Mesh fabric is a versatile, breathable textile characterized by its open-hole structure, typically created through knitting or weaving synthetic fibers into a consistent grid pattern. Many textile designers struggle to find a material that balances extreme durability with high-performance breathability for technical and fashion applications. Choosing the wrong textile can lead to poor moisture management, structural failure in sportswear, or a lack of aesthetic depth in modern collections. This guide explores why mesh is the definitive answer for versatile design, providing technical insights into the properties and maintenance of mesh fabric material .

What is the origin of mesh fabric material?

Mesh fabric material originated in 1888 when a British mill owner sought to create a breathable textile for humid climates. When analyzing the history of mesh fabric material , it is clear that its inception was purely functional. It was designed specifically to solve the problem of heat retention found in traditional dense weaves.

The 1888 British textile breakthrough?

The first iteration of this material was created using specialized looms that allowed for deliberate open spaces between the yarns. This structural innovation introduced the “leno weave” to a wider market.

- Initial purpose: Temperature regulation for outdoor wear.

- Structural innovation: Introduction of the open-grid leno weave.

- Market shift: Transitioned from industrial utility to breathable undergarments.

Evolution from sports to high fashion?

The 1980s marked the era when this textile moved from the sidelines to the center of the fashion industry. You might be wondering: how did it happen?

- Athletic brands adopted the material for jersey production.

- Medical industries utilized its strength for surgical applications.

- High-fashion designers integrated it for its transparent, layered aesthetic.

Key Takeaway: Mesh has evolved from a nineteenth-century functional experiment into a cornerstone of modern athletic and high-fashion design.

| Historical Milestone | Development | |

|---|---|---|

| 1888 | Invention of the first breathable mesh loom | |

| 1980s | Mass adoption in the sportswear industry | |

| Modern Era | Transition to sustainable, recycled mesh variants |

The progression of mesh from a utility fabric to a luxury staple demonstrates its incredible structural adaptability.

Which fibers compose mesh fabric material?

Most modern mesh fabric material consists of synthetic polymers like polyester, nylon, and elastane to ensure maximum durability and elasticity. Selecting the right mesh fabric material requires an understanding of fiber chemistry and how it affects the final product’s performance.

Polyester and nylon foundations?

Synthetic polymers are the most common choice for creating the structural “grid” of the fabric. Polyester offers excellent UV resistance and colorfastness, while nylon provides superior abrasion resistance and a softer hand-feel.

- Polyester: Ideal for outerwear and high-sun exposure.

- Nylon: Preferred for linings and skin-contact garments.

- Blends: Often used to balance cost and performance.

The role of spandex in elasticity?

Adding elastane fibers transforms a rigid net into a high-performance stretch material. Here is the deal: without spandex, mesh would lack the recovery needed for compression gear.

- Provides 4-way stretch capabilities.

- Ensures the garment returns to its original shape.

- Increases comfort during high-intensity movement.

Key Takeaway: While polyester provides the frame, the integration of nylon and spandex determines the texture and flexibility of the mesh.

| Fiber Type | Primary Benefit | Common Application | |

|---|---|---|---|

| Polyester | Durability/UV Resistance | Outerwear and Signage | |

| Nylon | Softness/Strength | Lingerie and Linings | |

| Spandex | Elasticity/Recovery | Sportswear and Shapewear |

Understanding these fiber characteristics allows manufacturers to tailor the mesh to specific environmental and physical demands.

What are the benefits of mesh fabric material?

