Waking up to the high-pitched whine of a mosquito inside your tent is a guaranteed way to ruin a wilderness experience. You have invested in high-end gear and planned your route for months, yet a single structural failure in your tent’s ventilation panels can lead to a night of itching and sleep deprivation. The solution lies in selecting the high-performance Mosquito Netting Fabric from TulleMesh that balances airflow with an impenetrable barrier against pests.

1. What is the Best Mosquito Netting Fabric for Tents?

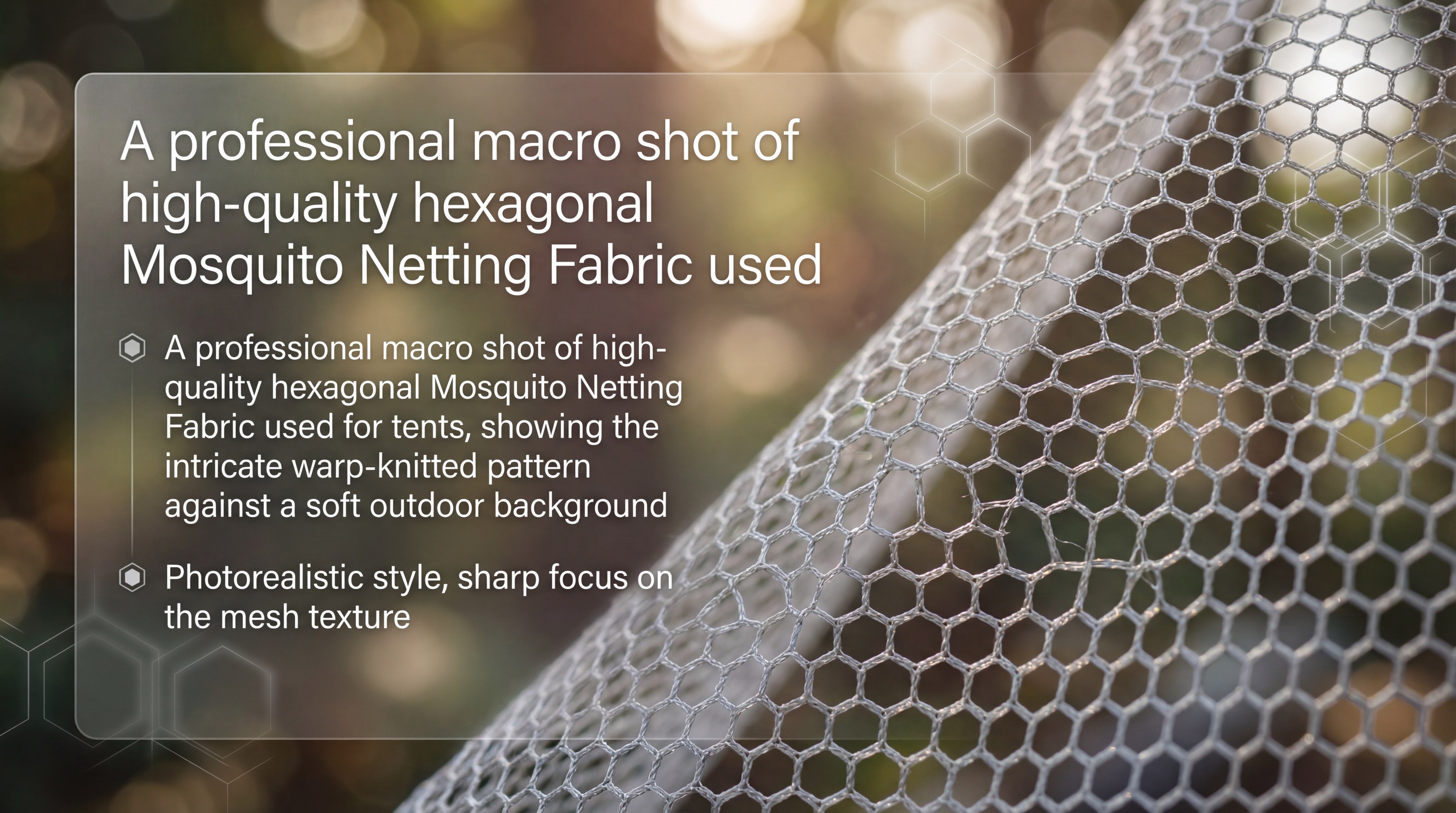

The best Mosquito Netting Fabric for tents is typically a high-tenacity polyester warp-knitted mesh because it offers superior dimensional stability and UV resistance compared to traditional nylon. Polyester does not absorb water, ensuring that your tent remains lightweight and sag-free even during heavy rain or high humidity. Choosing the right material involves balancing weight, hole density, and durability to suit your specific camping environment.

Does the Knit Pattern Affect Strength?

You might be wondering if the shape of the holes matters for the longevity of your tent.

The truth is:

- Hexagonal “honeycomb” patterns distribute stress more evenly across the fabric plane.

- Square meshes are often easier to manufacture but can be more prone to diagonal stretching.

- Warp-knitting ensures that if one thread breaks, the entire panel won’t unravel.

- High-quality mesh utilizes a multi-filament yarn to increase burst strength without adding bulk.

Think about it. When you are tensioning your tent poles, the mesh panels are often the first areas to show signs of stress, making the knit pattern a critical failure point.

Is Polyester Truly Better Than Nylon for Mesh?

Many campers assume nylon is the gold standard for strength, but the reality is more complex.

Here is the deal:

- Polyester has a higher modulus of elasticity, meaning it resists stretching when wet.

- Nylon mesh can sag significantly when exposed to morning dew, requiring constant readjustment of your rainfly.

- Modern polyester mesh can be engineered to be just as soft as nylon while maintaining better colorfastness.

- For ultralight gear, specialized high-density polyester provides the best weight-to-protection ratio.

| Feature | Polyester Mesh | Nylon Mesh | |

|---|---|---|---|

| Moisture Absorption | < 1% (Hydrophobic) | 4-5% (Hydrophilic) | |

| UV Resistance | High | Moderate | |

| Dimensional Stability | Excellent | Poor (Stretches when wet) | |

| Hand Feel | Firm to Soft | Generally Soft |

Analysis:Polyester dominates the tent industry because it maintains its shape under tension. If a tent mesh sags, it can touch the rainfly, causing condensation to wick through and soak your sleeping bag. By choosing a hydrophobic material, manufacturers ensure the structural integrity of the ventilation system remains constant regardless of weather changes.

Key Takeaway: For long-term reliability and weather resistance, polyester-based mosquito netting is the superior choice for tent construction.

2. Why Choose Durable Mosquito Netting Fabric for Outdoors?

Choosing a durable Mosquito Netting Fabric for outdoors is essential because tent mesh is constantly exposed to mechanical abrasion, snagging from gear, and the repetitive stress of folding and unfolding. A “no-run” warp-knit construction ensures that small punctures from thorns or zippers do not expand into gaping holes that invite insects. High-durability mesh acts as a secondary structural component of the tent, assisting in the overall tension of the canopy.

How Does Warp Knitting Prevent Unraveling?

Have you ever noticed how some fabrics seem to “run” like a pair of stockings?

That won’t happen here:

- Warp knitting loops threads zig-zagging along the length of the fabric.

- Each stitch is mechanically locked to its neighbor, preventing a single broken thread from cascading.

- This technique allows for complex hole geometries that remain stable under high wind loads.

- Industrial KARL MAYER machines produce a mesh that is significantly more robust than traditional woven netting.

Because of this interlocking structure, you can actually trim high-quality warp-knit mesh without the edges fraying immediately, though finishing is still recommended.

Can Mesh Quality Impact the Tent’s Lifespan?

The mesh is often the weakest link in a budget tent’s design.

