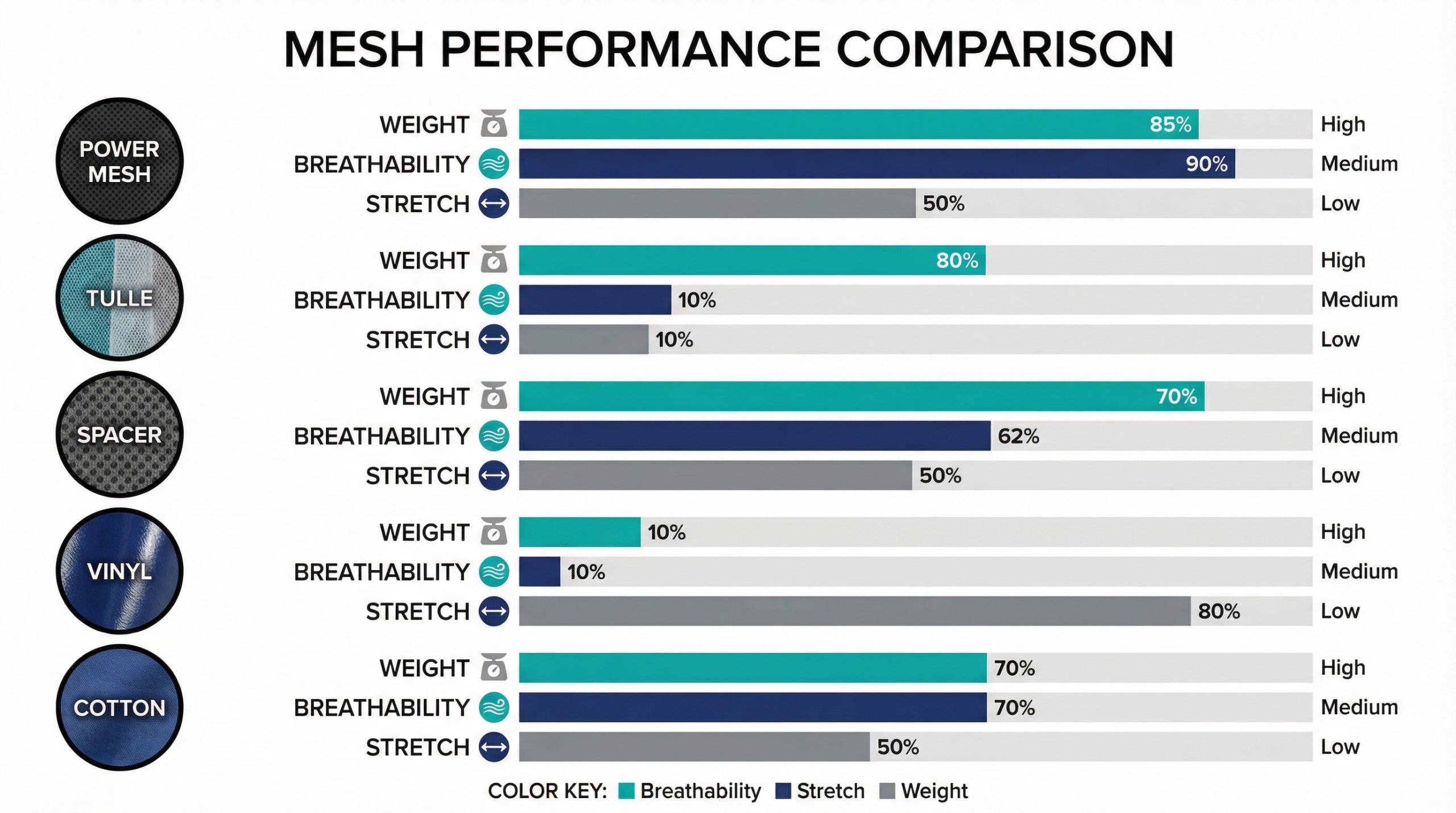

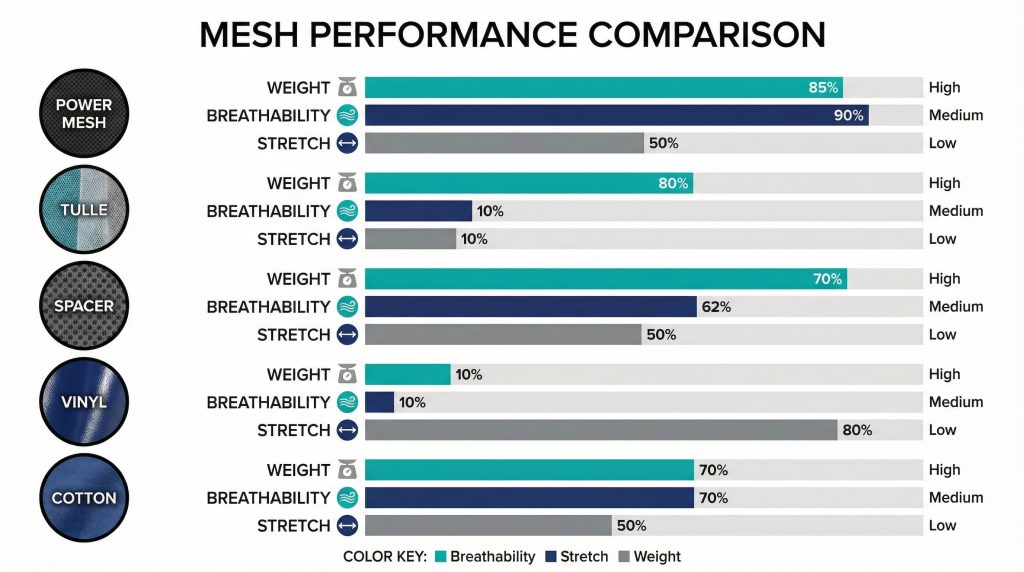

The 16 common types of mesh fabric range from high-performance power mesh to decorative tulle, each offering specific technical benefits for apparel, industrial, and medical applications. Selecting the wrong textile for a high-performance project can lead to catastrophic failure, such as sports garments that trap heat or industrial gear that tears under pressure. Imagine investing hours into a custom design only to find the material lacks the necessary stretch or fails to meet safety regulations for breathability. By understanding the technical specifications of each mesh type fabric , you can optimize for durability, comfort, and aesthetics in your next manufacturing endeavor.

Why is Power Mesh the best stretch mesh type fabric?

Power mesh is considered the ultimate stretch fabric because it combines high-density synthetic fibers with a unique interlocking knit that provides superior 4-way compression and recovery. This specific mesh type fabric is engineered to maintain its shape even after significant tension, making it a staple in the foundation garment and activewear industries.

You will find that its breathability remains uncompromised despite its high strength. The smooth “hand-feel” also ensures that it can be worn directly against the skin without causing irritation during movement.

Technical Performance Features

- 4-Way Stretch: Exceptional elasticity in all directions for maximum mobility.

- High Recovery: Returns to its original shape instantly without sagging or bagging.

- Breathable Texture: Fine gauge holes allow for constant air circulation and cooling.

- Soft Hand: A smooth finish that prevents chafing in high-friction zones.

Achieving Perfect Compression

Think about it: Most fabrics lose their “snap” after a few washes, but power mesh is built to last. If you are designing for high-impact sports or medical-grade compression, this material provides the consistent pressure your users require.

Designing for Durability

Key Takeaway: Power mesh is the industry standard for garments requiring both aesthetic transparency and functional body-shaping capabilities. It offers the most reliable “burst strength” for apparel that needs to work as hard as the athlete wearing it.

| Feature | Specification | |

|---|---|---|

| Material | Nylon/Spandex Blend | |

| Stretch | 4-Way Elasticity | |

| Durability | High Burst Strength | |

