Mesh fabric options including nylon, micro, and breathable variants are the primary technical textiles used to create high-performance athletic apparel and durable outdoor tents. Many manufacturers struggle to find a fabric mesh material that offers both high-tensile strength and maximum airflow, leading to products that tear easily or cause user discomfort. This lack of material reliability results in increased return rates and a tarnished brand reputation in competitive B2B markets. By selecting specialized mesh structures tailored to specific environmental demands, businesses can ensure product longevity and superior functional performance.

What is the best fabric mesh material for tents?

The best fabric mesh material for tents is a high-density “no-see-um” mesh made from polyester or nylon. These materials are engineered to provide a barrier against the smallest insects while maintaining excellent cross-ventilation.

Why use no-see-um fabric mesh material?

No-see-um mesh is essential for outdoor gear because the knit is tight enough to block tiny gnats but open enough for air. This specific fabric mesh material ensures that campers stay comfortable in humid environments without sacrificing protection.

Look:

- Exceptional insect protection.

- High transparency for scenic views.

- UV resistance for long-term outdoor exposure.

Think about it: When you are in the wilderness, the last thing you want is a compromised barrier. A reliable mesh is the difference between a restful night and a failed expedition.

Key TakeawayChoosing a high-density knit provides the necessary balance between visibility and protection for premium tent manufacturing.

| Feature | Specification | Benefit | |

|---|---|---|---|

| Mesh Type | No-See-Um | Blocks smallest insects | |

| Fiber | Polyester/Nylon | Weather resistance | |

| Airflow | High | Prevents condensation |

How does fabric mesh material enhance athletic wear?

Athletic fabric mesh material enhances performance by facilitating rapid moisture evaporation and targeted heat dissipation. These textiles are strategically placed in high-sweat zones to keep the athlete cool during intense physical exertion.

Is micro-mesh better for running?

Micro-mesh is often preferred for running apparel due to its incredibly soft hand-feel and lightweight properties. This fabric mesh material reduces chafing while allowing the skin to breathe during long-distance movements.

The best part?

- Moisture-wicking capabilities.

- Rapid drying times.

- Extremely low physical weight.

Think about it: An athlete’s performance is often limited by their gear’s ability to manage thermal loads. Lightweight mesh removes those barriers effectively.

Key TakeawayMicro-mesh structures are the gold standard for high-motion sports where comfort and weight are critical.

| Property | Micro-Mesh Value | Application | |

|---|---|---|---|

| Weight | Ultra-light | Running Vests | |

| Texture | Soft/Smooth | Base Layers | |

| Flexibility | High | Dynamic Movement |

Why choose nylon for your fabric mesh material needs?

