Mesh fabric is a lightweight, permeable textile characterized by its open-weave structure that creates thousands of tiny holes for maximum ventilation.

Finding a textile that offers both structural durability and extreme breathability is a persistent hurdle for B2B procurement officers and fashion designers alike. You likely face the frustration of dense materials trapping heat and moisture, which leads to performance degradation in athletic settings or equipment failure in industrial environments. This lack of airflow isn’t just uncomfortable—it’s a functional bottleneck. High-quality mesh material fabric from Tulle Mesh provides the engineered solution, utilizing a porous grid that facilitates cooling and moisture management without sacrificing the tensile strength required for demanding applications.

What is the origin of mesh material fabric?

The history of mesh material fabric is rooted in the late 19th-century British textile revolution. While basic netting has been used for millennia in fishing, the transition to wearable apparel was spearheaded by Lewis Haslam, who noticed that air trapped in the holes of his aunt’s gloves actually provided better temperature regulation than solid weaves.

The Invention of Aertex

Haslam’s discovery led to the founding of Aertex, the world’s first commercial producer of mesh. This innovation allowed for the creation of shirts that were both breathable and insulating, a concept that was revolutionary for the time.

Think about it: A material originally meant for undergarments eventually became the uniform of choice for global icons.

- 1888: Lewis Haslam founds Aertex in the UK.

- 1980s: Mesh gains massive pop-culture popularity via MTV.

- Modern Era: Synthetic fibers allow for specialized variations like Power Mesh.

Key Takeaway: Mesh material fabric transitioned from specialized British undergarments to a global sportswear staple by leveraging the science of air pockets for thermal regulation.

The following table outlines the historical milestones that shaped the development of modern mesh textiles.

