Tulle fabric is a lightweight, fine-meshed netting characterized by its open, hexagonal structure and delicate appearance. For many procurement managers and designers, finding the perfect balance between sheerness and structural integrity is a constant struggle. You might encounter fabrics that are either too limp for a structured gown or too abrasive for a bridal veil, leading to production delays and inconsistent quality. Understanding what is tulle fabric made of is the first step toward optimizing your supply chain and ensuring your final products meet global standards of excellence.

What defines the structure of tulle?

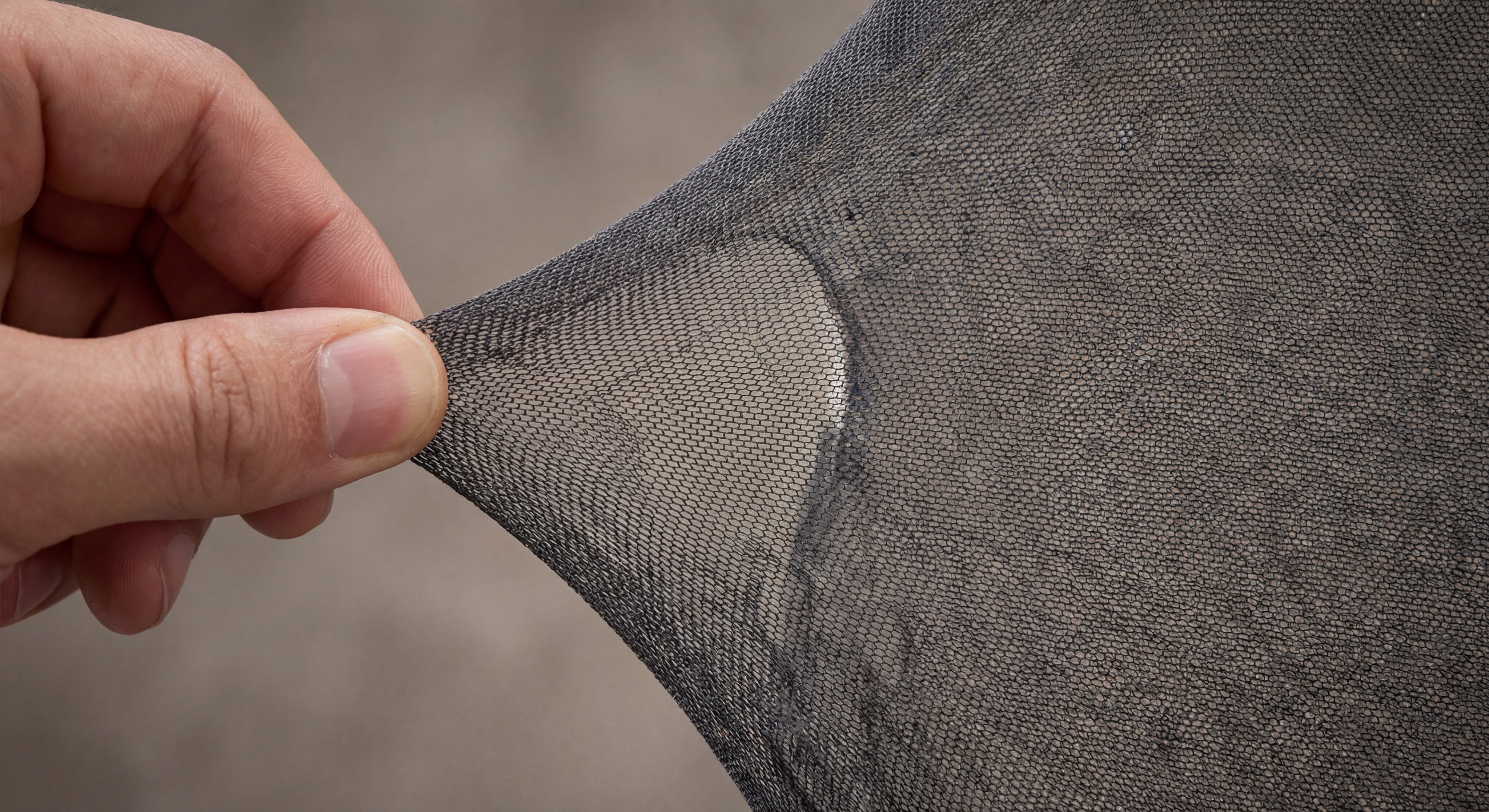

Tulle is defined by its distinctive hexagonal or honeycomb mesh pattern that provides both sheerness and structural integrity. This geometry allows the fabric to be incredibly light while resisting tearing under moderate tension. When you investigate what is tulle fabric made of , you find that the precision of these holes determines the fabric’s softness and “drape.” High-end manufacturing ensures that every hexagonal cell is uniform across the entire bolt.

