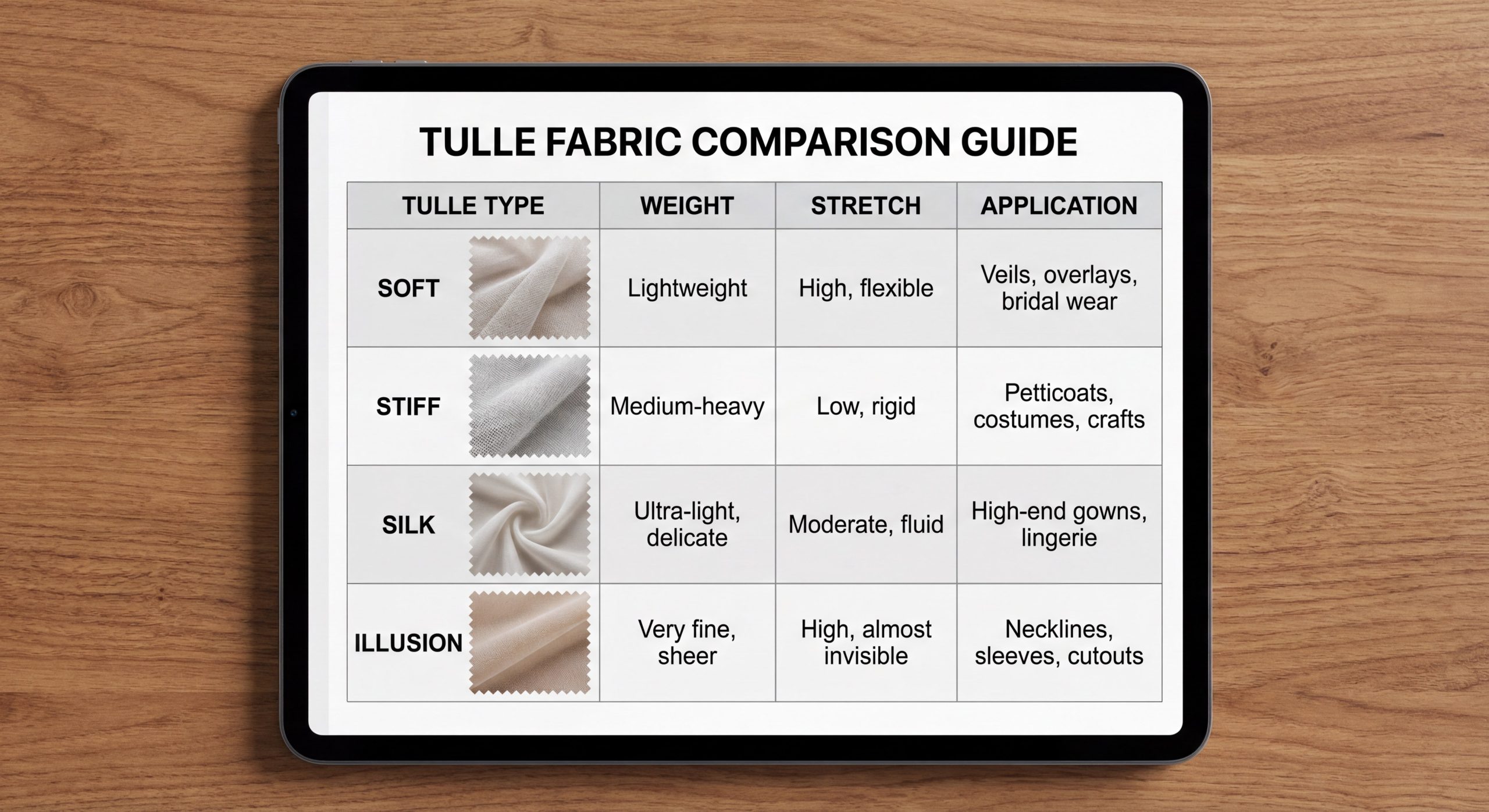

Types of tulle fabric encompass a diverse range of fine, hexagonal mesh textiles categorized by fiber content, stiffness, weight, and finish to suit specific industrial and fashion applications. Navigating the global textile market for the perfect mesh can often lead to procurement delays and inconsistent product quality that impacts your bottom line. You may find that a fabric which looks perfect in a digital catalog fails to meet the structural requirements of your garment designs once it arrives in bulk. By understanding the technical nuances behind every tutu material name , you can bridge the gap between creative vision and manufacturing reality. This comprehensive guide provides the technical insights necessary to streamline your sourcing process and ensure every yard of fabric aligns with your professional standards.