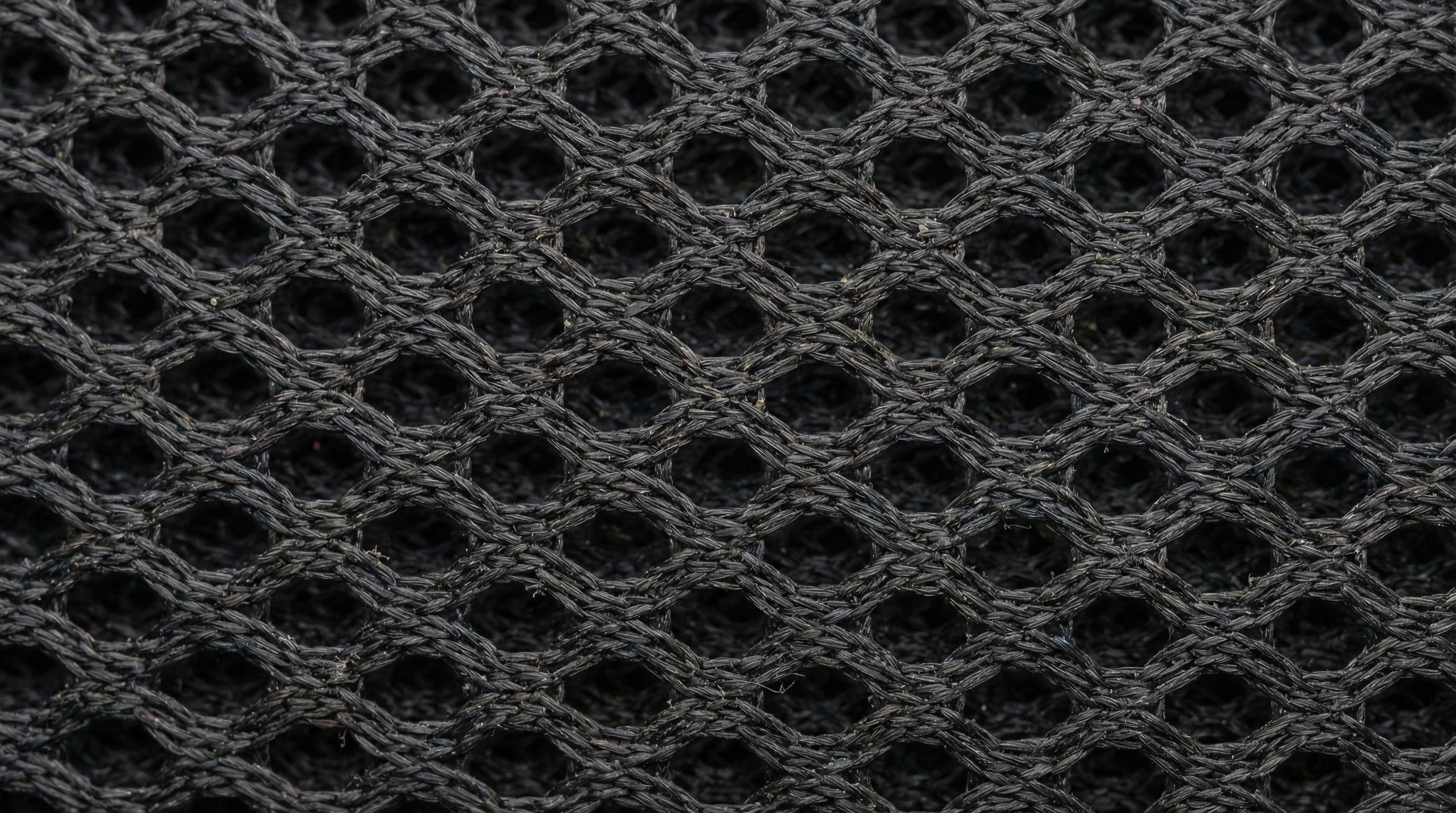

Nylon is the preferred choice for fabric mesh material when superior abrasion resistance and high tensile strength are required. It outperforms many other synthetics in rugged environments where the textile is subject to frequent friction.

What makes nylon mesh durable?

The molecular structure of nylon allows this fabric mesh material to stretch under load and return to its original shape without tearing. It is highly resistant to chemicals and oils, making it ideal for tactical and industrial gear.

Look:

- High abrasion resistance.

- Superior elastic recovery.

- Resistance to mold and mildew.

Think about it: For backpacks and outdoor equipment, the mesh must withstand heavy loads and rough handling. Nylon provides the structural insurance necessary for these high-stress applications.

Key TakeawayNylon mesh is the most resilient option for products that require long-term durability and mechanical strength.

| Criterion | Nylon Performance | Ideal Use | |

|---|---|---|---|

| Strength | Very High | Heavy-duty Bags | |

| Abrasion | Excellent | Tactical Gear | |

| Elasticity | Moderate | Form-fitting Packs |

Where can you source bulk fabric mesh material?

Sourcing bulk fabric mesh material is most efficiently done through specialized wholesalers who understand technical textile specifications. Direct factory partnerships ensure that the mesh meets specific denier and weight requirements for industrial production.

Should you buy wholesale?