How does the weave affect performance?

The tightness of the weave directly influences how the fabric reacts to manipulation and stitching. A smaller hole size generally results in a softer hand-feel, whereas larger holes are typical of more rigid, structural variants.

- Uniformity: Consistent hole size prevents snagging.

- Resilience: The hexagonal shape distributes stress evenly.

- Airflow: High permeability makes it ideal for layering.

Think about it: the geometry of the mesh is exactly what allows a single layer to look nearly invisible while ten layers create a bold, voluminous silhouette.

Key TakeawayThe hexagonal structure is the signature of true tulle, providing the mechanical properties required for both volume and transparency.

| Feature | Characteristic | Benefit | |

|---|---|---|---|

| Mesh Shape | Hexagonal/Honeycomb | High strength-to-weight ratio | |

| Hole Size | Variable (Fine to Large) | Controls stiffness and sheerness | |

| Weave Style | Warp Knitted | Prevents unraveling when cut |

Where can you find high-quality tulle?

High-quality tulle is best sourced directly from specialized manufacturers who utilize advanced warp-knitting technology like KARL MAYER machines. These professional facilities maintain strict climate controls to ensure the synthetic fibers do not become brittle or static-heavy during production. When evaluating what is tulle fabric made of, professional buyers look for fiber purity and dye consistency across large batches. A controlled studio environment ensures that the pastel shades you order today will match your production run six months from now.

Why choose factory-direct sourcing?

Sourcing directly from the manufacturer allows you to request specific finishes, such as flame-retardant coatings or anti-static treatments. It eliminates the middleman, ensuring that technical specifications are met precisely for your specific industry needs.

- Quality Control: Direct oversight of the knitting process.

- Customization: Ability to request custom GSM and colors.

- Scalability: Large machine counts support high-volume orders.

Here is the kicker: factory-direct relationships often grant you access to “virgin” fiber blends that offer superior clarity compared to secondary-market fabrics.

Key TakeawayProfessional sourcing ensures consistency in color and texture, which is critical for brands maintaining a high-end market position.

| Sourcing Factor | Factory Direct | Retail/Wholesale | |

|---|---|---|---|

| Color Matching | Precise Pantone Matching | Limited Stock Colors | |

| Lead Times | Predictable Production | Subject to Inventory | |

| Technical Support | Direct Engineer Access | General Sales Info |

How is tulle used in evening fashion?

In evening fashion, tulle serves as the primary material for creating volume, ethereal layers, and intricate overlays on formal gowns. It is favored for its ability to create a “cloud-like” effect without adding the significant weight associated with heavy satins or velvets. Designers often ask what is tulle fabric made of to determine how many layers can be stacked before the garment becomes unwieldy. The synthetic nature of most tulle ensures that these voluminous skirts hold their shape throughout an entire event.

Can you create volume without weight?

Layering is the secret to the dramatic silhouettes seen on international runways. Because tulle is mostly air, you can stack dozens of layers to create a ballgown shape while keeping the wearer comfortable.

- Gradation: Using different shades to create depth.

- Texturing: Ruffling or pleating layers for visual interest.

- Structure: Supporting heavier top fabrics with a tulle substructure.

Let’s face it: no other fabric can provide the same level of drama while remaining as light as a feather.

Key TakeawayEvening wear relies on the lightweight stacking properties of tulle to achieve high-fashion volume and movement.

| Application | Tulle Type | Effect | |

|---|---|---|---|

| Skirt Overlays | Soft/Fine Tulle | Dreamy, blurred aesthetic | |

| Petticoats | Stiff/Structural Tulle | Maximum volume and “lift” | |

| Illusion Sleeves | Ultra-Sheer Mesh | Skin-matching transparency |

What makes power mesh different from tulle?