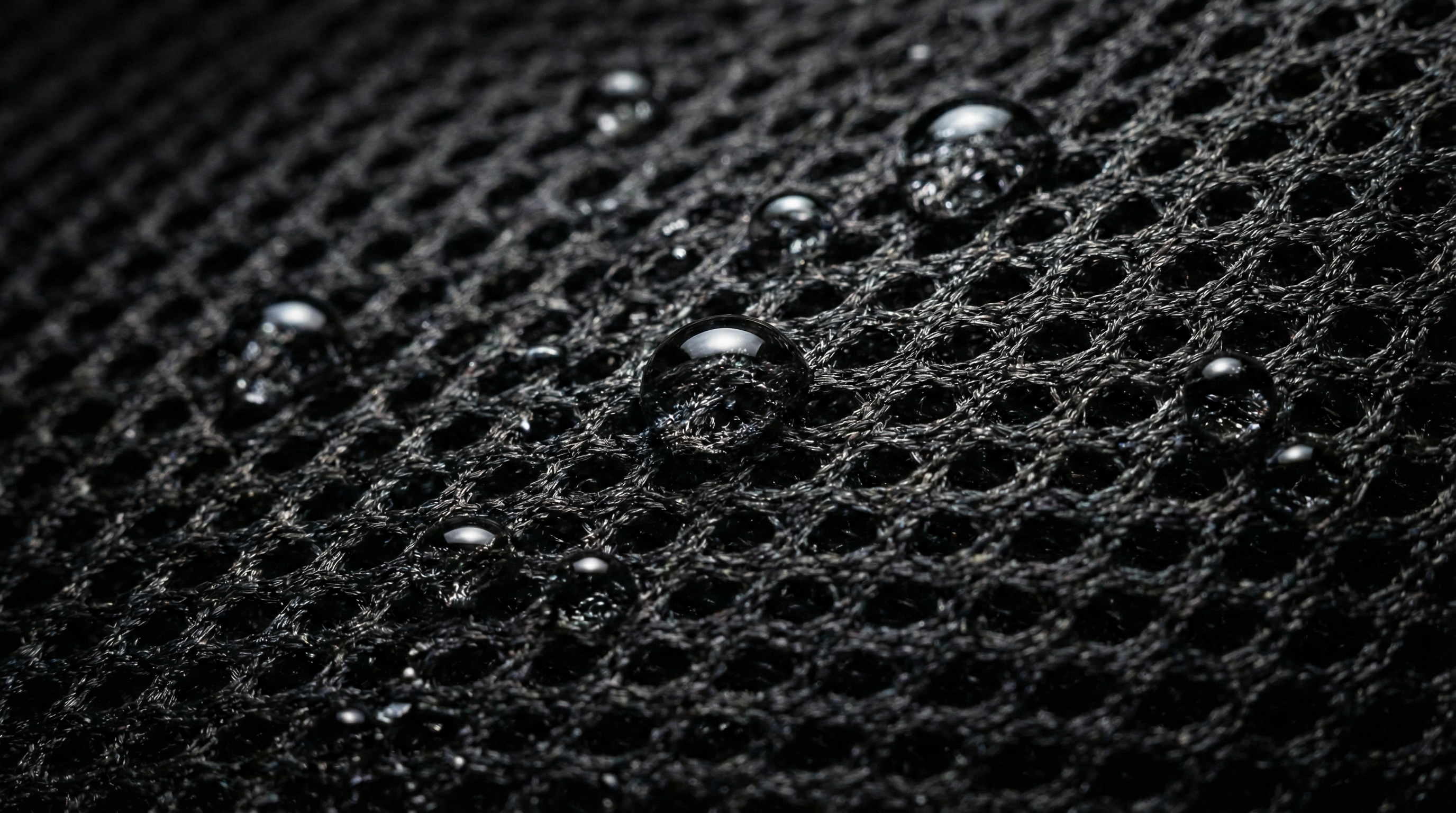

The primary benefits of mesh fabric material include superior moisture wicking, extreme breathability, and high tear resistance. The unique structure of mesh fabric material allows it to remain lightweight while providing the structural integrity required for heavy-use items.

Superior moisture and thermal management?

The open-weave construction acts as a natural ventilation system for the wearer. Hydrophobic synthetic fibers dry significantly faster than natural alternatives like cotton.

- Airflow: Promotes rapid evaporation of sweat.

- Weight: Reduces the overall bulk of the garment.

- Drying Speed: Minimizes moisture retention during activity.

Structural durability and maintenance?

Despite its “holey” appearance, the interlocking knit prevents easy tearing or unraveling. Think about it: a fabric that doesn’t wrinkle and requires minimal ironing is a dream for logistics and end-users alike.