What defines the basic tulle fabric?

Tulle is defined by its open-mesh, hexagonal structure, typically constructed via warp knitting to create a lightweight yet durable fabric that maintains its shape under tension. Identifying the correct tutu material name is the first step in establishing a quality control baseline for your manufacturing projects. This textile is unique because it does not unravel like woven fabrics, providing you with a stable edge for intricate cutting and layering. When you evaluate basic varieties, you must consider the denier of the yarn and the density of the holes per square inch.

What is its unique weave shape?

The hexagonal weave of tulle is its most distinguishing feature, providing a balance of strength and transparency that other mesh types cannot replicate. This geometry ensures that the fabric can withstand multi-directional stress, which is essential for structured garments.

Think about it:

- Hexagonal cells provide uniform tension distribution.

- Diamond-shaped variants offer more vertical stretch.

- Reinforced edges prevent fraying during industrial laser cutting.

But that’s not all. The shape of the hole directly influences the “hand” of the fabric, determining whether it feels crisp or fluid against the skin.

Which fibers are commonly used?

Fiber selection dictates the durability, sheen, and price point of the tulle, with nylon and polyester being the most prevalent choices in the B2B sector. Most commercial-grade textiles utilize synthetic polymers because they offer superior resistance to environmental factors and repeated laundering.

Here is the kicker:

- Nylon 6 or 6,6 provides the highest level of resilience and “bounce.”

- Polyester is preferred for its UV resistance and colorfastness.

- Specialized blends can incorporate spandex for enhanced recovery.

Key Takeaway: The fundamental quality of tulle is determined by its hexagonal geometry and synthetic fiber base, which provide the structural integrity required for professional garment construction.

| Feature | Nylon Tulle | Polyester Tulle | |

|---|---|---|---|

| Durability | High | Medium-High | |

| Elasticity | Excellent | Low | |

| Softness | Very Soft | Moderate | |

| Heat Resistance | Low | High |

This structural foundation allows for the creation of more specialized varieties, such as the delicate options used in the wedding industry.

Why is illusion tulle used in bridal?

Illusion tulle is a specialized, ultra-fine mesh used in bridal wear to create invisible necklines and sleeves that mimic the appearance of skin while providing support for lace appliques. When you are sourcing this delicate tutu material name , the primary goal is to find a fabric that disappears against the wearer’s complexion. This transparency is achieved through a very high hole count and extremely fine filaments that reduce light refraction. In the B2B bridal sector, consistency in dye lots is critical to ensure the “nude” shades remain invisible across different lighting conditions.

Can it create a bare skin effect?

The “bare skin” effect is the hallmark of high-quality illusion tulle, made possible by its incredible fineness and specific matte or semi-gloss finishes. You can achieve a seamless look by matching the mesh denier to the specific needs of the bodice design.

Believe it or not:

- 10-denier yarns are virtually invisible from a distance.

- High-transparency finishes minimize the “grid” look of the mesh.

- Flesh-tone palettes must include a wide range of undertones.

The best part? This effect allows designers to place lace motifs in floating patterns that seem to defy gravity on the wearer’s body.

Is it lightweight for the wearer?

Weight is a critical factor for bridal comfort, and illusion tulle provides the necessary volume and support with almost zero added mass. This allows for grand, multi-layered designs that do not fatigue the client during long events.

Now, consider this:

- Standard illusion tulle weighs between 10 and 15 grams per square meter.

- Breathability is maintained despite the dense hole count.

- Layering multiple plies increases opacity without sacrificing the airy feel.

Key Takeaway: Illusion tulle is the industry standard for creating “naked” fashion elements due to its high transparency, skin-matching capabilities, and lightweight structural support.

| Property | Illusion Tulle | Standard Mesh | |

|---|---|---|---|

| Weight (GSM) | 10-15 | 25-40 | |

| Transparency | Ultra-High | Moderate | |

| Texture | Silky/Smooth | Crisp/Grainy | |

| Application | Veils, Sleeves | Skirts, Linings |

Beyond invisible support, many designers look for ways to add shimmer and light-catching properties to their collections.

How does crystal tulle add glamour?