Power mesh differs from standard tulle through its significant elastic content, typically spandex, allowing for four-way stretch and compression. While you might wonder what is tulle fabric made of, power mesh introduces elastomer fibers into the warp-knit process to create a functional, body-contouring material. Unlike traditional tulle, which has very little “give,” power mesh is designed to move with the body and return to its original shape. It is a staple in the athletic and shapewear industries where durability and flexibility are paramount.

Is stretch essential for your design?

Understanding the recovery rate of a mesh fabric is vital for performance apparel. If your design requires the fabric to provide support or compression, power mesh is the superior choice over standard decorative tulle.

- Recovery: The ability to snap back after being stretched.

- Breathability: Maintained even when the fabric is under tension.

- Smoothness: Low-friction surface for skin-contact applications.

The truth is: choosing standard tulle for a garment requiring high mobility will lead to fabric failure and customer dissatisfaction.

Key TakeawayPower mesh adds functionality and elasticity to the aesthetic properties of traditional netting, making it suitable for active applications.

| Property | Standard Tulle | Power Mesh | |

|---|---|---|---|

| Elasticity | Minimal/None | High (Four-way stretch) | |

| Fiber Content | 100% Nylon/Polyester | Nylon + Spandex/Elastane | |

| Primary Use | Fashion/Decor | Activewear/Shapewear |

Why is tulle the standard for bridal veils?

Tulle is the industry standard for bridal veils because of its extreme sheerness, lightweight drape, and ability to remain nearly invisible while holding shape. When manufacturers explain what is tulle fabric made of , they often highlight “Illusion Tulle,” which uses ultra-fine yarns to maximize transparency. This allow the bride’s features and the dress details to show through clearly. The fabric’s edges can also be cut cleanly without fraying, which is essential for raw-edge veil designs.

Which bridal tulle is right for you?

Different bridal styles require different drape characteristics. Silk tulle offers a liquid-like flow, while nylon variants provide the “pouf” often desired in traditional cathedral-length veils.

- Italian Silk Tulle: The pinnacle of luxury and soft drape.

- Nylon Illusion: The standard for clarity and cost-effectiveness.

- English Net: A heavier, more durable alternative with a distinct look.

It’s a no-brainer: the veil is the most scrutinized accessory, and the quality of the tulle can make or break the bridal look.

Key TakeawayThe choice of bridal tulle dictates the veil’s transparency and how it interacts with the light and the bride’s movement.

