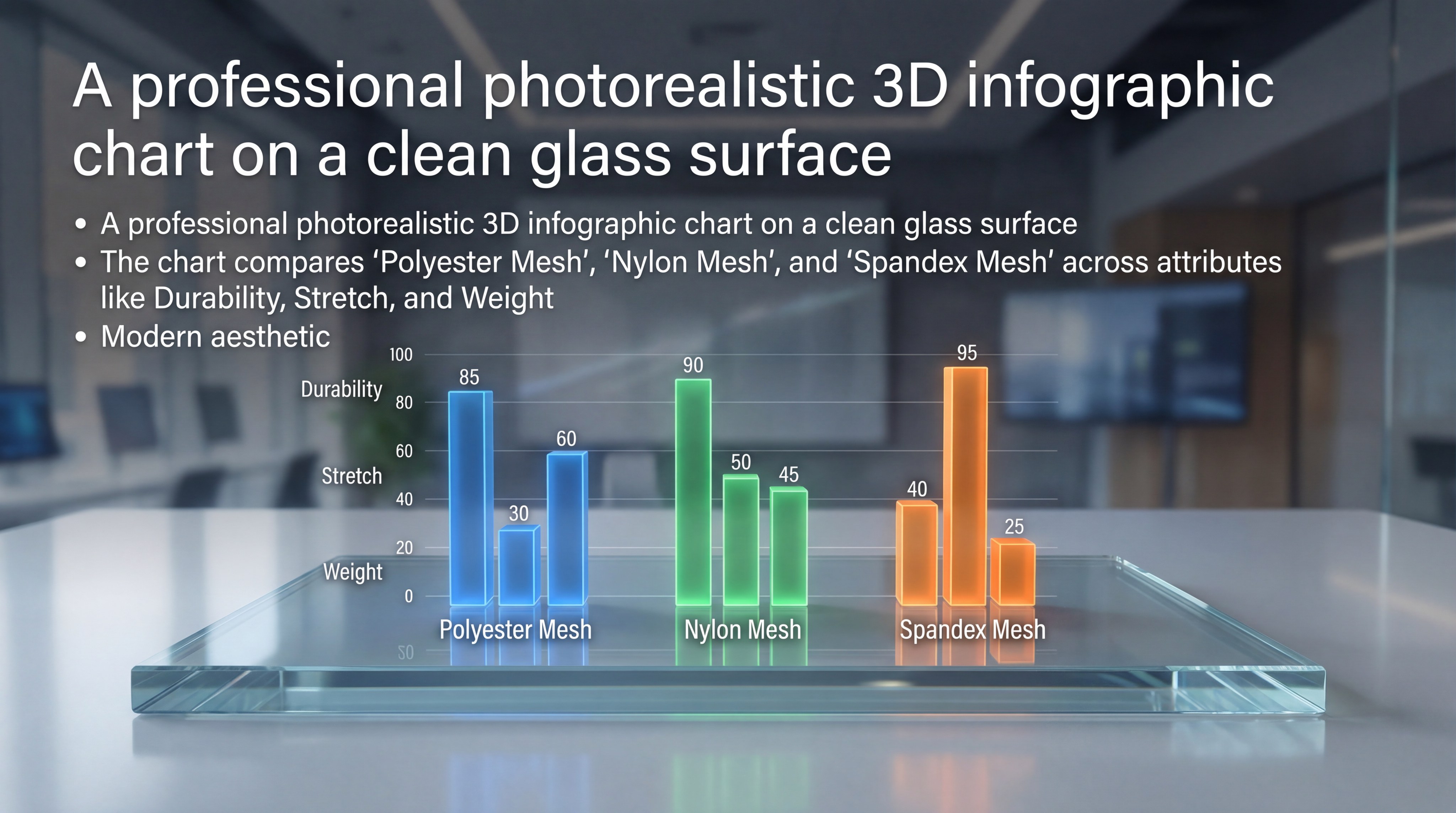

Identifying what fabric is mesh requires looking at the fiber content, with polyester, nylon, and power mesh being the three most prevalent wholesale categories. Each type is engineered for specific load-bearing or aesthetic requirements. You must choose based on whether you need moisture-wicking properties, abrasion resistance, or high-compression stretch.

