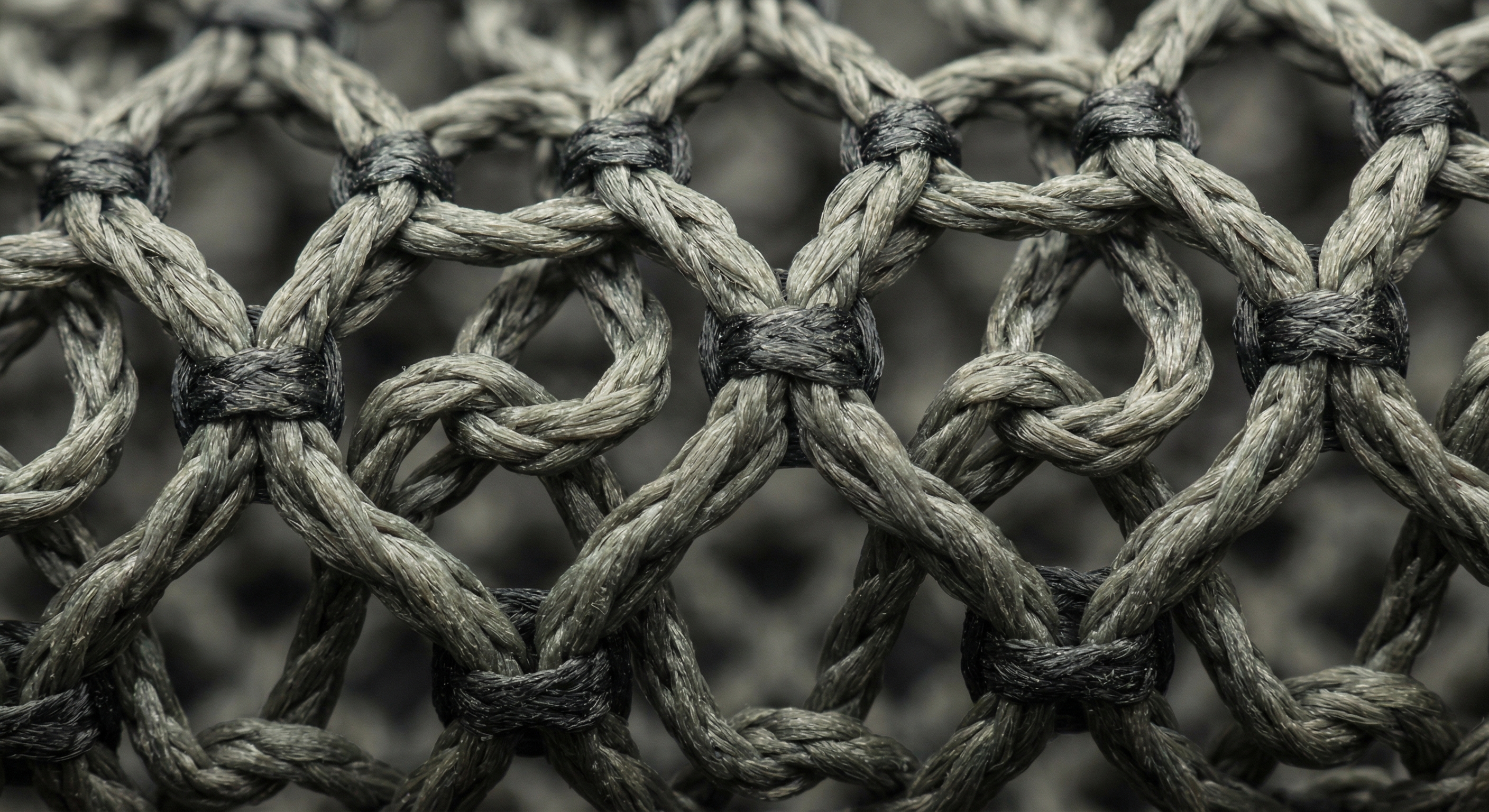

Heavy-duty nylon mesh fabric is a high-tenacity, warp-knitted material engineered for superior tensile strength, abrasion resistance, and breathability in industrial and commercial applications. You are likely searching for a material that can withstand extreme tension and harsh environments without tearing or losing its structural shape. Relying on standard fabrics often leads to frequent equipment failures, compromised safety in load-bearing scenarios, and skyrocketing replacement costs.

The solution lies in the advanced engineering of power mesh , which combines the resilience of synthetic polymers with the ventilation of a knit structure. This specific construction ensures that the material remains lightweight while offering the heavy-duty performance required for rigorous usage. By integrating these materials, industries can achieve a balance between protective durability and functional airflow.

