Mesh fabric is a lightweight, open-weave textile characterized by its net-like structure and extreme breathability. Imagine wearing a heavy, non-breathable shirt during a high-stakes outdoor product launch in the peak of summer. The sweat pools, the fabric clings to your skin, and you feel increasingly claustrophobic and unprofessional. You need a textile solution that provides ventilation and comfort without sacrificing structural integrity.

When selecting materials for activewear, a primary question manufacturers ask is mesh fabric stretchy , as this determines the final garment’s performance.

What exactly is mesh fabric?

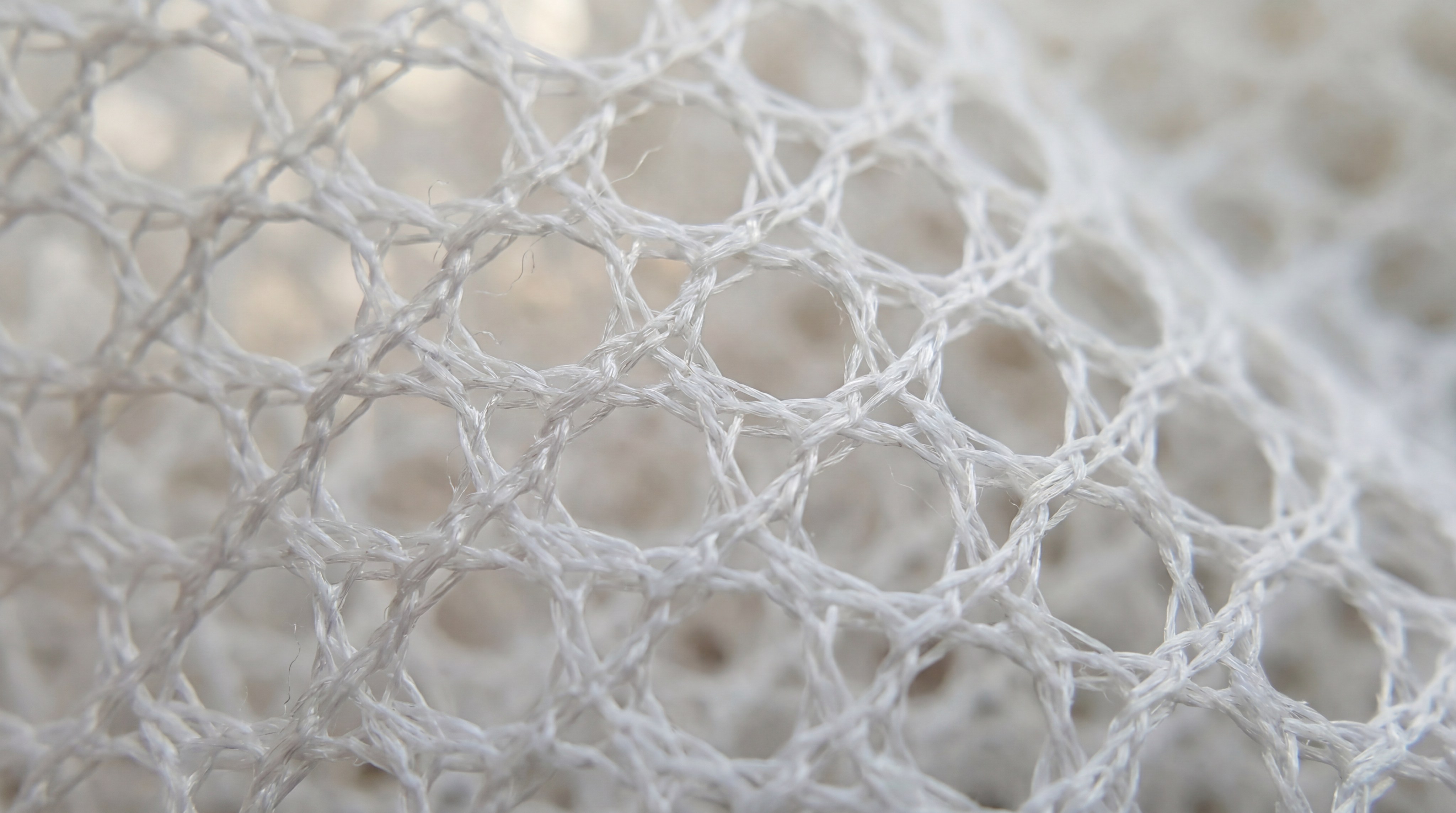

Mesh fabric is a permeable material defined by its loosely woven or knitted construction that creates a signature net appearance. When considering this material for your production line, you might wonder is mesh fabric stretchy enough to handle the rigors of athletic movements. This fabric is highly valued in B2B sectors for its ventilation and moisture-wicking properties.

How is the open-weave structure defined?

The structure is defined by the spacing between the yarns, often measured in holes per inch (HPI). But here’s the kicker:

- HPI ranges typically from 6 to 16.

- The weave can be square or hexagonal.

- Larger holes increase breathability but reduce opacity.

What materials are typically used for mesh?

Synthetics like polyester and nylon are the primary fibers used to create durable mesh textiles. The secret lies in the polymer:

- Polyester for moisture-wicking activewear.

- Nylon for strength in industrial netting.

- Occasional silk blends for luxury fashion.

What distinguishes mesh from other textiles?