Consider this:

- Cheap mesh uses low-denier yarns that brittle quickly when exposed to heat and sunlight.

- Durable mesh incorporates chemical stabilizers during the extrusion process of the yarn.

- High-tenacity fibers resist the “snagging” common when Velcro or zippers catch on the netting.

- Reinforced mesh panels allow for tighter pitching, which improves wind shedding and water runoff.

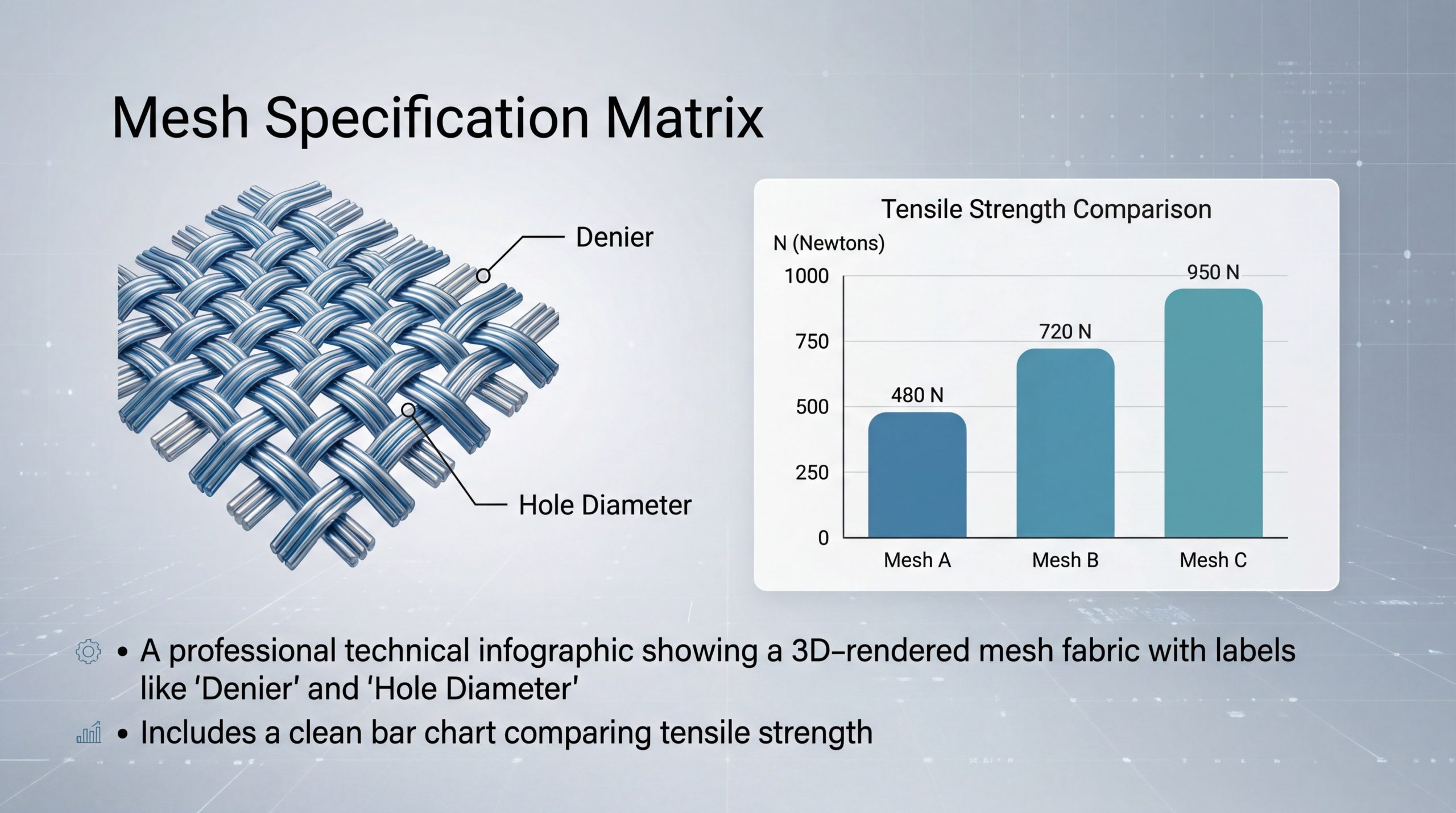

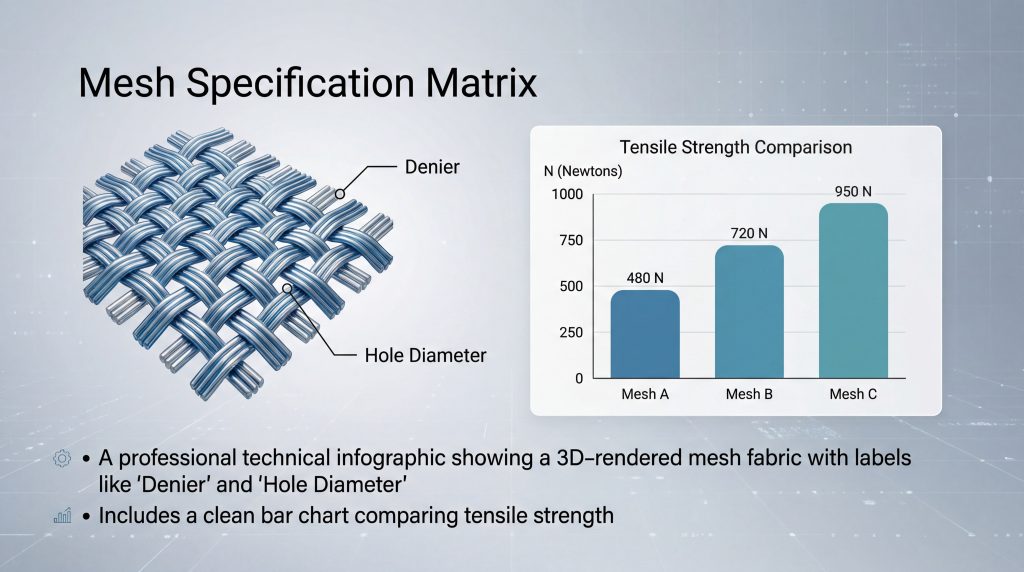

| Durability Factor | Impact on Performance | Long-term Benefit | |

|---|---|---|---|

| Denier Count | Higher denier increases tear strength. | Resists damage from pets or gear. | |

| Yarn Type | Multi-filament is more flexible than mono-filament. | Better packability and fold resistance. | |

| Finish | Heat-setting locks the knit pattern in place. | Maintains hole size consistency over years. |

Analysis:The manufacturing process is the primary driver of durability. Using high-end warp-knitting machines allows for a dense, consistent structure that resists the mechanical stresses of the trail. While a lighter mesh might save a few grams, a durable mesh prevents the catastrophic failure of the insect barrier during a multi-day trip.

Key Takeaway: Investing in a durable, warp-knitted mesh prevents minor snags from becoming tent-ending disasters.