Why choose heavy duty nylon mesh fabric for industrial use?

Industrial environments demand materials that do not quit under pressure or extreme mechanical stress. When you select a heavy-duty nylon mesh, you are investing in a fabric known for its exceptional strength-to-weight ratio. This makes it ideal for components that must be moved or handled frequently without sacrificing the safety of the load.

Superior tensile strength and durability

The core advantage of high-tenacity nylon lies in its ability to resist snapping under sudden loads. Unlike traditional woven materials, the knit structure allows for a degree of energy absorption that prevents catastrophic failure. This reliability is essential for maintaining safety standards in high-stakes environments.

Understanding high-level abrasion resistance

Abrasion resistance is a critical metric for fabrics used in rough-handling scenarios or high-friction zones. Heavy-duty nylon fibers are naturally tougher than most organic or low-grade synthetic alternatives, resisting pilling and thinning. This ensures a longer service life even when the material is in constant contact with abrasive surfaces.

Key Takeaway: Heavy-duty nylon is the gold standard for applications requiring maximum “grab” strength and resistance to friction.

- Impact Resistance: High energy absorption capabilities protect internal components.

- Flexibility: Maintains structural integrity after repeated bending or folding cycles.

- Weight: Provides a lightweight alternative to heavy canvases without losing toughness.