What makes polyester mesh ideal for activewear?

Polyester is the industry standard for athletic jerseys and workout gear because it is naturally hydrophobic. This means it does not absorb water, allowing it to dry incredibly fast during and after exercise.

- Colorfastness: Holds vibrant dyes even after repeated washing.

- Stability: Does not shrink or stretch out of shape easily.

- Cost-Effective: Offers a high performance-to-price ratio for bulk orders.

- Softness: Modern knits are finished to be smooth against the skin.

But that’s not all. Polyester is also highly resistant to UV rays, making it great for outdoor gear.

When should you choose nylon mesh?

Nylon mesh should be your first choice for heavy-duty applications like bags, tents, or industrial filters. It has a higher strength-to-weight ratio than polyester and offers better resistance to friction and rough handling.

It gets even better. Nylon remains flexible in cold temperatures, which is vital for outdoor and winter equipment.

Key Takeaway: Selecting between polyester and nylon depends on whether you prioritize moisture management or pure mechanical strength.

| Material Type | Best Use Case | Key Attribute | |

|---|---|---|---|

| Polyester | Sportswear / Jerseys | Moisture-wicking | |

| Nylon | Bags / Tents / Filters | High abrasion resistance | |

| Cotton Pique | Polo Shirts | Softness and absorbency |

Different material bases allow mesh to transition seamlessly from soft apparel to rugged industrial applications.

How do you define what fabric is mesh for athletic gear?

In the professional world of what fabric is mesh , athletic mesh is defined by its ability to support high-intensity movement while keeping the athlete dry. These fabrics are often knitted with a specific “birds-eye” or “dimple” pattern to enhance the surface area for evaporation. Designers rely on these textiles to create jerseys that feel virtually weightless.

What is the role of power mesh in performance?

Power mesh stands out due to its high spandex content, providing the compression and support needed for compression wear and sports bras. It bridges the gap between a standard breathable net and a functional support garment.

- Recovery: Snaps back to its original shape instantly.

- Support: Provides firm pressure without restricting breathing.

- Versatility: Used in everything from yoga pants to medical braces.

- Invisible Finish: Often used as a lining for a smooth appearance.

Think about this. Power mesh allows for “zonal ventilation,” where specific areas of a garment are more breathable than others.

Why is stretch power mesh vital for shapewear?

Stretch power mesh provides body-contouring support while remaining invisible under clothing, making it the primary material for the shapewear industry. Its 4-way stretch ensures that it moves with the body rather than resisting it.

Here is the kicker. It offers a “cooling” compression that prevents the wearer from overheating while wearing multiple layers.

Key Takeaway: Performance mesh variants like power mesh are essential for any garment that requires both high elasticity and structural support.

| Variant | Application | Stretch Type | |

|---|---|---|---|

| Power Mesh | Lingerie, Shapewear | High Compression | |

| Stretch Mesh | Dancewear, Activewear | 4-Way Stretch | |

| Athletic Mesh | Sports Uniforms | Breathable Knit |

Specialized athletic meshes provide the necessary compression and airflow required for modern high-performance apparel.

What makes tulle different from what fabric is mesh?

Tulle is distinguished from other types of what fabric is mesh by its incredibly fine, hexagonal netting structure that is typically lightweight and sheer. While standard mesh is often functional and rugged, tulle is primarily decorative and aesthetic. It is most commonly used in bridal veils, evening gowns, and ballet costumes to create volume without adding weight.

Is tulle considered a fine hexagonal mesh?

Yes, tulle is technically a variant of mesh that uses a specific hexagonal knit to achieve its delicate appearance. The holes are much smaller and more uniform than those found in athletic or industrial mesh.

