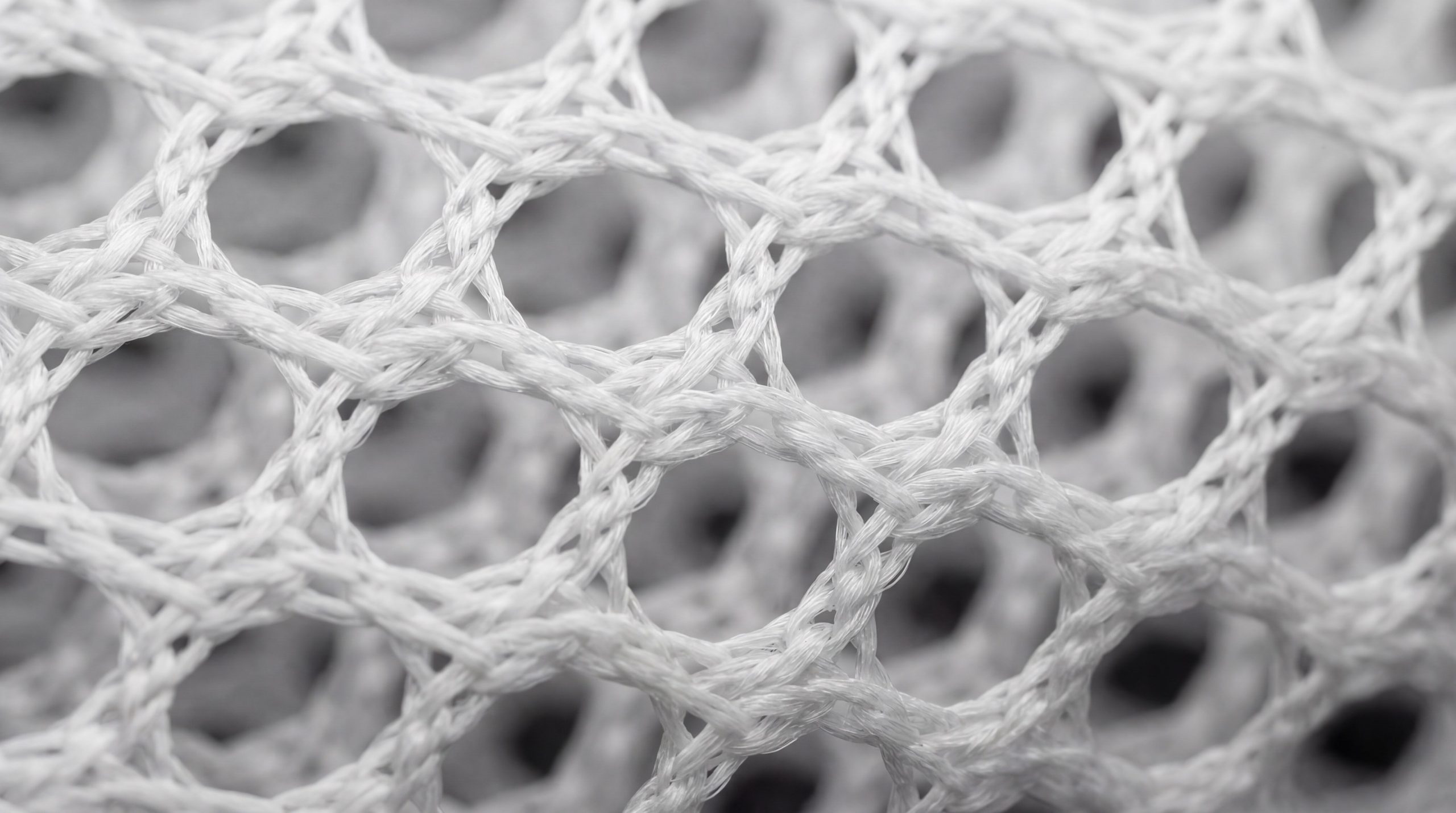

Mesh is a lightweight, permeable fabric characterized by its open-hole structure and loosely woven or knitted appearance. Finding a material that offers high breathability without sacrificing structural durability is a major challenge for modern designers and manufacturers. Many settle for solid textiles that trap heat and moisture, leading to discomfort and poor performance in high-intensity environments. You can solve this ventilation crisis by understanding what fabric is mesh , a versatile solution that optimizes airflow across fashion and industrial applications.

