Mesh fabric is a lightweight, permeable textile characterized by its open-weave structure that creates thousands of tiny perforations. Selecting the right textile for high-performance apparel often leads to a compromise between durability and breathability, as most densely woven fabrics trap heat and moisture. This trapped heat actively degrades athletic performance and causes skin irritation, increasing the weight of the garment as it absorbs sweat. Fabric mesh material offers the perfect engineering solution by ensuring maximum airflow while maintaining structural integrity for diverse applications.

What exactly is fabric mesh material?

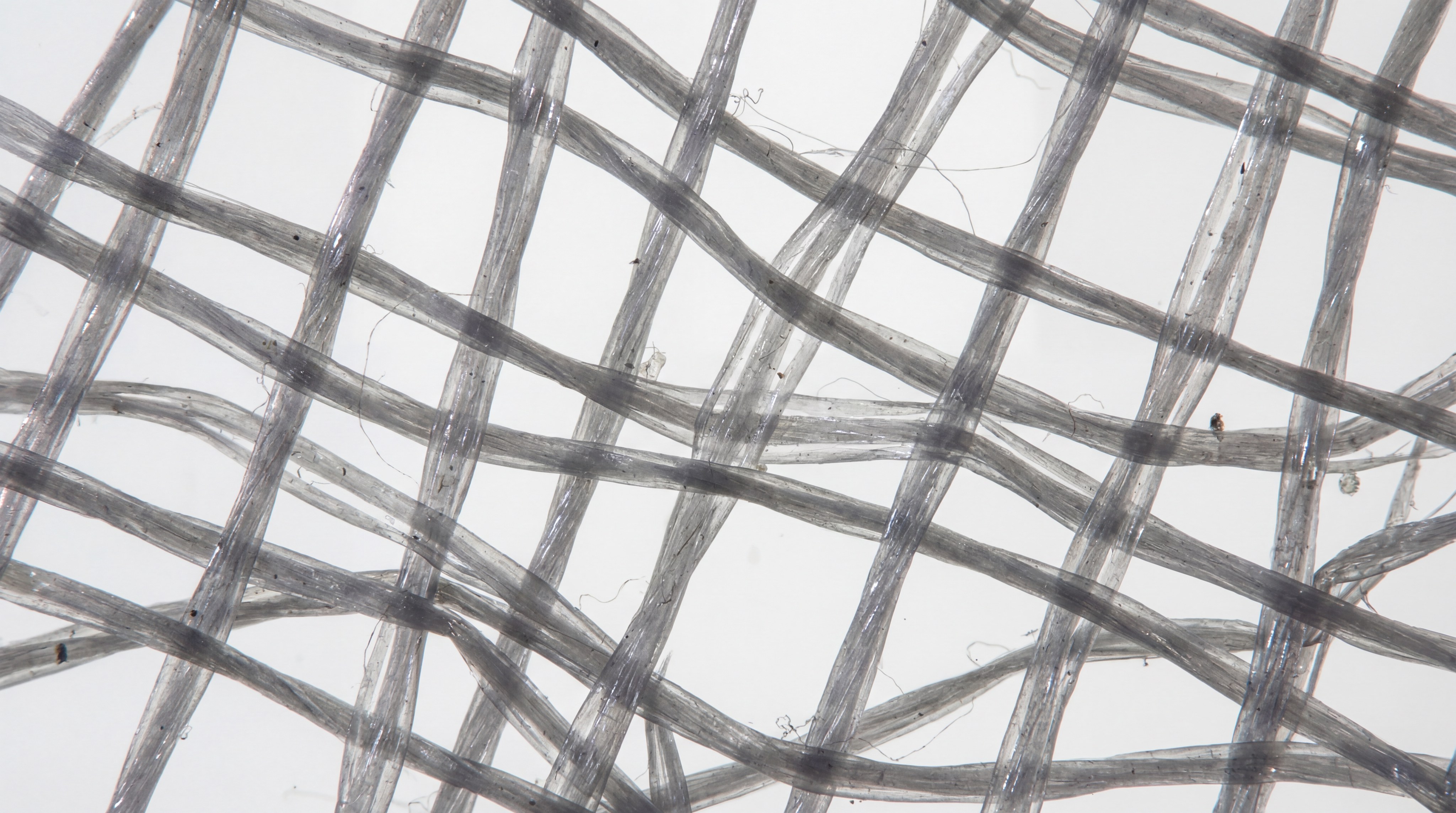

Fabric mesh material is a textile defined by its loose, grid-like weave and high level of permeability. This material differs from traditional solid knits because it prioritizes air passage through intentional gaps in the fiber structure.