| Primary Use | Shapewear & Sports Bras |

While power mesh handles the body’s movement, other synthetic options prioritize environmental resistance.

Which polyester or nylon mesh type fabric fits your project?

Choosing between polyester and nylon depends on whether your project requires moisture management or pure abrasion resistance. This mesh type fabric selection dictates how your product will perform under sunlight exposure and heavy physical wear.

Polyester is generally the preferred choice for dye-sublimation and moisture-wicking apparel. Nylon, on the other hand, offers a higher strength-to-weight ratio and is better suited for rugged outdoor gear.

Material Comparison Points

- UV Resistance: Polyester maintains its color and integrity longer in direct sunlight.

- Wicking: Polyester fibers push moisture away from the skin for faster evaporation.

- Tensile Strength: Nylon is significantly harder to tear, making it ideal for safety gear.

- Dyeability: Polyester accepts vibrant digital prints, while nylon offers deep, rich solid tones.

Selecting the Right Fiber

The best part? You don’t have to guess which one is better once you identify your environment. If your gear is going to be used in the water or heavy sun, go with polyester; if it’s going through the woods, choose nylon.

Material Longevity Standards

Key Takeaway: Balancing the chemical properties of polyester and nylon ensures your product meets its expected lifespan. Always match the fiber type to the specific stressors of the end-user’s environment.

| Property | Polyester Mesh | Nylon Mesh | |

|---|---|---|---|

| UV Resistance | Excellent | Fair | |

| Drying Speed | Very Fast | Fast | |

| Abrasion Resistance | Moderate | High | |

| Weight | Lightweight | Lightweight |

Beyond basic fibers, apparel-specific weaves offer a different level of comfort and drape.

How do you choose an apparel-grade mesh type fabric?

You choose an apparel-grade mesh by evaluating the balance between its tactile softness and its structural ability to hold a garment’s silhouette. This mesh type fabric category includes everything from jersey linings to decorative tricot, focusing heavily on how the material feels against the body.

Jersey mesh is often used for athletic uniforms due to its classic look and high breathability. Meanwhile, tricot mesh offers a flatter, smoother surface that works perfectly for lining jackets or creating lightweight shorts.