- Fine Gauge: Created with very thin yarns for a misty look.

- Transparency: Offers the highest level of sheerness in the mesh family.

- Drapability: Soft versions can flow like liquid.

- Volume: Stiff versions can stand out to create dramatic shapes.

Wait, there’s more. Tulle can be made from nylon, polyester, or even silk for high-end couture.

How do stiff and soft tulle applications differ?

Stiff tulle is engineered with a starch-like finish to hold its shape, making it perfect for tutus and structural underskirts. Soft tulle, on the other hand, is treated to be silky and fluid for veils and dress overlays.

But that’s not all. You can also find embellished tulle with glitter or embroidery for specialized fashion projects.

Key Takeaway: Tulle is the “elegant” sibling of the mesh family, used when aesthetic volume and transparency are more important than moisture-wicking.

| Tulle Type | Primary Use | Texture | |

|---|---|---|---|

| Soft Tulle | Bridal Veils, Gowns | Fine, silky feel | |

| Stiff Tulle | Tutus, Petticoats | Rigid, holds shape | |

| Embellished | Couture, Costumes | Beaded or glittered |

Tulle offers a delicate, decorative alternative to functional mesh while maintaining the characteristic open-weave structure.

Can you explain what fabric is mesh for industrial uses?

For manufacturers asking what fabric is mesh in a utility context, the focus shifts toward load-bearing capabilities, chemical resistance, and drainage. Industrial mesh is often made from heavy-duty monofilament yarns that can withstand significant environmental stress. These materials are essential for everything from filtration systems to safety equipment.

Why is mesh preferred for bag production?

Mesh is the ideal material for produce bags, laundry bags, and gym sacks because it allows moisture to escape while keeping contents secure. This prevents the growth of mold and odors that would occur in a solid plastic or fabric bag.

- Visibility: Allows users to see contents without opening the bag.

- Drainage: Water flows through instantly, making it perfect for aquatic gear.

- Weight: Reduces the overall tare weight of luggage and storage.

- Durability: Heavy-duty polyester mesh can hold hundreds of pounds.

Think about this. High-strength mesh is used as a reinforcement layer inside other materials to prevent ripping.

How does automotive mesh meet safety standards?

Automotive interior mesh is designed to meet strict fire-retardant and UV-resistance standards for use in seat backing and door panels. It provides the necessary ventilation to keep passengers cool while ensuring the seats remain durable over years of use.

Here is the kicker. These meshes are often “3D” or “Spacer” meshes that provide a cushioned, breathable layer.

Key Takeaway: Industrial mesh is a high-performance material valued for its strength, visibility, and ability to handle moisture in harsh conditions.

| Industry | Application | Essential Property | |

|---|---|---|---|

| Luggage | Pockets, Linings | Visibility & Airflow | |

| Automotive | Seat Covers, Panels | UV & Fire Resistance | |

| Safety | High-Viz Vests | Lightweight Durability |

Industrial applications leverage the open structure of mesh to solve drainage, visibility, and airflow challenges in heavy-duty environments.