3. How Does Mosquito Netting Fabric Prevent Small Insect Intrusion?

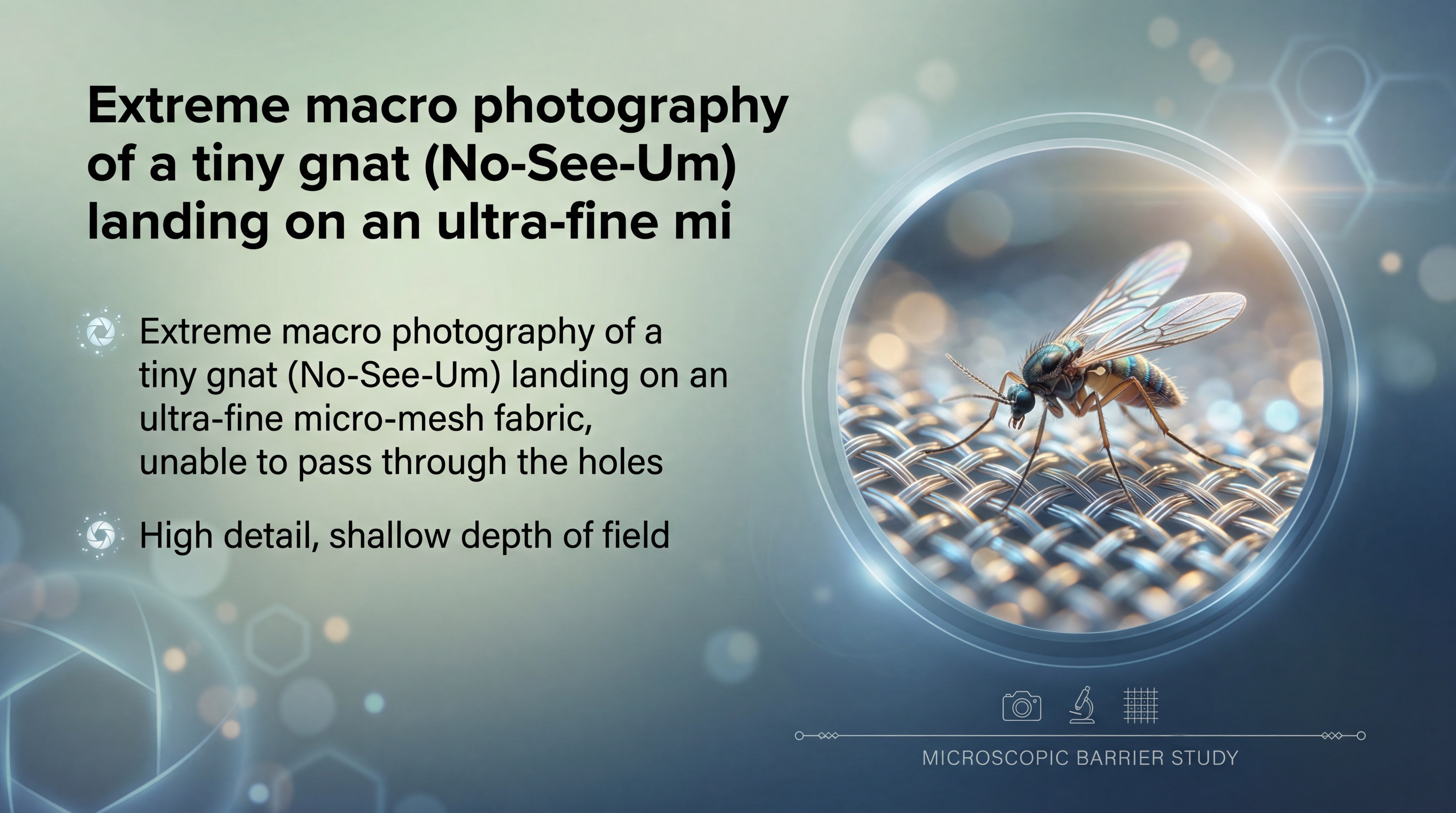

A specialized Mosquito Netting Fabric prevents small insect intrusion by utilizing a high hole-per-square-inch (HPSI) count that physically blocks even the smallest pests like “no-see-ums” or midges. For extreme environments, Polyester Mesh with a micro-pore structure is required to stop insects that are less than 1mm in size. The effectiveness of a mesh is measured by its ability to stop the head of the insect from passing through the aperture, effectively halting its progress.

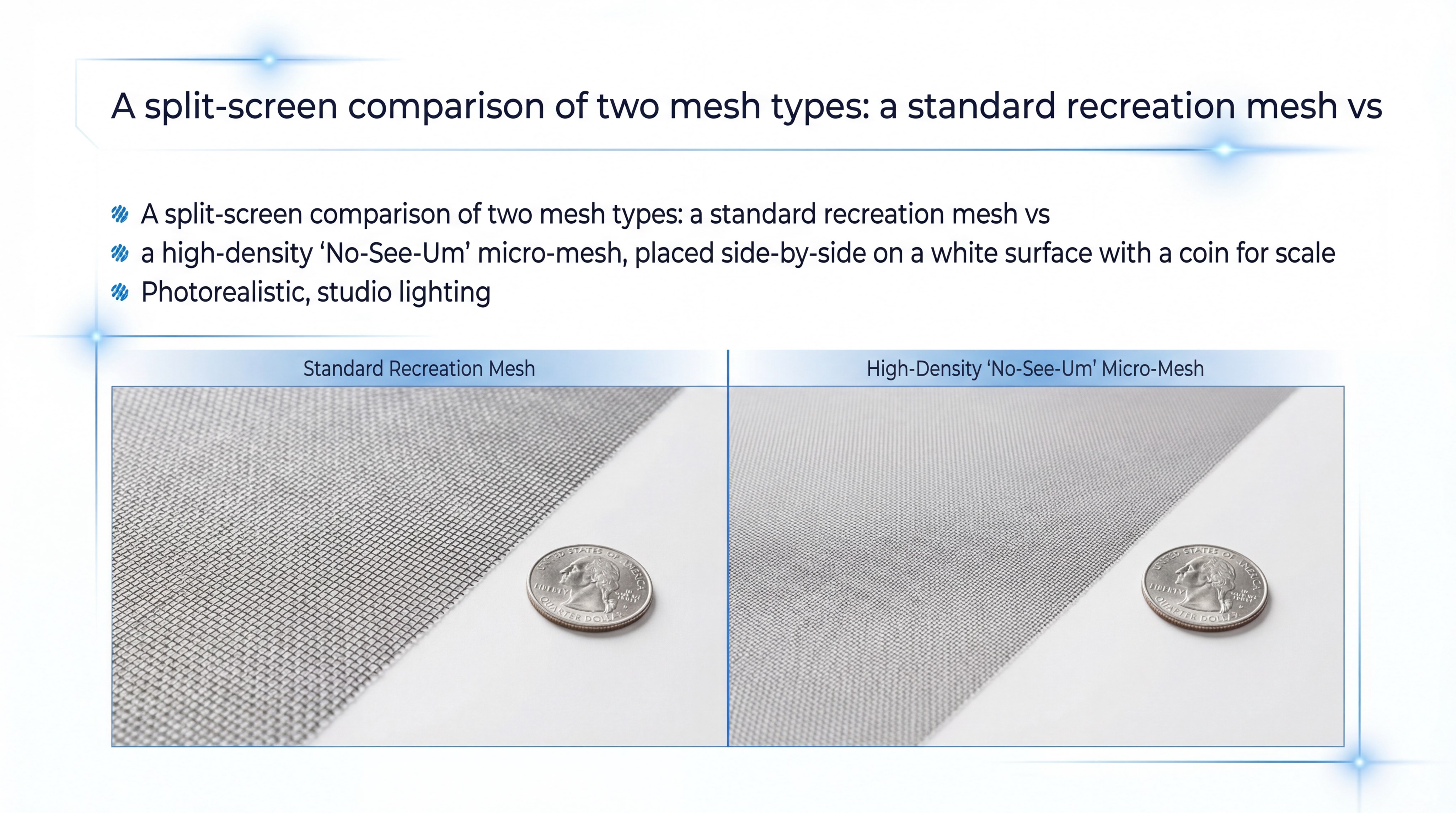

What is the Difference Between Standard Mesh and No-See-Um Mesh?

You might think all mesh is created equal until you camp near a marsh.

The difference is staggering:

- Standard mesh typically has about 150 to 300 holes per square inch.

