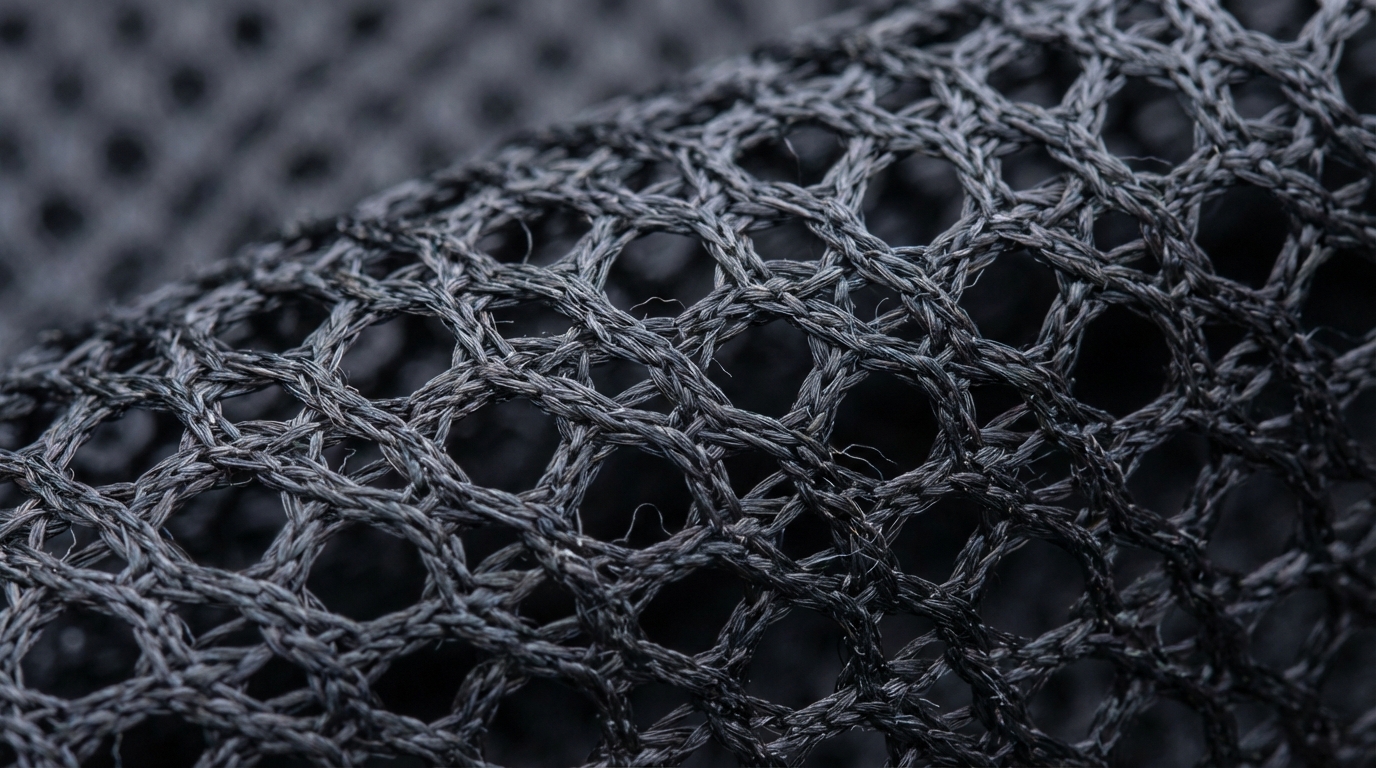

Mesh is a specialized textile distinguished by its open-hole construction and interlocking yarns that provide unique ventilation.

Are you struggling to find a material that combines extreme lightness with professional durability? Many fabrics sacrifice airflow for strength, leaving your high-performance designs feeling heavy and stifled. Our premium mesh material fabric solves this dilemma by engineering consistent voids into the textile structure without compromising its structural integrity.

What is the Definition of Mesh Material Fabric?