Purchasing wholesale allows companies to maintain consistent quality across large production runs. This sourcing method for fabric mesh material provides significant cost advantages and allows for custom color matching.

The best part?

- Lower per-yard costs.

- Quality consistency.

- Access to custom technical specs.

Think about it: Scaling production requires a supply chain that can keep up with volume without sacrificing the material’s integrity. Wholesale sourcing provides that stability.

Key TakeawayWholesale procurement is the most strategic way to manage costs while ensuring high material standards for B2B manufacturing.

| Sourcing Factor | Wholesale | Retail | |

|---|---|---|---|

| Unit Cost | Low | High | |

| Customization | Available | Limited | |

| Lead Times | Planned | Immediate |

Is polyester fabric mesh material better than nylon?

Polyester fabric mesh material is better than nylon for applications requiring UV resistance and superior colorfastness. While nylon is stronger, polyester maintains its integrity much better when exposed to prolonged sunlight.

When should you pick polyester?

You should choose polyester fabric mesh material for outdoor furniture, flags, and marine equipment. It absorbs very little water, ensuring that the mesh does not sag or become heavy when wet.

The reality?

- Exceptional UV stability.

- Hydrophobic properties.

- Better dye sublimation results.

Think about it: If your product is destined for the outdoors, UV degradation is your biggest enemy. Polyester is the shield that keeps your product from fading and crumbling.

Key TakeawayPolyester is the superior technical choice for any mesh product that faces constant environmental exposure.