Mesh stands out because of its transparency and its unique ability to allow air to flow directly through the garment. This makes it fundamentally different from tightly woven cotton or wool, which trap heat.

Key Takeaway: Mesh is a versatile, synthetic-based textile defined by its “holey” structure, making it the premier choice for applications requiring high airflow.

| Feature | Characteristic | |

|---|---|---|

| Composition | Mostly Polyester or Nylon | |

| Breathability | Extremely High | |

| Common HPI | 6 to 16 Holes | |

| Primary Use | Sportswear and Industrial |

Where did mesh fabric originate?

Mesh fabric as a modern apparel textile originated in the United Kingdom during the late 19th century. If you are developing a vintage-inspired sportswear line, you must ask is mesh fabric stretchy in the same way modern variants are. While basic nets have been used for fishing for centuries, the transition into a wearable textile was a significant industrial milestone.

When was the first mesh textile patented?

The first version of what we recognize as mesh was developed by a British mill owner who noticed the warmth provided by porous gloves. You might be wondering:

- The company Aertex was the original producer.

- It gained massive popularity in the 1980s.

- It was eventually adopted by global athletic brands.

How has the fabric evolved over the centuries?

The evolution moved from simple cotton-based porous weaves to high-tech synthetic polymers that offer better durability. The change was dramatic:

- Early mesh was prone to shrinking.

- Modern versions are UV resistant.

- Development of “power mesh” added compression.

Key Takeaway: From its humble beginnings in British mills, mesh has evolved through chemical innovation to become a staple of global athletic markets.

