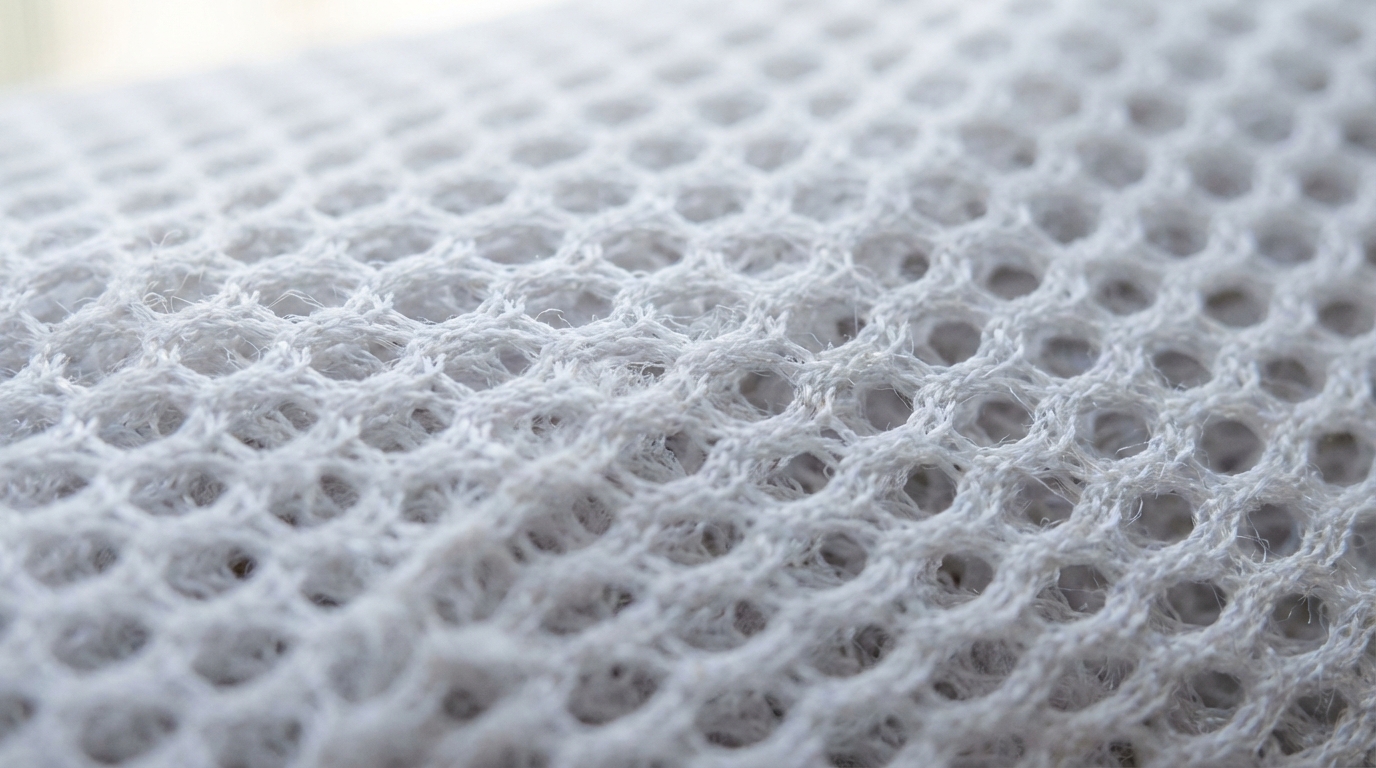

Mesh fabric is a lightweight, permeable material characterized by its open-weave structure that creates thousands of tiny holes for maximum breathability. Finding the right balance between durability and ventilation for high-performance apparel is often a complex challenge for professional designers. If you choose the wrong textile, your products might trap heat and moisture, leading to poor user experiences and diminished brand trust. By understanding the various types of mesh fabric , you can source the ideal material for everything from athletic jerseys to delicate evening wear.

What are the core characteristics of mesh?

The fundamental [types of mesh fabric] are distinguished by their open-knit patterns and exceptional moisture management properties. You will notice that unlike solid textiles, these materials prioritize airflow and lightness above all else. They are typically made from synthetic fibers to ensure they remain strong despite the many apertures in the weave.

Why is breathability the primary feature?

Think about it. The “holes per inch” (HPI) rating directly dictates how much air can pass through the garment. When you design for high-intensity movement, you need a material that allows heat to escape instantly.

- High HPI leads to more transparency.