| Milestone | Year | Impact | |

|---|---|---|---|

| First Production | 1888 | Introduction of Aertex breathable weave | |

| Sportswear Adoption | 1970s | Major brands utilize mesh for team jerseys | |

| Synthetic Shift | 1980s | Polyester replaces cotton for better wicking |

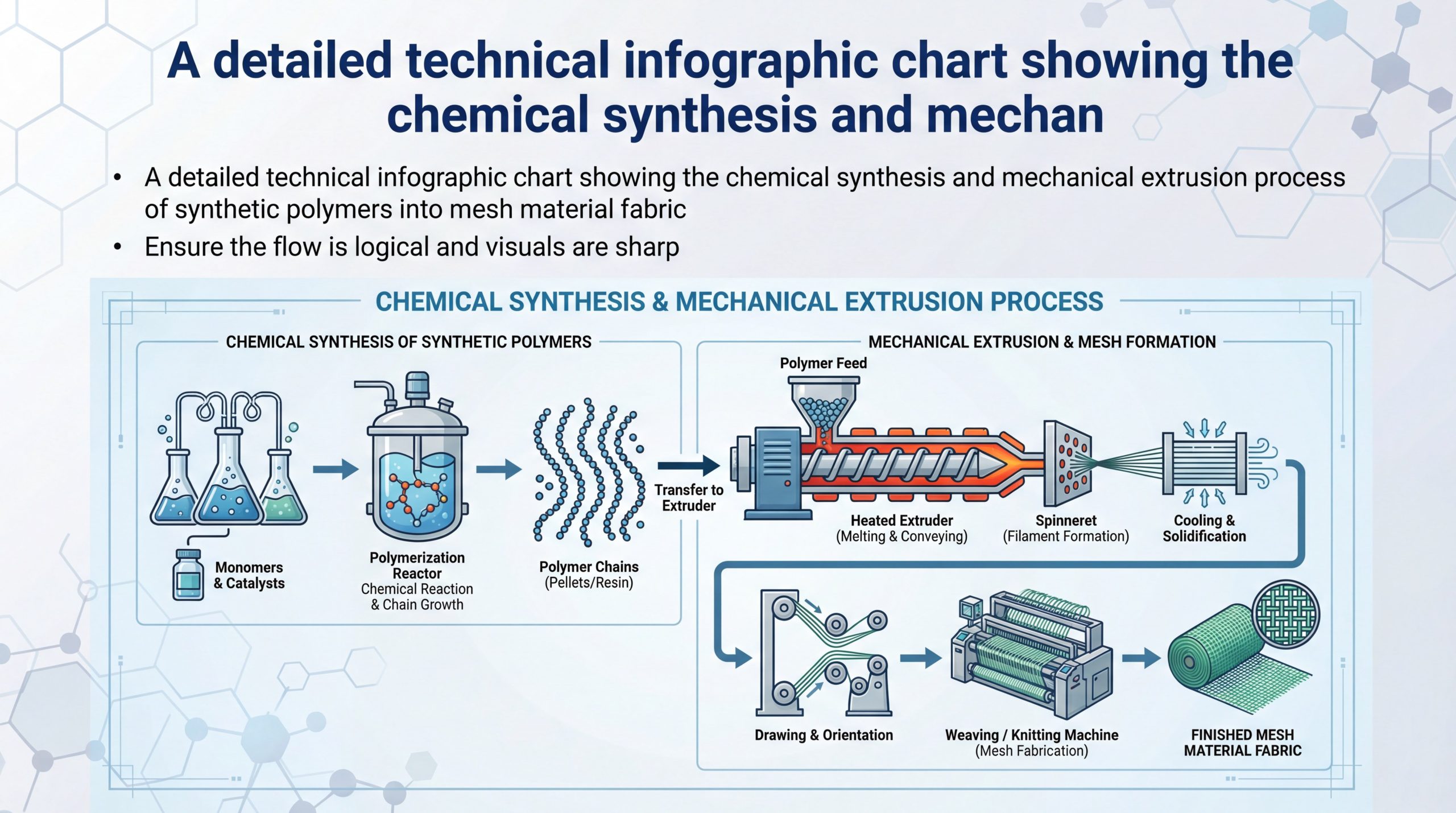

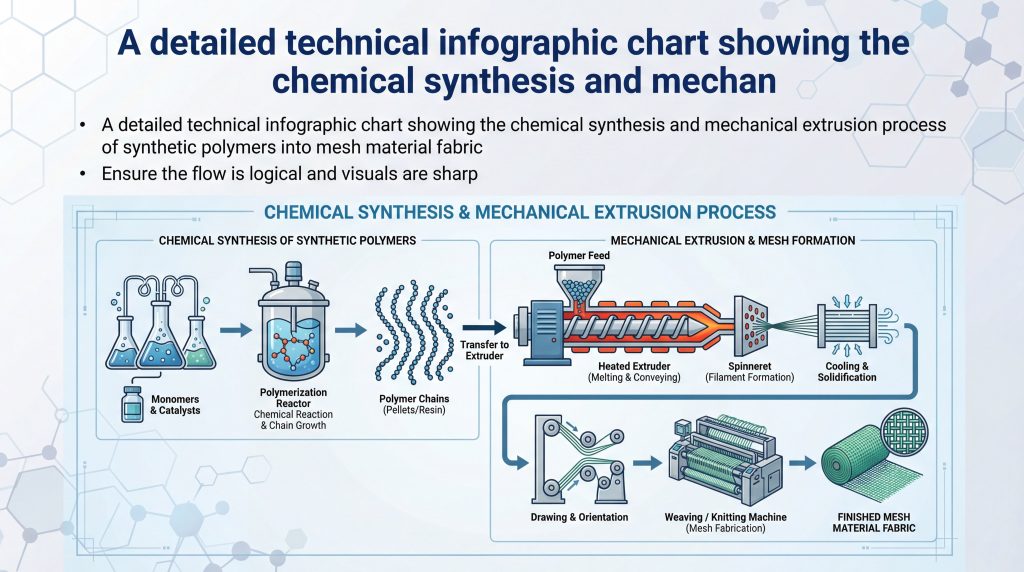

How is mesh material fabric made currently?