| Veil Type | Recommended Tulle | Visual Result | |

|---|---|---|---|

| Cathedral Veil | Illusion Tulle | Crystal clear, ethereal trail | |

| Drop Veil | Soft Silk Tulle | Delicate, face-contouring drape | |

| Blusher | Fine Nylon Mesh | Holds shape away from the face |

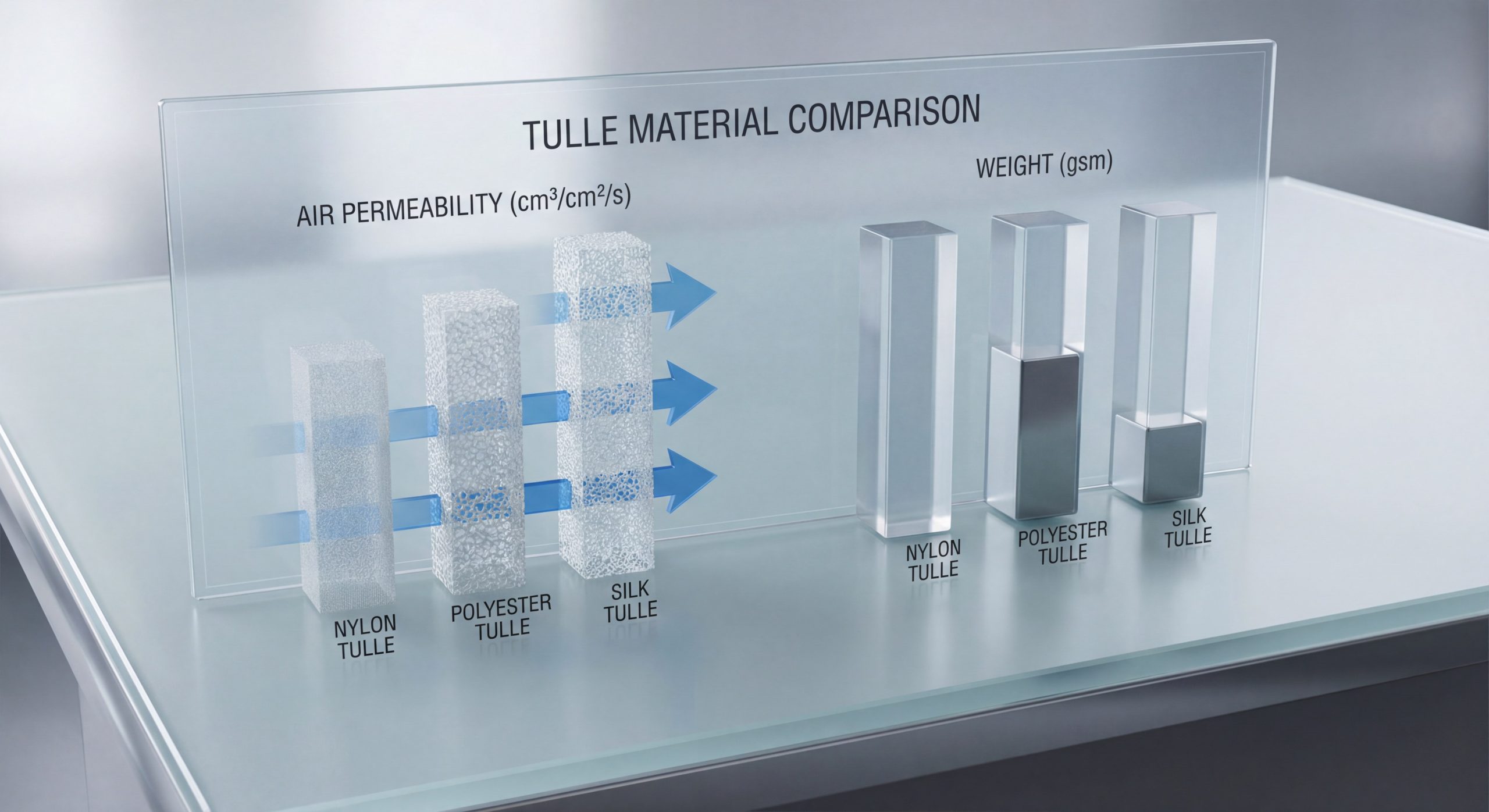

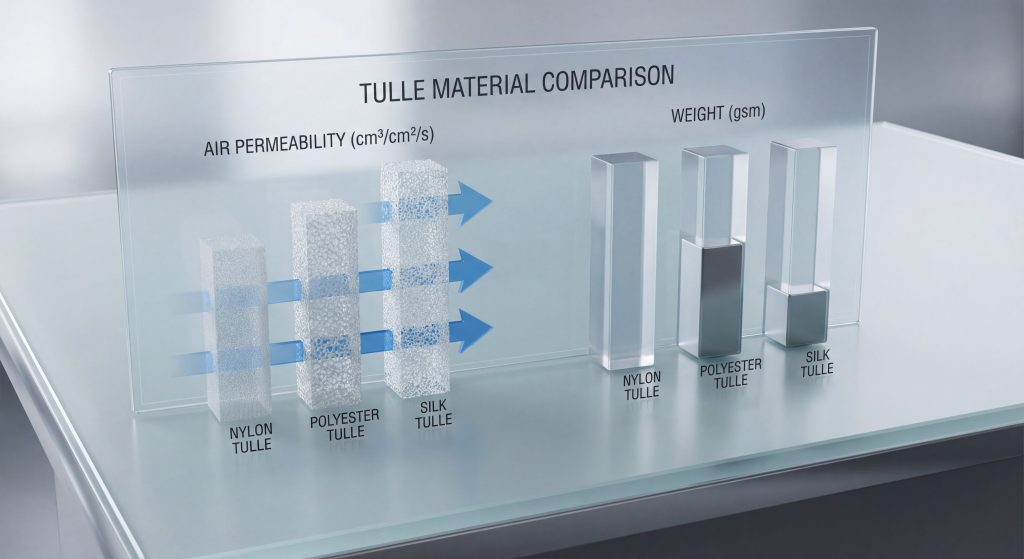

How do you compare fabric weights?

