Tulle is a lightweight, very fine, stiff netting fabric typically used to create volume in bridal wear, evening gowns, and tutus. You may find yourself envisioning a masterpiece design, only to realize the mesh you purchased sags under the weight of delicate embroidery. Choosing the wrong material leads to ruined silhouettes, wasted budget, and a garment that lacks the professional “wow” factor your clients expect. By mastering the technical details of what is tulle fabric made of , you can confidently select premium textiles that provide both ethereal beauty and structural integrity.

Why Is Finding the Perfect Tulle So Challenging?

To start, you must understand what is tulle fabric made of to select the right grade for your specific creative project. Many designers encounter “hobby-grade” meshes that feel scratchy against the skin or lack the necessary “spring” for high-fashion layering.

Is your design lacking the necessary ethereal volume?

Believe it or not, the difference between a flat skirt and a voluminous ballgown often comes down to denier and weave density. If you use a mesh that is too soft, the layers will collapse under their own weight.

- Softness vs. Stiffness balance.

- Denier count for weight management.

- Hexagonal hole size for transparency.

- Material recovery after compression.

Why do low-quality meshes ruin bridal silhouettes?

Think about it: a wedding gown is often the most important garment a person will ever wear. Using sub-standard mesh results in snagging, visible seams, and a lack of the “airiness” that defines luxury bridal couture.

Key Takeaway: Success in high-end garment construction requires a deep understanding of fabric mechanics and sourcing professional-grade materials.

What Is Tulle Fabric Made Of and How Is It Produced?

When evaluating what is tulle fabric made of , you will find that the raw materials dictate the final hand-feel and durability of the mesh. While historically made of silk, modern production relies on advanced polymers to achieve consistent results at scale.

Does the fiber origin change the fabric’s drape?

The best part? Synthetic fibers like nylon and polyester offer much higher durability and “memory” than traditional silk. This allows the fabric to maintain its crisp, hexagonal shape even after hours of wear.

- Polyester: Provides maximum stiffness and volume.

- Nylon: Offers a softer “hand” and better skin comfort.

- Silk: Extremely luxurious but very fragile and expensive.