| Property | Benefit | |

|---|---|---|

| High Tenacity | Prevents tearing under heavy loads | |

| Open Knit | Allows for debris and fluid drainage | |

| Internal Link | Bag & Luggage Mesh |

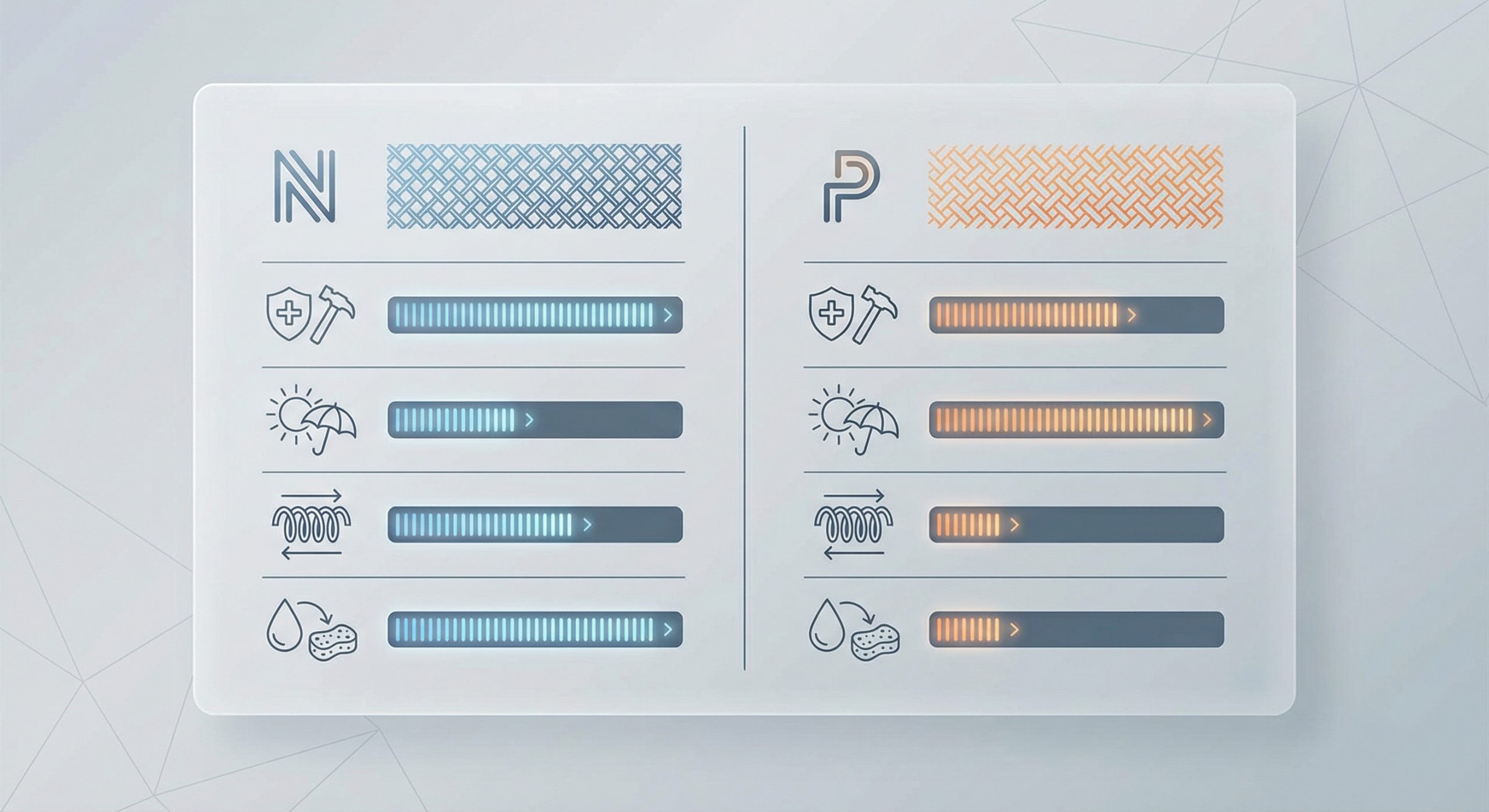

What makes heavy duty nylon mesh fabric different from polyester?

Choosing between nylon and polyester depends entirely on your specific environment and mechanical requirements. While they may look similar to the untrained eye, their chemical reactions to moisture and sunlight differ significantly. Understanding these nuances allows engineers to select the right polymer for the job.

Nylon vs. Polyester: A performance comparison

Nylon is generally preferred for its superior elasticity and “break strength,” making it the better choice for dynamic loads. Conversely, polyester offers better dimensional stability and resists stretching when wet. For projects where the fabric must stay exactly the same size regardless of humidity, polyester is often the superior candidate.

Elasticity and recovery properties

Nylon’s ability to stretch and return to its original shape is a defining characteristic of high-performance mesh. This recovery prevents the material from becoming “baggy” or distorted after being subjected to heavy weight. Polyester lacks this level of elasticity, which can lead to permanent deformation if overloaded.

Key Takeaway: Nylon offers more “give” and elasticity, whereas polyester excels in UV stability and dimensional consistency.

“The selection of a synthetic polymer must be a deliberate choice based on the second-order effects of environmental exposure, such as UV degradation or moisture absorption.”

| Feature | Nylon Mesh | Polyester Mesh | |

|---|---|---|---|

| Stretch | High Recovery | Low/Stable | |

| UV Resistance | Moderate | High | |

| Wet Strength | Decreases slightly | Stays constant |

How does heavy duty nylon mesh fabric improve cargo safety?

In the logistics world, material failure is not just an inconvenience; it is a liability. Heavy-duty mesh provides the containment needed for transport without the bulk or wind-resistance of solid tarps. This allows for safer hauling of irregular loads while maintaining high visibility and airflow.

Applications in heavy-duty cargo netting

Cargo nets made from heavy-duty mesh are essential for securing loose items in transit. The warp-knit construction ensures that if one section is damaged, the hole does not “run” or expand rapidly. This containment strategy is significantly more reliable than using simple ropes or low-grade plastics.

Can it handle extreme weather conditions?

High-grade mesh is designed to withstand a variety of environmental stressors, from freezing temperatures to high winds. The open structure prevents the “sail effect,” reducing the strain on vehicle mounting points during high-speed transport. Furthermore, specialized footwear and gear mesh technologies ensure the fibers do not rot when exposed to rain.

Key Takeaway: The open-knit structure reduces wind drag on vehicles while securely containing loose items.

- Load Distribution: Spreads weight evenly across the entire knit surface.

- Anti-Fray: Specialized warp-knit construction prevents small holes from expanding.

- Tension Management: Resists snapping even when pulled taut over sharp edges.

Where can you use heavy duty nylon mesh fabric in medical gear?

The medical industry relies on heavy-duty mesh for patient safety and long-term comfort, particularly in mobility devices. Because these fabrics are in close contact with skin or supporting human weight, they must be both strong and non-abrasive. This dual requirement makes high-tenacity knit mesh a staple in healthcare settings.

Supporting patient lift slings

Patient lift slings require extreme tensile strength to ensure safe transport between beds and chairs. The mesh must be rated for high weight capacities to prevent accidents while remaining flexible enough to contour to the body. This ensures that the patient is securely held without the risk of fabric failure.

Breathability for long-term comfort

Breathability is crucial in medical gear to prevent skin irritation and heat buildup during extended use. The open-cell structure of the mesh allows air to circulate freely, which is vital for patients with limited mobility. Additionally, the fabric is easy to decontaminate and allows for quick drying during patient bathing or cleaning.