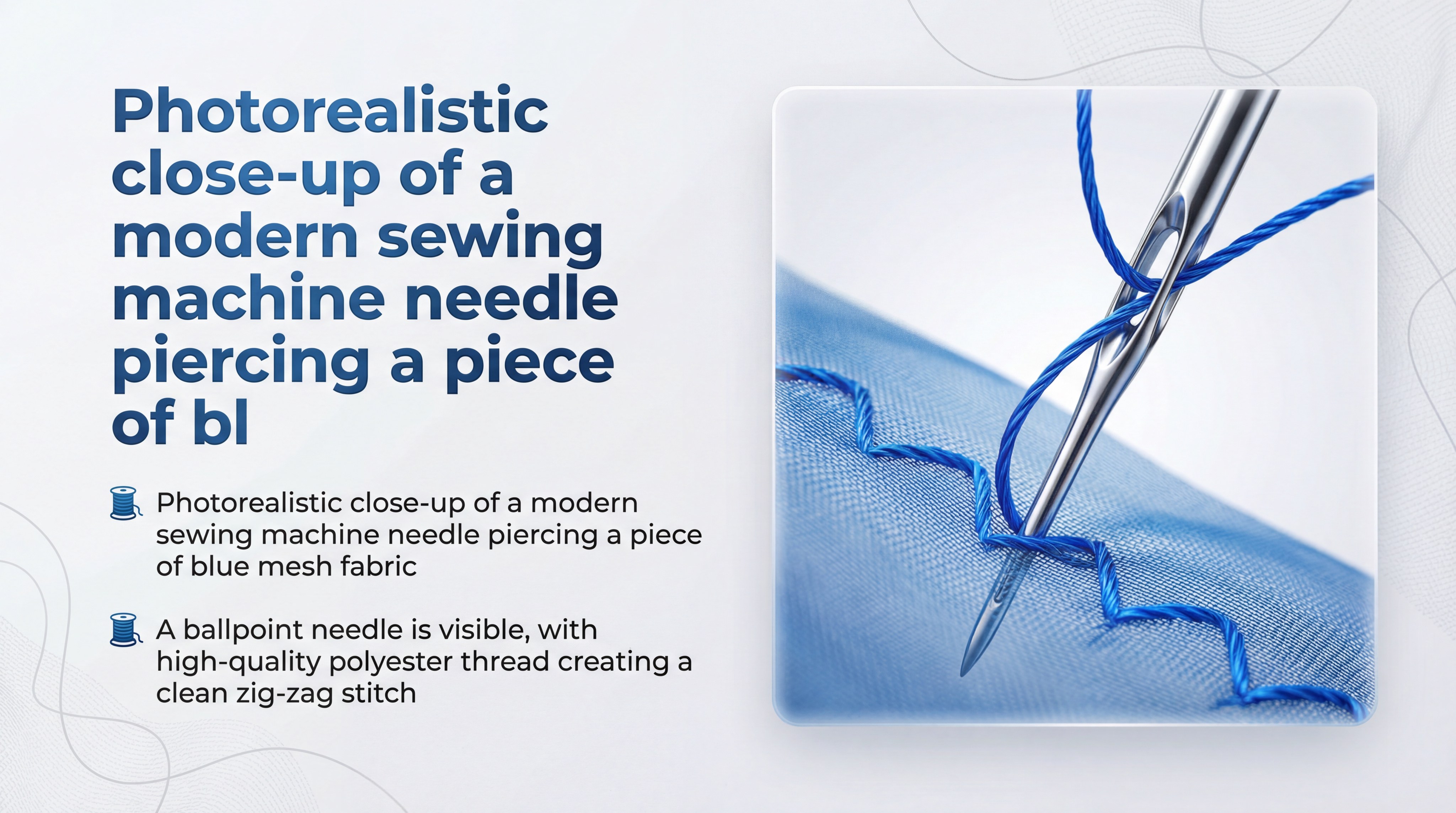

What are the best ways to sew what fabric is mesh?

Sewing what fabric is mesh requires specific tools and techniques because the open holes and slippery synthetic fibers can cause traditional needles to skip or snag. Professional manufacturers use ballpoint needles and high-quality polyester threads to ensure the seams are as durable as the fabric itself. Proper handling during the cutting and sewing stages prevents the mesh from distorting or stretching out of alignment.

Which needles and threads work best?

You should always use a ballpoint or “stretch” needle, which has a rounded tip designed to slide between the yarns rather than piercing and breaking them. This prevents small holes from turning into large runs or tears.

- Polyester Thread: Offers the strength and slight give needed for synthetic fabrics.

- Ballpoint Needle: Protects the integrity of the knit structure.