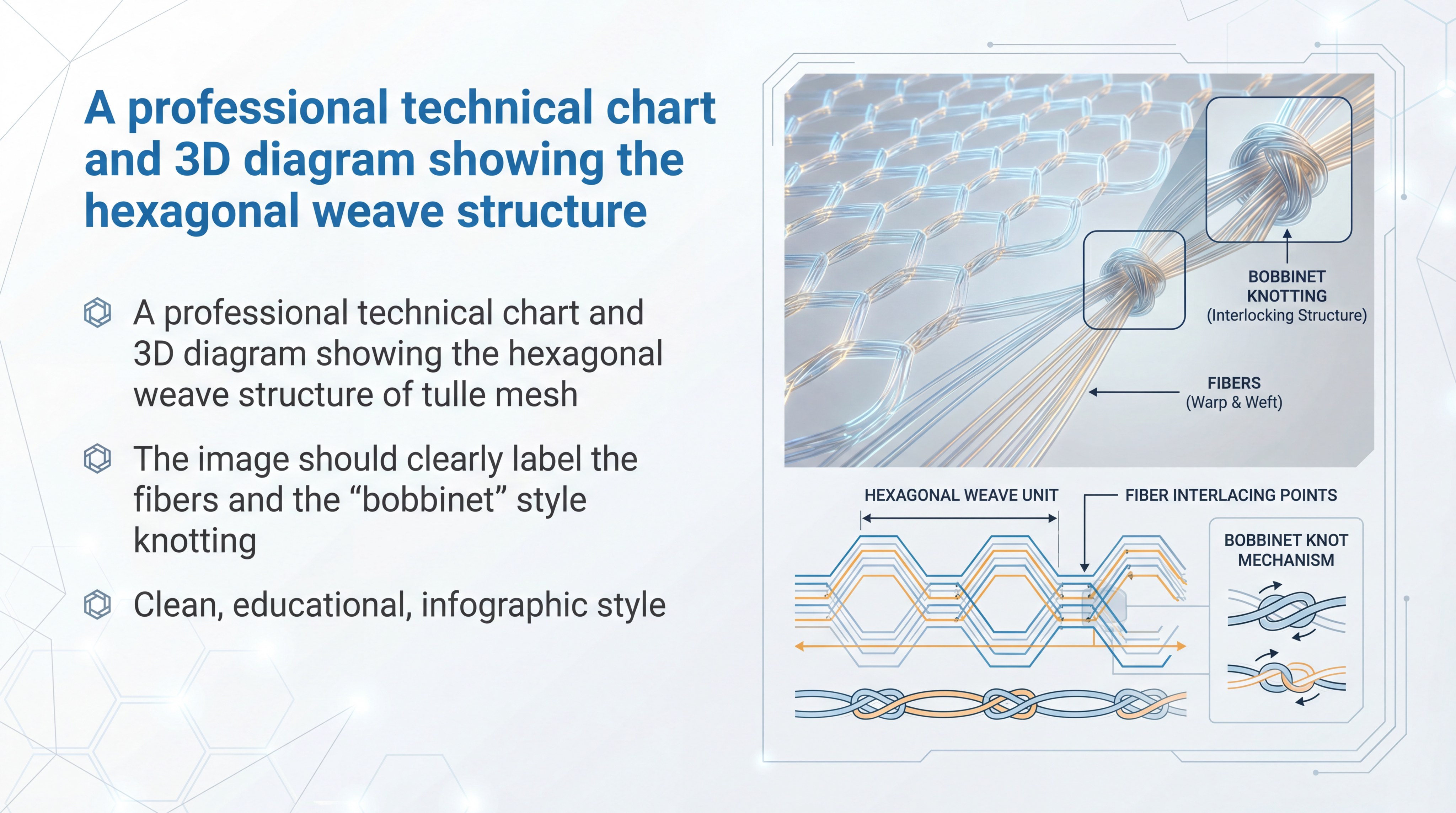

How does the hexagonal weave provide its strength?

But wait, there’s more to the production than just the fiber itself. The “bobbinet” process creates an interlocking structure that prevents the fabric from unravelling when cut, making it ideal for raw-edge finishes.

Key Takeaway: The combination of high-quality polymers and a precise hexagonal grid ensures the fabric remains resilient under tension.

| Material | Durability | Softness | Common Use | |

|---|---|---|---|---|

| Polyester | High | Low | Structural Skirts | |

| Nylon | Medium | High | Apparel Overlays | |

| Silk | Low | Extreme | Luxury Veils |

The analysis shows that polyester is the superior choice for garments requiring significant structural support and volume.

Which Tulle Varieties Best Suit Your Specific Needs?

You might ask what is tulle fabric made of when browsing different styles like illusion, stretch, or glitter variants to ensure the base material supports the finish. Selecting the wrong type can lead to glitter shedding or a lack of stretch in performance-wear.

What makes Soft Tulle ideal for delicate apparel?

Here’s the deal: Soft Tulle is specifically engineered with a finer denier to prevent skin irritation. You should choose this for garments that have direct skin contact, such as sleeves or bodice overlays.

- Superior drape for flowing skirts.

- Reduced friction against sensitive skin.

- High transparency for a “barely there” look.

Is Illusion Tulle the best choice for wedding veils?

Make no mistake, Illusion Tulle is the gold standard for veils because of its incredible clarity. It allows the bride’s features and hair to remain visible while providing a misty, romantic halo effect.

Key Takeaway: Matching the specific “hand” of the tulle to the garment’s function is the most critical decision in the design process.

| Tulle Type | Elasticity | Weight | Primary Benefit | |

|---|---|---|---|---|

| Soft Tulle | Low | Very Light | Comfort | |

| Illusion | None | Ultra Light | Transparency | |

| Stretch | High | Medium | Movement |

The data indicates that Illusion Tulle is unmatched for transparency, making it the primary choice for bridal headpieces.

Why Is Tulle Essential for Modern Bridal Couture?

Identifying what is tulle fabric made of is crucial for bridal designers who require structural support for heavy lace appliqués and beadwork. Without a strong mesh foundation, expensive embellishments can cause the gown to sag or tear.

How can you create layers without adding weight?

Look at it this way: tulle offers the highest volume-to-weight ratio of any textile. You can stack twenty layers of fine mesh to create a dramatic skirt that still feels light enough for the wearer to move comfortably.

- Adds “pouf” without the bulk of petticoats.

- Creates depth and shadow through layering.

- Supports heavy satin or silk top-layers.

Can tulle overlays transform a simple gown?

You might be wondering if a single layer can make a difference. Adding a tinted or glittered tulle overlay can completely change the color profile and texture of a basic crepe or satin base.