Mesh is defined by its open-hole structure, created through specialized knitting or weaving that balances void space with durability. You will find that this mesh material fabric is engineered to maintain its shape even under significant tension.

Historical Origins of Netting

Traditional netting has evolved significantly over the centuries to meet modern industrial needs.

- Started as hand-knotted fishing nets.

- Transitioned to industrialized lace during the Victorian era.

- Evolved into high-tech synthetic textiles.

- Now utilizes precision machinery for consistent hole sizing.

Modern Synthetic Blends

Today, you can choose from a variety of synthetic fibers to achieve specific performance goals.

- Polyester provides excellent UV resistance.

- Nylon offers superior abrasion protection.

- Spandex adds essential four-way stretch.

- Recycled polymers support eco-friendly initiatives.

Key Takeaway

| Feature | Description | |

|---|---|---|

| Construction | Warp-knitted or woven | |

| Common Fibers | Polyester, Nylon, Spandex | |

| Primary Trait | High Breathability |

The technical definition of mesh centers on its ability to provide structural support while remaining porous and lightweight.

Why Choose Versatile Mesh Material Fabric?

You choose this material because it offers unmatched breathability and a superior strength-to-weight ratio for demanding applications. Integrating mesh material fabric into your product line ensures that users stay cool while enjoying long-lasting equipment.

Superior Breathability and Airflow

Why does this matter? Because thermoregulation is critical for comfort in both apparel and upholstery.

- Facilitates constant air circulation.

- Promotes rapid heat dissipation.

- Prevents moisture buildup against the skin.

- Reduces the overall weight of the finished product.

Elasticity and Recovery

High-quality mesh is designed to return to its original shape after being stretched to its limit.

- Incorporates elastane for flexible movement.

- Maintains structural integrity over time.

- Resists sagging in high-use areas.

- Provides a snug, conforming fit for garments.

Key Takeaway

| Benefit | Impact | |

|---|---|---|

| Ventilation | Constant airflow for cooling | |

| Flexibility | High range of motion | |

| Weight | Minimal bulk for layering |

The primary advantage of mesh lies in its ability to provide structural support and durability without adding significant weight or trapping heat.

How is Quality Mesh Material Fabric Made?

Quality mesh material fabric is primarily produced via warp knitting, which ensures the holes remain consistent and the fabric does not unravel. This complex manufacturing process involves hundreds of fine threads feeding into specialized needle bars simultaneously.

The Warp Knitting Process

Look at the technical details: warp knitting is the preferred method for creating stable and run-resistant mesh structures.

- Uses multiple yarn beams for strength.

- Creates interlocking loops in a vertical direction.

- Prevents fraying when the fabric is cut.

- Allows for precision control over hole size and shape.

Post-Production Finishing Treatments

Once the knitting is complete, the fabric undergoes several treatments to enhance its functional properties.

- Heat-setting locks the dimensions.

- Dyeing provides vibrant, lasting colors.

- Chemical coatings can add flame retardancy.

- Softening agents improve the tactile feel.

Key Takeaway

| Stage | Purpose | |

|---|---|---|

| Warping | Preparing yarn beams | |

| Knitting | Forming the net structure | |

| Heat-Setting | Locking dimensions and stretch |

Understanding the manufacturing process reveals why warp-knitted mesh is the superior choice for high-stress applications.

Where Can You Use Mesh Material Fabric?

This fabric is a cross-industry staple that moves seamlessly from the aesthetic requirements of couture to the rigorous demands of industrial safety. You can find mesh material fabric in everything from high-fashion gowns to heavy-duty safety screens.

High Fashion and Sheer Layers

Designers utilize sheer fabrics to create volume, mystery, and intricate textures in bridal and evening wear.

- Adds structural volume to skirts.

- Creates delicate, breathable veils.

- Serves as a base for intricate embroidery.

- Offers a lightweight alternative to heavy linings.

Industrial Utility and Safety

Beyond aesthetics, mesh serves a vital role in protecting workers and managing industrial environments.