- Low HPI provides more structural coverage.

- Synthetic fibers prevent water absorption.

Key Takeaway: Choosing the right breathability level ensures your end-users remain cool and comfortable during physical exertion.

| Feature | Mesh Specification | |

|---|---|---|

| Weight | Typically 50-150 GSM | |

| Pore Size | Variable based on HPI | |

| Fiber Base | Primarily Polyester/Nylon |

Analysis: The structural design of mesh is inherently engineered for thermal regulation in active environments.

How is this material actually manufactured?

When exploring the manufacturing of various types of mesh fabric , you will find that the process begins with the extraction of polyamide monomers from petroleum. These monomers are reacted with acids to create polymers, which are then melted and extruded through spinnerets. This creates long, durable strands that serve as the foundation for the weaving process.

How does the weaving process work?

You might be wondering how those distinct holes are formed so consistently. High-speed industrial looms use specific knitting patterns, such as the Raschel technique, to lock the fibers in place while leaving gaps. This ensures the fabric does not unravel even if a single thread is damaged.

- Raschel knitting for intricate patterns.

- Heat-setting to stabilize the mesh structure.

- Dying processes performed at the fiber or bolt level.

Key Takeaway: Precision manufacturing ensures that the fabric maintains its shape and structural integrity under significant tension.

| Production Stage | Key Action | |

|---|---|---|

| Polymerization | Chemical formation of synthetic chips | |

| Extrusion | Creating fine yarn filaments | |

| Knitting | Forming the open-grid pattern |

Analysis: The move toward automated knitting technology has drastically improved the uniformity and strength of modern mesh.