| Environmental Factor | Polyester Performance | Nylon Performance | |

|---|---|---|---|

| UV Resistance | Excellent | Poor/Moderate | |

| Moisture Absorption | Low | Moderate | |

| Color Retention | High | Moderate |

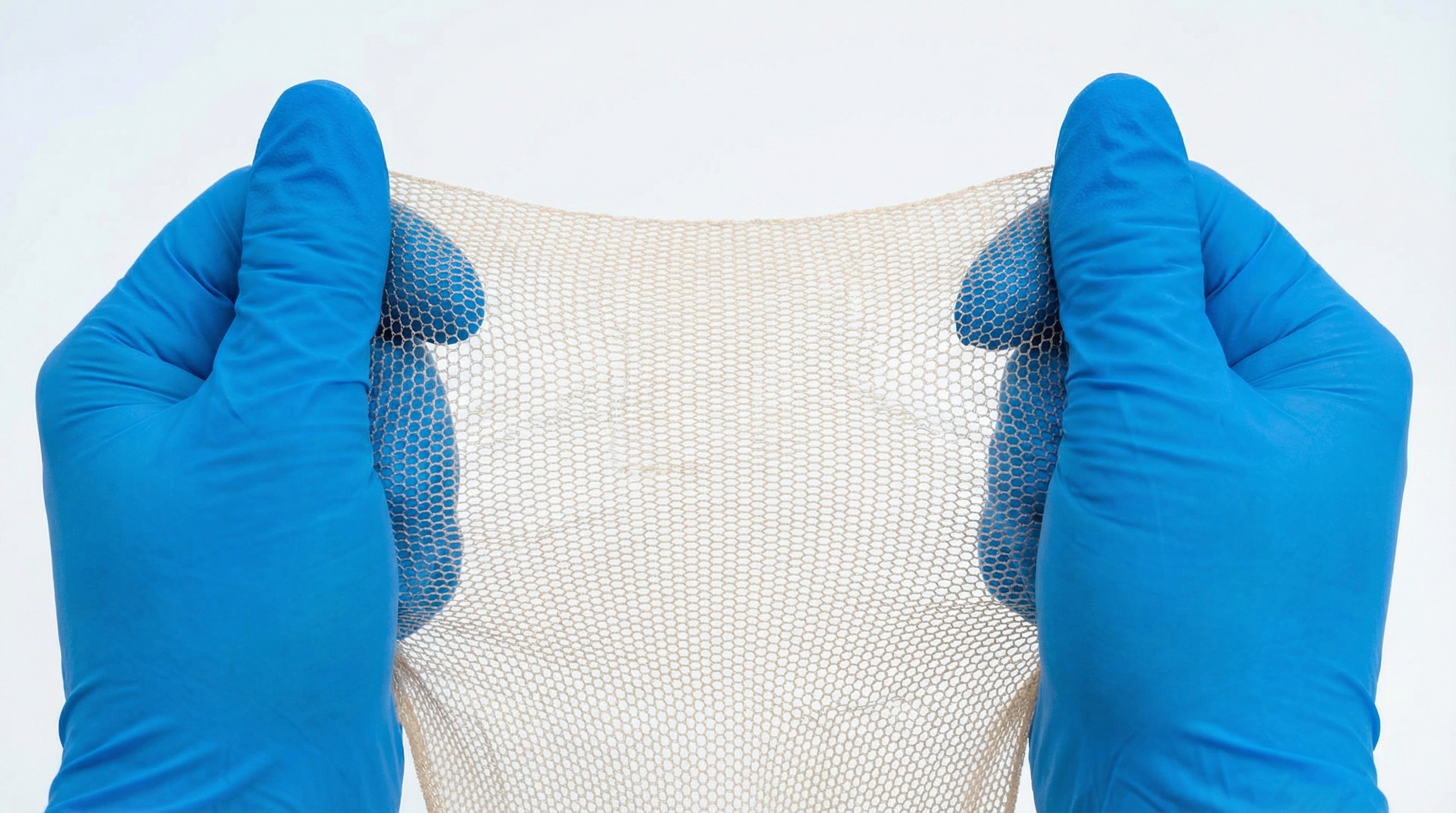

Can fabric mesh material be used for industrial filters?

Yes, specialized fabric mesh material is frequently used in industrial filtration to separate solids from liquids or gases. These meshes are characterized by precise micron ratings and uniform hole sizes to ensure filtration accuracy.

What are the industrial requirements?

Industrial fabric mesh material must be resistant to high temperatures and corrosive chemicals found in manufacturing plants. It requires a stable weave that does not shift or distort under high pressure.

The bottom line:

- Precise pore size.

- Chemical inertness.

- Structural stability under pressure.

Think about it: In a filtration system, the mesh is the functional core. Any variation in the weave can lead to system failure and contaminated outputs.

Key TakeawayIndustrial-grade mesh requires a level of precision and chemical resistance that goes beyond standard apparel textiles.