- Constructs high-visibility safety vests.

- Creates durable filtration systems.

- Provides debris protection in construction.

- Ensures ventilation in heavy-duty luggage.

Key Takeaway

| Domain | Common Usage | |

|---|---|---|

| Apparel | Linings, overlays, veils | |

| Industrial | Safety screens, filters | |

| Home | Mesh curtains, storage bags |

Mesh is a cross-industry staple, moving seamlessly from the aesthetic requirements of couture to the rigorous demands of industrial safety.

What are Types of Mesh Material Fabric?

Choosing the right mesh material fabric depends on balancing moisture-wicking properties with tensile strength and abrasion resistance. You must evaluate whether your project requires the softness of polyester or the ruggedness of nylon.

Polyester vs. Nylon Composition

Here is the deal: both synthetic bases offer distinct advantages depending on the final environment of the product.

- Polyester is highly resistant to UV rays.

- Nylon offers superior resistance to tearing.

- Polyester dries faster than most synthetics.

- Nylon has a slightly more “slippery” hand-feel.

Power Mesh and Spandex Blends

Power mesh is specifically engineered for compression and body-contouring applications that require high recovery.

- Offers four-way stretch capabilities.

- Provides firm support for activewear.

- Ideal for shapewear and medical braces.

- Maintains tension after repeated laundry cycles.

Key Takeaway

| Material | Best For | Key Property | |

|---|---|---|---|

| Polyester | Sportswear | Quick-drying | |

| Nylon | Luggage/Bags | Tear resistance | |

| Spandex | Activewear | 4-way stretch |

The selection of a mesh type should always align with the mechanical demands and environmental exposure of the final product.

How to Wash Durable Mesh Material Fabric?

You should wash this fabric in cold water using a delicate cycle and always prioritize air drying to maintain fiber integrity. Protecting your mesh material fabric from snags and high heat will significantly extend the lifespan of your products.

Machine Washing Guide

To prevent damage, you must take specific precautions when using mechanical washing machines.

- Use a protective mesh laundry bag.

- Select the cold or lukewarm water setting.

- Choose a mild, liquid-based detergent.

- Avoid washing with items that have hooks or zippers.

Drying and Heat Management

Heat is the enemy of synthetic mesh, as it can cause the fibers to melt or lose their elasticity.

- Never use high-heat dryer settings.

- Line drying is the safest method.

- Keep fabric away from direct sunlight while drying.

- Avoid ironing unless using a very low setting.

Key Takeaway

| Action | Recommendation | |

|---|---|---|

| Water Temp | Cold/Lukewarm | |

| Detergent | Mild/Liquid | |

| Drying | Line dry only |

Longevity is guaranteed by using cold water cycles and mesh wash bags, followed exclusively by air drying.

Is Mesh Material Fabric Good for Sports?

Yes, mesh material fabric is considered the gold standard for high-performance sportswear due to its exceptional thermoregulation. It allows athletes to perform at their peak by moving sweat away from the body for rapid evaporation.

Moisture Wicking Performance

Why does this work? It is all about capillary action and surface area.

- Transports sweat away from the skin.

- Increases the surface area for evaporation.

- Keeps the athlete dry during intense activity.

- Prevents the fabric from becoming heavy with water.

Compression and Muscle Support

High-denier mesh provides the necessary tension for athletic recovery and performance enhancement.

- Stabilizes muscles during explosive movements.

- Improves blood circulation through compression.

- Reduces muscle vibration and fatigue.

- Offers breathable support in medical-grade sleeves.

Key Takeaway

| Feature | Athlete Benefit | |

|---|---|---|

| Porosity | Temperature regulation | |

| Stretch | Unhindered movement | |

| Weight | Reduced fatigue |

Mesh is the gold standard for sportswear due to its dual ability to provide mechanical support while maintaining maximum thermal comfort.

Can You Use Mesh Material Fabric for Bags?