- No-See-Um mesh can exceed 600 to 1,200 holes per square inch.

- Micro-mesh uses finer yarns to maintain airflow while drastically reducing the hole size.

- Standard mesh is great for airflow but is a “highway” for tiny biting gnats.

But wait, there’s more. The color of the mesh—usually black—actually makes it easier to see through while making it harder for insects to navigate.

Is Airflow Sacrificed for Better Protection?

This is the classic trade-off in tent design.

The bottom line?

- More holes mean more surface area is covered by yarn, which can restrict breeze.

- Thinner yarns (lower denier) help reclaim some of that lost airflow in high-density meshes.

- In stagnant, humid conditions, a No-See-Um mesh will feel noticeably warmer than a wide-aperture mesh.

- Most premium tents use a hybrid approach, placing finer mesh where pests are likely to enter.

| Insect Type | Minimum HPSI Required | Recommended Mesh Type | |

|---|---|---|---|

| Large Mosquitoes | 150 – 200 | Standard Recreation Mesh | |

| Small Midges/Gnats | 300 – 600 | Fine Grade Mesh | |

| No-See-Ums (Ceratopogonidae) | 900+ | Micro-Mesh / Ultra-Fine |

Analysis:Preventing insect intrusion is a game of geometry. A gnat’s wingspan and body thickness dictate the maximum allowable aperture. By increasing the density of the knit, we create a mechanical filter. While this does marginally reduce CFM (Cubic Feet per Minute) of airflow, it is the only reliable way to prevent the psychological and physical toll of an insect-infested sleeping area.

Key Takeaway: Match your mesh HPSI to your destination; No-See-Um mesh is mandatory for coastal or swampy regions.

4. Is Mosquito Netting Fabric Breathable Enough for Summer Camping?

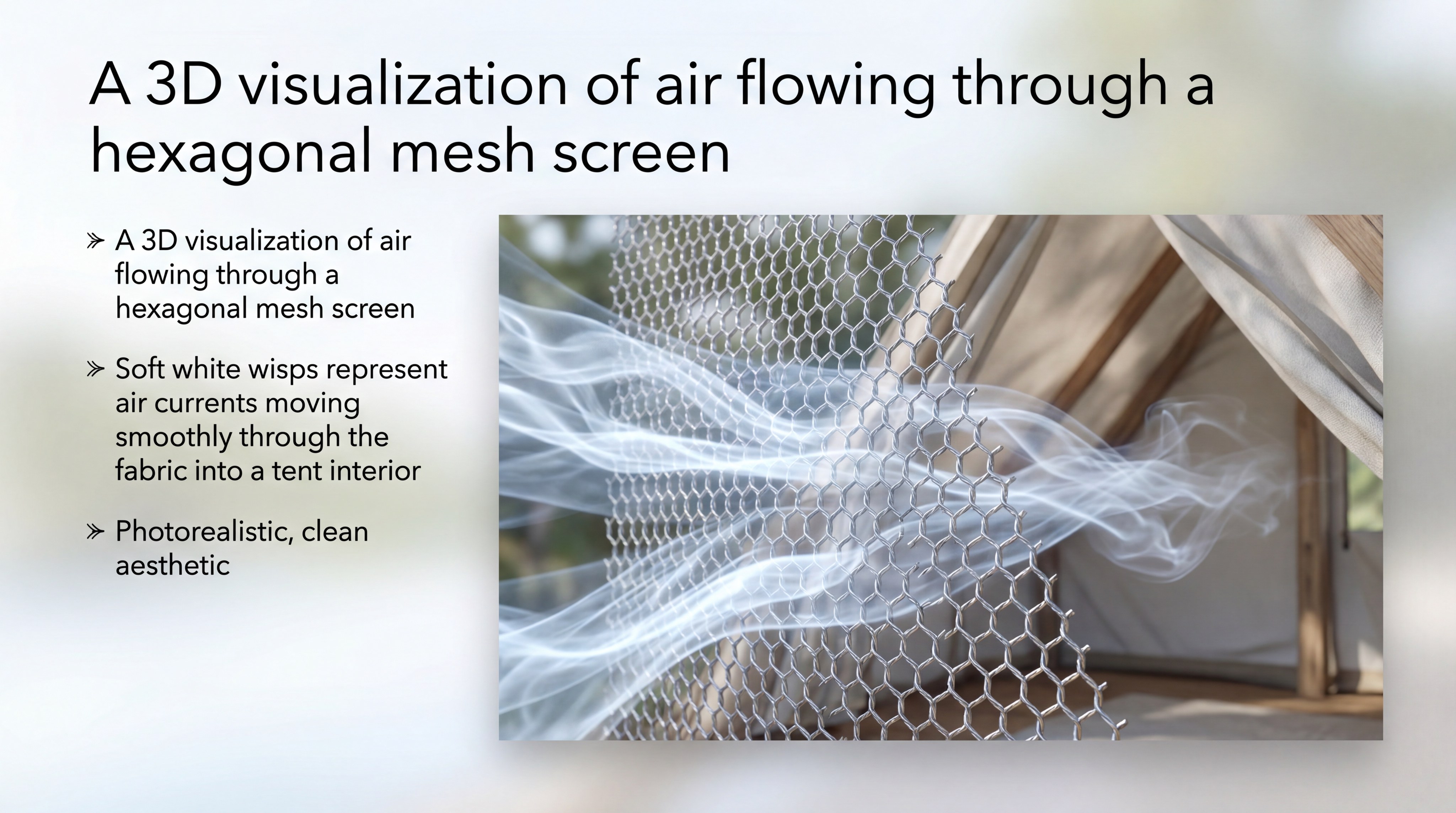

Modern Mosquito Netting Fabric is engineered specifically for maximum breathability, allowing for natural convection to move warm, moist air out of the tent while drawing cooler air in. The “open area” percentage of a mesh—the ratio of holes to solid yarn—is the key metric that determines how “stuffy” a tent will feel. For summer camping, a mesh with a high open-area percentage ensures that body heat does not build up inside the canopy during the night.

How Does Convection Work in a Mesh Tent?

Ever wonder why your tent feels cooler when you remove the rainfly?

It is all about the “chimney effect”:

- Warm air rises and escapes through the top mesh panels.

- This creates a low-pressure zone that pulls fresh air through the side mesh.

- Hexagonal mesh structures facilitate smoother laminar airflow compared to irregular weaves.

- Even a slight breeze is amplified when it can pass through the mesh with minimal resistance.

Why does this matter? Without this exchange, humidity from your breath condenses on the walls, making the interior feel damp and oppressive.

Can Mesh Orientation Impact Airflow?

Believe it or not, the way a mesh is sewn can change your experience.

Think about this:

- The “stretch” axis of the mesh should ideally be aligned with the tent’s tension lines.

- When mesh is pulled too tight, the holes can deform, slightly reducing their effective area.

- Some fabrics feature a “3D” knit that provides even more surface area for gas exchange.

- Darker colors absorb solar heat, which can actually help drive air movement via thermal buoyancy.

| Ventilation Metric | Standard Mesh | High-Density Micro-Mesh | |

|---|---|---|---|

| Open Area % | 65% – 75% | 45% – 55% | |

| Air Permeability | Very High | Moderate | |

| Heat Retention | Low | Low-Moderate |

Analysis:Breathability is not just about the size of the holes, but the total volume of air that can pass through the barrier. While micro-meshes have smaller holes, they compensate by using more of them. However, in a dead-calm summer night, a standard recreation mesh will always outperform a dense No-See-Um mesh in terms of pure air volume exchange.

Key Takeaway: For maximum summer comfort, choose a mesh with the largest hole size that still provides protection against the local insect population.