| Industry | Use Case | Material Priority | |

|---|---|---|---|

| Automotive | Oil Filtration | Heat Resistance | |

| HVAC | Air Scrubbing | Airflow Efficiency | |

| Food Processing | Sifting | FDA Compliance |

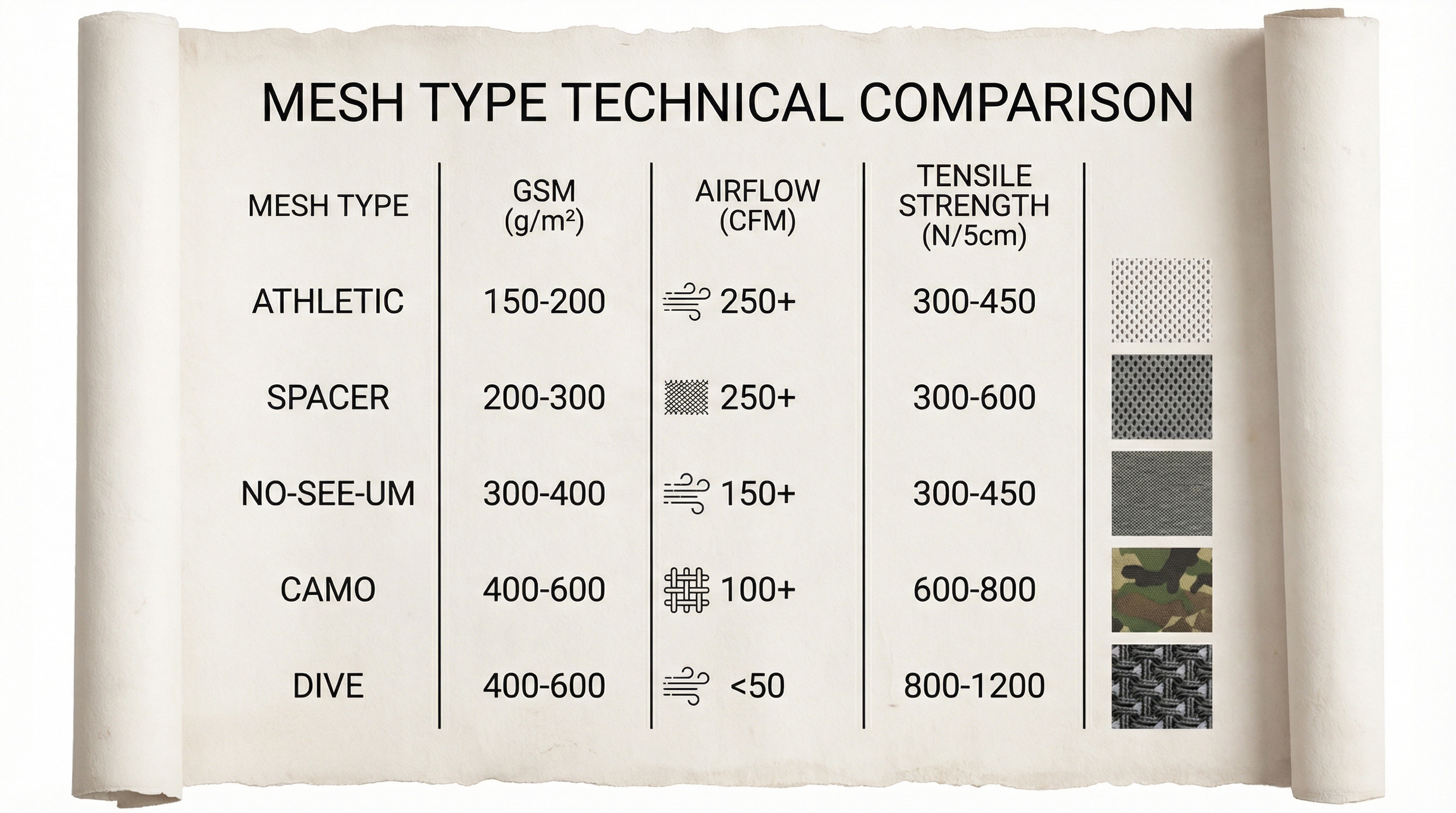

How do you measure fabric mesh material weight?

The weight of fabric mesh material is primarily measured in Grams per Square Meter (GSM), which indicates the density of the knit. A higher GSM typically correlates with a thicker, more durable mesh, while a lower GSM indicates a sheerer, more breathable fabric.

Why does GSM matter for apparel?

GSM directly influences the drape and opacity of the fabric mesh material used in garments. Designers use these measurements to ensure the fabric provides enough structure without becoming too heavy for the wearer.

In other words:

- Determines fabric thickness.

- Affects garment durability.

- Influences manufacturing costs.

Think about it: Getting the GSM right is a balancing act between making a garment feel premium and keeping it functional for athletic use.