Mesh is an essential material in bag manufacturing because it provides visibility and allows damp items to breathe. You will find that high-quality mesh material fabric is the backbone of durable backpacks and utility gear.

Heavy Duty Luggage Mesh

For outdoor and tactical gear, reinforced mesh provides the necessary strength to carry heavy loads.

- Resists punctures and abrasions.

- Allows for easy identification of contents.

- Provides ventilation for back panels.

- Reduces the overall weight of the luggage.

Utility and Laundry Bag Construction

Lightweight mesh is perfect for organizing gear and ensuring that damp items do not develop odors.

- Allows airflow to dry wet swimsuits.

- Provides visibility in packing cubes.

- Resists mold and mildew growth.

- Withstands frequent machine washing cycles.

Key Takeaway

| Requirement | Mesh Type | |

|---|---|---|

| Load Bearing | Coated Polyester | |

| Flexibility | Small-hole Nylon | |

| Ventilation | Large-hole Spacer |

In bag manufacturing, mesh provides essential visibility of contents and allows damp items to breathe, preventing odors.

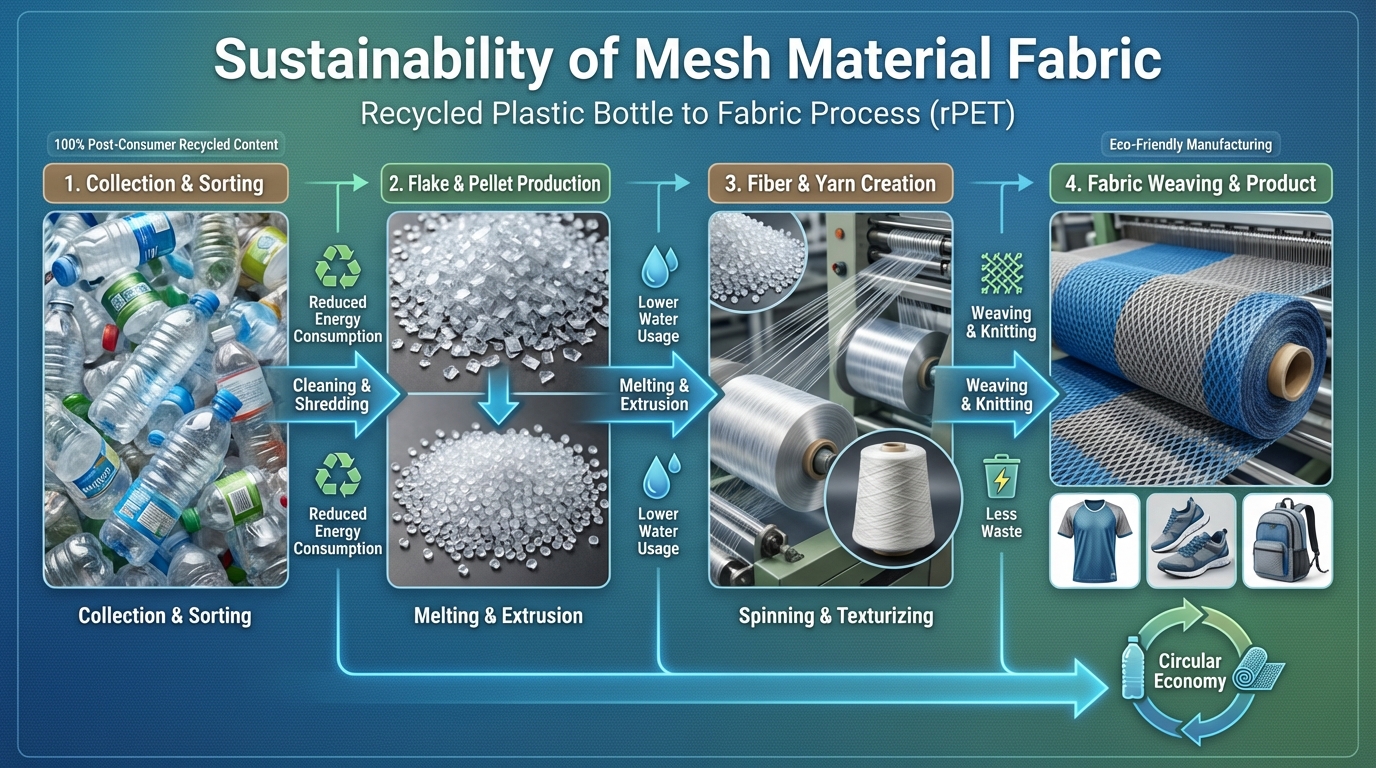

Is Sustainable Mesh Material Fabric Real?

Sustainable mesh material fabric is a reality in the modern market, created through recycled polymers and eco-friendly manufacturing. You can now source high-performance materials that align with global environmental standards and consumer demands.

Recycled Polyester (rPET) Fibers

The industry is shifting toward using post-consumer plastic waste to create high-quality yarns.

- Reduces the reliance on virgin petroleum.

- Lowers the carbon footprint of production.

- Keeps plastic bottles out of landfills.

- Maintains the same performance as standard polyester.

Eco-friendly Dyeing and Finishing

Innovative plants are now using closed-loop systems to minimize the environmental impact of textile production.

- Uses significantly less water during dyeing.

- Reduces chemical runoff into local ecosystems.

- Utilizes non-toxic finishing agents.

- Lowers energy consumption during heat-setting.

Key Takeaway

| Innovation | Environmental Impact | |

|---|---|---|

| rPET Yarn | 50% less energy used | |

| Dry Dyeing | 90% water reduction |

Sustainability in mesh production is rapidly evolving through the use of recycled polymers and closed-loop manufacturing processes.

How to Select the Best Mesh Material Fabric?