| Era | Primary Material | Main Application | |

|---|---|---|---|

| 19th Century | Cotton | Undergarments | |

| Mid-20th Century | Nylon | Industrial Netting | |

| Modern Day | Polyester/Elastane | High-Performance Activewear |

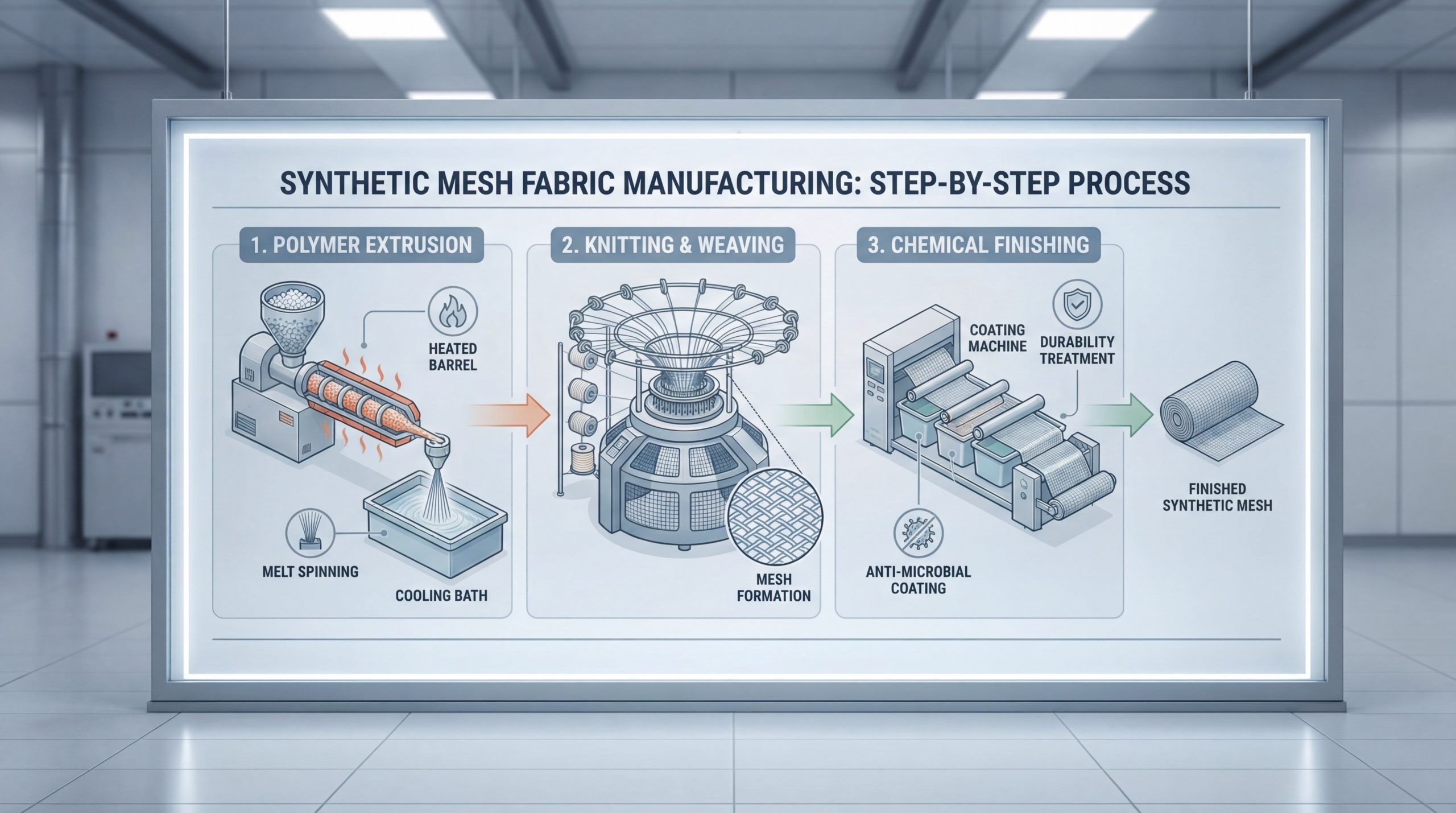

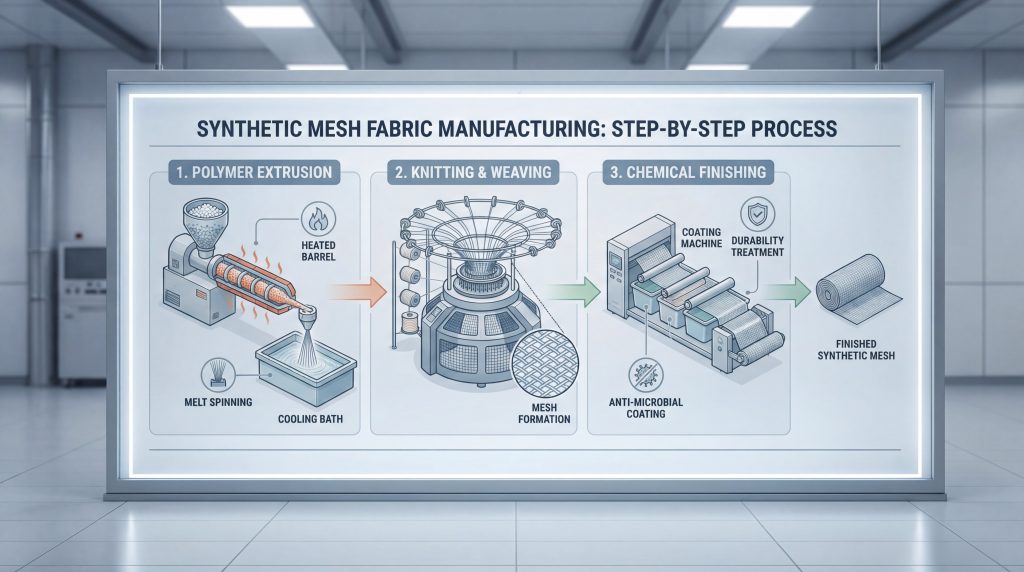

How is mesh fabric manufactured today?

Modern mesh fabric is produced through advanced knitting or weaving processes, typically starting with the refinement of petroleum into synthetic polymers. Manufacturers frequently inquire, is mesh fabric stretchy, during the extrusion process because the polymer tension affects the final product’s flexibility. To learn more about our specific production standards, you can visit our about us page.

Is the fabric typically woven or knitted?

Most mesh used in the apparel industry today is knitted rather than woven to increase its durability and give. It comes down to this:

- Knitted mesh resists fraying when cut.

- Woven mesh is often stiffer and industrial.

- Raschel knitting is the most common method.

How are the signature holes created?

The holes are not punched out but are created by the specific spacing of the yarns on the loom or knitting machine. Consider the process:

- Yarns are looped to leave intentional gaps.

- Computerized looms control the HPI precisely.

- Tension is maintained to keep holes uniform.

Key Takeaway: Contemporary manufacturing relies on high-speed knitting and chemical finishing to produce mesh that is both functional and comfortable.