What exactly defines mesh fabric?

Mesh is defined by its distinctive pattern of open spaces or “holes” created through specific weaving or knitting techniques. When determining what fabric is mesh , the primary identifier is the deliberate gap between yarns that allows air, light, and liquids to pass through freely. These gaps are measured by holes per inch (HPI), typically ranging from 6 to 16. The structure provides a unique combination of transparency and strength that solid fabrics cannot replicate.

What are the core characteristics of open weaves?

The most striking feature is the sheer nature of the material, which varies based on the density of the weave. Most variants offer exceptional stretch and recovery, particularly when synthetic fibers are used.

But there is more.

- Extreme breathability and ventilation

- Rapid moisture evaporation

- High resistance to pilling or bubbling

- Lightweight heft for easy layering

How does mesh differ from standard textiles?

Standard textiles prioritize a closed surface to provide warmth or total coverage, whereas mesh prioritizes the movement of elements. It is engineered to be a functional barrier that does not obstruct airflow.

Key Takeaway: Mesh is a functional textile defined by intentional porosity and high breathability, making it the ideal choice for environments requiring thermal regulation and moisture management.

| Feature | Mesh Fabric | Standard Solid Fabric | |

|---|---|---|---|

| Structure | Open-hole / Porous | Closed / Solid weave | |

| Airflow | Maximum | Restricted | |

| Stretch | High (usually) | Variable |

This comparison highlights why mesh is irreplaceable in technical applications where standard weaves would fail to provide cooling.