Selecting the best material requires you to evaluate a hierarchy of needs, starting with safety compliance and mechanical performance. You must ensure that the mesh material fabric you choose meets the specific demands of your industry and end-user.

Testing for Stretch and Recovery

Before purchasing for large-scale production, you should conduct manual tests to ensure quality.

- Perform a manual pull test for elasticity.

- Observe how quickly the fabric recovers.

- Inspect the consistency of the hole shapes.

- Check for any signs of yarn slippage.

Safety and Fire Ratings

For specialized applications like aviation or public installations, flame retardancy is a non-negotiable requirement.

- Verify certification for fire resistance.

- Ensure compliance with local safety codes.

- Check for UV stability in outdoor use.

- Evaluate the chemical resistance for industrial gear.

Key Takeaway

| Criteria | Assessment | |

|---|---|---|

| Hole Size | Visual inspection | |

| Stretch % | Manual pull test | |

| Compliance | Certification review |

Selection should be based on a hierarchy of needs: first safety/compliance, then mechanical performance, and finally aesthetic finish.

Frequently Asked Questions

- Can I sew mesh fabric with a regular sewing machine?Yes, but you should use a ballpoint stretch needle and a zigzag stitch to accommodate the fabric’s natural elasticity.

- What’s the best way to prevent mesh from fraying?Most knitted mesh does not fray, but for woven types, you should use a serger or bind the edges with bias tape.

- Is mesh fabric itchy on the skin?Modern synthetics are engineered for softness, though you should choose high-quality polyester blends for the best skin comfort.

- How long does mesh fabric last?With proper care and by avoiding high heat, high-quality mesh can maintain its shape and strength for many years.

- Does mesh fabric shrink in the wash?Polyester and nylon mesh are generally shrink-resistant as long as you wash them in cool water and avoid the dryer.

Conclusion

Our vision is to provide designers and manufacturers with the highest quality textiles that push the boundaries of performance and sustainability. Understanding the technical nuances of mesh—from its warp-knitted construction to its diverse application range—empowers you to create superior products. Whether you are developing the next generation of athletic gear or a high-fashion masterpiece, we have the material expertise to support your goals. For personalized advice on sourcing the perfect material for your next design, contact us today .