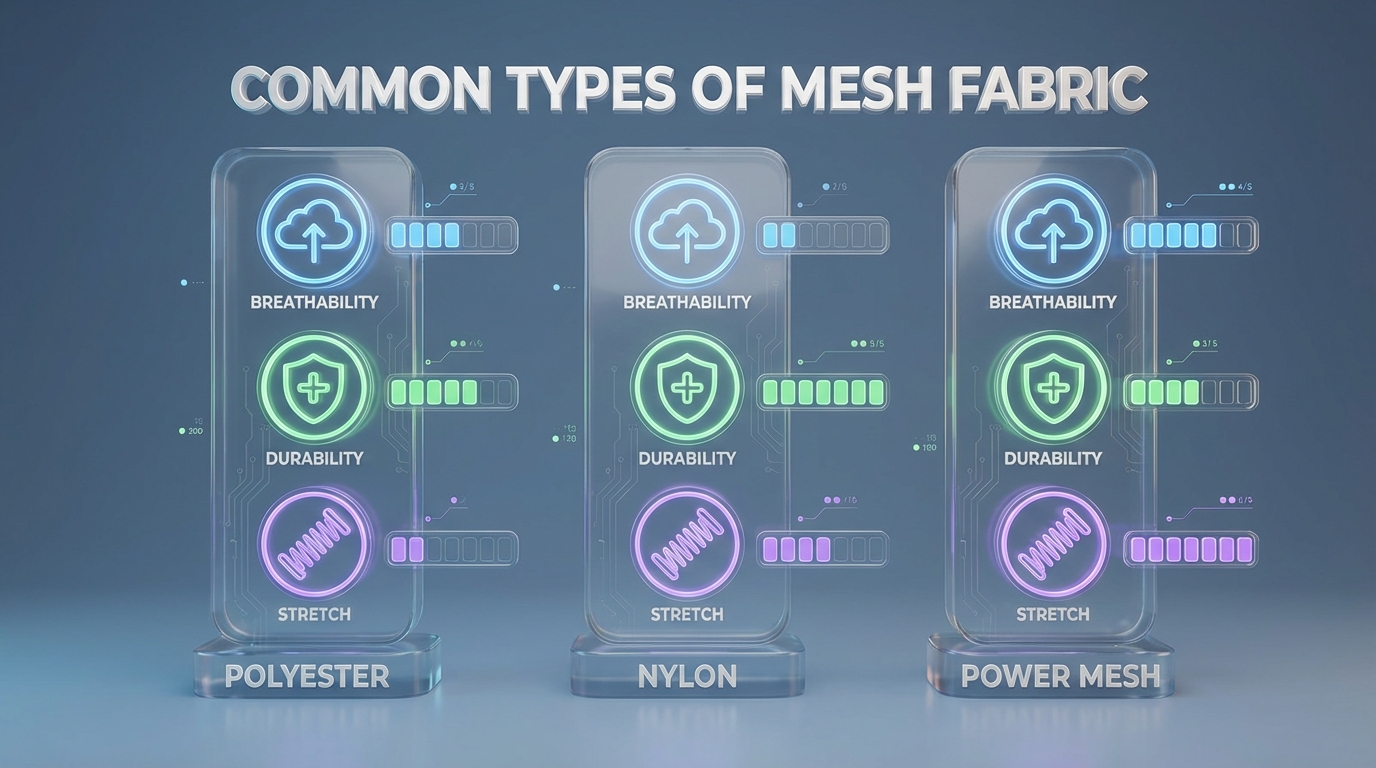

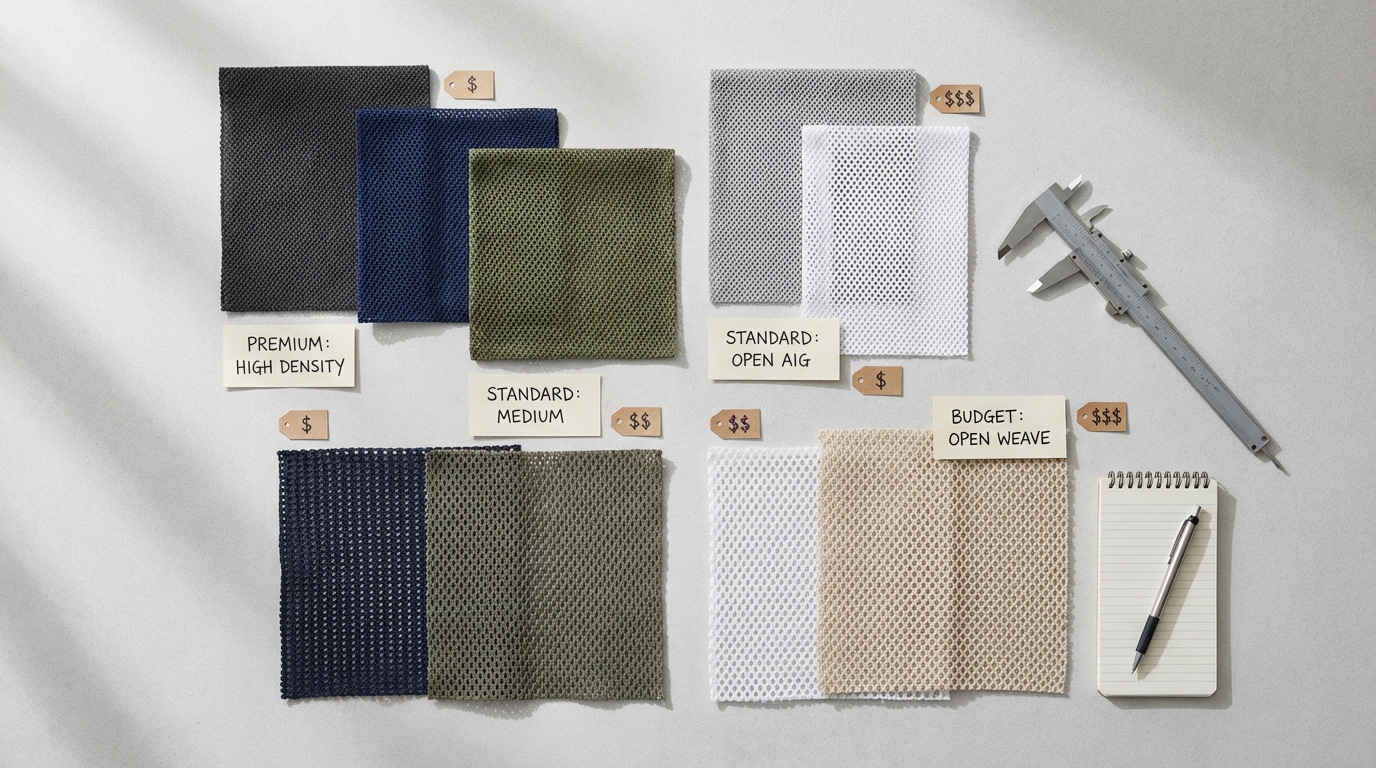

What are the most common variants available?

The diverse [types of mesh fabric] available on the market today range from basic polyester grids to highly specialized compression nets. You must identify which variant suits your specific application, whether it is for lining a jacket or creating a structured tutu. Polyester and nylon remain the dominant choices due to their resilience and low cost.

What is the difference between Power Mesh and Tulle?