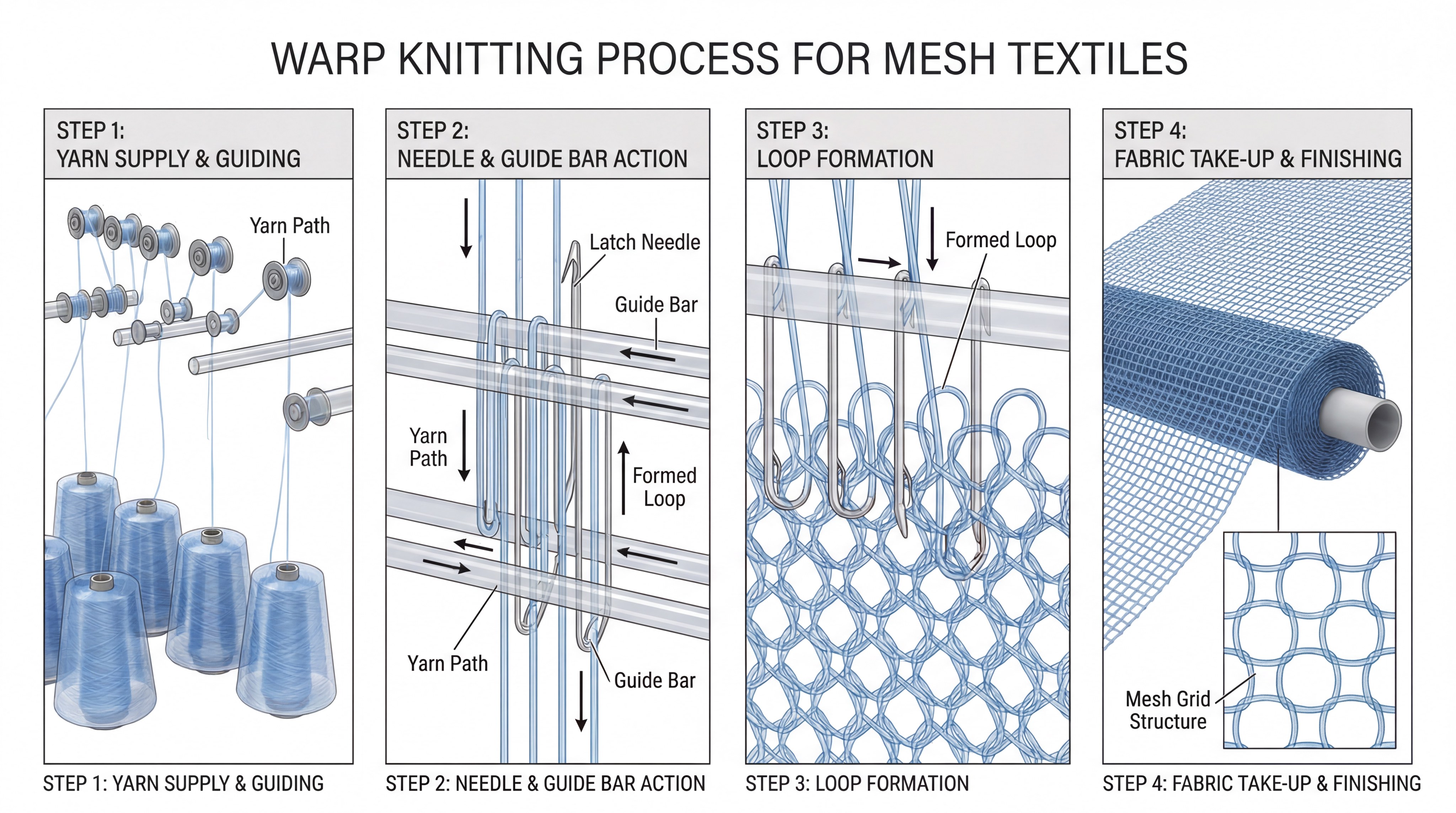

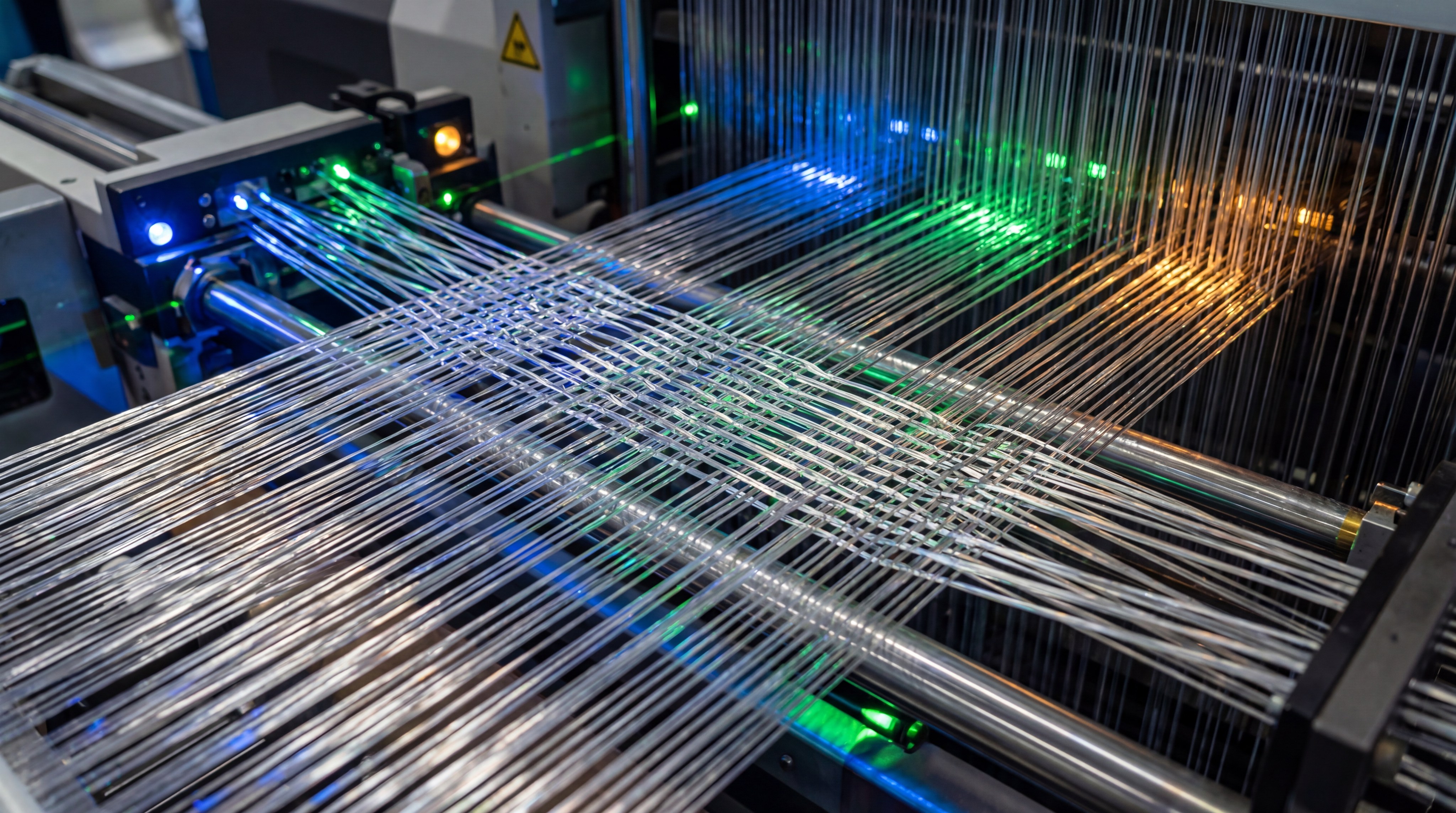

How is mesh fabric manufactured today?

Modern mesh is manufactured primarily through a process called warp knitting, where yarns are interlaced zigzag-wise along the length of the fabric. To understand what fabric is mesh in a technical sense, one must look at how the machinery creates loops that form a stable, non-fraying grid. This method ensures that if one hole is snagged, the entire structure does not unravel. Large-scale industrial machines can produce thousands of meters of consistent netting in a single run.

What is the polymer extraction process?

The journey begins with the refining of petroleum oil to extract polyamide or polyester monomers. These chemical components are then reacted with acids to form solid polymers that are later melted.

Here is the kicker:

- Polymers are forced through spinnerets

- Molten strands are cooled into filaments

- Filaments are wound onto spools

- Threads are then prepared for the loom

How does the knitting stage create the grid?

During the knitting stage, thousands of needles work in sync to loop the yarn into the desired hexagonal or square pattern. This precision allows for the creation of specific HPI counts tailored to the fabric’s end use.

Key Takeaway: The manufacturing of mesh is a high-tech synthetic process that relies on polymer chemistry and warp knitting to achieve its signature durability and permeability.

| Stage | Process | Outcome | |

|---|---|---|---|

| Extrusion | Melting polymer chips | Synthetic yarn filaments | |

| Knitting | Warp-knit interlacing | Open-hole fabric grid | |

| Finishing | Heat setting | Dimensional stability |

Understanding these stages helps designers select the right mesh based on the precision and consistency of the manufacturing process.

Which raw materials are used for mesh?

Synthetic polymers like polyester and nylon are the primary raw materials used to create the majority of mesh fabrics available today. When investigating what fabric is mesh , it becomes clear that these materials are favored for their high tensile strength and resistance to environmental stress. Polyester is often chosen for its moisture-wicking properties, while nylon offers superior elasticity. These synthetic origins allow the fabric to remain lightweight while providing the necessary “give” for activewear.

Why is polyester the preferred choice?

Polyester fibers are naturally hydrophobic, meaning they do not absorb water, which allows sweat to evaporate quickly. This makes it the standard for athletic gear and jerseys.

But wait, there is more:

- Resistant to shrinking and stretching

- Dries significantly faster than cotton

- Holds vibrant dyes exceptionally well

- Low production cost for high volume

When is nylon used instead of polyester?

Nylon is typically reserved for applications where extreme durability or a softer touch is required. It is frequently found in high-end lingerie, delicate evening wear, and heavy-duty industrial screens.