- Zig-Zag Stitch: Allows the seam to stretch along with the fabric.

- Overlock/Serger: The best way to finish raw edges and prevent fraying.

Wait, there’s more. Using a walking foot on your sewing machine can help feed the slippery mesh evenly.

How can you prevent snagging or slipping?

Using a water-soluble stabilizer or tissue paper underneath the mesh while sewing can provide the necessary traction for the machine’s feed dogs. This prevents the fabric from being sucked down into the needle plate.

Think about this. Pinning mesh can be difficult, so using wonder clips is a safer way to hold layers together without creating permanent holes.

Key Takeaway: Using the correct specialized needles and stabilizers is the only way to achieve professional, snag-free results when working with mesh.

| Tool/Method | Purpose | Recommendation | |

|---|---|---|---|

| Needle Type | Prevent holes/snags | Ballpoint or Stretch | |

| Stitch Type | Maintain stretch | Zig-zag or Serger | |

| Cutting | Accuracy | Rotary cutter on flat surface |

Success in sewing mesh depends on selecting tools that respect the fabric’s unique knit and elastic properties.

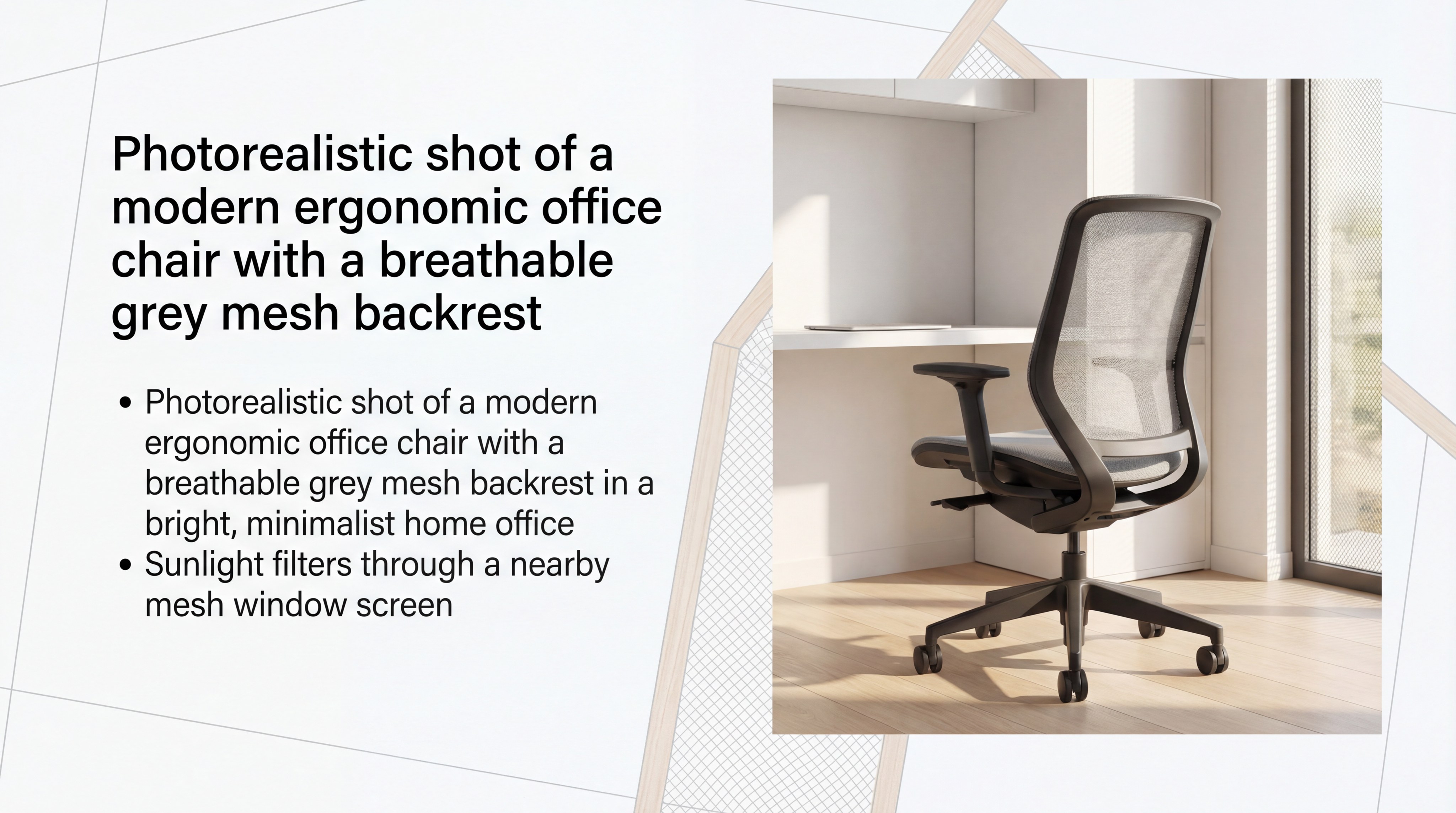

How can you identify what fabric is mesh for home decor?

Identifying what fabric is mesh in a home environment is easy when you look at ergonomic furniture and modern window treatments. Mesh has become a preferred material for office chairs because it contours to the body while allowing heat to escape through the backrest. It is also found in screen doors and outdoor shades where visibility and airflow are required.