Key Takeaway: Tulle acts as the architectural framework for bridal gowns, providing the volume and support necessary for luxury aesthetics.

| Layer Count | Opacity | Visual Effect | Weight | |

|---|---|---|---|---|

| 1-3 | Sheer | Delicate Hint | Negligible | |

| 5-10 | Semi-Opaque | Ethereal Glow | Light | |

| 15+ | Opaque | Dramatic Volume | Moderate |

Analysis confirms that moderate layering (5-10 layers) provides the best balance between visual impact and garment weight.

How Does Tulle Impact Professional Costume Design?

Costume directors often investigate what is tulle fabric made of to ensure the fabric can withstand the rigors of stage performances and repeated cleaning. Performance-wear requires a level of resilience that standard fashion mesh simply cannot provide.

Why is stiffness a virtue in performance tutus?

In simple terms, a classical ballet tutu must remain perfectly horizontal during spins and jumps. You need a high-stiffness polyester mesh that “defies gravity” and maintains its crisp edge under stage lights.

- Classical Tutu: Requires maximum stiffness.

- Romantic Tutu: Needs soft, flowing nylon mesh.

- Character Wear: Uses medium-grade mesh for durability.

What are the secrets to layering for stage volume?

Bottom line? Stage volume is achieved through graduated layering techniques. By using stiffer mesh on the inner layers and softer mesh on the exterior, you create a structure that is both functional and beautiful.

Key Takeaway: Costume design requires a strategic mix of mesh stiffness levels to balance performer mobility with theatrical impact.

| Metric | Performance Tulle | Standard Tulle | Significance | |

|---|---|---|---|---|

| Stiffness | 9/10 | 4/10 | Shape retention | |

| Recovery | High | Low | Withstands action | |

| Dye Take | Fast | Slow | Custom color needs |

Professional performance tulle significantly outperforms retail versions in both stiffness and structural recovery.

Can Tulle Fabric Be Utilized for Industrial Solutions?