5. What Are the Weight Benefits of Mosquito Netting Fabric?

The weight benefits of Mosquito Netting Fabric are most apparent in ultralight backpacking, where high-tenacity Nylon Mesh allows for massive weight savings without sacrificing safety. Because mesh is essentially “mostly air,” it provides the necessary volume of a tent at a fraction of the weight of solid fabric walls. By replacing heavy ripstop nylon panels with lightweight mesh, manufacturers can reduce a tent’s total carry weight by 20% to 40%.

Why is Mesh the “Secret Weapon” of Ultralight Gear?

If you are counting every gram, mesh is your best friend.

Here is why:

- It provides a 360-degree view and bug protection with minimal material usage.

- 10D or 15D (Denier) meshes are incredibly light yet surprisingly strong.

- It allows for “double-wall” tent designs that weigh less than old-school single-wall tents.

- You can pack a mesh-heavy tent into a much smaller volume in your backpack.

The bottom line? Mesh allows you to carry a larger, more comfortable shelter without the penalty of a heavy pack.

Does Lightweight Mesh Mean Less Durability?

Many hikers fear that “gossamer” mesh will tear at the first touch.

But wait:

- Modern high-tenacity yarns have incredible tensile strength for their diameter.

- The “give” in a knit structure acts as a shock absorber against wind.

- Strategic reinforcement at pole clips and zippers prevents the mesh from over-stressing.

- Properly cared for, a 15-denier mesh can last for thousands of trail miles.

| Mesh Denier | Weight (oz/sq yd) | Typical Application | |

|---|---|---|---|

| 10D – 15D | 0.5 – 0.7 | Ultralight / Thru-hiking | |

| 20D – 30D | 0.9 – 1.2 | Standard Backpacking | |

| 40D+ | 1.5+ | Car Camping / Heavy Duty |

Analysis:Weight savings in mesh come from thinning the yarn, not just increasing the hole size. By using premium polymers, we can maintain the structural integrity of the “struts” in the mesh while reducing their mass. This allows a tent designer to create a “full mesh” inner body that provides ultimate ventilation and visibility for a negligible weight penalty.

Key Takeaway: High-tenacity, low-denier mesh is the most efficient way to reduce gear weight while maintaining a comfortable, insect-free interior.

6. How Do You Maintain Mosquito Netting Fabric Longevity?

Maintaining your Mosquito Netting Fabric longevity requires a combination of gentle cleaning, UV protection, and careful storage to prevent fiber degradation and “set” creases. Unlike solid fabrics, mesh has thousands of tiny edges that can trap dirt and oils, which eventually abrade the fibers. Regularly shaking out debris and using a mild, non-detergent soap for occasional deep cleans will keep the mesh supple and strong for years.

What is the Biggest Killer of Tent Mesh?

You might think it’s the wind, but the enemy is actually invisible.

The main culprits:

- UV Radiation: Long-term sun exposure breaks down polymer chains, making mesh “crunchy” and brittle.

- Debris: Pine needles and sand act like tiny saws against the yarn when the tent is packed.

- Zippers: Snagging the mesh in a zipper slide can shear the delicate threads.

- Mildew: Storing a mesh tent while damp can lead to fungal growth that weakens the knit.

Think about it. Most mesh failures happen at the edges or where dirt has accumulated, not in the center of a clean panel.

Can You Repair a Hole in the Mesh?

Accidents happen on the trail, but a hole isn’t the end of the world.

Try these steps:

- Use a specialized mesh repair patch (essentially a “sticker” made of matching mesh).

- For small tears, a drop of seam sealer can “glue” the broken threads back together.

- Never use a standard needle and thread unless you are an expert, as you may create new stress points.

- Always clean the area with alcohol before applying a patch to ensure a permanent bond.

| Maintenance Task | Frequency | Purpose | |

|---|---|---|---|

| Shake Out | After every trip | Remove abrasive grit and needles. | |

| Gentle Wash | Once per season | Remove body oils and salt. | |

| Air Dry | Before storage | Prevent mold and hydrolysis. | |

| Zipper Lube | Twice per year | Prevent snags and mechanical stress. |

Analysis:Longevity is a function of “cleanliness and care.” Because mesh is a high-surface-area material, it is more susceptible to environmental pollutants than flat fabrics. By managing the mechanical stresses (zippers/packing) and the chemical stresses (UV/dirt), the service life of a polyester or nylon mesh can easily exceed a decade of regular use.

Key Takeaway: Keep your mesh clean and dry; a few minutes of maintenance prevents the brittleness that leads to catastrophic tearing.

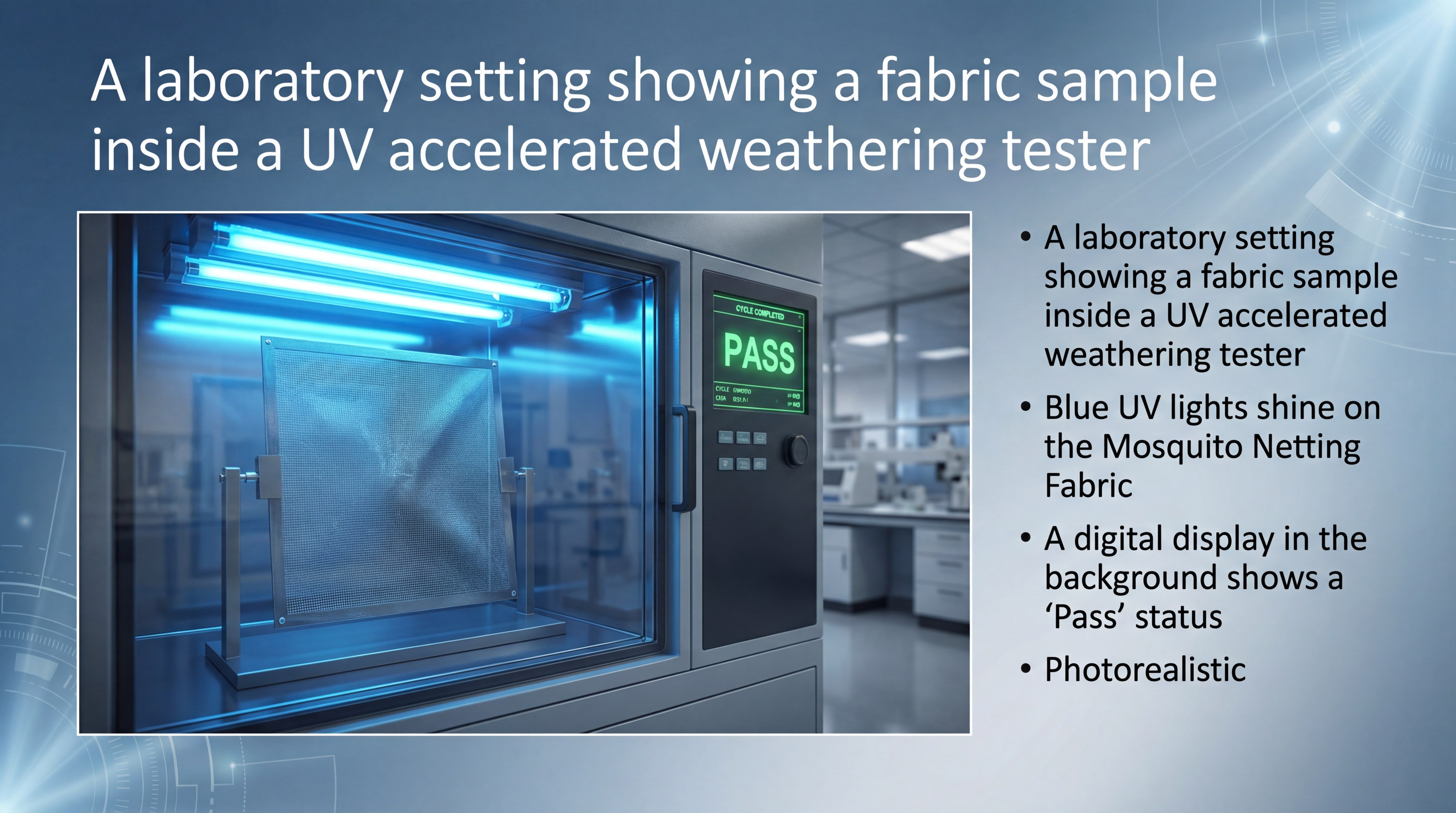

7. Can Mosquito Netting Fabric Withstand Harsh UV Exposure?

While all polymers eventually degrade under the sun, high-quality Mosquito Netting Fabric is treated with UV inhibitors during the manufacturing process to significantly slow this process. If you require maximum resistance, sourcing Tulle Fabric with a black pigment is often best, as the carbon black acts as a natural UV stabilizer. However, mesh should always be protected by a rainfly when not in use to avoid unnecessary exposure to the most damaging wavelengths of light.