Key Takeaway: Heavy-duty mesh is essential for slings because it is easy to decontaminate and allows for quick drying during patient bathing.

- Hygiene: Naturally resistant to mold and mildew growth.

- Drainage: Water passes through instantly, making it ideal for shower chairs.

- Strength: Engineered to meet strict medical safety ratings for weight.

Is heavy duty nylon mesh fabric suitable for outdoor equipment?

Outdoor gear must face the triple threat of UV rays, moisture, and rough handling in the field. Heavy-duty mesh is frequently used in backpacks, tents, and tactical vests because it offers ventilation without sacrificing durability. This balance is critical for equipment that must perform in unpredictable wilderness environments.

UV resistance and moisture management

While nylon is strong, it requires specific treatments to survive prolonged exposure to direct sunlight. By using flame retardant mesh options with UV coatings, manufacturers can ensure that outdoor gear remains safe and durable. These treatments prevent the fibers from becoming brittle and snapping over time.

Benefits for tactical and hunting gear

Tactical gear often utilizes mesh for internal pockets and hydration sleeves where visibility and drainage are required. The high-tenacity nature of the fabric ensures that heavy items like ammunition or tools don’t tear through the mesh. This ruggedness is a primary reason why it remains the preferred material for military-grade equipment.

Key Takeaway: Specialized coatings and high-tenacity fibers make heavy-duty mesh the ideal choice for survival and tactical gear.

| Application | Key Feature Needed | |

|---|---|---|

| Tactical Vests | High Abrasion Resistance | |

| Hydration Packs | Moisture Management | |

| Gear Pockets | Visual Identification |

What are the key benefits of knitted heavy duty nylon mesh fabric?

The secret to the fabric’s exceptional performance lies in the knitting process itself, specifically warp knitting. This technique creates a series of interlocking loops that provide multi-directional strength. Unlike woven fabrics, warp-knit mesh offers a level of structural stability that is difficult to replicate with other methods.

Dimensional stability and structural integrity

Dimensional stability refers to the fabric’s ability to maintain its original shape under stress. Warp-knit mesh is particularly good at this because the loops are locked into place during production. This prevents the fabric from sagging or stretching out of proportion even after years of heavy use.

Why warp knitting matters for longevity

Warp knitting is superior to standard knitting because it prevents the material from unravelling if a single thread is cut. This “ladder-proof” quality is essential for industrial applications where sharp objects might snag the fabric. The integrity of the nodes ensures that the mesh remains a cohesive unit under tension.

Key Takeaway: Unlike woven fabrics, warp-knit mesh won’t unravel if a single strand is cut or damaged.

“The structural integrity of the ‘nodes’ in the knit ensures the fabric maintains its shape even under multi-directional tension.”

| Knit Type | Run Resistance | Airflow | |

|---|---|---|---|

| Warp Knit | Excellent | Maximum | |

| Standard Weave | Poor | Moderate |

Can heavy duty nylon mesh fabric enhance automotive interiors?

Automotive manufacturers use mesh for both aesthetic and functional purposes, ranging from seat pockets to safety barriers. The material’s ability to provide transparent storage while maintaining a sleek look is highly valued in modern vehicle design. It adds utility without adding the weight of solid plastic panels.

Durability in high-traffic seating

In vehicles, seat pockets and dividers are subjected to constant pulling and stuffing by passengers. Heavy-duty mesh can handle this high-traffic usage without losing its elasticity or tearing at the seams. This durability ensures that the interior of the vehicle looks new and remains functional for the life of the car.

Safety barrier and storage solutions

Using mosquito net style fine meshes or heavier cargo variants within a vehicle adds utility and safety. Barriers made of mesh can prevent cargo from flying forward during sudden stops while still allowing the driver to see through the rearview mirror. This combination of transparency and strength is unique to mesh materials.

Key Takeaway: Mesh provides a lightweight storage solution that allows passengers to see contents clearly while maintaining tension.

- Space Saving: Low profile storage that collapses when empty.

- Visual Access: Easily identify items in pockets without digging.

- Weight Reduction: Replaces heavy plastic components in the cabin.

How to maintain your heavy duty nylon mesh fabric products?

Proper care extends the life of synthetic meshes, ensuring they remain strong and effective for years of service. While these fabrics are incredibly tough, they can be damaged by improper cleaning methods or harsh chemicals. Following a standardized maintenance routine will protect your investment and ensure continued safety.