Where is mesh used in modern interior design?

Designers use fine-gauge mesh for window treatments that filter light while maintaining a view of the outdoors. It provides a more contemporary, industrial look compared to traditional lace or heavy curtains.

- Office Seating: Provides lumbar support and temperature control.

- Window Screens: Keeps insects out while letting fresh air in.

- Speaker Grilles: Protects electronics while allowing sound waves to pass.

- Storage Organizers: Helps closets stay ventilated and tidy.

But that’s not all. Mesh is also used in bedding as a perimeter strip to help mattresses breathe.

Does mesh fabric provide UV resistance for outdoors?

Yes, specialized outdoor mesh is treated with UV inhibitors to prevent it from becoming brittle or fading under constant sunlight. These fabrics are essential for patio furniture, sunshades, and pool enclosures.

It gets even better. Many outdoor meshes are also coated with PVC to make them waterproof and easy to clean.

Key Takeaway: Home decor mesh focuses on enhancing comfort through ergonomics and providing durable solutions for light and air management.

| Application | Benefit | Material Focus | |

|---|---|---|---|

| Curtains | Light Filtering | Fine Sheer Mesh | |

| Furniture | Ergonomic Support | Heavy-duty Power Mesh | |

| Outdoor | Weather Protection | UV-treated Polyester |

Mesh in home decor combines modern aesthetics with functional benefits like light filtering and ergonomic ventilation.