Does Color Matter for UV Protection?

It’s not just an aesthetic choice; color plays a functional role.

The science is clear:

- Black and dark grey mesh absorb and dissipate UV energy more effectively than white or bright colors.

- White mesh tends to scatter light, which can lead to faster degradation of the internal fibers.

- Specialized “solution-dyed” yarns have the color integrated into the fiber, providing better stability.

- UV-stabilized mesh can last 2-3 times longer in high-altitude environments than untreated mesh.

This is why you rarely see professional-grade expedition tents with white mesh panels; the trade-off in longevity simply isn’t worth the look.

How Can You Tell if Your Mesh is Sun-Damaged?

Before your next trip, you should perform a “stress test” on your gear.

Watch for these signs:

- Color Fading: If your black mesh is looking purple or grey, the UV inhibitors are exhausted.

- The “Crunch” Test: Gently squeeze the mesh; if it feels stiff or makes a crackling sound, it’s brittle.

- Powdering: If a fine dust comes off the mesh when rubbed, the polymer is disintegrating.

- Loss of Elasticity: If the mesh no longer “snaps back” after being pulled, it has lost its structural integrity.

| UV Resistance Rank | Material/Color | Expected Performance | |

|---|---|---|---|

| Best | Solution-Dyed Black Polyester | Maximum longevity in high sun. | |

| Good | Dyed Charcoal Nylon | Reliable for standard forest camping. | |

| Poor | Untreated White Mesh | High risk of brittleness after 1-2 seasons. |

Analysis:UV degradation is a cumulative process. Every hour the mesh is exposed to direct sunlight, the molecular bonds are weakened. By using laboratory-tested fabrics that have passed accelerated weathering tests, manufacturers can guarantee that the tent remains a safe haven. For the user, the best defense is simply using the rainfly as a “sunshield” even when it isn’t raining.

Key Takeaway: Choose black, UV-stabilized polyester mesh for the best balance of visibility and long-term sun resistance.

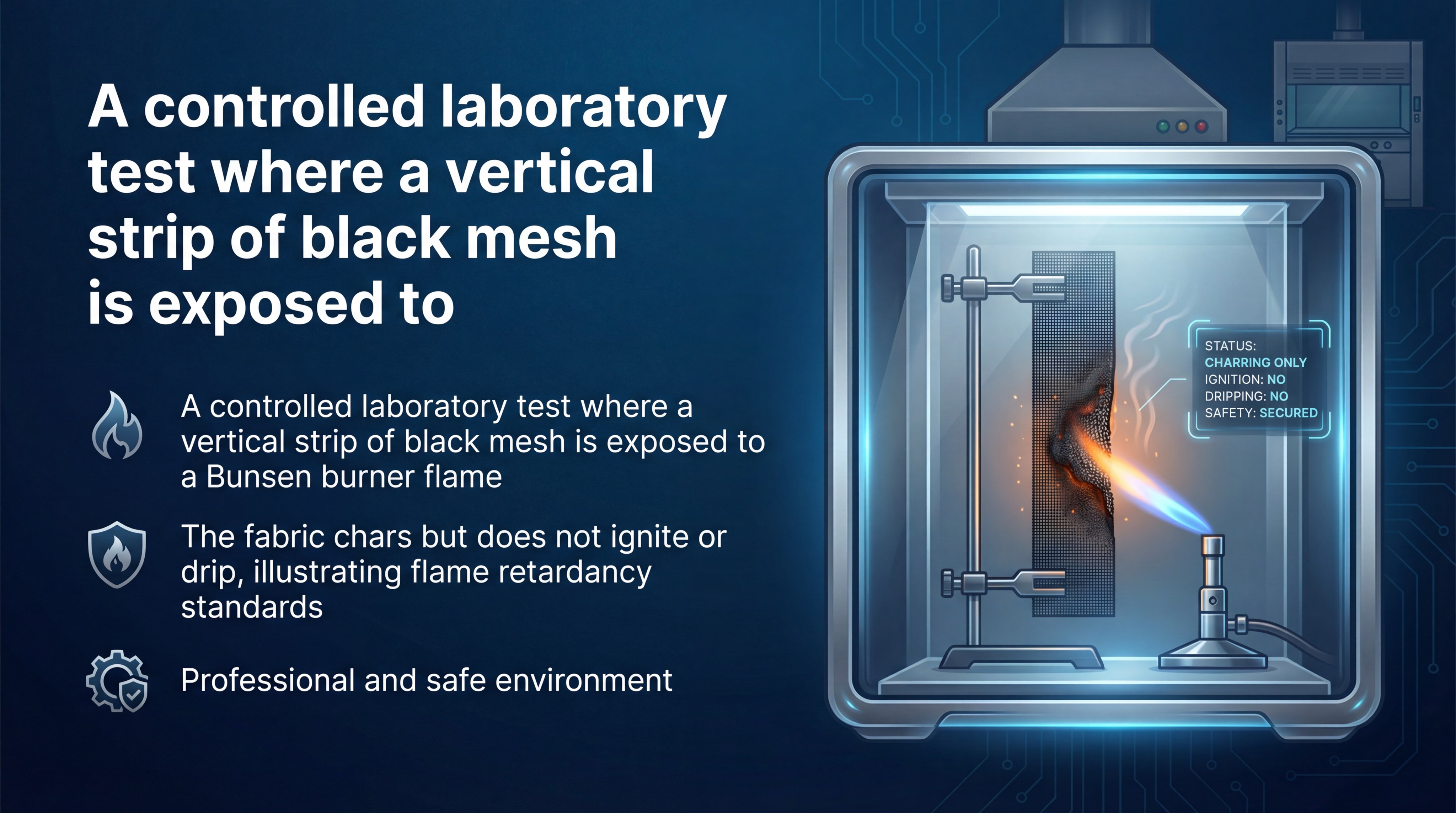

8. Is Flame Retardant Mosquito Netting Fabric Necessary for Tents?

Flame retardant Mosquito Netting Fabric is often a legal requirement in many jurisdictions (such as California and several Canadian provinces) to meet the CPAI-84 safety standard. Because mesh has a high surface-area-to-mass ratio, it can ignite and melt very quickly if exposed to a stray campfire spark or a knocked-over lantern. Flame-retardant (FR) treatments do not make the fabric “fireproof,” but they ensure that the material self-extinguishes or chars rather than fueling a rapid fire.

What Does CPAI-84 Actually Mean for You?

You see the tag on your tent, but what is it doing?

Essentially:

- It measures the “burn rate” and “after-flame” time of the tent materials.

- FR-treated mesh will melt away from a heat source rather than catching fire.

- It prevents “flaming drops” of plastic from falling onto occupants or sleeping bags.