Crystal tulle incorporates high-shine finishes or metallic fibers to produce a shimmering, light-reflective surface suitable for evening gowns and theatrical costumes. This specific tutu material name is engineered to catch and disperse light, giving the fabric a “frozen” or crystalline appearance. Unlike glitter-coated fabrics, high-quality crystal tulle often uses trilobal fibers that have a natural luster embedded in the yarn itself. This ensures that the sparkle does not wear off or leave residues on other garments during storage or transport.

Are metallic threads embedded?

Many premium crystal tulles feature genuine metallic filaments or Lurex yarns woven directly into the hexagonal structure for a permanent shimmer. This technique provides a more sophisticated look than surface-applied finishes.

Here is the deal:

- Metallic yarns increase the tensile strength of the mesh.

- Embedded fibers won’t flake off during the manufacturing process.

- Multi-colored metallics can create iridescent or holographic effects.

It gets better. Because the shine is part of the weave, the fabric retains its drape and “swish” without becoming overly stiff or abrasive.

Does the glitter shed easily?

Shedding is a common complaint with low-end sparkling fabrics, but professional-grade crystal tulle utilizes bonding agents or trilobal yarns to prevent this issue. You should test any sample for “rub-off” to ensure it meets commercial standards for high-end retail.

Don’t forget:

- Vacuum-set applications offer superior glitter adhesion.

- Trilobal polyester yarns provide shine without any loose particles.

- Foil-stamping techniques can create localized patterns with high durability.

Key Takeaway: Crystal tulle provides a permanent, high-luster finish through specialized yarn geometry or bonded metallic elements, ensuring long-lasting glamour without the mess of shedding.

| Factor | Embedded Metallic | Surface Glitter | |

|---|---|---|---|

| Shine Longevity | Permanent | Temporary | |

| Fabric Hand | Slightly Coarse | Very Stiff | |

| Shedding Risk | Zero | High | |

| Cost | Premium | Economical |

If your design requires movement and a soft touch rather than sparkle, the next category of tulle is the ideal solution.

What are the perks of soft tulle?

Soft tulle is characterized by its high drape and gentle hand-feel, making it the preferred choice for flowing garments, luxury lingerie, and high-end children’s wear. When searching for this tutu material name , you will notice it lacks the “crunch” associated with standard nylon netting. This softness is achieved through a lower tension during the knitting process and the use of multi-filament yarns that feel like silk against the skin. In a B2B context, soft tulle is often sold as “English Net” and is prized for its ability to flow with the body.

Does it offer a romantic drape?

The drape of soft tulle is its most valuable asset, allowing it to fall in graceful folds rather than sticking out horizontally. This makes it the go-to material for boho-style wedding dresses and sophisticated evening wraps.

Make no mistake:

- Multi-filament yarns increase the fabric’s flexibility.

- Fluidity of the mesh allows for bias-cut designs.

- It mimics the movement of expensive silk chiffon at a lower cost.

The best part? You can layer ten or more plies of soft tulle without creating a bulky or rigid silhouette, maintaining a slim and elegant profile.

Is it ideal for layered skirts?

Layering soft tulle creates a “cloud-like” effect that is highly sought after in modern fashion design. Because the fabric is so thin and pliable, the layers blend into one another to create depth and soft color transitions.

Think about it:

- Raw edges remain soft and do not scratch the wearer’s legs.

- It provides volume that is “crushable” and returns to its shape.

- Soft tulle is less prone to snagging compared to its stiffer counterparts.

Key Takeaway: Soft tulle offers a luxurious, silk-like drape and skin-friendly texture, making it the superior choice for garments requiring movement and layered elegance.

| Spec | Soft Tulle | Rigid Tulle | |

|---|---|---|---|

| Flexibility | High | Low | |

| Skin Comfort | Excellent | Poor | |

| Acoustics | Silent | Noisy/Crinkly | |

| Volume Style | Flowing | Architectural |

While synthetic soft tulle is popular, some high-end or eco-conscious projects may require natural fiber alternatives.

Why choose cotton over synthetics?

Cotton tulle is a natural fiber alternative that offers a distinct matte aesthetic and superior breathability compared to common synthetics, making it ideal for vintage-inspired designs. When you specify this tutu material name, you are choosing a fabric that is biodegradable and hypoallergenic. Cotton mesh has a heavier weight and a more pronounced “net” look, which provides a rustic or artisanal feel to your products. In the B2B market, cotton tulle is often used as a base for heavy embroidery because the natural fibers can withstand high needle heat better than nylon.