But here is the kicker: not all mesh is designed to stretch the same way. While Tulle is often used for decorative purposes and stiff structures, Power Mesh contains elastane to provide significant compression.

- Polyester Mesh: Ideal for athletic jerseys and shorts.

- Nylon Mesh: Often found in industrial filters and bags.

- Powernet: Used for high-compression medical or shapewear gear.

Key Takeaway: Selecting the correct mesh variant allows you to balance aesthetic transparency with the required mechanical stretch.

| Mesh Variant | Primary Material | Best Use Case | |

|---|---|---|---|

| Soft Tulle | Nylon/Polyester | Bridal and Decorative | |

| Power Mesh | Spandex Blend | Shapewear and Lingerie | |

| Air Mesh | Polyester | Shoe linings and Backpacks |

Analysis: Categorizing mesh by stretch capacity helps designers match fabric performance to garment function.

Where is mesh production centered globally?

The global supply chain for different types of mesh fabric is heavily concentrated in Asian markets, particularly China. You will find that these regions benefit from advanced petroleum refining capabilities and massive textile infrastructure. While historical production began in the United Kingdom, the scale of Asian manufacturing now dictates global pricing and availability.

Why is China the leading exporter?

Believe it or not, the integration of chemical plants and textile mills in the same region reduces costs significantly. This vertical integration allows for faster production cycles and lower logistics expenses for bulk orders.

- Proximity to raw petroleum resources.

- Massive labor force trained in synthetic textiles.

- High-volume export facilities for international shipping.

Key Takeaway: Sourcing from global hubs ensures you have access to a wide variety of mesh styles at competitive price points.

| Export Region | Market Role | Focus Area | |

|---|---|---|---|

| East Asia | Dominant Supplier | Mass production of polyester | |

| Southeast Asia | Growing Hub | Competitive labor for finishing | |

| Europe/USA | Niche Producer | Specialized technical mesh |

Analysis: Geographical proximity to raw material processing remains the primary driver of textile manufacturing locations.

How does the apparel industry utilize mesh?

The application of various [types of mesh fabric] has expanded far beyond the traditional athletic jersey. You can now see mesh utilized in luxury fashion, medical compression garments, and even high-end footwear. Its versatility lies in its ability to provide structure without adding weight or trapping heat.

Why is mesh essential for activewear?

It’s a no-brainer. Athletes generate significant sweat, and mesh is the only material that allows for rapid evaporation while maintaining a professional appearance. You can strategically place mesh panels in “high-heat” zones like the underarms or back for targeted cooling.

- Ventilated jerseys for team sports.

- Breathable uppers for running shoes.

- Compression layers for muscle support.

Key Takeaway: Implementing mesh in apparel design directly improves user performance by regulating body temperature.

| Industry Sector | Application Method | Material Choice | |

|---|---|---|---|

| Sportswear | Full garment or paneling | Polyester Mesh | |

| High Fashion | Overlays and veiling | Soft Tulle | |

| Footwear | Lining and exterior | Spacer Mesh |

Analysis: The functional versatility of mesh makes it a staple component across diverse garment categories.

What technical properties define its performance?