Modern production of mesh material fabric relies on the precise extrusion of synthetic polymers, primarily polyester or nylon. Unlike traditional weaving where threads are packed tightly, mesh is created on specialized knitting machines that maintain consistent spacing between the yarns to form a grid of holes.

Chemical Synthesis and Extrusion

The process begins with the refining of petroleum to extract monomers, which are then polymerized into chips. These chips are melted and forced through a spinneret to create long, continuous filaments that are cooled and spun onto spools.

Here is the kicker: The density of the fabric, measured in Holes Per Inch (HPI), is determined entirely during the knitting phase, allowing for total customization of breathability.

- Polymerization: Converting oil into polymer resin.

- Extrusion: Creating thin filaments via spinnerets.

- Knitting: Creating the open-cell structure on industrial looms.

Key Takeaway: The manufacturing of mesh material fabric is a high-tech chemical and mechanical process that allows for variable densities and specific functional properties.

The production stages are summarized below to show how raw petroleum is transformed into a functional textile.

| Stage | Process | Result | |

|---|---|---|---|

| Synthesis | Polymerization | Solid polymer chips | |

| Filament Creation | Melting & Extrusion | Synthetic yarn | |

| Fabrication | Warp Knitting | Open-weave mesh fabric |

Why use mesh material fabric in design?

The primary appeal of mesh material fabric lies in its unique combination of lightness and airflow. Designers choose it because it offers a “barely there” feel while providing enough structural integrity to hold shapes or support weight in layered garments.

Unparalleled Breathability

Because the fabric is mostly composed of air gaps, it allows for 100% ventilation. This makes it the only viable choice for high-intensity sportswear where heat dissipation is critical for athlete performance.

The best part? Mesh doesn’t just let air in; it facilitates the movement of moisture away from the skin, preventing the “heavy” feeling of sweat-soaked cotton.

- Weight: Extremely low grams per square meter (GSM).

- Elasticity: High stretch-recovery in variants like power-net.

- Durability: Resistant to tearing despite the holes.

Key Takeaway: Mesh material fabric is the gold standard for performance design due to its weightless feel and superior moisture-wicking capabilities.

The physical properties of mesh make it a versatile tool for both aesthetic and functional design requirements.

| Property | Benefit | Performance | |

|---|---|---|---|

| Permeability | Maximum airflow | Exceptional | |

| Tensile Strength | Resists stretching/tearing | High | |

| Weight | Reduces garment bulk | Minimal |

Where is mesh material fabric used most?

While most people associate mesh material fabric with sports jerseys, its utility spans across critical medical and industrial sectors. Its ability to act as a barrier while remaining permeable makes it indispensable for filtration and internal medical supports.

Sportswear and Activewear

In the athletic world, mesh is used for everything from the uppers of running shoes to the lining of gym shorts. It ensures that the wearer stays cool during aerobic activity by promoting constant air exchange.

Believe it or not: Mesh is even used inside the human body for hernia repairs and surgical slings due to its biocompatibility and strength.

- Fashion: Tulle skirts and sheer overlays.

- Industrial: Screen printing and safety netting.

- Medical: Surgical mesh and orthopedic supports.

Key Takeaway: The versatility of mesh material fabric allows it to serve as both a high-fashion decorative element and a life-saving medical tool.

The diverse applications of mesh across different professional sectors are detailed in the following analysis.