Apparel Mesh Varieties

- Jersey Mesh: Features visible holes and a traditional athletic aesthetic for sports.

- Tricot Mesh: A run-resistant knit with a smooth side and a textured side.

- Lining Mesh: Ultra-lightweight and soft, designed to prevent outer fabrics from sticking to the skin.

- Pointelle Mesh: Features delicate, decorative patterns often used in feminine leisurewear.

Fashion and Function

Here is the deal: Apparel mesh isn’t just about airflow; it’s about the drape. If the fabric is too stiff, the garment will look bulky, but if it’s too soft, it won’t support the weight of the seams.

Optimization for Wearables

Key Takeaway: Successful apparel design requires a mesh that complements the primary fabric’s weight and stretch. Choosing the right lining or jersey knit can transform a standard garment into a premium, high-performance piece.

| Mesh Type | Best For | Hand-Feel | |

|---|---|---|---|

| Jersey | Sports Uniforms | Textured | |

| Tricot | Athletic Shorts | Smooth | |

| Lining | Windbreakers | Silky | |

| Pointelle | Casual Tops | Soft/Decorative |

When your design calls for volume rather than athletic performance, specialized fine netting is required.

When should you use a fine tulle mesh type fabric?

You should use a fine tulle when your project requires lightweight volume, transparency, or decorative layering for formal attire. This specific mesh type fabric is characterized by its hexagonal holes and “misty” appearance, making it the standard for bridal and evening wear.

Tulle can be made from silk, nylon, or polyester, with each offering a different level of stiffness. While nylon tulle is standard for tutus due to its “body,” silk tulle provides a liquid-like drape for luxury veils.

Decorative Application Uses

- Bridal Veils: Provides an ethereal, transparent layer that catches the light.

- Gown Support: Stiffer tulle layers underneath skirts create classic “ballgown” volume.

- Event Decor: Used for draping, floral arrangements, and delicate table runners.

- Millinery: Fine netting used in hats and hairpieces for a vintage aesthetic.

Creating the Ethereal Look

But wait, there’s more. Tulle isn’t just for weddings; it is increasingly used in modern “streetwear” as an overlay to add depth to basic garments. Its ability to hold shape without adding weight makes it a favorite for avant-garde designers.

Aesthetic Design Value

Key Takeaway: Tulle is the premier choice for visual impact and silhouette construction. Its variety of “hand” options—from soft to stiff—allows you to control the exact volume and movement of your design.

| Tulle Type | Material | Characteristic | |

|---|---|---|---|

| Soft Tulle | Polyester/Silk | Drapes beautifully | |

| Stiff Tulle | Nylon | Holds high volume | |

| Illusion Tulle | Fine Nylon | Nearly invisible | |

| Glitter Tulle | Synthetic | Reflective finish |

While tulle handles the delicate side of design, industrial gear requires a much more rugged solution.