Comparing fabric weights involves measuring grams per square meter (GSM) to determine the density and opacity of the specific mesh variant. This analytical approach is crucial when deciding what is tulle fabric made of for a particular project, as GSM affects everything from airflow to cost. A lower GSM indicates a more “open” and sheer fabric, while higher GSM values are associated with industrial-strength meshes or heavy decorative tulles. Professionals use standardized charts to ensure that the fabric’s air permeability aligns with the intended functional use.

Why does GSM matter in B2B sourcing?

In business-to-business transactions, specifying the exact GSM ensures that you receive a consistent product that matches your prototypes. Variations in weight can lead to differences in dye absorption and structural behavior.

- Cost Control: Heavier weights typically use more raw material.

- Performance: Higher GSM often correlates with higher bursting strength.

- Aesthetics: Determines the level of sheerness and “body” of the drape.

Think about it: a 5-gram difference in GSM might seem small, but across a 10,000-meter order, it changes the entire character of your product line.

Key TakeawayGSM is the primary metric for ensuring technical consistency and cost-efficiency in bulk fabric procurement.

| Fabric Category | Typical GSM Range | Common Use Case | |

|---|---|---|---|

| Ultra-Light | 8 – 15 GSM | High-end bridal veils | |

| Standard Fashion | 18 – 30 GSM | Evening gown skirts/layers | |

| Industrial Mesh | 50 – 150+ GSM | Bags, filters, and safety gear |

How is structured tulle used in couture?

Structured tulle is utilized in couture to create architectural silhouettes, rigid pleats, and avant-garde shapes that softer fabrics cannot support. By manipulating what is tulle fabric made of through chemical sizing or heat-setting, manufacturers produce a “stiff” version of the mesh. This material acts as a scaffolding for fashion designers, allowing them to build shapes that defy gravity. In B2B fashion manufacturing, these structured tulles are essential for internal supports in garments that must maintain their runway shape during shipping and wear.

Can tulle support architectural shapes?

When you use high-denier fibers and a rigid finish, tulle becomes a structural element rather than just a decorative one. This allows for the creation of sharp angles and standing collars.

- Sizing Agents: Chemical finishes that increase stiffness.

- Layer Stiffening: Bonding layers to increase the fabric’s “memory.”

- Wire Integration: Using tulle as a base for wired architectural elements.

Believe it or not: many of the most dramatic “rigid” shapes you see on the red carpet are actually supported by internal layers of stiff tulle.

Key TakeawayStiffened tulle is a critical engineering tool in couture, enabling the creation of shapes that softer textiles could never achieve.

| Silhouette Goal | Tulle Requirement | Technique | |

|---|---|---|---|

| Sharp Pleats | High Stiffness | Heat-setting & Sizing | |

| Standing Collar | Heavy-duty Mesh | Layered structural bonding | |

| Bell Shape | Medium-Stiff Tulle | Multi-tier gathered construction |

Can tulle be used for industrial purposes?

Yes, tulle and mesh fabrics are frequently engineered for industrial purposes, including filtration, protective netting, and heavy-duty luggage components. While fashion designers focus on aesthetics, industrial engineers focus on what is tulle fabric made of in terms of tensile strength and chemical resistance. These heavy-duty meshes often use reinforced yarns and specialized coatings to withstand harsh environments. From pool filters to safety vests, the warp-knit structure of mesh provides the necessary durability and airflow for utility-grade applications.

What are the utility applications?

Industrial mesh is selected based on its “burst strength” and resistance to environmental factors like UV light or moisture. It is a versatile material that bridges the gap between textile and hardware.

- Filtration: Precisely sized holes for liquid or air flow.

- Cargo Nets: High-tensile strength for securing loads.

- Protective Gear: Breathable base layers for safety equipment.

Here is the kicker: the same basic knitting technology used for a wedding veil is what protects workers in the world’s most dangerous factories.

Key TakeawayThe versatility of the mesh structure extends far beyond fashion, providing essential solutions for the automotive, industrial, and safety sectors.

| Industrial Use | Key Metric | Material Choice | |

|---|---|---|---|

| Filtration | Micron Rating | Precision-knitted Polyester | |

| Luggage Pockets | Abrasion Resistance | High-Denier Nylon Mesh | |

| Safety Vests | Visibility/Airflow | Fluorescent Warp-Knit Mesh |

Is there a sustainable option for tulle?