Key TakeawayUnderstanding GSM allows manufacturers to specify the exact density required for their product’s intended use case.

| Mesh Type | Typical GSM | Common Application | |

|---|---|---|---|

| Power Mesh | 150 – 250 | Shapewear | |

| Athletic Mesh | 120 – 180 | Team Jerseys | |

| Heavy Cargo Mesh | 300+ | Bag Pockets |

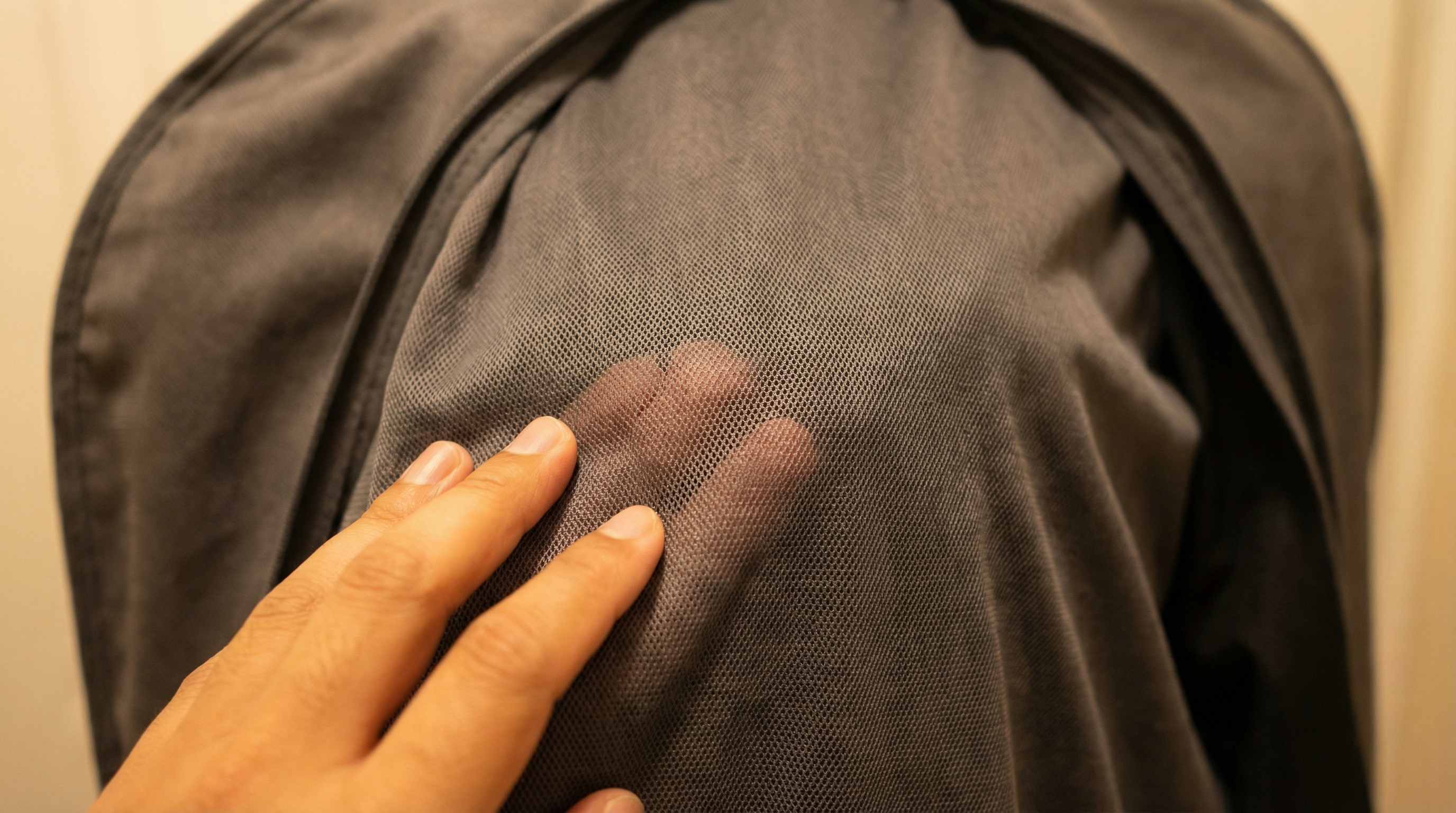

Is micro fabric mesh material suitable for linings?

Micro fabric mesh material is highly suitable for linings because of its smooth texture and ability to wick sweat away from the body. It provides a comfortable buffer between the skin and the outer shell of a garment.