Is it safer for sensitive skin?

Because cotton is a natural, organic fiber, it lacks the chemical irritants sometimes found in low-grade synthetic dyes and finishes. This makes it the safest choice for infant wear and medical-grade applications.

Here is the kicker:

- It is naturally moisture-wicking and breathable.

- No static build-up occurs, unlike with polyester mesh.

- It is less likely to cause heat rashes in warm climates.

But wait, there’s more. Cotton tulle can be laundered at higher temperatures, ensuring a level of hygiene that is difficult to maintain with delicate synthetic nets.

Where is the matte finish used?

The matte finish of cotton tulle is highly valued in the luxury interior design and “cottagecore” fashion sectors. It provides a sophisticated, understated look that complements natural fabrics like linen and silk.

Now, consider this:

- It eliminates the “plastic” sheen often seen in budget tulle.

- The texture provides a better grip for ribbon or lace attachments.

- It is the traditional choice for heirloom veils and baptismal gowns.

Key Takeaway: Cotton tulle is the premier natural alternative, offering a matte finish, hypoallergenic properties, and a vintage aesthetic that synthetics cannot replicate.

| Feature | Cotton Tulle | Nylon Tulle | |

|---|---|---|---|

| Fiber Origin | Natural/Plant | Synthetic | |

| Sheen | Matte | Shiny/Satin | |

| Breathability | Very High | Low | |

| Biodegradable | Yes | No |

For those specifically in the performance and dance industry, the requirements for tulle change significantly toward stiffness and shape retention.

What is the right tutu material name?

The professional tutu material name refers primarily to stiff nylon hexagonal mesh, engineered specifically for high-impact structural garments used in classical ballet. When you are sourcing this tutu material name , you must look for “ballet grade” or “diamond net” varieties that possess high rigidity. This stiffness is what allows a pancake tutu to stand out horizontally from the dancer’s hips without collapsing under its own weight. It is typically finished with a resin coating that “locks” the hexagonal shape in place, providing the architectural support required for stage performance.

Is nylon the standard choice?

Nylon is the undisputed leader for performance tutus because of its high melting point and incredible “memory” for its original shape. If you fold a nylon tutu, it will eventually bounce back, whereas polyester may retain the crease.

Believe it or not:

- Nylon 6,6 is often used for professional-grade stiffness.

- The chemical bond of the resin is more effective on nylon fibers.

- It is lighter than polyester for the same level of rigidity.

The best part? Nylon can be heat-set into specific shapes, allowing costume shops to achieve the iconic flat disc appearance.

How does it maintain its shape?

The shape retention of a professional tutu comes from a combination of the hexagonal weave and the starch or resin finish applied during manufacturing. This ensures the garment remains a “prop” for the dancer rather than just a piece of clothing.

Here’s the deal:

- Higher hole density leads to greater structural integrity.

- Double-diamond weaves offer extra resistance against sagging.

- Resin-dipped finishes provide a permanent stiffness that survives stage use.

Key Takeaway: Professional tutus require high-rigidity nylon mesh with resin finishes to ensure the iconic horizontal silhouette and long-term durability under performance conditions.

| Spec | Ballet Grade Nylon | Craft Grade Polyester | |

|---|---|---|---|

| Stiffness | Very High | Medium | |

| Memory | Excellent | Poor | |

| Finish | Resin-Coated | Uncoated/Light Starch | |

| Use Case | Professional Stage | Party Decorations |

While nylon serves the performance world, the pinnacle of luxury in the tulle world is found in the natural silk varieties.

Do silk tulle varieties vary much?

Silk tulle varieties differ significantly based on their origin, weight, and weaving technique, offering unparalleled luxury for the highest tier of the fashion market. When you mention this tutu material name, you are discussing the most expensive and delicate mesh available in the global textile trade. Silk tulle is not warp-knitted like its synthetic counterparts; it is often made on traditional Bobbinet machines, which create a true knotted mesh. This process results in a fabric that is remarkably soft and possesses a natural glow that synthetics can only try to imitate.

What makes French silk unique?

French silk tulle is renowned for its “whisper-light” quality and is often much narrower than synthetic rolls due to the limitations of traditional Bobbinet looms. It is the softest textile in the tulle family and has a distinct hexagonal shape that is slightly irregular.