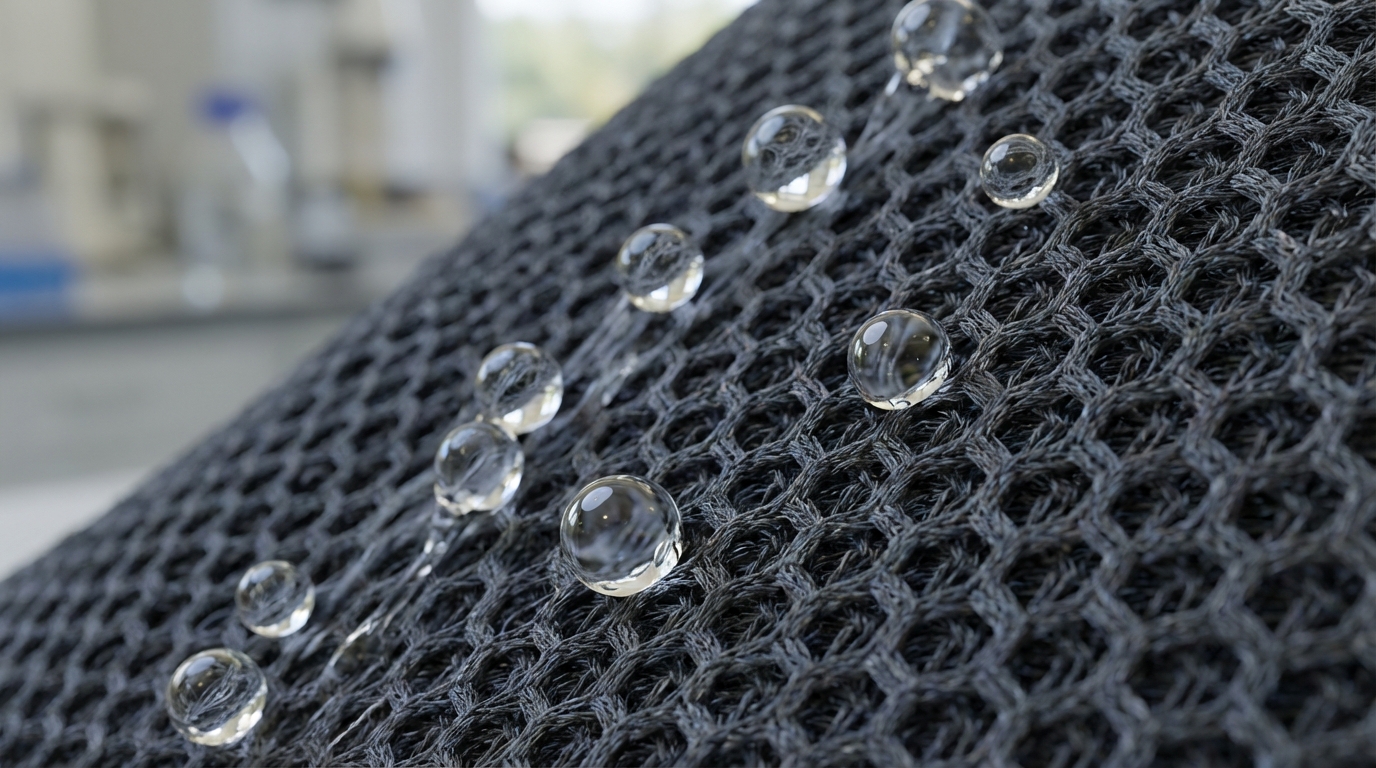

The performance of various types of mesh fabric is measured by its durability, moisture-wicking ability, and UV resistance. You should evaluate these metrics based on the intended environment of the final product. For instance, outdoor gear requires higher UV stability to prevent the synthetic fibers from becoming brittle.

How does moisture wicking work in mesh?

Think about it. Synthetic fibers like polyester are naturally hydrophobic, meaning they don’t absorb water. Instead, the capillary action of the weave pulls moisture away from the skin and spreads it across the fabric surface.

- Hydrophobic fibers prevent water weight gain.

- Open weave increases surface area for drying.

- High tensile strength prevents tearing under stress.

Key Takeaway: Technical mesh properties ensure that your garments remain lightweight and dry even during intense physical activity.

| Technical Metric | Performance Level | Benefit | |

|---|---|---|---|

| Drying Speed | Extremely Fast | Improved comfort | |

| Tensile Strength | High | Longevity of use | |

| Stretch Recovery | Excellent (if blended) | Retains garment shape |

Analysis: Engineering mesh for specific moisture-wicking targets is the key to creating superior performance apparel.

Does manufacturing impact the environment?

Understanding the environmental footprint of different [types of mesh fabric] is increasingly important for modern B2B procurement. You must be aware that because these fabrics are synthetic, they are derived from non-renewable fossil fuels. The chemical processes involved in polymerization and dyeing can lead to water contamination if not managed correctly.

Can mesh be sustainable?

The truth is, traditional mesh does not biodegrade and can contribute to microplastic pollution. However, you can mitigate this by sourcing recycled polyester (rPET) which turns post-consumer plastic waste into high-quality fiber.

- Recycled polyester reduces energy consumption.

- Water-free dyeing processes limit chemical runoff.

- Long-lasting durability reduces the need for frequent replacement.

Key Takeaway: Opting for recycled or responsibly manufactured mesh helps your brand meet sustainability goals without sacrificing quality.

| Impact Factor | Traditional Mesh | Sustainable Alternative | |

|---|---|---|---|

| Raw Material | Virgin Petroleum | Recycled Plastics | |

| Degradability | Non-biodegradable | Recyclable | |

| Water Usage | High | Optimized/Closed-loop |

Analysis: The industry shift toward recycled synthetics is the most effective way to reduce the ecological impact of mesh.

What factors influence the wholesale cost?