| Sector | Common Application | Primary Function | |

|---|---|---|---|

| Professional Sports | Team jerseys | Heat management | |

| Medical | Hernia mesh | Structural support | |

| Industrial | Filtration nets | Particle separation |

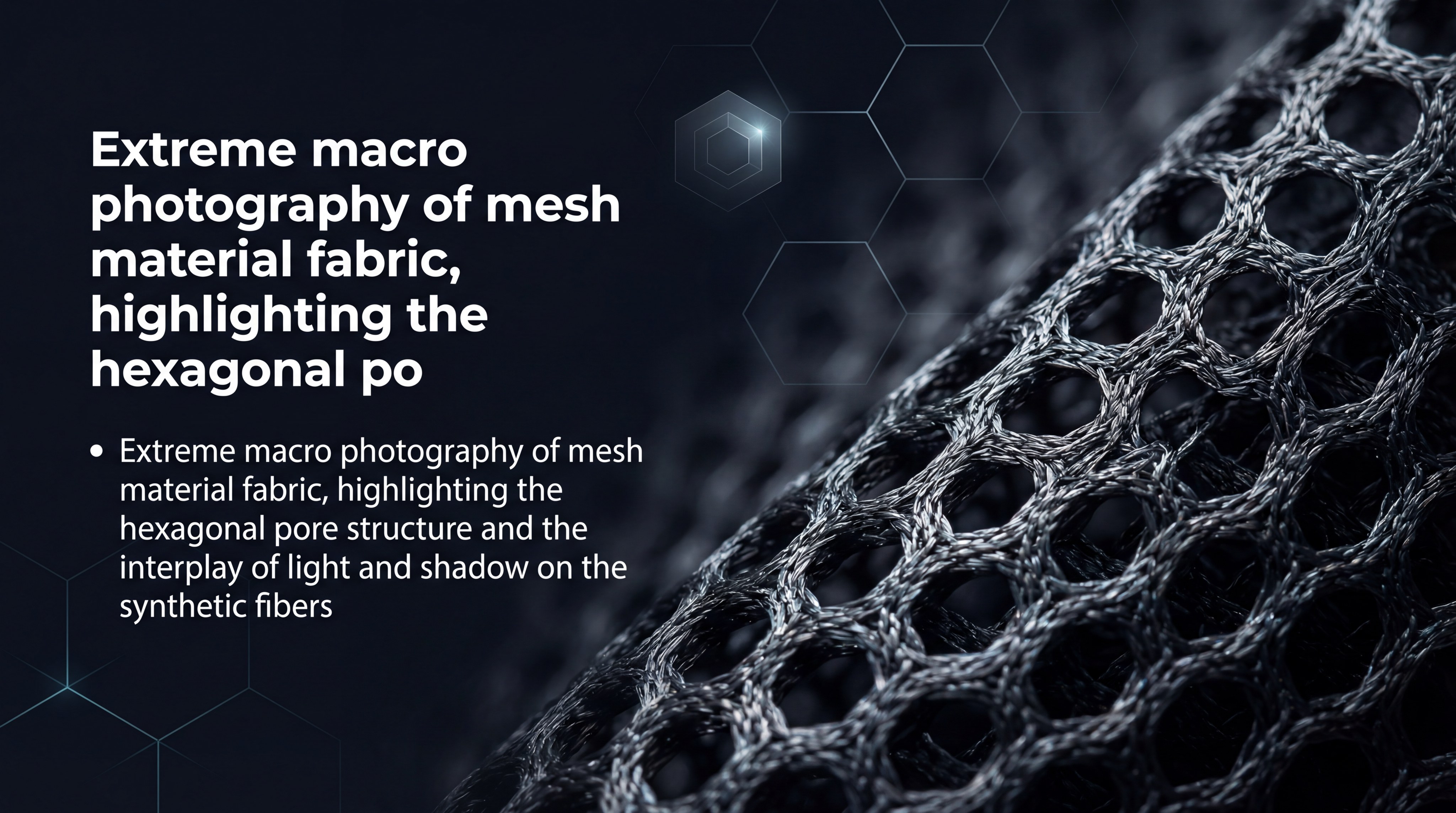

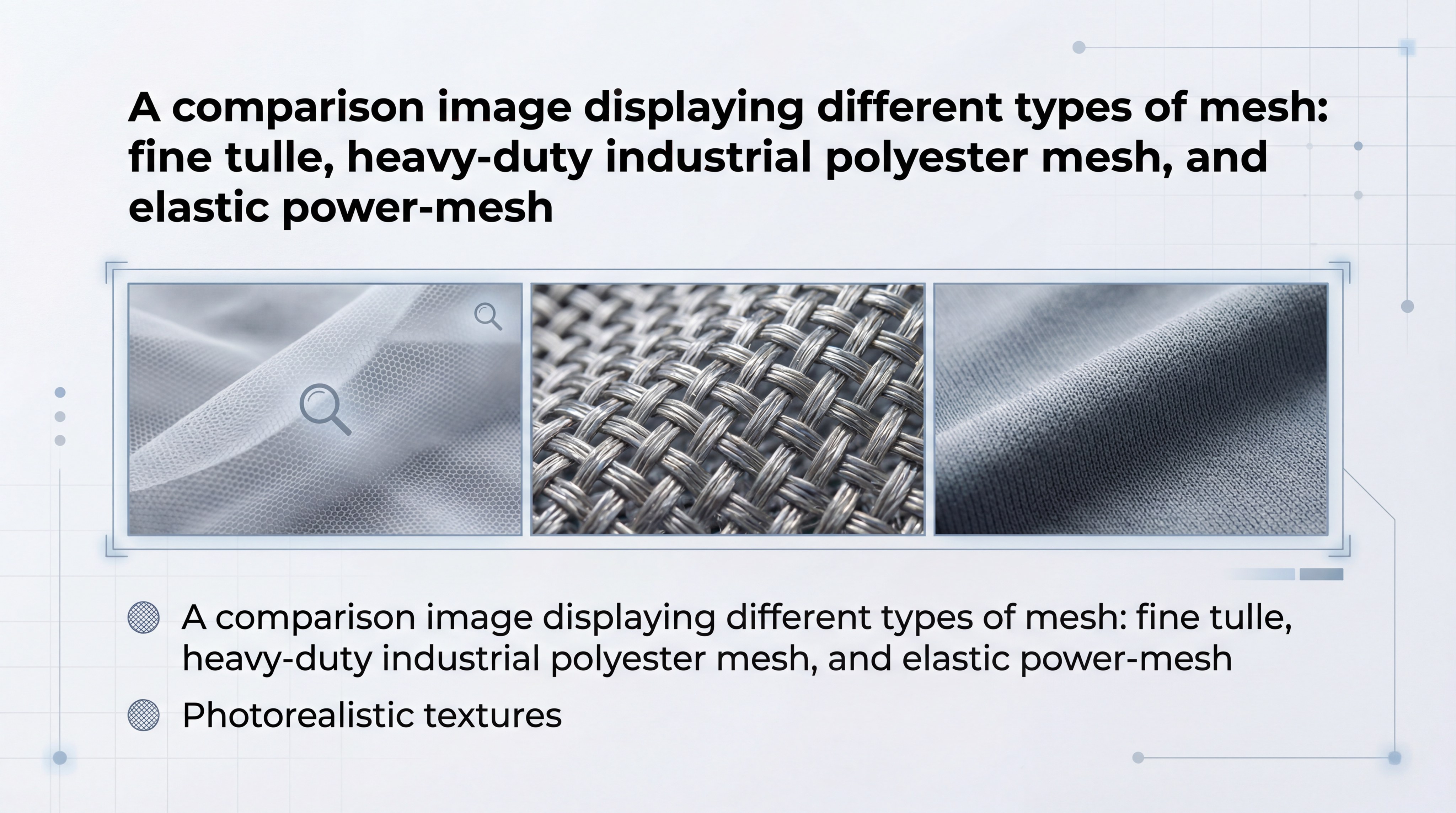

What types of mesh material fabric exist?

There are several distinct categories of mesh material fabric, each engineered for a specific end-use. The choice between polyester and nylon variants often comes down to the required hand-feel and the environment in which the fabric will be used.

Polyester vs. Nylon Mesh

Polyester mesh is the industry standard for athletic wear because it is durable and wicks moisture effectively. Nylon mesh, by contrast, is softer to the touch and is frequently used for delicate items like bridal veils or mosquito nets.