Think about it:

- It is woven with 100% mulberry silk filaments.

- The texture is incredibly smooth and non-abrasive.

- It is the traditional choice for the world’s most famous wedding veils.

But that’s not all. French silk tulle has a unique “stretch” that comes from the knotting process, allowing it to mold to the body in a way that synthetic mesh cannot.

Is English silk known for drape?

English silk tulle, specifically that produced in the Midlands, is known for having slightly more body and “crispness” than the French variety. It is often the preferred bridal dress tulle when a designer wants the luxury of silk but needs a bit more volume in a veil or overlay.

Here is the kicker:

- It provides a more defined silhouette for tiered veils.

- The “drip” of the fabric is heavier, creating a stately movement.

- It is often more durable than the ultra-fine French varieties.

Key Takeaway: Silk tulle is a pinnacle luxury textile, with French varieties offering ultimate softness and English varieties providing a slightly more structured drape for high-end couture.

| Detail | French Silk Tulle | English Silk Tulle | |

|---|---|---|---|

| Production | Bobbinet Loom | Bobbinet Loom | |

| Hand-feel | Ultra-Soft/Buttery | Soft/Crisp | |

| Weight | Extremely Light | Light-Medium | |

| Price Point | Highest | Very High |

For high-volume production where silk is not feasible, polyester offers a durable and budget-friendly alternative.

Which tulle is most cost-effective?

Polyester is the most cost-effective tulle variety due to its efficient production cycle, high durability in commercial applications, and lower raw material costs. When you are managing large-scale manufacturing, this tutu material name allows you to hit price points that are impossible with nylon or silk. Polyester mesh is highly versatile and can be manufactured to mimic the look of more expensive fabrics. It is also the most common type found in “event decor” and “craft” sectors because of its availability in an endless array of colors.

Is polyester wrinkle resistant?

Polyester fibers are naturally hydrophobic and resilient, meaning they do not absorb moisture and return to their flat state easily. This makes it the best choice for products that will be folded or packed tightly for long periods.

Make no mistake:

- It requires minimal steaming upon arrival at the factory.

- The mesh maintains its integrity even in high-humidity environments.

- It is less prone to “static cling” than low-grade nylon.

The best part? You can use polyester tulle for outdoor events because it does not wilt or lose its shape when exposed to damp air or light rain.

Are synthetic colors vibrant?

The chemical structure of polyester allows it to take “disperse dyes” extremely well, resulting in colors that are vibrant and highly resistant to fading. This is essential for theatrical costumes that undergo intense stage lighting.

Now, consider this:

- Neon and “electric” shades are most stable in polyester.

- Color bleeding is almost non-existent during washing.

- Multi-tonal or “ombre” prints are more crisp on polyester mesh.

Key Takeaway: Polyester tulle is the workhorse of the B2B textile industry, providing the best balance of cost, color vibrance, and logistical durability for mass-market products.

| Property | Polyester Tulle | Nylon Tulle | |

|---|---|---|---|

| Cost | Lowest | Moderate | |

| Wrinkle Resistance | High | Medium | |

| Colorfastness | Excellent | Good | |

| Feel | Slightly Rough | Soft |

Regardless of the fiber you choose, you must have a system in place to evaluate the quality of the incoming fabric.