Key Takeaway: The choice between polyester and nylon dictates the fabric’s performance, with polyester excelling in moisture control and nylon offering superior strength and stretch.

| Material | Primary Benefit | Common Application | |

|---|---|---|---|

| Polyester | Moisture Wicking | Athletic Jerseys | |

| Nylon | Elasticity / Softness | Lingerie / Tulle | |

| Recycled PET | Sustainability | Eco-conscious fashion |

Choosing the correct raw material is the first step in ensuring your mesh project meets its specific performance requirements.

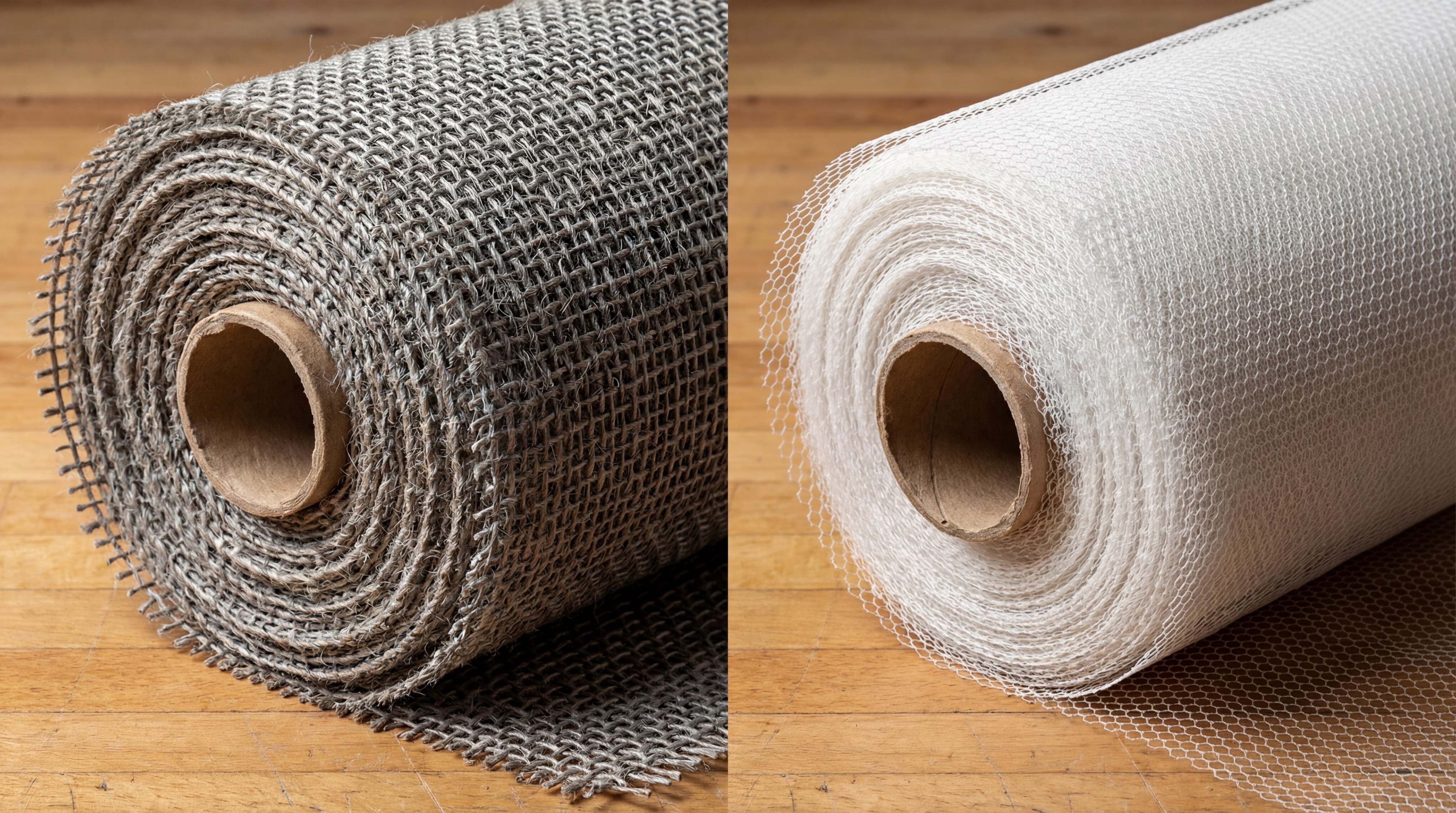

What are the most popular mesh variants?