- Resists wrinkles and creases during storage.

- Interlocking knit prevents ladders and runs.

- High strength-to-weight ratio for industrial use.

Key Takeaway: Mesh offers a rare combination of technical performance and low-maintenance care, making it ideal for active lifestyles.

| Benefit | Impact on User | Business Value | |

|---|---|---|---|

| Breathability | Improved comfort | Higher customer satisfaction | |

| Wrinkle Resistance | No ironing needed | Reduced returns for “damaged” looks | |

| High Strength | Long-lasting gear | Better brand reputation for quality |

These benefits make mesh the preferred choice for sectors where performance cannot be sacrificed for aesthetics.

Where is mesh fabric material used in industry?

Mesh fabric material is widely used across the athletic apparel, medical, automotive, and safety equipment industries. The versatility of mesh fabric material stems from its ability to be manufactured in various weights and hole sizes to meet specific industrial standards.

Performance sportswear and footwear?

Athletic brands utilize mesh to target heat zones in the body during high-intensity movement. This helps regulate body temperature while maintaining the structural integrity of the shoe or garment.

- Running Shoes: Layered mesh provides support and ventilation.

- Team Jerseys: Large-hole mesh allows for maximum cooling.

- Equipment Bags: Prevents odor buildup by allowing moisture to escape.

Industrial and medical applications?

Beyond clothing, the material serves critical roles in safety and healthcare. But wait, there’s more: mesh is used in surgical implants and even as filtration screens in complex manufacturing.

- Surgical Mesh: Provides internal support during recovery.

- Safety Vests: High-visibility mesh keeps workers cool and seen.

- Automotive: Seat upholstery uses mesh for airflow and durability.

Key Takeaway: Mesh is not just a fashion choice; it is a vital industrial component used in everything from high-performance sneakers to life-saving medical devices.

| Sector | Specific Use | Key Property Required | |

|---|---|---|---|

| Sportswear | Ventilation panels | High breathability | |

| Medical | Surgical mesh | Biocompatibility/Strength | |

| Automotive | Seat upholstery | Abrasion resistance |

The wide range of applications highlights the material’s status as an indispensable asset in modern manufacturing.

How should you maintain mesh fabric material?

You should maintain mesh fabric material by washing it in cool water and avoiding high-heat dryers to prevent fiber melting. To ensure the longevity of your mesh fabric material , you must protect it from abrasive surfaces that can cause snagging.

Washing and drying protocols?

Gentle handling is the secret to maintaining the “spring” and elasticity in the mesh. Excessive heat is the primary enemy of synthetic fibers, as it can cause them to warp or lose their shape permanently.

- Temperature: Keep it under 30°C to prevent degradation.

- Protection: Use a laundry bag to prevent snagging on zippers.

- Drying: Air drying is always the safest bet for synthetics.

Ironing and storage tips?

Most mesh textiles are naturally wrinkle-free, but they still require proper storage techniques to avoid stretching. Here is the point: if you must iron, use the lowest setting or a professional steamer.

- Steaming: Gently removes any rare creases without contact.

- Folding: Preferred over hanging to prevent vertical stretching.

- Chemicals: Avoid bleach, which can weaken synthetic bonds.

Key Takeaway: Low heat and protection from snags are the two most important factors in mesh maintenance.

| Action | Recommended | Avoid | |

|---|---|---|---|

| Washing | 30°C / Gentle Cycle | Hot water / Bleach | |

| Drying | Air dry / Flat | High-heat tumble dry | |

| Ironing | Steaming | Direct high-heat contact |

Proper care ensures that the fabric retains its technical properties and visual appeal for years of heavy use.

Is mesh fabric material an eco-friendly choice?

Mesh fabric material can be eco-friendly when produced from recycled polyester (rPET) or designed for mono-material circularity. Modern production of mesh fabric material increasingly focuses on reducing the environmental footprint of synthetic textiles.

The rise of recycled polyester (rPET)?

Recycled mesh offers the same technical benefits as virgin polyester but with a significantly lower carbon footprint. Look at it this way: using post-consumer plastic bottles as raw material keeps waste out of our oceans.