Defining the physical properties of mesh

Here is the deal: the “holes” in the fabric are its most vital functional feature. These spaces range from microscopic pores used in filtration to large honeycomb structures found in heavy-duty safety netting.

- Weight: Extremely low heft compared to solid textiles.

- Composition: Usually crafted from synthetic polymers for high tensile strength.

- Flexibility: Offers significant mechanical stretch depending on the knit pattern.

The result is a fabric that feels almost weightless on the skin. It remains the top choice for any environment where temperature regulation is the primary concern.

The historical evolution of the weave

But wait, there is more to the story than modern polyester. While the term is contemporary, the concept of netting dates back to prehistoric fishing and trapping tools.

- 19th Century: British mill owners began experimenting with hole-filled gloves for warmth.

- Aertex: The first commercial producer of breathable mesh garments for the masses.

- Fashion Surge: The 1980s saw mesh transition from purely functional gear to a global style staple.

Key Takeaway: Understanding the historical shift from survival tools to high-fashion textiles helps brands appreciate the mechanical reliability of the fabric mesh material .

| Property | Description | Benefit | |

|---|---|---|---|

| Permeability | High airflow through open pores | Superior cooling and drying | |

| Material | Synthetic (Polyester/Nylon) | High durability and moisture resistance | |

| Texture | Grid-like or hexagonal | Lightweight and structural |

Review this table to determine if the physical properties of the weave align with your specific product requirements.

How is fabric mesh material manufactured?

The production of fabric mesh material involves advanced chemical engineering and high-precision industrial looms. It starts with the transformation of raw petroleum into synthetic filaments that can withstand the rigors of open-weave knitting.

Creating the synthetic polymer filaments

Check this out: the process begins at the molecular level. Monomers are extracted from oil and reacted with acids to create long-chain polymers.

- Polymerization: The chemical reaction that creates the base plastic material.

- Melting: Solid chips are heated into a liquid state for processing.

- Extrusion: Liquid polymer is forced through a spinneret to create fine strands.

These strands are then cooled and stretched to increase their tensile strength. This ensures the final fabric won’t snap under pressure despite its airy design.

The specialized knitting and weaving process

You might be wondering: how do they get the holes so perfect? Specialized machines, such as Raschel knitting looms, interlock the yarns in specific patterns.

- Square Mesh: A basic grid pattern used for utility nets and laundry bags.

- Hexagonal Weave: Often used for decorative tulle or lightweight apparel.

- Power Mesh: Incorporates elastane to provide four-way stretch and compression.

Key Takeaway: The manufacturing precision of fabric mesh material ensures that every perforation remains consistent across large production runs.

| Manufacturing Step | Process | Goal | |

|---|---|---|---|

| Extrusion | Forcing liquid through tiny holes | Creating continuous fiber strands | |

| Drawing | Stretching the cooled fibers | Increasing the thread strength | |

| Knitting | Interlocking yarns in open grids | Forming the final permeable textile |

Consult this production guide to understand the technical milestones required for high-quality mesh manufacturing.

Why is fabric mesh material used in fashion?

In the apparel industry, fabric mesh material is utilized to provide structure and ventilation without adding unnecessary bulk to a design. It allows designers to create garments that are both visually interesting and functionally superior in warm climates.

High-performance athletic applications

The secret is out: almost all modern sportswear relies on some form of mesh. It is strategically placed in high-heat zones to manage sweat and airflow.

- Jerseys: Lightweight polyester mesh is the standard for team sports.

- Footwear: Upper sections of running shoes use mesh for weight reduction.

- Gym Wear: Wicking properties keep athletes dry during intense sessions.

By using the fabric mesh material , brands can ensure their athletes stay cool under pressure. This performance boost is why it remains a staple in every major athletic catalog.