Mesh variants are categorized by their weave density, stretch capability, and intended aesthetic, ranging from delicate bridal tulle to heavy powernet. To identify what fabric is mesh in your closet, look at the hole shape; tulle often features a fine hexagonal pattern, while athletic mesh uses a larger square grid. Power mesh is a specific variant that incorporates elastane to provide compression for shapewear and medical garments. Each variant serves a unique purpose based on its balance of transparency and tension.

What defines tulle and bridal netting?

Tulle is a very fine, lightweight mesh that is often starched to provide volume and structure for gowns. It is synonymous with luxury and ceremony due to its misty, ethereal appearance.

Check this out:

- Extremely small HPI for a sheer look

- Available in soft or stiff finishes

- Can be embellished with glitter or beads

- Ideal for veils and tutus

What makes power mesh different?

Power mesh is engineered for “power” and support, meaning it can hold its shape under significant tension. It is the backbone of the shapewear industry and high-performance athletic leggings.

Key Takeaway: From the softness of bridal tulle to the compression of power mesh, the variety of mesh types allows it to serve both decorative and functional roles.

| Variant | Characteristics | Best Used For | |

|---|---|---|---|

| Tulle | Fine, sheer, lightweight | Bridal / Fashion | |

| Power Mesh | High stretch, firm support | Shapewear / Activewear | |

| Sandwich Mesh | Three-layered, cushioned | Footwear / Backpacks |

Matching the variant to the application is essential for achieving the desired drape or support in a finished product.

How is industrial mesh fabric utilized?

Industrial mesh is designed for high-stress environments where strength, air circulation, and visibility are critical safety factors. Determining what fabric is mesh in an industrial context involves checking for high-denier yarns that can withstand heavy loads or weather exposure. You will find these rugged nets in everything from automotive cargo systems to commercial filtration units. Its ability to secure items while remaining lightweight makes it a superior alternative to solid plastic or heavy canvas.

How is mesh used in the automotive sector?

Automotive manufacturers utilize mesh for seat pockets, ceiling linings, and cargo nets to reduce vehicle weight. The fabric allows passengers to see stored items easily while keeping them securely in place during travel.

Think about it:

- Reduces overall vehicle weight

- Improves interior airflow

- Provides visible storage solutions

- Resists wear from constant friction

Is mesh effective for industrial filtration?

Yes, specialized mesh screens are used to filter particles in water treatment and chemical processing. The precise hole sizes ensure that only specific sizes of matter can pass through the system.

Key Takeaway: Industrial mesh provides the durability of hard materials with the flexibility of textiles, making it indispensable for safety, storage, and filtration.

| Application | Benefit | Mesh Type | |

|---|---|---|---|

| Cargo Nets | Securement / Visibility | Heavy-duty Nylon | |

| Safety Vests | Breathability / High-Vis | Polyester Mesh | |

| Filtration | Particle control | High-precision weave |

Industrial-grade mesh ensures that performance remains consistent even under the most demanding physical and environmental conditions.

Why is mesh the standard for activewear?

Activewear relies on mesh because it is the only textile that can facilitate the rapid cooling required during intense physical exertion. Every athlete understands what fabric is mesh because it appears in the “hot zones” of jerseys, leggings, and footwear to allow heat to escape the body. Without these breathable panels, moisture would be trapped against the skin, causing chafing and overheating. Its ability to stretch also ensures that the garment moves with the athlete rather than restricting their range of motion.

How does moisture-wicking actually work?

Moisture-wicking occurs when the fabric pulls sweat away from the skin to the exterior of the garment. The open-hole structure of the mesh then exposes that moisture to airflow for instant evaporation.

It gets better:

- Prevents bacterial growth from sweat

- Reduces garment weight when wet

- Maintains body temperature balance

- Enhances overall athletic comfort

Why is durability important in sports mesh?