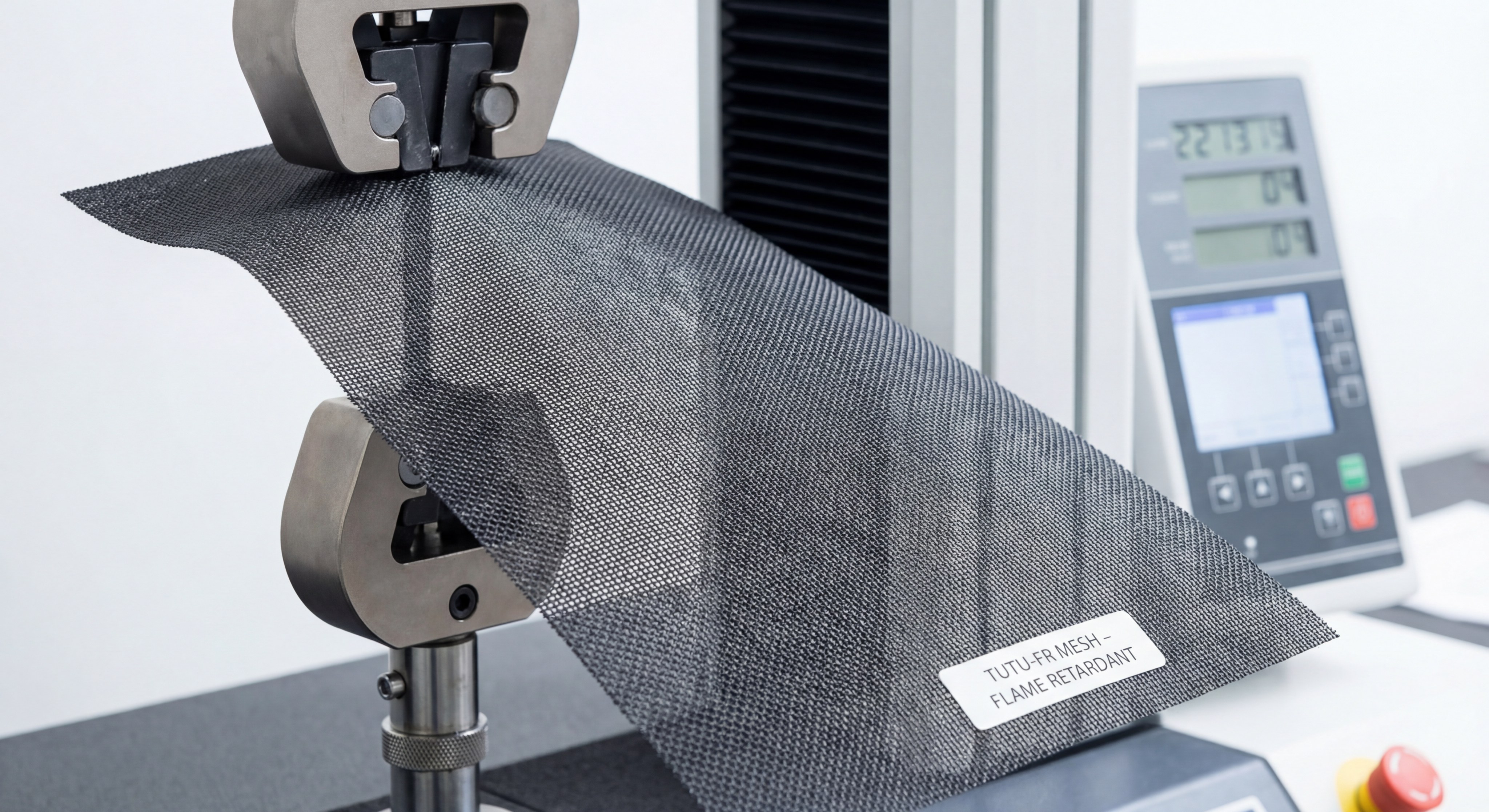

How do you judge tulle quality?

Judging tulle quality involves assessing hole uniformity, tensile strength, and the precision of the finishing process to ensure the fabric meets your production specifications. When you receive a shipment of any tutu material name, your first step should be a visual inspection against a high-contrast background. Look for “thick and thin” spots in the yarn, which indicate a poor extrusion process. Quality tulle should have a perfectly consistent hexagonal grid without any skipped stitches or “ladders” in the weave.

Is weave consistency critical?

Weave consistency is the primary indicator of a well-maintained warp-knitting machine and high-quality yarn. Any irregularities will be magnified once the fabric is layered or pleated in a finished garment.

Here’s the deal:

- Inconsistent holes create “shadows” in layered skirts.

- Weak spots in the weave can lead to catastrophic tears during sewing.

- Uniformity ensures that the fabric drapes predictably every time.

But wait, there’s more. A consistent weave also ensures that any surface treatments, like glitter or flocking, are applied evenly across the entire surface of the fabric.

How do you test fabric stretch?

Tulle is generally stable, but it does have a degree of mechanical stretch that you must account for in your patterns. Testing the recovery of this stretch is vital for garments that need to maintain a tight fit.

Believe it or not:

- Nylon tulle usually has better “snap-back” than polyester.

- Stretching the fabric should not result in permanent distortion.

- Testing across the grain (crosswise) is more critical than length.