Lingerie and high-fashion aesthetics

But that is not all it can do. Fine mesh variants like tulle and organza are essential for creating volume and sheer effects in luxury garments.

- Layering: Adds depth and texture to evening gowns.

- Shapewear: High-compression mesh provides body contouring without the heat.

- Detailing: Used for veils, sleeves, and decorative inserts.

Key Takeaway: Whether for a professional basketball court or a high-end runway, the fabric mesh material provides a unique balance of transparency and strength.

| Fashion Sector | Usage | Key Advantage | |

|---|---|---|---|

| Activewear | Vented panels and jerseys | Moisture management and cooling | |

| Couture | Decorative overlays and volume | Aesthetic depth without weight | |

| Shapewear | Compression layers | Breathable body contouring |

Analyze these fashion applications to identify where mesh can solve ventilation or weight issues in your designs.

Where is fabric mesh material produced globally?

Global production of fabric mesh material is centered in major textile hubs that possess the chemical infrastructure for synthetic fiber creation. China remains the dominant player, though other regions are emerging as specialized competitors.

The dominance of East Asian manufacturing

Here is the deal: China controls the majority of the world’s polyester and nylon output. This is due to their massive oil refining and textile finishing capabilities.

- Scale: Integrated supply chains allow for high-volume production.

- Cost: Efficiency in East Asia keeps the price per yard competitive.

- Variety: These hubs offer every conceivable type of weave and color.

Most mass-market apparel brands source their mesh from these regions. The sheer infrastructure available makes it difficult for smaller markets to compete on price alone.

High-tech Western and South Asian mills

But wait, there is more to consider. Western mills often focus on high-performance technical mesh for medical or military applications.

- USA/EU: Specialization in medical-grade and flame-retardant mesh.

- India: Rapidly growing market for apparel-grade polyester mesh.

- Indonesia: A significant player in the footwear mesh supply chain.

Key Takeaway: While mass production of fabric mesh material is centered in China, specialized technical variants are often sourced from advanced Western facilities.

| Region | Primary Focus | Best For | |

|---|---|---|---|

| China | Volume and cost-efficiency | Mass-market apparel and bags | |

| USA/Europe | Technical and medical grade | Specialized industrial or safety gear | |

| South Asia | Apparel and footwear | Competitive pricing for medium volume |

Use this geographic breakdown to determine the best sourcing location for your specific quality and price targets.