Bottom line: Selecting the wrong mesh type can compromise the entire product’s functionality—especially if stretch is required.

- Power Mesh: High spandex content for compression.

- Tulle: Fine, hexagonal mesh for volume.

- Powernet: Tighter weave for shapewear support.

Key Takeaway: Understanding the differences between polyester, nylon, and specialized power-mesh is crucial for selecting the right material for your specific B2B needs.

This table compares the most common types of mesh to help you identify the best fit for your production line.

| Mesh Type | Material Base | Best For | |

|---|---|---|---|

| Polyester Mesh | 100% Polyester | Sports jerseys | |

| Power Mesh | Polyester/Spandex | Shapewear | |

| Tulle | Nylon or Silk | Evening wear |

Is mesh material fabric eco-friendly?

The environmental profile of mesh material fabric is complex because it is primarily derived from petroleum. However, the industry is making significant strides toward sustainability through the use of recycled polyester (rPET) sourced from post-consumer plastic bottles.

The Impact of Synthetic Fibers

Traditional mesh production is energy-intensive and involves the release of greenhouse gases. Additionally, as a synthetic material, standard mesh does not biodegrade, meaning it can persist in landfills for centuries if not recycled.

Let’s face it: The textile industry’s shift toward circularity is the only way to mitigate the plastic waste associated with synthetic meshes.

- Microplastics: Shedding during wash cycles.

- Recycling: Increasing availability of rPET mesh.

- Longevity: Durable structure reduces frequent replacement.

Key Takeaway: While petroleum-based, mesh material fabric is becoming more sustainable through advanced recycling technologies and “closed-loop” manufacturing processes.

The environmental factors surrounding mesh production are analyzed below, highlighting both challenges and solutions.

| Environmental Factor | Impact | Mitigation | |

|---|---|---|---|

| Resource Use | Petroleum extraction | Transition to rPET | |

| End of Life | Non-biodegradable | Textile recycling programs | |

| Production | High energy use | Low-impact dyeing methods |

Can mesh material fabric be industrial?

In industrial settings, mesh material fabric serves as a critical component in filtration and safety systems. Its precision-engineered hole sizes allow for the separation of particles in everything from water treatment plants to high-tech clean rooms.

Technical Filtration Applications

Industrial mesh is often made from heavy-duty polymers that can withstand chemical exposure and high pressure. It is used in sieves, filters, and even as a substrate for screen printing, where the consistency of the mesh count is vital for print quality.

It gets better: Industrial-grade mesh can be coated with specialized resins to make it fire-retardant or anti-microbial for harsh environments.

- Sieving: Precise particle size control.

- Safety: High-visibility construction vests.

- Protection: Debris netting for architectural sites.

Key Takeaway: Beyond apparel, mesh material fabric is a high-performance industrial tool used for precise filtration and specialized safety applications.

This table highlights the technical specifications that make mesh suitable for industrial utilization.