Key Takeaway: High-quality tulle is defined by a uniform hexagonal weave, consistent roll width, and excellent elastic recovery, all of which are essential for minimizing waste in mass production.

| Quality Check | Pass Criteria | Fail Criteria | |

|---|---|---|---|

| Hole Shape | Consistent Hexagons | Distorted/Oval | |

| Yarn Quality | Smooth/No Slubs | Fuzzy/Broken Filaments | |

| Edge Finish | Straight/Clean | Frayed/Curled | |

| Stretch | Returns to Shape | Stays Deformed |

With these quality metrics in mind, you can finally make an informed decision on which variety best suits your specific project needs.

Which tulle fits your next project?

Selecting the right tulle depends on balancing your requirements for stiffness, transparency, and the intended garment silhouette to ensure the final product meets market expectations. For example, if you are designing a high-volume “princess” dress, the tutu material name you need is a medium-stiff nylon. However, if you are creating a luxury bridal veil, your focus should shift toward silk or high-denier illusion tulle. You must also consider the “noise” factor; stiff tulles crinkle loudly, which may not be appropriate for intimate settings.

Does transparency affect design?

The level of transparency determines how many layers you will need to achieve opacity, which directly impacts your material costs and the weight of the garment. You should choose your denier based on the visual “depth” you want to create.

Think about it:

- Higher transparency requires more layering for color depth.

- Opaque meshes are better for hidden structural linings.

- Layering different colors creates unique “shot” effects.

It gets better. Using a high-transparency tulle as an overlay for a solid silk fabric can add a sophisticated “mist” of color without obscuring the base material’s sheen.

Should you check colorfastness?

For B2B applications, colorfastness is non-negotiable, especially for garments that will be exposed to perspiration or dry cleaning chemicals. You must ensure the dye is “locked” into the fiber to prevent staining of adjacent fabrics.

Here is the deal:

- Test for “crocking” (color transfer) by rubbing the tulle against white cloth.

- Check for “sublimation” if the fabric will be heat-pressed.

- Ensure the color remains stable under intense UV exposure.

Key Takeaway: The ideal tulle for your project is the one that aligns with your structural goals, cost requirements, and the regulatory standards of your specific industry.

| Project Type | Recommended Tulle | Key Reason | |

|---|---|---|---|

| Classic Ballet Tutu | Stiff Nylon (Resin-Coated) | Maximum Rigidity | |

| Modern Bridal Veil | Silk or Illusion Tulle | Superior Drape | |

| Prom/Evening Wear | Soft or Crystal Tulle | Aesthetic Versatility | |

| Craft/Decor | Polyester Mesh | Cost Efficiency |

The challenges of sourcing the right tulle—from inconsistent stiffness to shedding glitter—can disrupt even the most established B2B supply chains. This article has solved these problems by categorizing fabrics based on technical performance, ensuring your procurement is backed by science rather than guesswork. We understand that your reputation rests on the quality of every garment you deliver. Our vision is to provide the technical clarity and high-performance textiles you need to maintain excellence in your manufacturing. By choosing the correct material specifications today, you ensure a smoother production cycle tomorrow. For personalized consultations or to request high-grade samples for your next collection, contact us today and let our experts help you find the perfect mesh solution.

FAQ

Can I wash all types of tulle fabric?Most synthetic tulles are hand-washable in cool water, but silk and resin-coated ballet tulles should be dry-cleaned or spot-treated only. This prevents the delicate fibers from breaking and the stiffening agents from dissolving.

What’s the best tulle for a child’s garment?Soft nylon tulle or cotton tulle is best for children’s wear. These varieties are non-abrasive against sensitive skin and do not have the sharp, irritating edges often found in stiffer “craft-grade” mesh.

Can I use a regular sewing machine for all tulle?Yes, though it requires a fine needle (70/10) and a zig-zag or serger stitch. These settings accommodate the fabric’s mechanical stretch and prevent the needle from creating large, unsightly holes in the mesh.

What’s the best way to remove wrinkles from tulle?Steaming is the safest and most effective method for all tulle types. You must never use a traditional iron directly on synthetic mesh, as the high heat will melt the plastic fibers instantly.

Can I dye synthetic tulle at home?Nylon tulle can be successfully colored using standard acid dyes, but polyester is very difficult to dye outside of an industrial setting. Polyester requires high-pressure, high-temperature disperse dyes to achieve any significant color saturation.