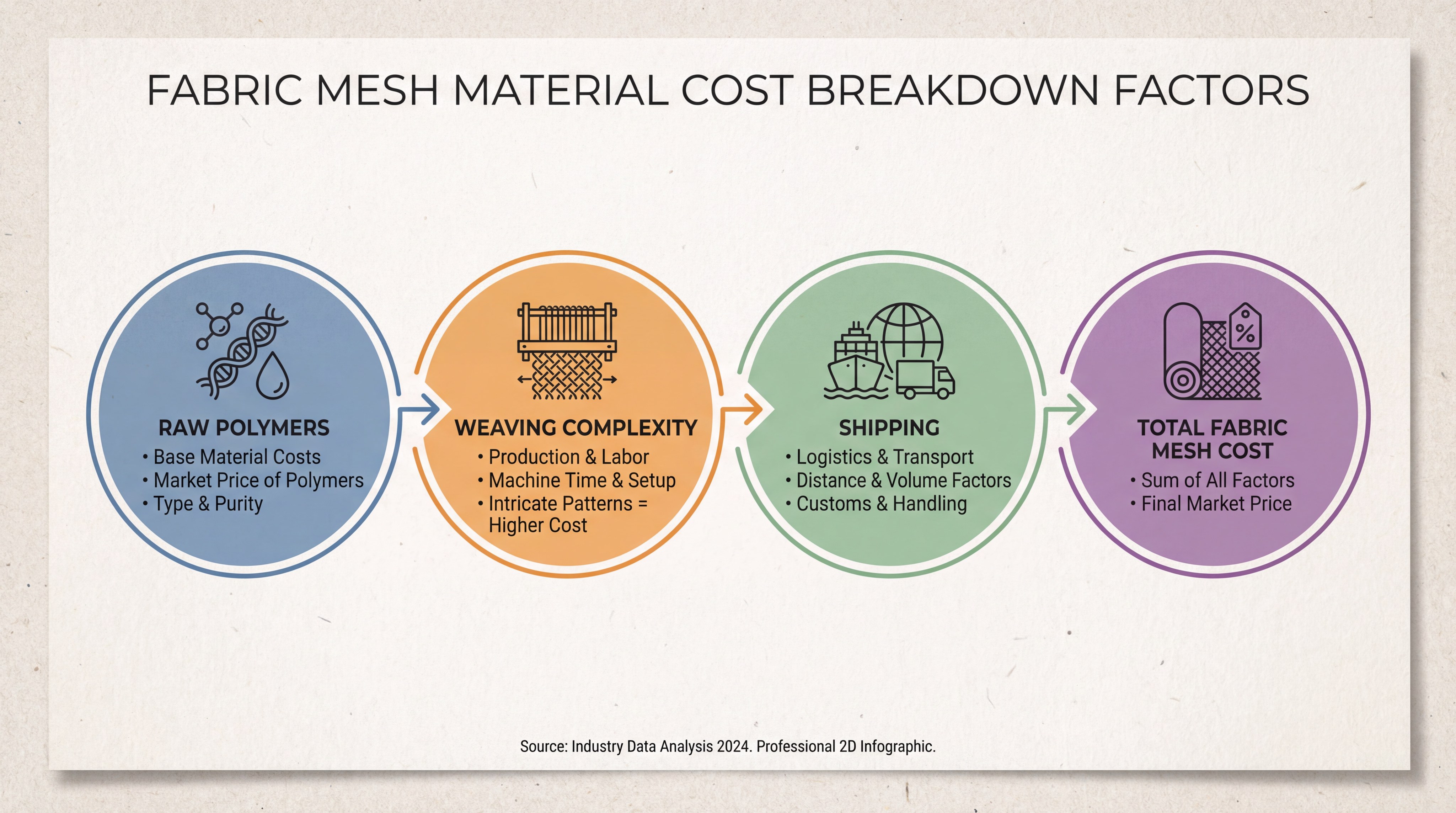

What is the cost of fabric mesh material?

The price of fabric mesh material is determined by fiber type, weave complexity, and the geographic location of the mill. Generally, polyester-based mesh is more affordable than nylon or specialized silk variants.

Raw material and fiber influences

Look at the numbers: polyester is typically the most cost-effective option for brands. It is widely available and easier to process than many natural fibers.

- Polyester: Lowest cost, high durability, excellent wicking.

- Nylon: Mid-range cost, softer hand-feel, better elasticity.

- Specialty Fibers: Higher cost for antimicrobial or recycled options.

When choosing a fabric mesh material , you must balance the desired tactile feel against the production budget. Nylon is often preferred for skin-contact items like lingerie.

Complexity of the weave and finishing

It gets even more detailed: simple square grids are cheaper to produce than intricate patterns. Every time a loom must be adjusted for a complex knit, the cost increases.

- Standard Mesh: Fast production speeds lead to lower prices.

- Jacquard/Hexagonal: Slower speeds and precision settings add a premium.

- Coatings: UV resistance or glitter finishes will further increase the price.

Key Takeaway: To keep costs low, stick to standard polyester fabric mesh material in high-volume orders; otherwise, prepare for a premium on custom weaves.

| Cost Driver | Lower Price | Higher Price | |

|---|---|---|---|

| Fiber | Pure Polyester | Recycled Nylon or Silk | |

| Weave | Basic Square Grid | Complex Raschel or Tulle | |

| Finishing | Untreated / Raw | Antimicrobial or Custom Dye |

Refer to this cost matrix to build a realistic budget for your upcoming textile procurement cycle.

Which types of fabric mesh material exist?

There are several distinct versions of fabric mesh material, each engineered for a specific functional or aesthetic outcome. Understanding the differences between these types is crucial for selecting the right textile for your project.

Athletic polyester and beekeeping nylon

Check this out: functionality varies wildly between the two most common synthetics. Polyester is the king of the gym, while nylon serves more industrial purposes.

- Polyester Mesh: Does not absorb water; perfect for sports jerseys.