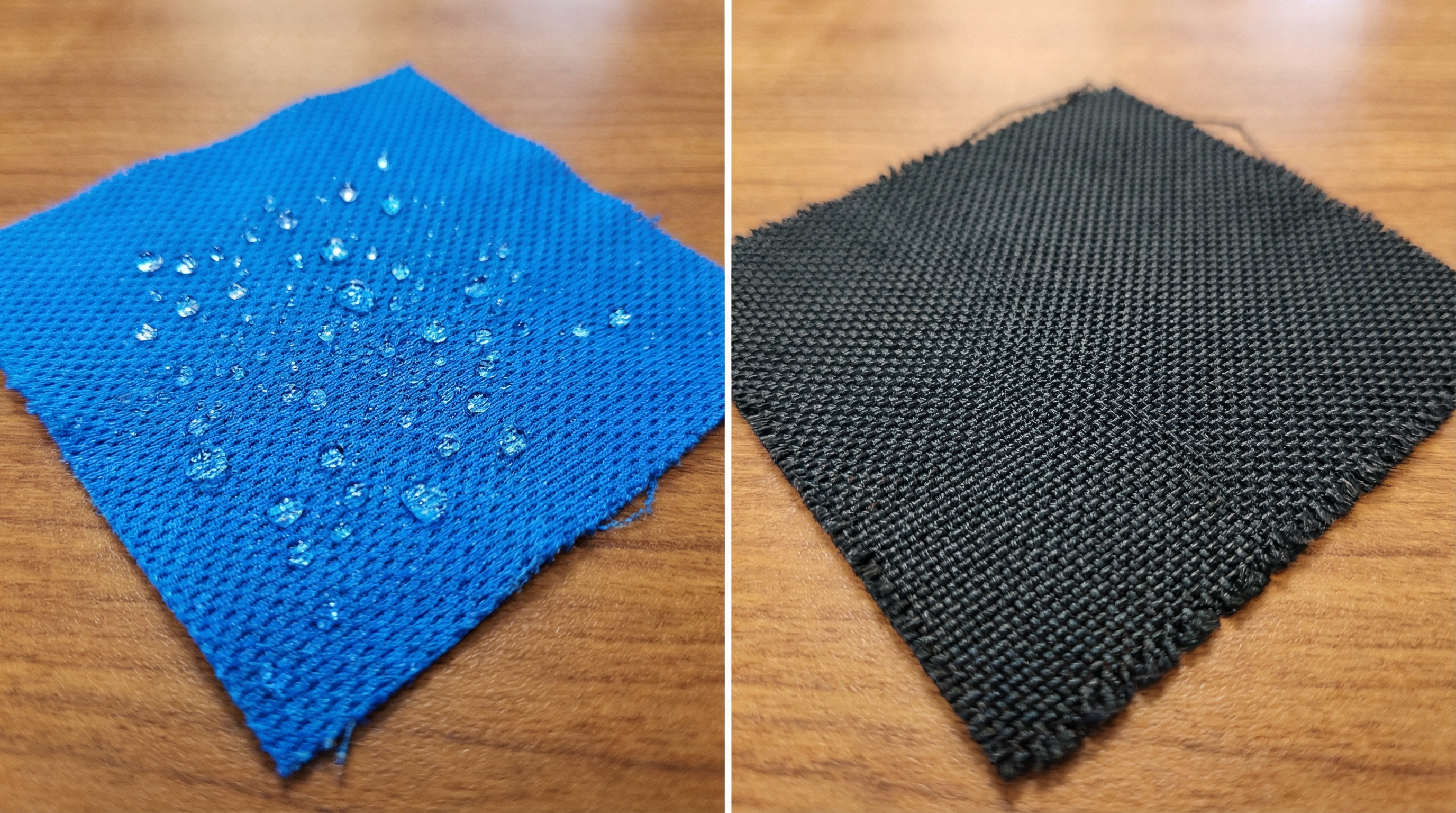

Is heavy-duty bag mesh the best mesh type fabric for gear?

Heavy-duty bag mesh is the best choice for gear because it is often reinforced with PVC or vinyl coatings to withstand extreme abrasion and heavy loads. This mesh type fabric is specifically designed to act as a structural component rather than just a decorative or breathable layer.

You will typically find this material on the exterior of backpacks, equipment bags, and outdoor furniture. Its plastic-coated fibers prevent the fabric from fraying or tearing even when subjected to the weight of metal tools or water bottles.

Durability Features for Gear

- Vinyl Coating: Protects the inner fibers from moisture and UV degradation.

- High Denier: Thicker yarns provide the “backbone” needed for structural integrity.

- Abrasion Resistance: Designed to survive being dragged across rough surfaces.

- Non-Absorbent: Plastic coatings ensure the mesh won’t hold water or become heavy when wet.

Building Reliable Equipment

The bottom line: If your product is meant for the outdoors, don’t settle for apparel-grade mesh. Bag mesh provides the “industrial strength” that ensures your customers won’t deal with ripped pockets or sagging bottoms.

Structural Integrity Focus

Key Takeaway: Coated meshes are essential for longevity in the luggage and outdoor industries. They offer the breathability of a mesh with the strength of a solid textile, providing the best of both worlds.

| Feature | Specification | Benefit | |

|---|---|---|---|

| Coating | PVC or Vinyl | Water Resistance | |

| Structure | Semi-Rigid | Holds Shape | |

| Strength | Heavy-Duty | Supports Weight | |

| Cleanup | Wipeable | Low Maintenance |

Innovation in gear doesn’t stop at coatings; 3D engineering has introduced a new way to handle airflow.