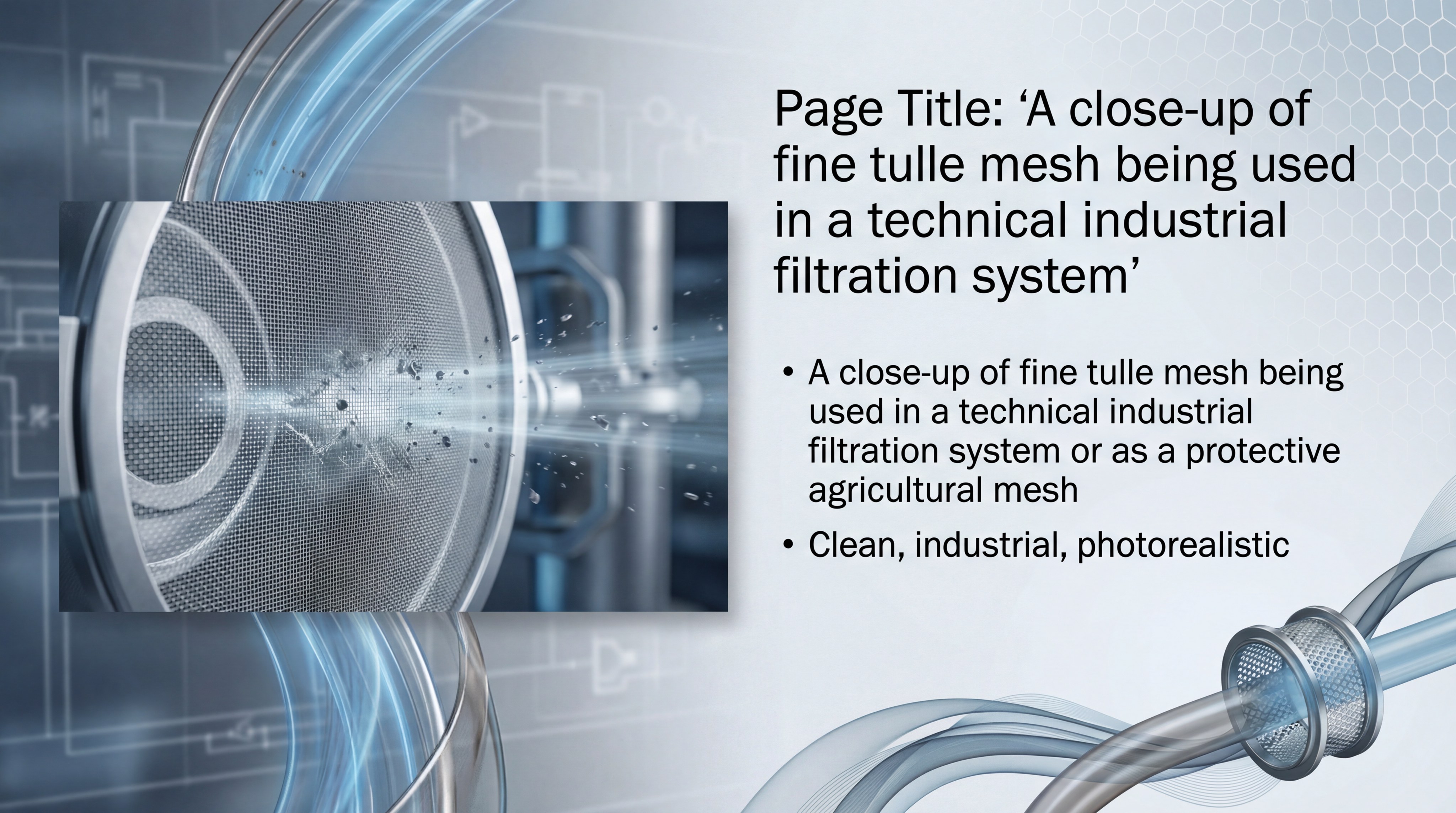

Technical engineers must know what is tulle fabric made of to assess chemical compatibility in filtration and protective applications. Beyond the runway, the hexagonal mesh structure serves critical functions in diverse commercial sectors.

Is tulle strong enough for commercial applications?

Believe it or not, industrial-grade tulle is used in everything from pool filters to agricultural crop protection. You will find that the uniform hole size makes it an excellent medium for sifting and separation.

- Consistent micron-level filtration.

- Resistance to UV degradation.

- High tensile strength for tensioning.

Have you seen tulle in medical or technical fields?

Think about it: the “open-cell” nature of mesh is perfect for supporting healing tissues or as a base for technical composites. It provides a lightweight framework that allows for maximum airflow and fluid drainage.

Key Takeaway: The structural uniformity of tulle mesh makes it a versatile tool for precision engineering and industrial protection.

| Industry | Application | Key Requirement | |

|---|---|---|---|

| Agriculture | Insect Barrier | UV Resistance | |

| Medical | Support Mesh | Biocompatibility | |

| Filtration | Fluid Sifting | Precise Pore Size |

Industrial applications rely heavily on the precise mesh geometry of tulle to ensure consistent filtration performance.

What Defines the Quality of Professional Tulle Mesh?

Quality inspectors focus on what is tulle fabric made of to determine if the polymers meet global safety and performance standards. When you are buying in bulk, a single defect in the hexagonal grid can lead to thousands of dollars in lost production time.

Why does “hand-feel” matter for luxury designers?

The best part? Professional tulle should feel smooth, not “crunchy” or plastic-like. You can distinguish high-quality mesh by its ability to bend without creating sharp, permanent creases.

- Uniformity: No irregular hole sizes.

- Dyeing: No streaks or splotches in color.

- Edges: Clean, stable selvedge lines.

How do you spot manufacturing defects in mesh?

But wait, there’s more to look for than just feel. You should inspect the mesh against a light source to check for “slubs” or broken filaments that could snag delicate laces during the assembly process.

Key Takeaway: Rigorous quality control ensures that the mesh you receive is free of structural weaknesses and aesthetic inconsistencies.

| Quality Marker | High-End Tulle | Budget Tulle | Impact | |

|---|---|---|---|---|

| Grid Symmetry | Perfect | Irregular | Visual Clarity | |

| Fiber Purity | 100% Polymer | Recycled Mix | Strength | |

| Dye Level | Consistent | Faded Edges | Color Matching |

Investing in high-end tulle prevents production delays caused by fabric inconsistencies and material failure.

What Are the Best Techniques for Sewing Delicate Tulle?