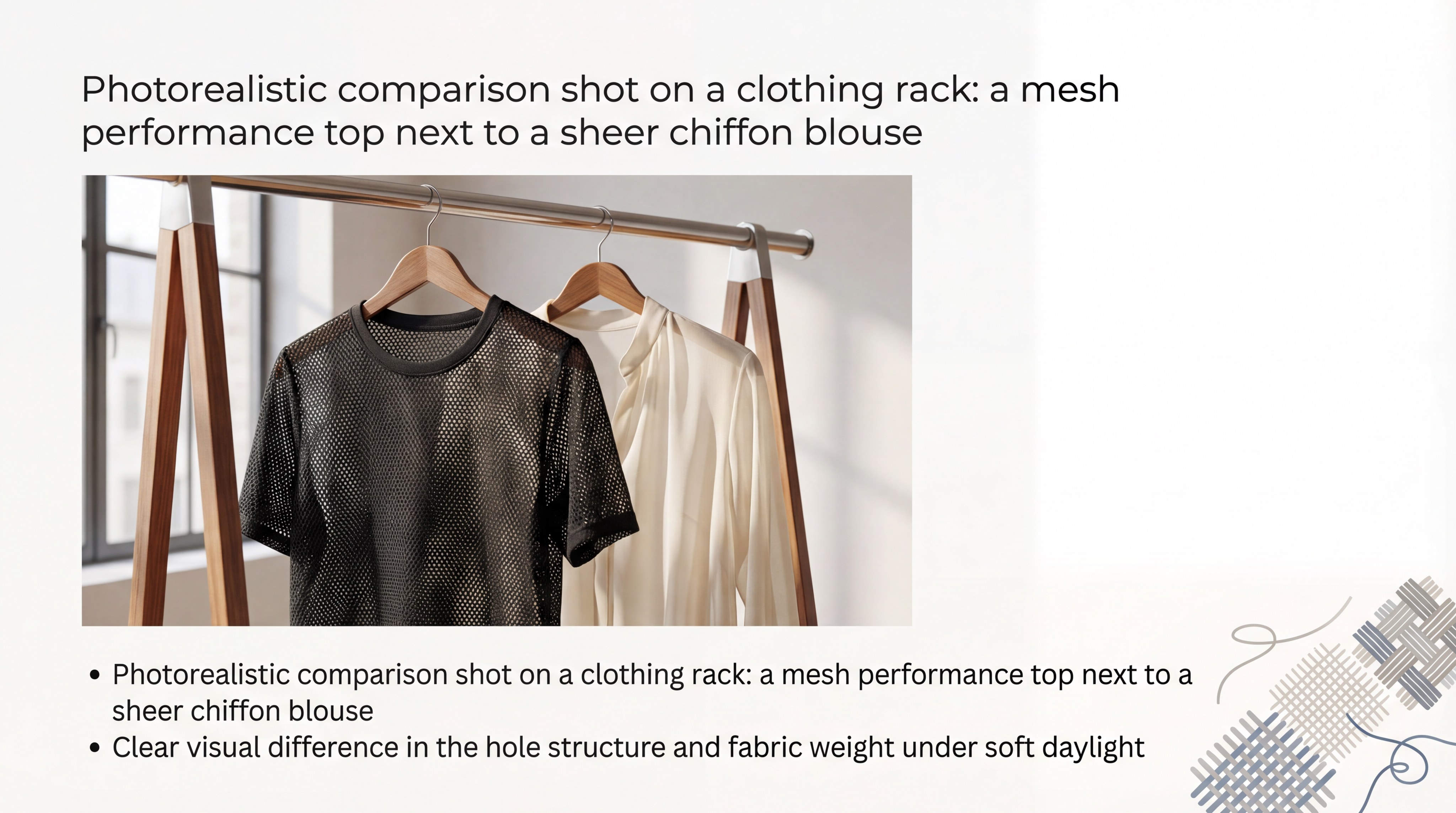

What is the difference between what fabric is mesh and sheer?

The fundamental difference lies in the visibility of the hole structure and the intended use of the textile. While both are translucent, mesh is defined by a deliberate, visible grid of holes designed for function, whereas sheer fabrics like chiffon have a tight, nearly invisible weave designed for aesthetic drape. Mesh is typically a performance-oriented material, while sheer fabrics are usually reserved for fashion-focused layering.

Does the weave pattern separate mesh from sheer?

Yes, mesh is almost always a knit or an open-weave that creates a net-like appearance with clear apertures. Sheer fabrics are woven so tightly that you cannot see individual holes, though light still passes through the thin fibers.

- Mesh: Visible holes, high airflow, functional performance.

- Sheer: Invisible holes, low airflow, aesthetic drape.

- Stretch: Mesh often has more stretch; sheers are often rigid.

- Texture: Mesh can be textured or “crunchy”; sheers are usually smooth.

Wait, there’s more. Mesh is much more likely to be snag-resistant than a delicate sheer silk.

Which fabric offers better durability and support?