- Nylon Mesh: Extremely strong and durable; used for beekeeping veils and nets.

- Utility Mesh: Heavy-duty version used for laundry bags and screens.

These materials are highly resistant to pilling and bubbling. This makes them ideal for items that undergo frequent friction and heavy usage.

Tulle and compression power mesh

But wait, there is more for the fashion world. Fine, sheer mesh is used for volume, while power mesh is used for structural support.

- Tulle: Very fine, often stiff mesh used for bridal and dance wear.

- Power Mesh: High-stretch material used in sports bras and leggings.

- Powernet: A denser compression fabric used in high-end shapewear.

Key Takeaway: Choosing the right fabric mesh material requires a deep understanding of whether you need moisture-wicking, volume, or compression.

| Mesh Type | Primary Use | Feel | |

|---|---|---|---|

| Polyester | Sportswear | Crisp and textured | |

| Tulle | Formalwear | Soft to very stiff | |

| Power Mesh | Shapewear | Smooth and highly elastic |

Evaluate these material types to ensure your selection matches the intended end-user experience.

Is fabric mesh material eco-friendly?

As a petroleum-based product, fabric mesh material has a significant environmental footprint that manufacturers are now striving to reduce. The industry is moving toward recycled polymers to mitigate the reliance on fossil fuels.

Carbon footprint and microplastics

Here is the deal: the production of synthetic mesh is energy-intensive and relies on non-renewable resources. It involves high heat and chemical reactions that release byproducts.

- Fossil Fuels: Petroleum is the base for both polyester and nylon.

- Microplastics: Washing synthetic mesh can release fibers into the water supply.

- Longevity: These materials do not biodegrade and can persist for centuries.

Brands using fabric mesh material are encouraged to implement recycling programs. This helps keep these durable fibers out of landfills and oceans.

Transitioning to recycled mesh options

But wait, there is a solution. Many modern factories now offer mesh made from 100% recycled plastic bottles.

- Recycled Polyester: Reduces energy consumption by up to 50%.

- Chemical Recycling: Breaking down old mesh into new fibers.

- Biodegradable Additives: New tech aimed at helping synthetics break down faster.

Key Takeaway: While traditional fabric mesh material is not eco-friendly, choosing recycled variants can significantly lower your brand’s environmental impact.

| Impact Area | Challenge | Innovation | |

|---|---|---|---|

| Resource Use | Oil dependency | Bio-based and recycled polymers | |

| Pollution | Microfiber shedding | Advanced filtration in laundering | |

| Waste | Landfill persistence | Closed-loop recycling systems |

Consider these environmental factors when marketing your brand’s commitment to sustainable textile sourcing.

What certifications verify fabric mesh material?

To ensure quality and ethical standards, fabric mesh material should be verified by international certification bodies. These labels provide confidence that the textile is safe for skin contact and environmentally responsible.

Global Recycle Standard (GRS)

Check this out: if you are claiming to use recycled mesh, this is the gold standard. It tracks the material from the source to the final garment.

- Traceability: Verifies the percentage of recycled content.

- Social Criteria: Ensures fair labor practices at the mill.

- Environmental: Monitors chemical use and water treatment.

Without this certification, it is difficult to prove that your fabric mesh material is truly sustainable. It provides the transparency modern B2B partners demand.

Quality and safety standards

But wait, there is more to check than just recycling. General manufacturing standards ensure that the mesh is consistent and safe.

- ISO 9001: Focuses on consistent production quality.

- OEKO-TEX: Verifies the fabric is free from harmful chemicals.

- ANSI: Important for industrial or safety-grade technical mesh.

Key Takeaway: Always request GRS or OEKO-TEX documentation when sourcing fabric mesh material to guarantee safety and ethical compliance.

| Certification | Focus | Industry Application | |

|---|---|---|---|

| GRS | Sustainability | Recycled polyester and nylon | |

| OEKO-TEX | Chemical Safety | Clothing and intimate apparel | |

| ISO 9001 | Quality Management | General manufacturing and supply |

Review your supplier’s certifications to mitigate risk and ensure high standards in your supply chain.

How do you clean fabric mesh material?