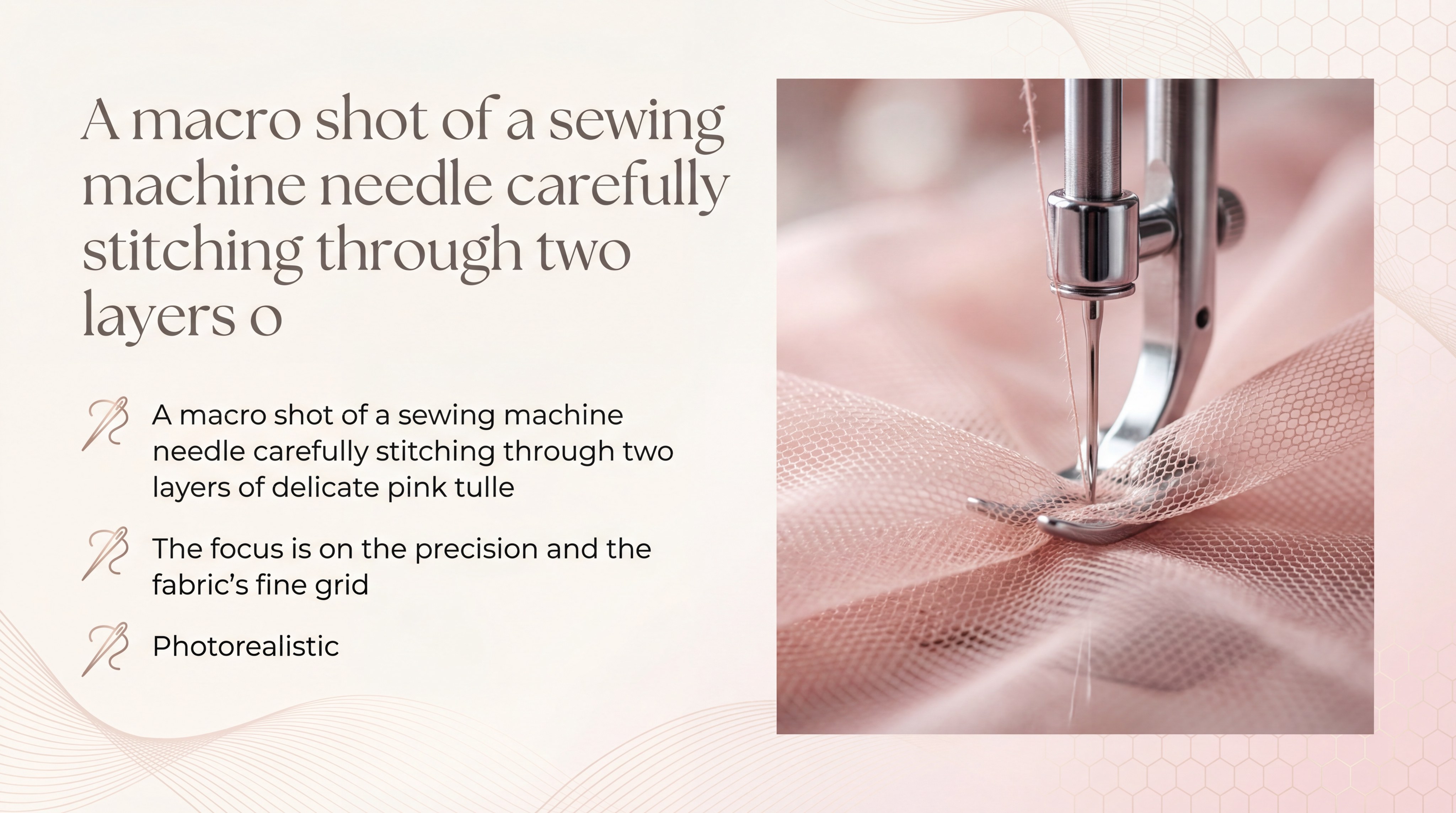

Your sewing success depends on knowing what is tulle fabric made of so you can adjust needle heat and thread tension correctly. Working with mesh is notoriously difficult because the fabric can easily get sucked into the throat plate of your machine.

Which needles prevent snagging during production?

Here’s the deal: you must use a brand-new “Microtex” or Sharp needle. Ballpoint needles are designed for knits and will simply push the tulle filaments aside, leading to skipped stitches or unsightly puckering.

- Size 60/8 or 70/10 needles.

- Fine 100% polyester thread.

- Short stitch length (2.0mm).

How do you finish edges without visible bulky seams?

Make no mistake, traditional serging is often too heavy for sheer tulle. You should utilize a rolled hem or a “French seam” to keep the construction as invisible and lightweight as the fabric itself.