| Industrial Use | Material Requirement | Key Benefit | |

|---|---|---|---|

| Air Filtration | High HPI (Holes Per Inch) | Efficient particle capture | |

| Screen Printing | Dimensional stability | Consistent ink flow | |

| Safety Nets | High tensile strength | Impact resistance |

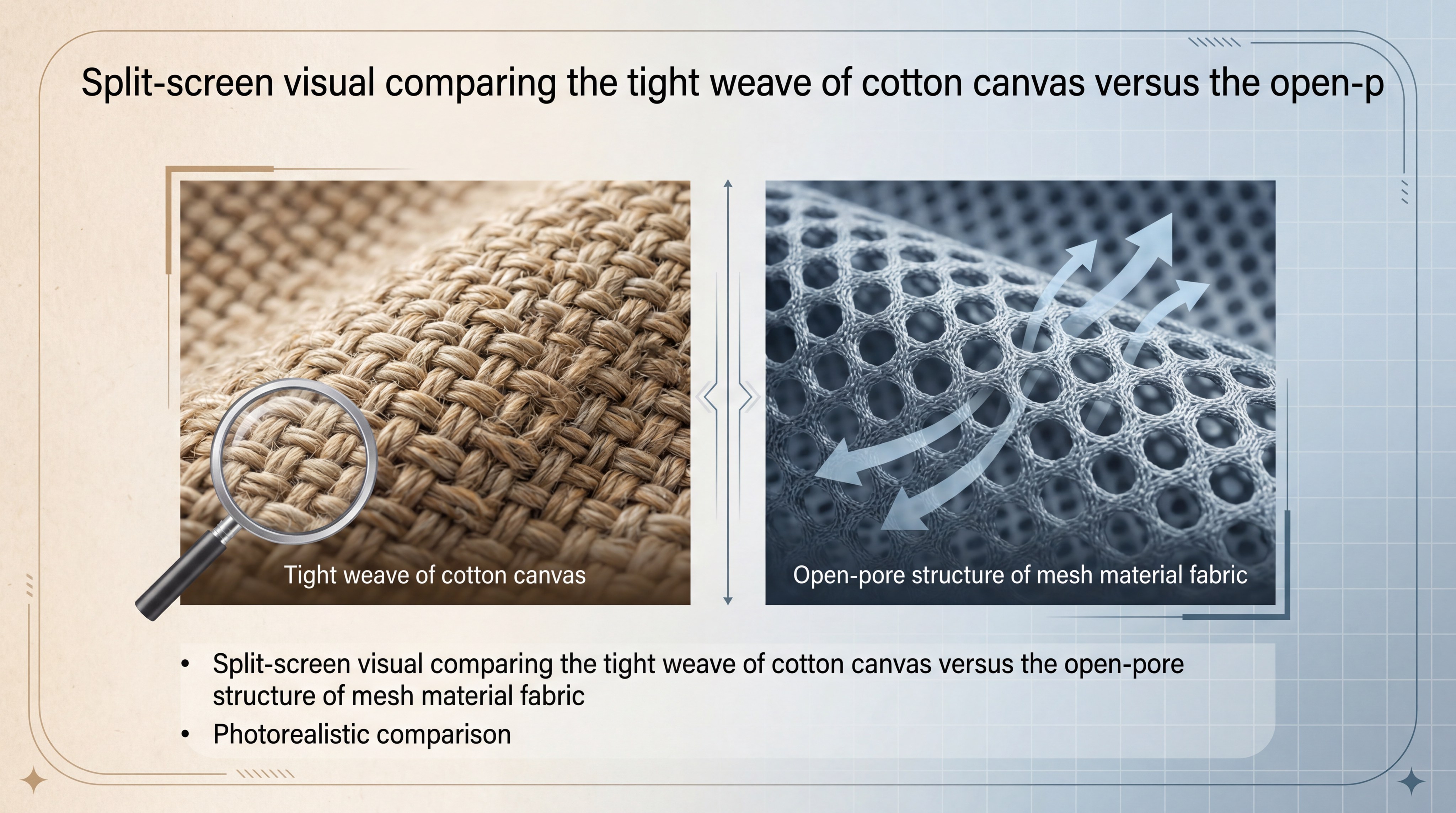

How does mesh material fabric compare to canvas?

Comparing mesh material fabric to a dense weave like cotton canvas reveals the stark difference in airflow philosophy. Canvas is designed for maximum protection and opacity, whereas mesh is designed for maximum interaction with the surrounding environment.

Airflow vs. Barrier Protection

Canvas creates a solid barrier that blocks wind and light, which is ideal for tents or bags. Mesh, however, is used when you need the container’s contents to “breathe,” such as in laundry bags or the ventilated panels of a hiking pack.

Look at it this way: Canvas is a wall; mesh is a window.

- Breathability: Mesh wins by a significant margin.

- Opacity: Canvas provides total coverage.

- Weight: Mesh is considerably lighter for the same surface area.

Key Takeaway: Choosing between mesh and canvas depends on whether your priority is total environmental protection (canvas) or thermal regulation (mesh).