Sports mesh must endure constant stretching, washing, and physical contact on the field. The warp-knit construction ensures that the fabric remains intact even after seasons of heavy use.

Key Takeaway: Mesh is the ultimate performance fabric because it combines advanced thermal regulation with the physical resilience needed for professional sports.

| Sportswear Item | Role of Mesh | Primary Material | |

|---|---|---|---|

| Running Shoes | Foot ventilation | Sandwich Mesh | |

| Gym Shorts | Airflow / Comfort | Polyester Knit | |

| Sports Bra | Support / Cooling | Power Mesh |

Integrating mesh into activewear designs is a proven strategy for improving user performance and garment longevity.

Where is mesh fabric primarily produced?

China currently leads the global market as the largest producer and exporter of all types of mesh textiles. When sourcing what fabric is mesh for large-scale production, most brands look to East Asian hubs due to their advanced infrastructure and integrated supply chains. These regions have mastered the chemical processes required for high-quality polyester and nylon extrusion. While Western nations maintain some specialized production, the sheer volume and cost-efficiency of Asian factories dominate the international landscape.

Why does China dominate mesh production?

China’s dominance is the result of decades of investment in textile technology and synthetic fiber research. Their factories can transition between different mesh types—from tulle to industrial net—with incredible speed.

The deal is this:

- Massive economies of scale

- Integrated chemical refineries

- Advanced automated knitting technology

- Expertise in global logistics

Are there other significant production hubs?

India, Indonesia, and Vietnam are also major players, focusing on different niches within the mesh market. India often excels in decorative and embroidered mesh, while Vietnam is a hub for athletic footwear mesh.

Key Takeaway: Global mesh production is centered in Asia, where specialized factories provide the technical expertise and scale required for modern textile demands.

| Region | Specialty | Production Scale | |

|---|---|---|---|

| China | All variants / Industrial | Global Leader | |

| India | Decorative / Tulle | High | |

| Southeast Asia | Footwear / Activewear | Rapidly Growing |

Sourcing from these hubs allows brands to access the latest innovations in mesh technology at competitive price points.

What factors influence the cost of mesh?

The cost of mesh is determined by the raw material quality, the complexity of the weave pattern, and any additional chemical treatments applied. You will find that what fabric is mesh in a luxury boutique costs significantly more than the mesh found in a discount gym bag due to fiber fineness. Fine-gauge tulle made with high-tenacity nylon or silk naturally commands a higher price than basic polyester netting. Additionally, custom colors and performance coatings like flame retardants or UV protection will increase the final wholesale price.

How does weave complexity affect price?

Simple square weaves are the fastest and cheapest to produce on standard looms. Hexagonal patterns or multi-layered “spacer” meshes require more complex machinery and longer production times, driving up costs.

The kicker is:

- Higher HPI increases yarn usage

- Custom dyes require specialized vats

- Small batch orders carry premiums

- Complex patterns slow down machines

Does the fiber type impact the budget?

Absolutely. Recycled polyester (rPET) often costs more than virgin polyester due to the processing required to clean and re-polymerize plastic waste.

Key Takeaway: Pricing for mesh is highly variable, reflecting the technological input and material purity required for specific fashion or industrial uses.

| Factor | Low Cost | High Cost | |

|---|---|---|---|

| Fiber | Virgin Polyester | Silk / Recycled Nylon | |

| Pattern | Square Grid | Hexagonal / 3D Spacer | |

| Treatment | None | Flame Retardant / Antimicrobial |

Understanding these cost drivers helps in budgeting for textile projects without compromising on essential performance features.

Does mesh fabric impact the environment?

Mesh fabric has a significant environmental footprint because it is almost exclusively made from non-biodegradable, petroleum-based synthetic fibers. When evaluating what fabric is mesh in the context of sustainability, one must consider the carbon-heavy extraction of fossil fuels. Furthermore, the open structure of mesh can lead to the shedding of microplastics during every wash cycle, which eventually enter our waterways. As a synthetic product, mesh garments can persist in landfills for hundreds of years without breaking down.