- Modern treatments are increasingly moving away from harsh halogens toward safer, eco-friendly chemistries.

The bottom line? It provides a crucial few seconds of exit time in the event of an accidental fire.

Are There Downsides to FR Treatments?

Some ultralight enthusiasts try to avoid FR chemicals for weight and health reasons.

Here is the trade-off:

- FR chemicals can add a microscopic amount of weight to the fabric.

- Some older treatments had a distinct “chemical” smell or a slightly stiffer hand-feel.

- In some cases, FR treatments can slightly reduce the ultimate tear strength of the mesh.

- However, for family tents or any gear used near stoves, the safety benefits far outweigh these minor costs.

| Safety Standard | Requirement | Typical Result on Mesh | |

|---|---|---|---|

| CPAI-84 | Self-extinguishes within seconds. | Localized charring, no spread. | |

| NFPA 701 | Industrial fire safety test. | High-level protection for large structures. | |

| Non-FR | No specific burn requirement. | Rapid melting and potential for fire spread. |

Analysis:Safety in the backcountry is about risk mitigation. While the chances of a tent fire are low, the consequences are extreme. FR-treated mosquito netting is a passive safety feature that works without user intervention. When selecting mesh, ensure it meets the local fire safety regulations of where you intend to camp to stay both legal and safe.

Key Takeaway: For any tent used with internal heating or near campfires, flame-retardant mesh is a critical safety investment.

9. How Does Mosquito Netting Fabric Improve Tent Ventilation?

High-quality Mosquito Netting Fabric from TulleMesh improves tent ventilation by acting as a passive air heat exchanger, facilitating the movement of moisture-laden air out of the shelter. This is particularly vital in “double-wall” tents, where the mesh inner body separates the sleeper from the cold, damp rainfly. By optimizing the placement and size of mesh panels, tent designers can eliminate “dead air” zones where CO2 and humidity tend to accumulate.

Why is Ventilation More Than Just “Air In”?

It’s not just about a breeze; it’s about moisture management.

Consider the “Breathability Cycle”:

- An average adult exhales about 1 liter of water vapor during a night’s sleep.

- Without mesh ventilation, this water clings to the tent walls (condensation).

- Mesh allows this vapor to pass through to the rainfly, where it can drain away.

- Cross-ventilation (placing mesh on opposite sides) creates a consistent airflow path.

Think about it. A tent with poor ventilation isn’t just hot—it’s wet, which can lead to hypothermia in cold environments.

Can You Control Ventilation in Cold Weather?

Ventilation is just as important in winter as it is in summer.

Here is how to manage it:

- Many 4-season tents use “closable” mesh panels with solid fabric covers.

- You want to keep the mesh at the highest point of the tent open to let steam escape.

- Lower mesh vents can be closed to prevent “spindrift” (blowing snow) from entering.

- Finding the “sweet spot” between warmth and airflow is the key to a dry winter camp.

| Ventilation Design | Airflow Efficiency | Best For | |

|---|---|---|---|

| Full Mesh Canopy | 100% | Hot, humid summer nights. | |

| Half Mesh / Half Solid | 50% | Windy areas / Shoulder seasons. | |

| Adjustable Vents | Variable | All-weather versatility. |

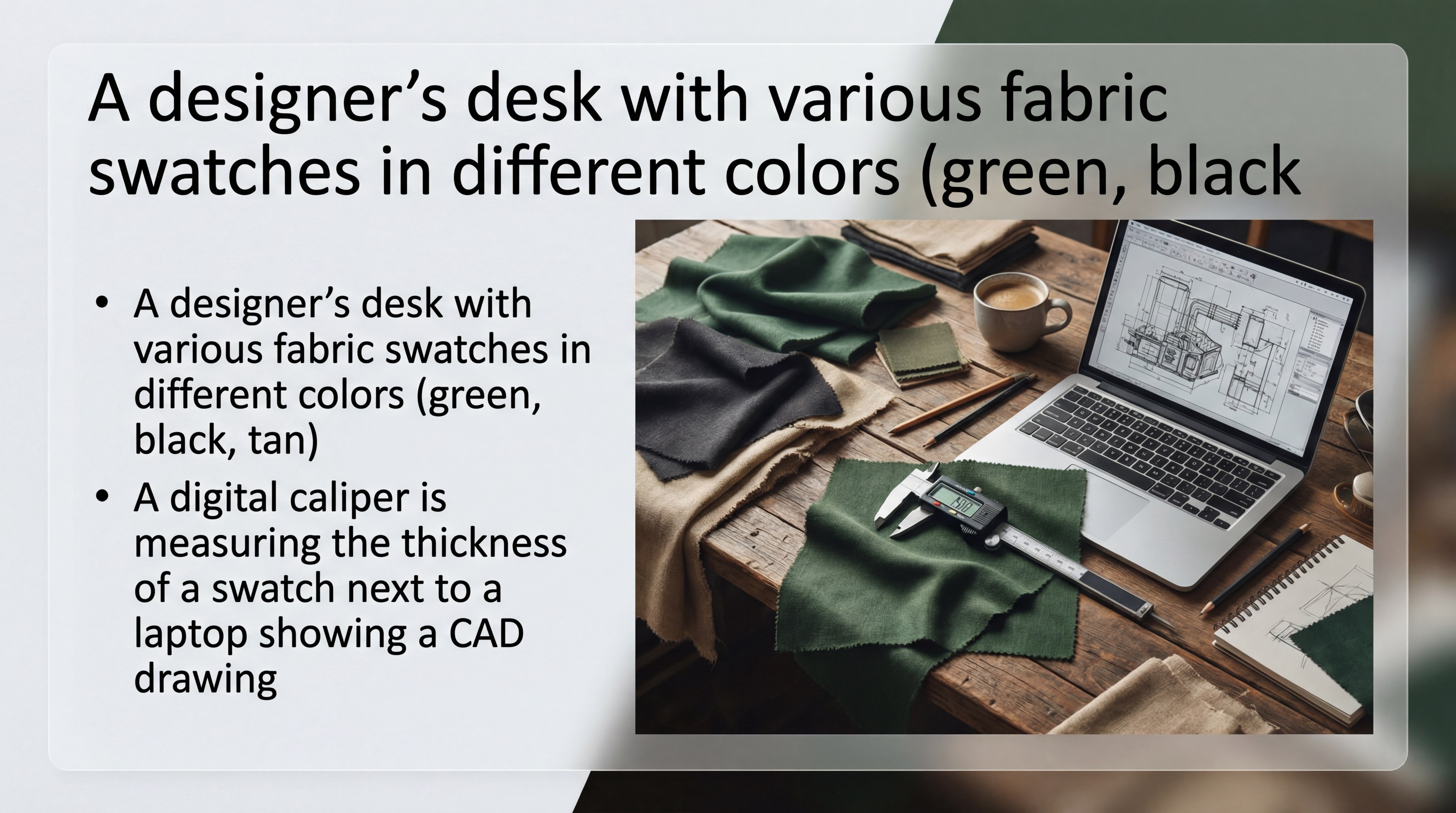

Analysis:Ventilation is the primary functional role of mesh after insect protection. The engineering challenge is providing enough “open area” to satisfy the laws of thermodynamics while maintaining the structure of the tent. By utilizing calipers and CAD software during the design phase, manufacturers ensure that mesh panels are placed exactly where the pressure differentials are greatest.

Key Takeaway: Proper mesh placement is essential for preventing condensation; always look for tents with high-level exhaust vents.