Cleaning and storage best practices

The best way to clean heavy-duty mesh is through gentle rinsing and air drying. Using high-heat dryers can cause the synthetic fibers to lose their “temper,” leading to a loss of elasticity. Storing the mesh in a cool, dry place away from direct sunlight when not in use will further prevent UV degradation.

Protecting fibers from chemical damage

Avoid using bleach or harsh industrial solvents, as these can break down the polymer chains in nylon and polyester. If the mesh is used in a marine environment, it is vital to rinse away salt crystals regularly. Salt can act as an abrasive within the knit, wearing down the fibers from the inside out.

Key Takeaway: Avoid high-heat drying, which can cause the nylon fibers to lose their elasticity and structural “temper.”

- Rinse: Use cool water to remove salt, grit, and surface debris.

- Soap: Use only mild detergents to avoid chemical breakdown.

- Dry: Always air dry away from direct heat sources to maintain fiber integrity.

| DO | DON’T | |

|---|---|---|

| Air Dry | Use High Heat | |

| Use Mild Soap | Use Bleach or Acid |

Why is heavy duty nylon mesh fabric vital for filtration?

In industrial filtration, the consistency of the “hole size” or aperture is critical for the accurate separation of materials. Heavy-duty mesh is used to create filters that can withstand high pressure and high flow rates without distorting. This precision is what makes synthetic mesh a staple in water treatment and manufacturing.

Flow rates and debris management

A high flow rate is essential for efficient industrial processes, and the open-knit structure of mesh facilitates this perfectly. Using a stiff tulle or rigid mesh allows for consistent filtration without the fabric sagging under the weight of the water. This ensures that the filtration process remains steady and predictable.

Precision in industrial screening

Precision-engineered mesh ensures that only particles of a certain size pass through the barrier. The smooth surface of synthetic fibers like nylon makes them “clog-resistant,” as debris is easily shed during backwashing. This reduces the frequency of filter maintenance and improves the overall efficiency of the system.

Key Takeaway: High flow rates and precise aperture sizes make heavy-duty mesh the preferred choice for industrial screening.

- Clog Resistance: Smooth synthetic fibers shed debris much easier than natural fibers.

- Chemical Stability: Resists many industrial solvents and common processing chemicals.

What is the cost-efficiency of heavy duty nylon mesh fabric?

While the upfront cost of heavy-duty mesh may be higher than standard cloth, the lifecycle value is significantly better. Long-term cost-efficiency is calculated by looking at the frequency of replacement and the labor costs associated with failure. Investing in high-quality mesh pays for itself through reduced downtime.

Analyzing long-term lifecycle savings

Durability equals sustainability in an industrial context; fewer replacements mean less waste and lower long-term expenditure. When a fabric lasts three times longer than its competitor, the initial price difference becomes negligible. This is a primary consideration for project managers looking to optimize their operational budgets.

Reducing replacement frequency

Frequent fabric failure leads to labor costs for installation and the potential for damage to the goods being protected. By using premium mesh, these risks are mitigated, and the replacement cycle is greatly extended. This reliability is a cornerstone of efficient supply chain and facility management.

Key Takeaway: Durability equals sustainability; fewer replacements mean less waste and lower long-term expenditure.

| Factor | Savings Impact | |

|---|---|---|

| Durability | High Lifecycle Value | |

| Maintenance | Low Operational Cost | |

| Replacement Rate | Minimal Downtime |

Frequently Asked Questions

Can I wash heavy-duty nylon mesh in a machine?Yes, most nylon mesh can be machine-washed using a cold, gentle cycle and a mesh laundry bag to prevent snagging. Always air dry the material to maintain the integrity of the synthetic fibers and prevent shrinkage.

What’s the best way to cut this fabric without fraying?The most effective way to cut heavy-duty mesh is with a hot knife or heat cutter, which seals the edges instantly. However, because it is warp-knit, it is naturally resistant to unravelling even if cut with standard industrial shears.

How does UV exposure affect the lifespan of the mesh?Prolonged UV exposure can eventually degrade nylon fibers, making them brittle over several years. For permanent outdoor installations, a polyester mesh or a UV-coated nylon variant is highly recommended for better longevity.

Are there specific coatings for chemical resistance?Yes, manufacturers can apply specialized PVC, urethane, or acrylic coatings to the mesh. These coatings enhance resistance to specific environmental hazards like oils, industrial chemicals, and acid rain.

Is nylon mesh more durable than polyester in wet conditions?Nylon is slightly more absorbent, which may cause it to stretch or “relax” slightly when wet. However, in terms of absolute mechanical break strength, nylon typically remains superior to polyester even in damp environments.