- Resource Saving: Uses less water and energy during production.

- Waste Reduction: Diverts plastic bottles from global landfills.

- Quality: rPET fibers perform exactly like virgin synthetics.

Circularity in textile design?

Sustainable designers look for mono-material mesh that is easier to recycle at the end of its life. But why does this matter?

- Simplifies the chemical recycling process.

- Ensures garments can enter a closed-loop system.

- Reduces the need for complex fiber separation.

Key Takeaway: Mesh is becoming a green leader through the use of recycled synthetics and designs optimized for circularity.

| Sustainability Feature | Description | Impact | |

|---|---|---|---|

| Recycled Content | Made from rPET bottles | Reduced landfill waste | |

| Longevity | Highly durable | Reduced consumption | |

| Circularity | Mono-material options | Easier textile recycling |

By choosing recycled variants, brands can offer high-performance gear while meeting their sustainability goals.

How can you customize mesh fabric material?

You can customize mesh fabric material using digital sublimation printing, specialized knit patterns, or aesthetic surface coatings. Adding a personal or brand-specific touch to mesh fabric material is straightforward with modern digital textile technologies.

Digital printing on open-weave structures?

Modern printers can apply intricate patterns even to fabrics with large holes. Consider this: because the ink fuses with the fiber, the breathability of the mesh remains completely unaffected.

- Sublimation: The most common method for polyester mesh.

- Precision: Ensures the holes remain open and functional.

- Vibrancy: Synthetic fibers hold deep colors exceptionally well.

Aesthetic finishes and coatings?

Beyond color, the physical appearance and texture of the mesh can be altered. You might be interested in this: manufacturers can apply metallic coatings for a futuristic look or use 3D textures for footwear.

- Metallic Coatings: Adds a reflective, high-fashion sheen.

- 3D Knitting: Creates structural depth and tactile interest.

- Resin Finishing: Increases the stiffness for industrial use.

Key Takeaway: Digital sublimation and structural knitting allow designers to treat mesh as a blank canvas for branding and artistic expression.

| Customization Method | Effect | Best For | |

|---|---|---|---|

| Sublimation | Permanent, vibrant color | Sportswear/Branding | |

| Metallic Coating | Shiny, reflective surface | High fashion | |

| 3D Knitting | Structural texture | Footwear/Outerwear |

Customization allows for a unique brand identity without sacrificing the airflow that makes mesh so valuable.

How to source quality mesh fabric material?

Sourcing quality mesh fabric material requires evaluating denier counts, weight consistency, and the stretch-recovery ratio of the weave. When a B2B buyer looks for mesh fabric material, they must prioritize technical specifications over aesthetics alone to ensure product performance.

Evaluating technical specifications?

The “hand-feel” is important, but the technical numbers tell the real story of the fabric’s quality. You must check the GSM and denier to ensure the material meets your specific durability requirements.

- Denier: Measures the thickness of the individual fibers.

- GSM: Indicates the weight and density of the mesh.

- Hole Size: Determines the balance between transparency and coverage.

Reliability of the supply chain?

Consistency is the most valuable trait in a textile partner for large-scale production. Look at it this way: a batch of mesh that varies in stretch by even 5% can ruin an entire production run.

- Verify supplier certifications for quality control.

- Request swatches to test the stretch-recovery ratio.

- Ensure the supplier can handle bulk volume consistently.

Key Takeaway: Quality sourcing requires a deep dive into GSM, denier, and supplier consistency to prevent production failures.

| Quality Metric | What to Look For | Why it Matters | |

|---|---|---|---|

| GSM | Consistent weight | Ensures uniform drape | |

| Stretch Recovery | Returns to original shape | Prevents “bagging” in joints | |

| Colorfastness | Minimal bleeding | Essential for multi-color designs |

Investing time in sourcing ensures that the final product maintains its integrity through rigorous use.

How do you sew and cut mesh fabric material?

You sew and cut mesh fabric material using rotary blades for precision and zigzag stitches to maintain seam elasticity. Processing mesh fabric material can be challenging, but following professional manufacturing standards ensures a clean finish.