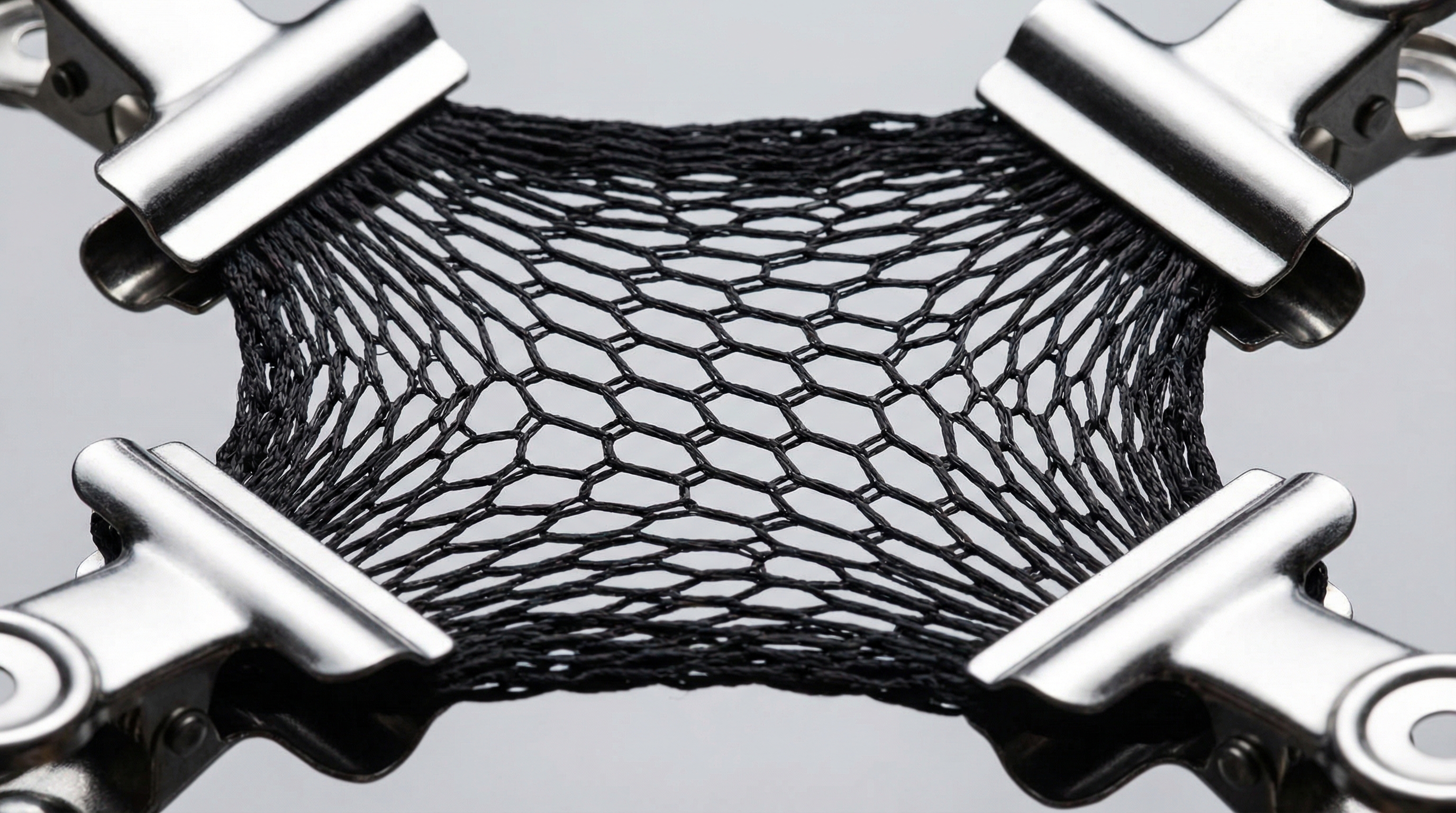

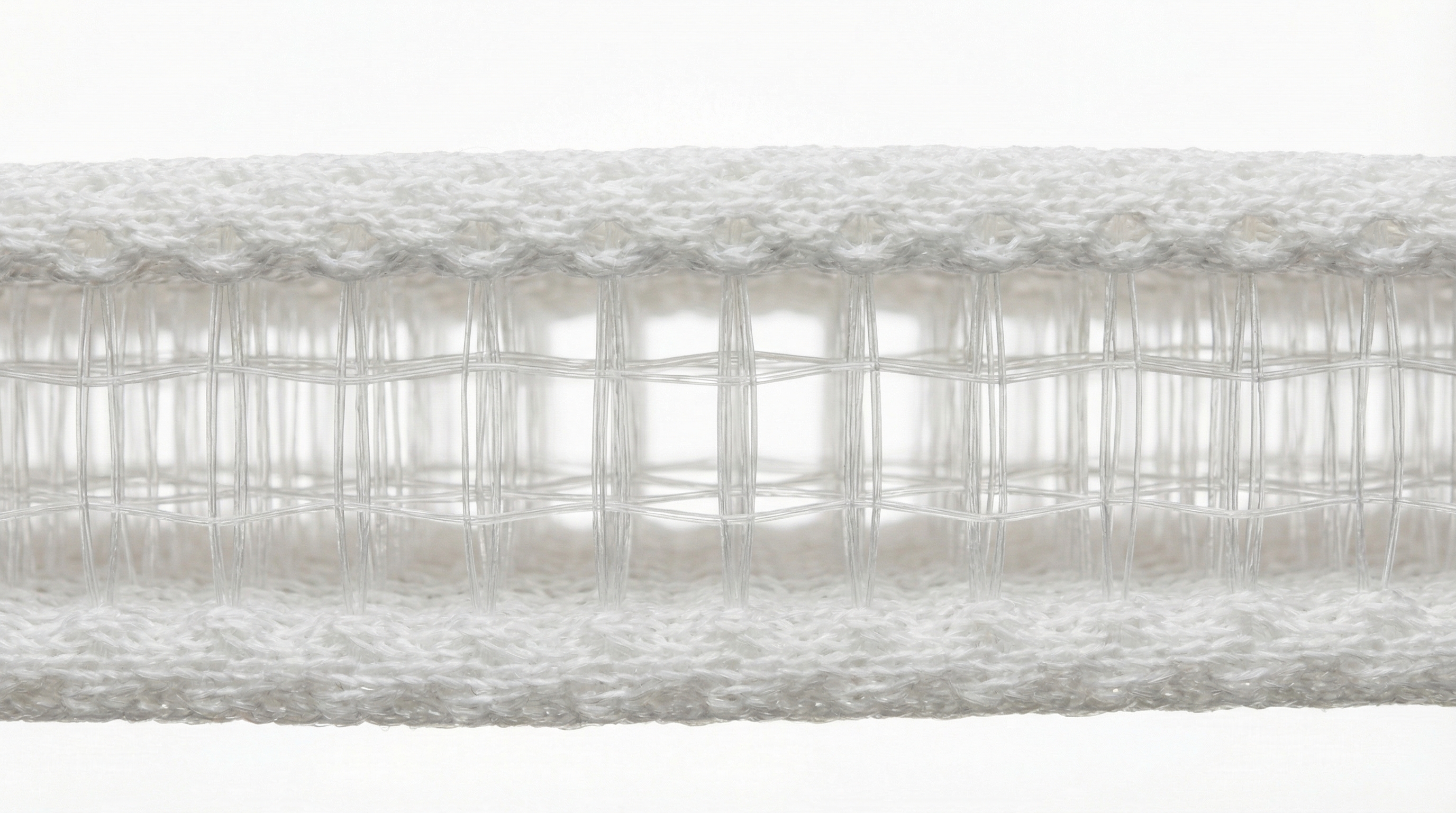

Can a 3D spacer mesh type fabric improve airflow?

Spacer mesh significantly improves airflow by utilizing a three-dimensional structure that creates a permanent air gap between two layers of fabric. This mesh type fabric uses vertical micro-filaments to hold the layers apart, acting like a breathable cushion that never goes flat.

This technology is widely used in footwear, backpack straps, and office chairs. By maintaining a physical space for air to travel, it prevents the buildup of heat and moisture against the user’s body.

Three-Dimensional Benefits

- Active Cooling: Constant air movement within the fabric core reduces sweat.

- Compression Comfort: Provides a “spring-like” cushioning effect without foam.

- Moisture Management: Liquid is quickly wicked away from the skin and evaporated.

- Lightweight Bulk: Adds thickness and protection without the weight of solid padding.

The Cushioning Revolution

Check this out: Most padding materials trap heat, but spacer mesh actually vents it. It’s the perfect solution for products that need to be “squishy” and comfortable but also cool and dry.

Engineering for Comfort

Key Takeaway: Spacer mesh is a superior alternative to traditional foam padding in performance applications. Its ability to provide both support and ventilation makes it indispensable for ergonomic product design.

| Layer | Function | Material | |

|---|---|---|---|

| Top Layer | Soft Contact | Polyester Knit | |

| Core Filaments | Air Gap/Support | Monofilament | |

| Bottom Layer | Stability | Reinforced Knit | |

| Total Effect | Breathable Cushion | 3D Composite |

While comfort is vital for footwear, industrial safety requires a different set of specialized certifications.

Why use a flame-retardant mesh type fabric for safety?

Flame-retardant mesh is essential for safety because it provides high visibility and breathability while meeting strict fire-resistance standards for hazardous work environments. This mesh type fabric is treated or woven with specialized fibers that self-extinguish when exposed to sparks or open flames.