Sustainable tulle is increasingly available, manufactured from recycled polyester (rPET) to reduce environmental impact while maintaining high performance. As global brands move toward greener supply chains, understanding what is tulle fabric made of helps identify eco-friendly alternatives to virgin petroleum-based plastics. These recycled variants offer the same clarity, strength, and dyeability as traditional tulle. For B2B buyers, switching to recycled mesh is a powerful way to meet ESG (Environmental, Social, and Governance) targets without sacrificing product quality.

Why transition to recycled mesh?

Consumer demand for sustainable fashion is at an all-time high, and using recycled materials can significantly enhance your brand’s market appeal. It’s a strategic move that aligns ethics with profitability.

- Lower Carbon Footprint: Uses significantly less energy during production.

- Waste Reduction: Repurposes post-consumer plastic bottles.

- Certification: Access to GRS (Global Recycled Standard) labels.

Think about it: you can deliver the same high-fashion look while actively contributing to a circular economy.

Key TakeawayRecycled tulle provides a sustainable path forward for the textile industry, matching the performance of virgin materials with a lower environmental cost.

| Sustainability Metric | Virgin Polyester | Recycled (rPET) | |

|---|---|---|---|

| Raw Material | Petroleum | Post-consumer Plastic | |

| Energy Usage | High | ~30-50% Lower | |

| Quality/Feel | Standard | Indistinguishable |

How does glitter tulle enhance designs?

Glitter tulle enhances designs by incorporating fine metallic particles or sequins directly into the mesh structure for a sparkling, high-impact aesthetic. When sourcing this material, B2B buyers must ask what is tulle fabric made of to ensure the glitter is bonded correctly and does not shed excessively during production. High-quality processed tulle uses specialized adhesives and heat-setting to keep the sparkle intact even when the fabric is handled. This makes it ideal for children’s costumes, holiday decor, and high-glamour evening wear where a “shimmer” effect is desired.

How is the glitter applied?

The application method determines the longevity of the sparkle. Modern factories use precision spraying or roll-printing techniques to ensure even coverage across the entire bolt.

- Non-Shedding Finish: Essential for clean production environments.

- Holographic Effects: Using multi-colored particles for depth.

- Patterned Glitter: Applying sparkle in specific motifs or shapes.

The bottom line is: glitter tulle adds a level of luxury and “wow factor” that plain mesh simply cannot replicate.

Key TakeawayDecorative tulle variants like glitter mesh allow designers to add visual texture and light-reflecting properties to their collections.

| Decorative Type | Aesthetic Effect | Application | |

|---|---|---|---|

| Glitter Tulle | Shimmer and Shine | Costumes & Holiday Decor | |

| Flocked Tulle | Velvet-like texture | Vintage-style fashion | |

| Sequin Mesh | High-impact sparkle | Red carpet evening wear |

Conclusion

Tulle is far more than a simple netting; it is a highly engineered textile that serves as the backbone of industries ranging from haute couture to industrial filtration. By mastering the nuances of its composition, weight, and structural variants, you can elevate your product offerings while optimizing your manufacturing costs. Whether you are seeking the ethereal drape of silk for a bridal collection or the high-tensile strength of industrial mesh for technical equipment, the right material choice is foundational to your success.

At Tullemesh, we are dedicated to providing global businesses with the highest quality tulle and mesh solutions. Our state-of-the-art facility and expert team are ready to help you navigate the complexities of textile sourcing and custom development. Experience the difference that professional manufacturing and direct factory access can make— contact us today to discuss your requirements and request your custom sample pack.

FAQ

Can I request custom colors for my tulle order?Absolutely. We specialize in precise Pantone matching to ensure your fabric aligns perfectly with your brand’s color palette and seasonal requirements.

How do I determine the right GSM for my project?It depends on your goals. Generally, lower GSM (8-15) is for delicate veils, while medium GSM (20-30) suits fashion layers, and higher GSM (50+) is for structural or industrial use.

Is your tulle flame-retardant?Yes, upon request. We can apply certified flame-retardant finishes that meet international safety standards for event decor and industrial applications.

What is the minimum order quantity (MOQ) for custom runs?Typically, our MOQ starts as low as 100 meters for stock items and varies for custom developments, allowing you to scale your business without excessive inventory risk.

Does your glitter tulle shed during the sewing process?Not significantly. We use advanced bonding agents and heat-setting techniques to minimize shedding, ensuring a cleaner production environment for your team.