Pre-processing and cutting techniques?

Proper preparation prevents the fabric from shifting during the manufacturing process. Here is the kicker: using pattern weights instead of pins prevents leaving permanent holes in the delicate knit.

- Precision: Use rotary cutters to avoid snagging the holes.

- Stability: Use self-healing mats to keep the fabric flat.

- Preparation: Remove factory sizing to prevent future shrinkage.

Stitch selection and yarn types?

The choice of stitch determines whether the seam will pop under pressure during physical activity. Consider this: a straight stitch will often snap when the mesh is stretched to its limit.

- Zigzag Stitch: Allows the seam to expand with the fabric.

- Overlock/Serger: Finishes the edges while maintaining stretch.

- Polyester Thread: Provides the necessary strength for synthetics.

Key Takeaway: Success in mesh manufacturing depends on using the right tools—specifically rotary cutters and stretch-compatible stitches.

| Manufacturing Step | Tool/Method | Expert Tip | |

|---|---|---|---|

| Cutting | Rotary Cutter | Cut on a self-healing mat | |

| Stitching | Zigzag or Serger | Matches fabric elasticity | |

| Threading | Polyester Thread | Provides necessary strength |

Mastering these techniques allows for the creation of high-quality garments that can withstand intense physical strain.

What else should you know about mesh fabric material?

Beyond standard uses, mesh fabric material serves as a high-fashion statement and a critical component in advanced filtration. This section addresses the most common technical questions regarding the selection and durability of mesh fabric material in professional settings.

Can it handle heavy-duty outdoor gear?

Yes, provided you select a high-denier polyester mesh with UV-resistant coatings. Heavy-duty mesh is engineered to survive harsh sunlight and abrasion while providing the necessary airflow for industrial equipment.

- UV Resistance: Essential for outdoor longevity.

- High Denier: Provides the required tensile strength.

- Coatings: Can add water repellency or flame retardance.

What is the best mesh for skin?

The best option for direct skin contact is a fine-gauge nylon mesh with a soft finish. Coarse “power mesh” should be avoided for next-to-skin layers as it can cause irritation during movement.

- Nylon: Offers the softest hand-feel.

- Micro-mesh: Minimal hole size reduces friction.

- Lining: Use a soft tricot if the mesh is coarse.

Key Takeaway: Choosing the correct denier and fiber type is essential for balancing comfort with the rugged durability required for industrial applications.

| Feature | Fashion Mesh | Industrial Mesh | |

|---|---|---|---|

| Fiber | Nylon/Spandex | High-Denier Polyester | |

| Hole Size | Varied/Decorative | Uniform/Functional | |

| Finish | Soft/Draped | Rigid/Coated |

Understanding these distinctions ensures that you select the perfect material for your specific project needs.

Whether you are designing the next generation of athletic footwear or sourcing materials for industrial safety, mesh fabric offers an unparalleled combination of breathability and strength. Its evolution from a functional 19th-century invention to a high-tech sustainable textile makes it an essential tool for modern creators. We are committed to providing the highest quality textiles to power your innovation. To find the perfect solution for your next project, contact us today .

FAQ

Can I use mesh for heavy-duty outdoor gear?Yes, but you must choose a high-denier polyester with UV-resistant coatings. Industrial-grade variants are specifically reinforced to withstand environmental stressors while maintaining airflow.

What’s the best mesh for sensitive skin?Nylon micro-mesh is the superior choice for comfort. Its fibers are significantly softer than polyester, making it ideal for lingerie or athletic linings.

Can I print high-resolution photos on mesh?Absolutely, though clarity depends heavily on the hole size. Fine micro-mesh supports higher detail for digital sublimation than large-hole athletic versions.

Is mesh fabric material prone to pilling?No, high-quality synthetic mesh is naturally resistant to pilling. Most visible damage is actually snagging caused by friction against rough surfaces or Velcro.

How do I prevent mesh from fraying at the edges?Use a serger or binding tape to finish the edges. While warp-knitted mesh is resistant to unraveling, a professional finish is the industry standard for durability.