Mesh is significantly more durable and supportive, especially in the case of power mesh, which can hold its shape under high tension. Sheer fabrics are delicate and can easily tear at the seams if they are subjected to any significant stress.

Here is the kicker. You can use mesh for structural reinforcement, but sheer is strictly for surface-level beauty.

Key Takeaway: Choose mesh for any project requiring airflow and durability; choose sheer for projects where a smooth, misty aesthetic is the goal.

| Feature | Mesh Fabric | Sheer Fabric | |

|---|---|---|---|

| Hole Visibility | Clearly visible | Minimal to none | |

| Main Use | Function/Sport | Decoration/Fashion | |

| Stretch | Often high | Usually low |

The distinction between mesh and sheer is a matter of prioritizing functional ventilation over decorative translucency.

Why buy from a wholesaler for what fabric is mesh?

Purchasing what fabric is mesh from a dedicated wholesaler allows you to secure the best possible prices while ensuring consistency across large production runs. Wholesalers offer technical expertise and a wider range of specialized mesh types, such as flame-retardant or high-compression variants, that are rarely available at retail. By buying in bulk, you maximize your profit margins and stabilize your supply chain.

How does bulk purchasing save on fabric costs?

When you buy by the bolt or the container, the price per yard drops significantly compared to retail pricing. This is vital for manufacturers who need to keep their Cost of Goods Sold (COGS) competitive in the global market.

- Volume Discounts: Drastic price reductions for larger quantities.

- Shipping Efficiency: Lower logistics costs when ordering in bulk.

- Inventory Control: Ensures you have enough stock for seasonal demands.

- Priority Access: Get first pick of new colors and technical innovations.

But that’s not all. Wholesale relationships often lead to custom manufacturing options for specific technical needs.

What quality standards should you look for?

You must evaluate wholesale mesh based on its stretch recovery, colorfastness, and the uniformity of the hole pattern. High-quality mesh should not have “slubs” or irregularities in the knit that could lead to weak points in the finished garment.

Think about this. A reliable wholesaler will provide technical data sheets detailing the weight (GSM) and tensile strength of the fabric.

Key Takeaway: Sourcing through a wholesaler provides the financial and technical advantages necessary to scale a professional fashion or industrial brand.

| Benefit | Impact on Business | Metric | |

|---|---|---|---|

| Best Prices | Lower Cost of Goods Sold | Per Yard Savings | |

| Consistency | Uniformity across production | Dye-lot Matching | |

| Availability | Reliable stock for orders | Lead-time reduction |

Wholesale sourcing is the strategic foundation for any business requiring high-quality, cost-effective mesh fabrics.

Ready to elevate your production?

Finding the perfect balance of breathability and durability is easy when you have access to the world’s finest textiles. At TulleMesh, we take pride in providing premium materials that meet the rigorous standards of professional designers and industrial manufacturers alike. Whether you need high-compression power mesh or delicate bridal tulle, our experts are here to help you source the right fabric at the most competitive wholesale prices. To start your next project with the best materials on the market, contact us today and experience the difference that quality makes.

FAQ

Can I use mesh fabric for outdoor furniture?Yes, but you must ensure it is a UV-treated polyester or PVC-coated mesh to prevent sun damage and weather-related wear.

What’s the best way to wash mesh garments?Machine wash on a gentle cycle in a mesh laundry bag and air dry to prevent the synthetic fibers from snagging or melting in high heat.

Does power mesh lose its stretch over time?High-quality power mesh maintains its elasticity for years, but low-grade versions may eventually sag if the spandex fibers break down.

Is mesh fabric safe for sensitive skin?Yes, because it promotes airflow and reduces moisture buildup, it is often recommended for people prone to heat-related skin irritations.

Can I dye synthetic mesh fabrics at home?It is difficult; synthetic fibers like polyester and nylon require specialized disperse dyes and high temperatures that are hard to achieve without professional equipment.