The pricing for bulk types of mesh fabric fluctuates based on raw material costs and the complexity of the finishing treatments. You will find that simple, undyed polyester mesh is the most budget-friendly option for mass production. However, adding features like flame retardancy or custom antimicrobial coatings will increase the per-yard price.

Why does “Power” mesh cost more?

But here is the kicker: the inclusion of spandex or elastane fibers significantly increases the manufacturing cost. These elastic fibers are more expensive to produce and require more complex knitting machines to handle the tension.

- Spandex content increases material cost.

- Custom dyes and patterns add labor hours.

- High-quality finishes (anti-odor) command a premium.

Key Takeaway: Understanding cost drivers allows you to optimize your budget by selecting the right level of technicality for your needs.

| Price Driver | Cost Impact | Why? | |

|---|---|---|---|

| Basic Polyester | Low | Mass-produced, simple weave | |

| Elastane Blends | Moderate | Complex fiber integration | |

| Technical Coatings | High | Additional chemical processing |

Analysis: Strategic material selection can significantly reduce production costs while maintaining the required functionality.

Which industry certifications should you verify?

When sourcing [types of mesh fabric], looking for specific certifications ensures that the materials meet international safety and quality standards. You should prioritize suppliers who can provide documentation for their environmental claims and structural testing. This is especially critical if you are selling into markets with strict regulatory requirements for textiles.

What does GRS certification mean?

You might be wondering if “recycled” claims are always legitimate. The Global Recycle Standard (GRS) tracks and verifies the recycled content throughout the entire supply chain, giving you peace of mind.

- ISO 9001: Ensures quality management consistency.

- GRS: Verifies recycled material origins.

- OEKO-TEX: Confirms the absence of harmful substances.

Key Takeaway: Verifying certifications protects your brand from liability and ensures the safety of the end-consumer.

| Certification | Focus Area | Market Relevance | |

|---|---|---|---|

| GRS | Sustainability | High for eco-conscious brands | |

| ISO 9001 | Operations | Essential for B2B reliability | |

| ANSI | Safety | Critical for industrial use |

Analysis: Third-party verification remains the only reliable way to confirm technical and ethical claims in textile sourcing.

How do you maintain mesh quality over time?

Proper care for types of mesh fabric is essential to prevent snagging and the loss of elasticity. You must educate your customers on the best laundering practices, as high heat can permanently damage synthetic fibers. Because of the open-weave structure, these fabrics are more prone to catching on sharp objects during the wash cycle.

Is machine washing safe for mesh?

Actually, it depends on the protection you provide. Using a dedicated mesh laundry bag prevents the fabric from tangling with zippers or hooks that could cause unsightly snags.

- Use cold water to protect synthetic bonds.

- Avoid the dryer; air drying is always safer.

- Use mild detergents to prevent fiber degradation.

Key Takeaway: Gentle care routines extend the lifespan of mesh garments and maintain their aesthetic and functional properties.

| Care Action | Recommendation | Result | |

|---|---|---|---|

| Washing | Cold Water/Delicate | Prevents fiber melting | |

| Drying | Air Dry | Maintains elasticity | |

| Protection | Laundry Bag | Prevents snags and tears |

Analysis: Thermal stress is the primary enemy of synthetic mesh, making temperature control the most vital aspect of maintenance.

Whether you are designing the next generation of athletic gear or a stunning collection of evening wear, understanding the technical nuances of mesh fabric is vital. From its petroleum-based origins to the precision of Raschel knitting, every detail impacts the final performance of your product. If you are ready to source high-quality materials or need further expert guidance on textile selection, contact us today to find the perfect solution for your business.

Frequently Asked Questions

Can I use mesh fabric for outdoor upholstery?Yes, but you should ensure it is specifically UV-treated. Most synthetic mesh will degrade under constant sun exposure unless it has been engineered with protective coatings.

What’s the best way to prevent mesh from fraying?Always use a serger or a zig-zag stitch when sewing. Because of the open weave, raw edges will unravel easily if they are not properly finished with a secure stitch.

How do I know if a mesh is high quality?Check the hole uniformity and the “snap-back” of the stretch. High-quality mesh will have perfectly consistent apertures and will immediately return to its original shape after being pulled.

Can I print designs directly onto mesh?Yes, but you should use sublimation printing for the best results. Since mesh has many holes, traditional screen printing may bleed, whereas sublimation dyes the actual fibers for a crisp look.

What’s the best mesh for compression garments?Powernet is the superior choice. It features a much denser weave than standard athletic mesh, providing the mechanical tension required for body contouring and support.