Maintaining fabric mesh material requires specific care to prevent the open weave from snagging or losing its elasticity. Because the fibers are synthetic, they are sensitive to high heat and aggressive agitation.

Washing temperatures and protective bags

Here is the deal: heat is the enemy of synthetic mesh. Washing in cold water is the best way to preserve the fiber’s integrity.

- Laundry Bags: Always place mesh items in a protective bag to prevent snags.

- Cold Water: Prevents the breakdown of the polymer structure.

- Gentle Cycle: Minimizes the mechanical stress on the open weave.

Using the fabric mesh material correctly involves educating the end consumer on these simple steps. This ensures the garment lasts for years instead of months.

Drying and storage best practices

But wait, there is one more step. You should never put high-performance mesh in a hot dryer.

- Air Dry: Hang or lay flat to dry to preserve elasticity.

- No Ironing: High heat can melt the fine synthetic strands.

- Flat Storage: Heavier mesh items should be stored flat to avoid stretching.

Key Takeaway: Proper maintenance of fabric mesh material hinges on avoiding heat and using protective laundry bags during every wash.

| Care Step | Recommended | Avoid | |

|---|---|---|---|

| Washing | Cold water / Gentle cycle | Hot water / Heavy agitation | |

| Protection | Mesh laundry bag | Washing with zippers/Velcro | |

| Drying | Air dry / Line dry | High-heat tumble drying |

Follow these care guidelines to extend the lifecycle of your mesh products and improve customer satisfaction.

Is fabric mesh material better than knits?

When comparing performance textiles, fabric mesh material offers distinct advantages in scenarios where maximum airflow is required. While solid knits are better for warmth, mesh excels in weight-to-strength ratios and drying speed.

Airflow vs. thermal retention

Check this out: the mechanical difference is all about the gaps. Solid knits trap air to keep you warm, while mesh lets it escape to keep you cool.

- Mesh: Superior for passive cooling and rapid sweat evaporation.

- Solid Knits: Better for insulation but prone to clinging when wet.

- Weight: Mesh provides the same coverage at a fraction of the weight.

For high-intensity training, the fabric mesh material is the undisputed winner. It prevents the “bogged down” feeling common with sweat-soaked cotton.

Stretch recovery and durability

But wait, there is more to the comparison. Synthetic mesh often has better “snap-back” than natural fiber knits.

- Recovery: Power mesh retains its shape even after extreme stretching.

- Abrasion: Synthetic fibers are highly resistant to tearing.

- Maintenance: Mesh dries much faster than heavy cotton or wool blends.

Key Takeaway: For any application requiring breathability and lightweight strength, the fabric mesh material outperforms traditional solid knits.

| Property | Mesh Fabric | Solid Knit Fabric | |

|---|---|---|---|

| Breathability | Maximum | Low to Moderate | |

| Drying Speed | Rapid | Slow | |

| Weight | Ultra-light | Moderate to Heavy |

Compare these metrics to determine if mesh or a solid knit is more appropriate for your next garment line.

Conclusion

You now understand that choosing the right textile doesn’t have to be a struggle between comfort and performance. By implementing fabric mesh material into your product lines, you solve the chronic issues of heat retention and moisture buildup that plague standard weaves. Whether you are designing the next generation of athletic gear or specialized industrial filtration, this material provides the ventilation and durability you need. For more technical data or to discuss wholesale requirements, feel free to contact us today.

Frequently Asked Questions

Can I use mesh fabric for outdoor applications?Yes, synthetic mesh is highly resistant to moisture and mildew, making it ideal for outdoor gear, tent screens, and patio furniture.

What’s the best way to prevent mesh from snagging?The most effective method is using a mesh laundry bag during washing and avoiding contact with abrasive surfaces like Velcro or rough metal.

Can I dye mesh fabric at home?Since most mesh is made of polyester or nylon, you must use specialized synthetic dyes and high heat; standard cotton dyes will not bond with the fibers.

What’s the best mesh type for compression wear?Power mesh or Powernet are the industry standards for compression, as they incorporate high percentages of elastane for superior stretch and recovery.

Can I recycle old mesh garments?While difficult to do at home, many commercial textile recyclers can process synthetic mesh back into raw polymer pellets for new production.