In construction, mining, and utility work, staying cool is a major safety concern. These meshes allow for maximum ventilation, reducing the risk of heat stroke while ensuring the worker remains visible and protected from thermal hazards.

Safety and Compliance Standards

- High-Visibility Tones: Available in fluorescent orange and yellow for 24/7 safety.

- Flame Resistance: Meets ISO or ASTM standards to prevent the spread of fire.

- Tear Resistance: Built to withstand the rigors of heavy industrial labor.

- Airflow Optimization: Open weave prevents heat exhaustion in high-temperature zones.

Protection in High-Heat Zones

Think about this: Standard mesh is often made of plastic that melts onto the skin in a fire, which is why FR (Flame Retardant) certification is non-negotiable. If your team is working around electricity or heat, the right mesh can literally be a lifesaver.

Industrial Protection Values

Key Takeaway: Safety mesh is not just a uniform; it is a piece of protective equipment. Prioritizing certified flame-retardant materials ensures compliance and protects your most valuable asset—your people.

| Feature | Standard Requirement | Performance | |

|---|---|---|---|

| Visibility | ANSI/ISEA 107 | High | |

| Fire Rating | NFPA 701 / ASTM | Self-extinguishing | |

| Weight | Lightweight | High Breathability | |

| Color | Fluorescent | Neon Orange/Yellow |

Safety is critical in industry, but in the lifestyle market, natural fibers are making a significant comeback.

Does a natural cotton mesh type fabric exist for summer?

Natural cotton mesh does exist and is highly sought after for its exceptional skin comfort and eco-friendly properties in casual summer apparel. This mesh type fabric offers a softer, more organic alternative to synthetic meshes, making it ideal for brands focusing on sustainability.

Unlike polyester, cotton mesh absorbs moisture into the fiber itself, providing a different kind of cooling sensation. It is particularly popular for “net” shirts, market bags, and casual beachwear where a relaxed, knit-like aesthetic is desired.