The following comparison helps distinguish when to use mesh versus traditional heavy-duty weaves.

| Feature | Mesh Material Fabric | Cotton Canvas | |

|---|---|---|---|

| Air Permeability | Very High | Very Low | |

| Visual Opacity | Sheer to Semi-Sheer | Opaque | |

| Moisture Retention | Low | High |

Which certifications verify mesh material fabric?

For B2B buyers, verifying the quality of mesh material fabric through international certifications is essential for brand trust and safety compliance. These standards ensure that the synthetic fibers are free from harmful chemicals and meet declared performance metrics.

Global Standards for Quality

The Global Recycle Standard (GRS) is the most critical certification for eco-friendly mesh, while OEKO-TEX Standard 100 ensures the fabric is safe for skin contact. ISO 9001 certifications further guarantee that the manufacturing plant follows strict quality management protocols.

That’s not all: Specific industrial meshes might also require ANSI certification if they are intended for use in safety equipment or construction.

- GRS: Verifies recycled content.

- OEKO-TEX: Guarantees no toxic substances.

- ISO: Standardizes production quality.

Key Takeaway: Always look for GRS or OEKO-TEX certifications when sourcing mesh material fabric to ensure both environmental responsibility and consumer safety.

The table below lists the most important certifications to look for in the mesh textile supply chain.

| Certification | Focus | Industry Standard | |

|---|---|---|---|

| GRS | Recycled Material | Global | |

| OEKO-TEX | Chemical Safety | Fashion/Apparel | |

| ANSI | Performance Safety | Industrial/USA |

How to maintain mesh material fabric garments?

Maintaining the integrity of mesh material fabric requires a gentle touch, as the open-weave structure is susceptible to snagging on sharp objects or rough hardware. Proper care ensures that the synthetic fibers maintain their elasticity and don’t melt under high heat.

Washing and Drying Best Practices

You should always wash mesh in a protective laundry bag to prevent zippers or buttons from other garments from catching on the holes. Avoiding the dryer is the most important rule; high heat can warp the polymer fibers, leading to a loss of shape.

A quick tip: If you must use a dryer, select the “air fluff” or lowest heat setting possible to protect the delicate grid.

- Wash: Cold water, gentle cycle.

- Dry: Air dry only.

- Detergent: Mild, non-bleach formulas.

Key Takeaway: The longevity of mesh material fabric depends on preventing mechanical damage during washing and avoiding high-temperature environments.

The following care guide summarizes the steps necessary to keep mesh products in peak condition.

| Care Step | Recommended Action | Avoid | |

|---|---|---|---|

| Laundering | Cold water in laundry bag | Hot water / Friction | |

| Drying | Hang dry near a window | Tumble dry high heat | |

| Storage | Folded or on padded hangers | Sharp hooks/Velcro |

Frequently Asked Questions

Can I use mesh fabric for heavy-duty upholstery?While standard mesh is too sheer for upholstery, specialized power-net and double-knit mesh can be used as backing or accent panels to provide breathability in office chairs and modern furniture.

What’s the best way to prevent mesh from snagging?The most effective method is to use a fine-mesh laundry bag during the wash cycle and to ensure the fabric never comes into contact with Velcro or open zippers during storage.

Can I print my own logos on mesh material?Yes, polyester mesh is ideal for sublimation printing and screen printing. Because it is synthetic, the ink bonds deeply with the fibers, resulting in vibrant, long-lasting designs that won’t peel.

What’s the best mesh type for a humid climate?Lightweight polyester mesh with a high HPI (Holes Per Inch) is best for humidity. It provides the necessary airflow to keep the skin dry while wicking away the moisture that naturally accumulates in damp environments.

Can I recycle old mesh garments?Yes, if they are made of 100% polyester or nylon, they can often be processed by specialized textile recyclers. Look for “take-back” programs from brands that prioritize circular fashion.

For expert guidance on selecting the perfect textile for your next project or to receive a quote on bulk orders, contact us today .