10. Where Should You Source Bulk Mosquito Netting Fabric?

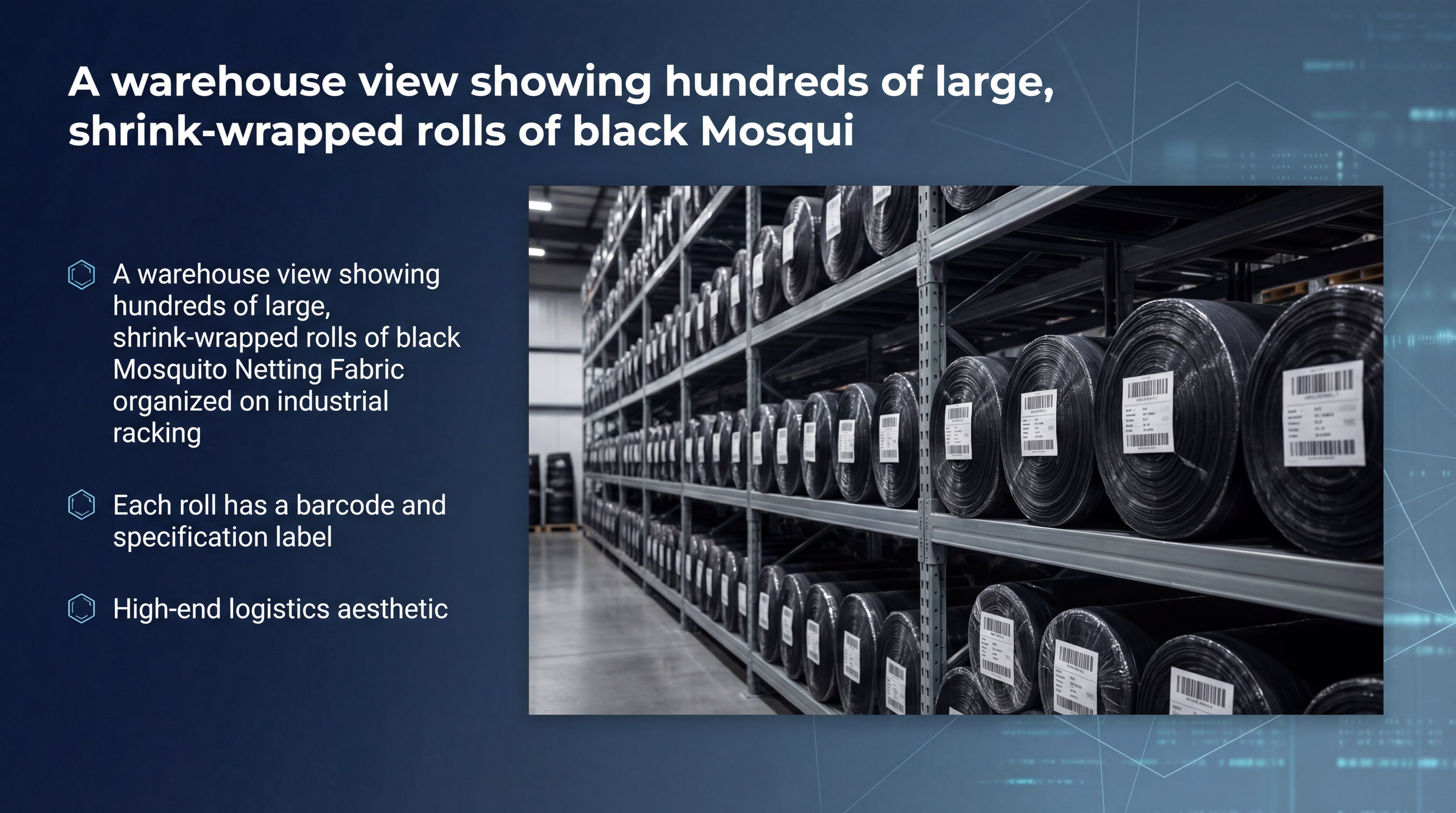

When looking to source bulk Mosquito Netting Fabric, it is vital to partner with a supplier that maintains consistent quality control and a robust inventory of various deniers and HPSI counts. Industrial-scale sourcing requires a partner who understands the technical specifications of warp-knitting and can provide certifications for UV resistance and flame retardancy. Whether you are a small gear manufacturer or a large-scale tent producer, reliability in the supply chain is the difference between a successful product launch and a production delay.

What Should You Look for in a Wholesale Supplier?

Don’t just go for the lowest price; look for the “Total Value.”

Key indicators of a quality source:

- Inventory Depth: Can they fulfill a 1,000-yard order immediately?

- Specification Consistency: Does every roll match the sample’s denier and HPSI?

- Packaging: Is the mesh shrink-wrapped and protected from warehouse dust and moisture?

- Technical Support: Can they provide data sheets on tensile strength and burst pressure?

Here is the deal: A cheap roll of mesh that arrives snagged or dirty is a total loss for your production line.

How Do You Verify Fabric Quality in Bulk?

Before you cut a single yard, you must perform an incoming inspection.

Check for these “Red Flags”:

- Barring: Horizontal lines across the fabric that indicate uneven knitting tension.

- Pin Holes: Unintentional gaps that are larger than the specified mesh size.

- Width Variation: If the roll width fluctuates, it will ruin your automated cutting patterns.

- Odor: Strong chemical smells can indicate improper finishing or “recycled” polymers of low quality.

| Sourcing Factor | Importance | Why It Matters | |

|---|---|---|---|

| Lead Time | High | Prevents production bottlenecks. | |

| MOQ (Minimum Order) | Medium | Affects cash flow for smaller brands. | |

| Certifications | Critical | Ensures legal compliance (FR/UV). |

Analysis:Sourcing is the foundation of any high-performance textile product. In the tent industry, where seasonal demand is high, having a warehouse-backed supplier ensures that you can scale production without compromising on the material specs. Professional sourcing involves vetting not just the fabric, but the logistics and quality assurance protocols behind every roll.

Key Takeaway: Partner with a specialist like TulleMesh to ensure your bulk fabric meets the rigorous demands of the outdoor industry.

Conclusion

Navigating the world of tent mesh fabrics requires an understanding of the delicate balance between protection, breathability, and durability. We have explored how polyester’s dimensional stability makes it the industry standard, how No-See-Um mesh density protects against the smallest predators, and why UV and FR treatments are non-negotiable for outdoor safety. Whether you are repairing a beloved shelter or designing the next generation of ultralight tents, the quality of your mesh determines the quality of your sleep.

At TulleMesh, we specialize in providing high-tenacity, laboratory-tested netting that stands up to the harshest environments on Earth. Our commitment to warp-knit excellence ensures that every yard of fabric we ship is a reliable barrier between you and the wild. Don’t let a sub-par mesh ruin your next adventure—reach out to our experts and contact us today for a consultation or bulk quote.

FAQ

Can I use standard window screen mesh for a tent?No, window screen mesh is typically made of rigid fiberglass or stiff vinyl which is not designed for the repetitive folding and tensioning required for a tent. It will crack, crease, and eventually fail at the seams.

What’s the best way to patch a No-See-Um mesh hole?The best method is using a “Gear Aid” style adhesive mesh patch. These allow you to maintain breathability and visibility while providing a permanent, flexible bond that won’t peel off during packing.

How do I know if my mesh is polyester or nylon?A simple “burn test” (with caution) can tell: Polyester smells sweet and produces black smoke, while nylon smells like celery and produces a hard, amber-colored bead. However, checking the manufacturer’s spec sheet is always safer.

Is it worth getting a tent with a “full mesh” inner?If you primarily camp in summer or humid environments, yes. The increased airflow and ability to “stargaze” without a rainfly are massive benefits, though you will sacrifice some warmth in the shoulder seasons.

Can insects bite through the mesh?Generally, no. Most mesh is thick enough that an insect’s proboscis cannot reach your skin if you are leaning against it. However, for maximum safety, always keep a small gap between your sleeping bag and the mesh wall.