Natural Fiber Advantages

- Eco-Friendly: Biodegradable and often available in organic certifications.

- Hypoallergenic: Ideal for sensitive skin that might react to synthetic chemicals.

- Static-Free: Natural fibers do not cling or spark like polyester or nylon.

- Soft Aesthetic: Offers a matte, “hand-knitted” look that synthetics cannot replicate.

Embracing the Organic Trend

You might wonder: Is cotton mesh durable enough for daily use? While it lacks the extreme burst strength of nylon, its comfort and breathability for casual fashion are unmatched, making it a favorite for sustainable summer collections.

Sustainable Fashion Value

Key Takeaway: Cotton mesh is the premier choice for ethical brands and casual comfort. It provides the air circulation needed for hot climates while maintaining a high-end, natural look and feel.

| Property | Cotton Mesh | Synthetic Mesh | |

|---|---|---|---|

| Material | Cellulose (Natural) | Petroleum (Synthetic) | |

| Feel | Soft / Matte | Silky / Shiny | |

| Sustainability | High | Variable | |

| Absorbency | High | Low |

While cotton protects your skin from the sun, other meshes are designed to protect you from nature’s pests.

How does an insect-proof mesh type fabric work?

Insect-proof mesh works by utilizing an ultra-fine “Noseeum” weave that is small enough to block the tiniest pests while still allowing for adequate ventilation. This mesh type fabric is a critical component for outdoor shelters, ensuring that hikers and campers can sleep safely without insect interference.

The hole size in this fabric is measured in microns, specifically engineered to stop midges and sandflies. Despite the dense weave, the material remains incredibly lightweight and nearly transparent, providing a clear view of the outdoors.

Insect Protection Engineering

- Micro-Hole Weave: Effectively blocks “noseeums,” mosquitoes, and ticks.

- High Transparency: Allows for excellent visibility from inside tents or headnets.

- Lightweight Packability: Can be folded into tiny spaces for ultraligth gear.

- Chemical-Free Barrier: Provides physical protection without the need for DEET.

Outdoor Survival Essentials

Here is the deal: If your mesh holes are too big, you are basically inviting the bugs in for dinner. Using a dedicated insect-proof mesh is the only way to ensure 100% protection in heavily infested forest or coastal areas.

Essential Outdoor Specs

Key Takeaway: For any product designed for sleeping or long-term outdoor exposure, insect-proof mesh is a functional requirement. It provides a vital health barrier while maintaining the comfort of fresh airflow.

| Feature | Specification | Protection Level | |

|---|---|---|---|

| Mesh Density | 600+ holes/sq inch | Total | |

| Weight | 0.5 – 0.9 oz/yd² | Ultra-light | |

| Visibility | High | Clear | |

| Pest Focus | Midges/Sandflies | Maximum |

Finally, some meshes move away from pure utility and embrace the world of high-fashion aesthetics.