Does it prevent skin irritation?

Micro fabric mesh material prevents irritation by reducing the friction caused by stiffer outer fabrics. The fine knit structure ensures that the material feels silky against the skin, even during repetitive movements.

Wait, there’s more:

- Enhances internal airflow.

- Adds minimal bulk to garments.

- Hypoallergenic options available.

Think about it: The comfort of a jacket is often determined by its lining. A high-quality micro mesh turns a standard garment into a premium experience.

Key TakeawayMicro mesh is the optimal choice for garment interiors where comfort and breathability are the highest priorities.

| Lining Type | Texture | Breathability | |

|---|---|---|---|

| Micro Mesh | Silky/Smooth | High | |

| Standard Mesh | Textured | Moderate | |

| Solid Taffeta | Slick | Low |

What is the stretch capacity of fabric mesh material?

The stretch capacity of fabric mesh material is determined by its knit pattern and the percentage of elastane or spandex fibers included. Power mesh, for instance, offers significant 4-way stretch, making it ideal for compression wear.

Is 4-way stretch necessary?

For high-performance gear, 4-way stretch fabric mesh material is necessary to allow for a full range of motion without the fabric binding. This flexibility ensures that the garment moves with the athlete rather than resisting them.

Think about it:

- Essential for activewear.

- Prevents fabric deformation.

- Improves garment longevity.

Look: If the mesh cannot stretch, it will eventually tear at the seams during physical activity. Stretch is a durability feature as much as a comfort one.

Key TakeawayStretch capacity should be matched to the intensity of movement required by the end-user for maximum performance.

| Stretch Type | Range | Application | |

|---|---|---|---|

| 2-Way | Horizontal only | Bag Pockets | |

| 4-Way | Horiz. & Vert. | Compression Wear | |

| Static | None | Tent Panels |

How do you maintain fabric mesh material over time?

Maintaining fabric mesh material involves gentle cleaning cycles and avoiding high heat, which can melt synthetic fibers. Proper care ensures that the knit remains open and the structural integrity of the mesh is preserved for years.

What are the cleaning best practices?

To clean fabric mesh material, use cold water and a mesh laundry bag to prevent the knit from snagging on zippers or buttons. Always air dry mesh products to avoid the shrinkage and fiber damage caused by industrial dryers.

The best part?

- Prevents snagging and tears.

- Maintains elasticity.

- Extends product lifecycle.

Think about it: Synthetic mesh is tough, but heat is its kryptonite. A little care in the laundry room protects your investment in high-quality materials.

Key TakeawayLow-heat maintenance is the most effective way to ensure the long-term functionality of technical mesh textiles.

| Care Step | Recommendation | Reason | |

|---|---|---|---|

| Washing | Cold/Gentle | Protects fibers | |

| Drying | Air Dry Only | Prevents melting | |

| Storage | Folded | Prevents stretching |

Strategic ConclusionAt Tullemesh, we believe that the foundation of any great product is the quality of its textile components. Whether you are engineering the next generation of athletic apparel or constructing rugged outdoor shelters, the right technical mesh is a non-negotiable requirement for success. Our commitment to providing high-performance, breathable, and durable materials ensures that your brand remains synonymous with quality and reliability. To find the perfect solution for your specific manufacturing needs, contact us today and let our experts guide your material selection.

FAQ

Can I use nylon mesh for permanent outdoor structures?Typically no, as nylon degrades faster than polyester under constant UV exposure.

What’s the best mesh for high-heat environments?Certainly, polyester mesh is the better choice due to its higher melting point and stability.

Can fabric mesh material be recycled?Absolutely, many modern polyester and nylon meshes are now available in rPET and recycled variants.

Is power mesh suitable for medical bracing?Yes, its high compression and breathability make it ideal for orthopedic supports.

What is the smallest mesh size available?Generally, no-see-um mesh represents the finest common industrial knit for preventing insect intrusion.