What are the main pollution concerns?

The primary concern is the release of nitrous oxide during nylon production, a greenhouse gas significantly more potent than carbon dioxide. Additionally, water used in the dyeing process can become contaminated with chemicals if not treated properly.

Think about it:

- Fossil fuel dependency

- Microplastic shedding in oceans

- Chemical runoff from dyeing

- Zero biodegradability in nature

Can mesh be recycled effectively?

Yes, polyester mesh can be recycled into new fibers, reducing the need for virgin petroleum. Many brands are now switching to rPET to close the loop in textile production.

Key Takeaway: While mesh offers unmatched performance, its synthetic nature poses long-term ecological challenges that require innovative recycling and filtration solutions.

| Impact Area | Problem | Solution | |

|---|---|---|---|

| Waste | Landfill persistence | Circular recycling (rPET) | |

| Water | Microplastic shedding | Washing bag filters | |

| Energy | High carbon footprint | Renewable energy factories |

By choosing recycled variants and practicing responsible washing, the environmental impact of mesh can be mitigated.

Which mesh certifications should you seek?

Professional buyers and designers look for international certifications to verify the quality, safety, and environmental standards of their mesh. To confirm what fabric is mesh and safe for consumer use, look for the OEKO-TEX Standard 100 or Global Recycle Standard (GRS) labels. These certifications ensure that the fabric is free from harmful levels of toxic substances and that any recycled claims are independently verified. Following these standards protects your brand from liability and ensures the end user receives a high-quality product.

Why is ISO 9001 important for mesh?

ISO 9001 certification indicates that a factory follows strict quality management systems. This ensures that every roll of mesh has consistent hole sizes, strength, and color across different production batches.

The best part?

- Guarantees batch-to-batch consistency

- Ensures structural safety standards

- Simplifies global trade compliance

- Builds consumer trust in quality

What does GRS certification cover?

The Global Recycle Standard tracks the recycled content through the entire supply chain. It also includes strict social and environmental requirements for the factories involved in production.

Key Takeaway: Certifications are the only reliable way to verify that your mesh fabric meets global safety, quality, and sustainability benchmarks.

| Certification | Focus Area | Benefit to Brand | |

|---|---|---|---|

| OEKO-TEX | Chemical Safety | Consumer protection | |

| GRS | Recycled Content | Sustainability claims | |

| ISO 9001 | Quality Management | Reliable production |

Checking for these seals of approval is a best practice for any business looking to source high-performance mesh responsibly.

Conclusion: Mastering the Versatility of Mesh

By understanding the technical properties and diverse variants of this unique textile, you are now equipped to choose the perfect material for your next project. Whether you need the delicate touch of bridal tulle or the rugged strength of industrial netting, mesh provides a solution that no other fabric can match. If you are ready to source high-quality materials or need expert guidance on your specific application, please contact us today .

Start your journey toward better design and performance now. Our vision is to empower global innovators with the most breathable, durable, and advanced mesh solutions on the market.

Frequently Asked Questions (FAQ)

Can I wash mesh fabric in a regular washing machine?Yes, most synthetic mesh is machine-washable on a gentle cycle. However, you should always use a mesh laundry bag to prevent the open weave from snagging on zippers or hooks.

What’s the best way to prevent mesh from fraying?The best way is to use a serger or a zig-zag stitch when sewing. Because most mesh is warp-knitted, it resists unraveling naturally, but finishing the edges ensures long-term structural integrity.

How do I know if my mesh is high quality?You can tell by performing a stretch and recovery test. High-quality mesh should return to its original shape immediately after being pulled, and the hole patterns should remain uniform without distortion.

Can I use mesh fabric for outdoor furniture?Absolutely. Synthetic polyester mesh is highly resistant to UV rays and mildew, making it a perfect choice for outdoor screens, slings, and breathable chair covers.

How do I know if a mesh is breathable enough for sports?Check the Holes Per Inch (HPI) and the weight. Generally, a mid-weight polyester mesh with visible hexagonal or square holes will provide the best balance of airflow and durability for activewear.