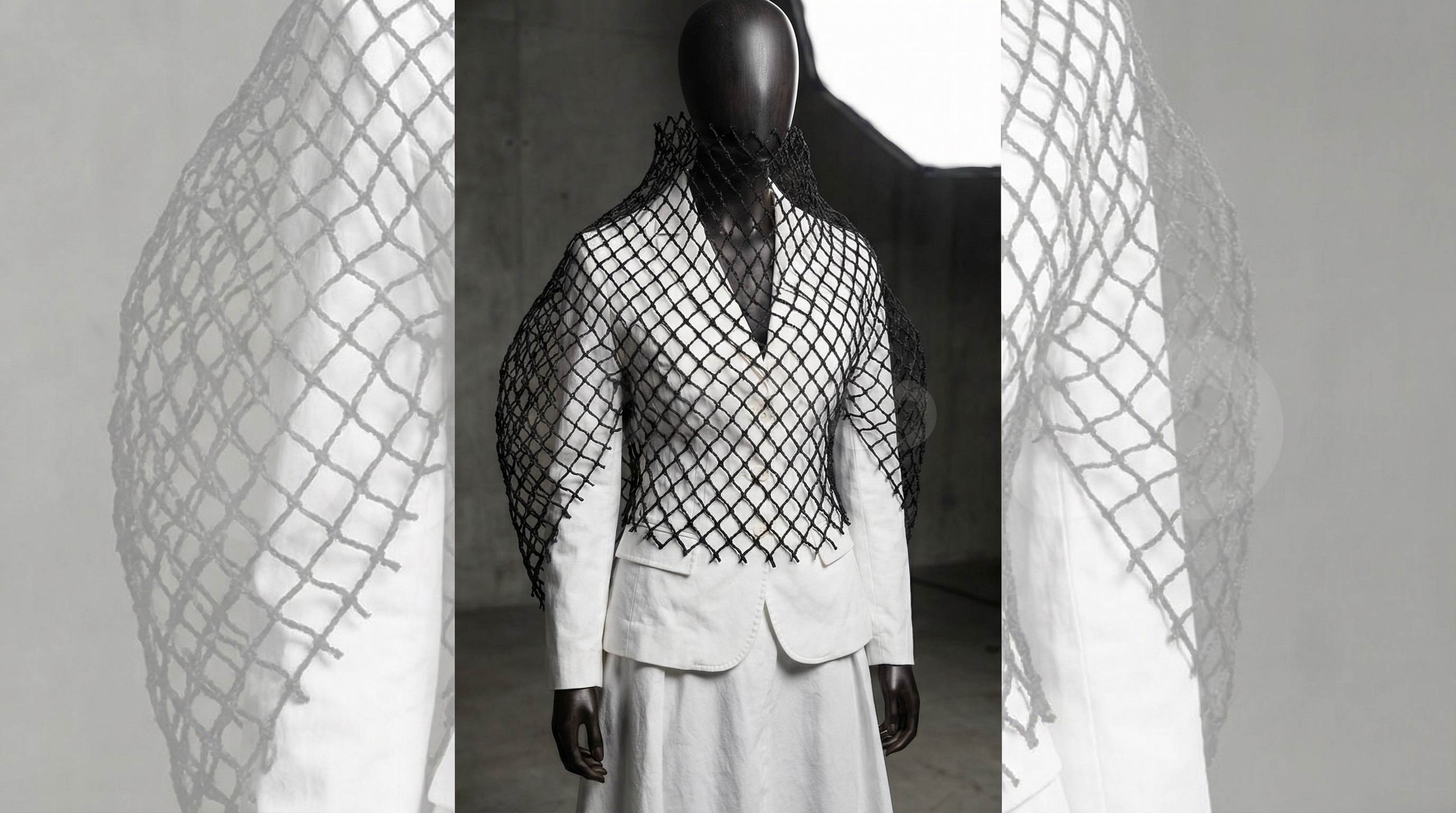

Where does fishnet rank as a trendy mesh type fabric?

Fishnet ranks as the most visually striking decorative textile because its large, diamond-shaped openings create bold geometric patterns on the body. This mesh type fabric has evolved from its origins in dancewear to become a staple of modern high-fashion and edgy streetwear overlays.

Because of its open structure, fishnet offers very little in terms of warmth or protection but excels in creating depth and texture. It is frequently layered over solid fabrics to add a “punk” or “industrial” aesthetic to a standard garment.

Fashion and Performance Roles

- Geometric Overlay: Creates dramatic shadows and visual interest in studio photography.

- Dancewear Standard: Highly elastic versions allow for total freedom of movement.

- Hosiery Classic: The most recognizable use of fishnet for a bold, leg-lengthening look.

- Texture Layering: Adds a 3D effect to jackets, tops, and even accessories like bags.

Styling the Bold Look

The best part? Fishnet is incredibly versatile; it can be made from delicate silk threads for luxury collections or heavy-duty cord for industrial-inspired streetwear. Its iconic look never goes out of style because it plays so well with light and layering.

Trend and Aesthetic Summary

Key Takeaway: Fishnet is the ultimate tool for designers looking to add “edge” and transparency to their collections. It prioritizes visual impact and silhouette over traditional fabric coverage.

| Feature | Detail | Impact | |

|---|---|---|---|

| Weave | Open Diamond | High Visual | |

| Elasticity | Variable | High (if spandex) | |

| Trend | Edgy / Alt | High | |

| Primary Goal | Decoration | Aesthetic |

From the rugged durability of vinyl-coated nylon to the delicate allure of bridal tulle, the world of mesh is defined by its ability to solve specific technical challenges. Whether you are engineering a tactical backpack or a high-fashion evening gown, your success depends on matching the mesh’s burst strength, stretch, and breathability to the user’s needs. At TulleMesh, we believe that the right material is the foundation of every great product. Explore our professional-grade selections and contact us today to find the perfect textile for your next manufacturing project.

FAQ: Frequently Asked Questions about Mesh

- What’s the best way to clean mesh fabric?Synthetic mesh is best cleaned with a gentle machine wash in a mesh bag to prevent snagging. Always air dry, as high heat in a dryer can melt fine synthetic fibers or damage elastic components like spandex.

- Can I use apparel mesh for outdoor gear?No, apparel-grade mesh generally lacks the UV resistance and abrasion strength required for outdoor environments. For gear like backpacks or tents, you should specifically look for vinyl-coated or high-denier nylon meshes.

- What is the difference between mesh and netting?Mesh is typically a knitted or woven fabric where the holes are part of the structure, while netting often refers to larger, knotted configurations. Mesh usually offers more stretch and a softer hand-feel than industrial netting.

- Does mesh fabric shrink after washing?Synthetic meshes made from polyester or nylon are naturally shrink-resistant. However, cotton mesh can shrink significantly if exposed to hot water or high-heat drying, so it must be handled with care.

- Is mesh fabric considered sustainable?Yes, many modern polyester meshes are now manufactured from recycled PET plastics, such as water bottles. This makes them a popular choice for eco-conscious athletic and outdoor brands.