Key Takeaway: Precision tools and specialized stabilizers are essential for maintaining the delicate aesthetic of tulle during the sewing process.

| Tool | Specification | Reason | |

|---|---|---|---|

| Needle | Microtex 60/8 | Prevents snagging | |

| Thread | Fine Poly | High Strength | |

| Foot | Walking Foot | Even Feeding |

The use of a Microtex needle is the single most important factor in achieving professional, pucker-free tulle seams.

How Should You Properly Clean and Store Tulle?

Maintenance protocols are derived from what is tulle fabric made of because different fibers react uniquely to steam and detergents. If you apply high heat directly to a nylon mesh, you risk melting the fibers and permanently ruining the garment.

Can you machine wash such a delicate material?

Look at it this way: hand washing is always the safest route. If you must use a machine, you should place the item in a protective mesh laundry bag and use the coldest setting available.

- Soak in cool water with mild soap.

- Rinse without wringing.

- Air dry on a flat surface.

What is the safest way to remove stubborn wrinkles?

You might be wondering if you can iron tulle. No, you should never touch an iron directly to the mesh; instead, use a professional steamer from a distance to gently release creases without damaging the polymer structure.

Key Takeaway: Gentle cleaning and vertical steaming are the only ways to preserve the loft and clarity of high-quality tulle over time.

| Action | Recommended | Prohibited | |

|---|---|---|---|

| Cleaning | Hand Wash | Dry Cleaning | |

| Wrinkles | Steaming | Flat Ironing | |

| Drying | Air Dry | Tumble Dry |

Steaming is the only safe method for wrinkle removal, as direct heat from an iron will compromise the mesh integrity.

Why Choose a Direct Supplier for Your Tulle Needs?

Sourcing efficiency begins with understanding what is tulle fabric made of through a direct manufacturer’s technical specifications. When you cut out the middleman, you gain access to consistent dye lots and significantly better wholesale pricing for bulk orders.

Does bulk sourcing improve your project margins?

In simple terms, buying direct allows you to scale your production without sacrificing quality. You will have a dedicated partner who understands the technical requirements of your industry, whether it’s bridal or industrial filtration.

- Volume discounts on large rolls.

- Direct access to custom colors.

- Guaranteed material consistency.

How do custom mesh solutions solve design hurdles?

Bottom line? A direct supplier can adjust the denier or stiffness of the mesh to meet your exact specifications. You no longer have to settle for “off-the-shelf” options that don’t quite fit your vision.

Key Takeaway: Direct manufacturer partnerships provide the technical support and cost-savings necessary for long-term business growth in the textile industry.

| Benefit | Direct Supplier | Retail Store | Impact | |

|---|---|---|---|---|

| Pricing | Wholesale | Premium | Higher Margins | |

| Customization | Available | None | Design Freedom | |

| Lead Times | Optimized | Variable | Better Planning |

The analysis shows that direct sourcing is the most strategic choice for businesses looking to maximize profit and design flexibility.

Frequently Asked Questions

Can I dye tulle fabric at home?

Yes, but you must use the correct dye for the fiber. Since most tulle is made of nylon or polyester, you will need a synthetic-specific dye like Rit Dyemore and high heat to ensure the pigment bonds to the polymer.

What’s the best way to cut tulle without it fraying?

Absolutely nothing special is required because the bobbinet weave is inherently stable. You can use sharp fabric shears or a rotary cutter to create clean, raw edges that will not unwrap or shed filaments.

Can I use tulle for outdoor event decorations?

Highly recommended, as polyester tulle is remarkably weather-resistant. It does not absorb water and dries quickly, making it the perfect choice for draping wedding arches or creating outdoor table runners.

What is the difference between tulle and net fabric?

Directly speaking, tulle is a specific, high-quality subtype of netting. While all tulle is net, not all net is tulle; tulle is distinguished by its much smaller hexagonal holes and softer, more refined hand-feel.

Is tulle fabric environmentally friendly?

Generally no, as most variants are petroleum-based synthetics. However, you can now source recycled polyester tulle that offers the same performance metrics while reducing the environmental impact of your production.

Conclusion

Mastering the nuances of tulle fabric allows you to elevate your designs from standard to extraordinary. By understanding the material composition, choosing the right variety for your application, and sourcing from professional manufacturers, you ensure every project meets the highest standards of quality. Whether you are crafting a dream wedding gown or engineering an industrial filter, the right mesh makes all the difference. We offer a comprehensive range of premium tulle solutions tailored to your specific needs. To discuss your next project or request samples, contact us today .