| Manufacturing Step | Purpose | |

|---|---|---|

| Polymer Extrusion | Creating the synthetic fiber | |

| Knitting/Weaving | Forming the open-cell structure | |

| Chemical Finish | Adding performance features |

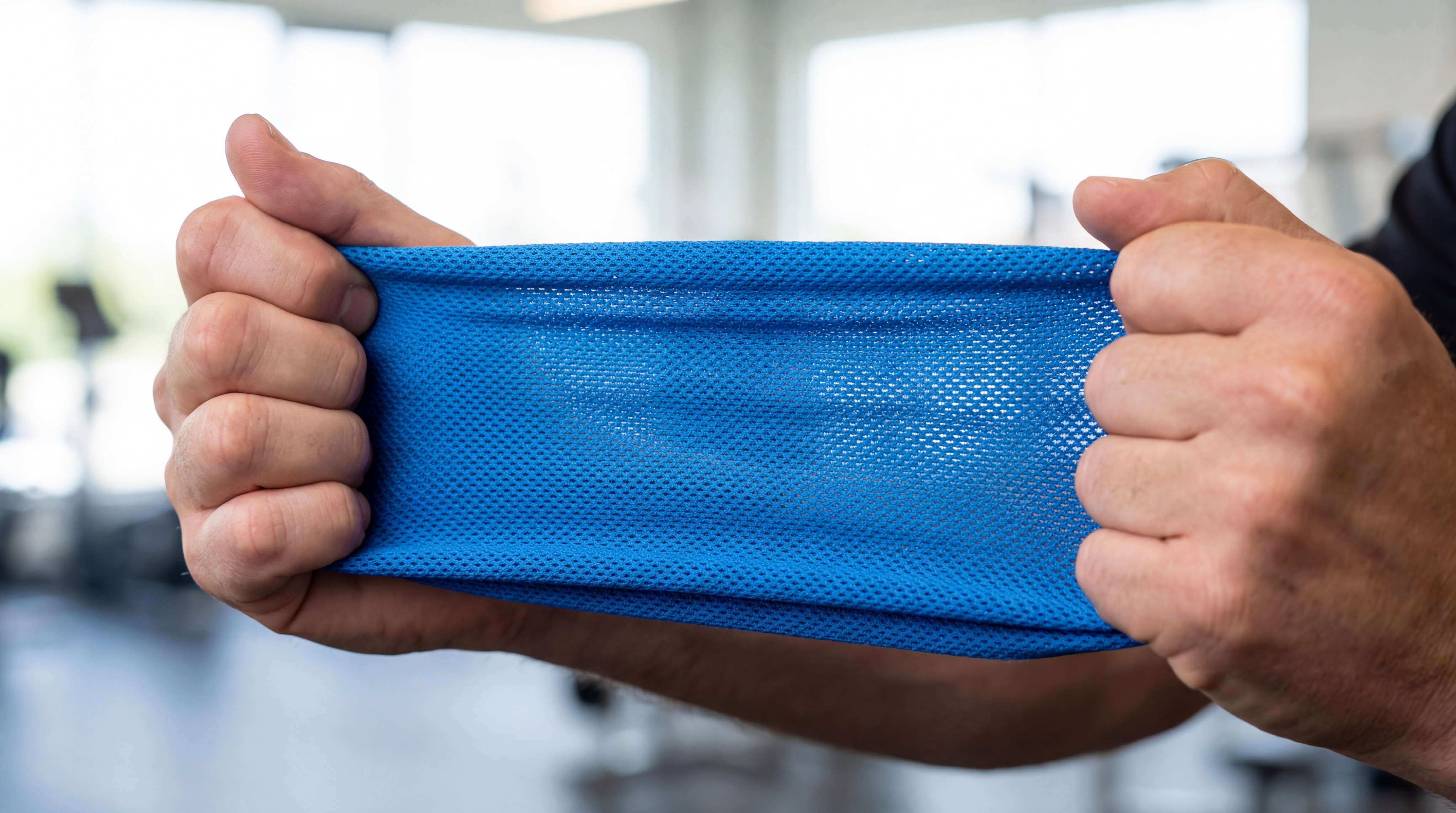

Is mesh fabric stretchy by nature?

Mesh fabric can be exceptionally stretchy, particularly when knitted into “power mesh” or blended with elastane fibers. For B2B buyers in the shapewear industry, the question of is mesh fabric stretchy is central to their sourcing strategy. While the open weave inherently allows for some mechanical give, the specific fiber chemistry determines the actual rebound.

Does the fiber content influence elasticity?

The inclusion of spandex or elastane is the most significant factor in determining how much a mesh fabric will stretch. Believe it or not:

- 100% polyester mesh has limited stretch.

- Spandex blends can reach 40% elasticity.

- Nylon mesh is generally stronger but less flexible.

How does the knit pattern impact flexibility?

The way the loops are interlocking in a knit pattern provides “mechanical stretch” even if the fibers themselves are rigid. Think about it this way:

- Interlock knits provide 4-way stretch.

- Tricot knits offer 2-way stretch.

- Hexagonal patterns distribute tension better.

Key Takeaway: Elasticity in mesh is a choice made during the design phase, achieved through a combination of elastane fibers and specific knitting techniques.

| Mesh Type | Stretch Level | Ideal Application | |

|---|---|---|---|

| Power Mesh | High (4-Way) | Shapewear/Lingerie | |

| Sports Mesh | Moderate (2-Way) | Jerseys/Shorts | |

| Tulle | Low/None | Tutus/Veils |

What are the main properties of mesh?

The primary properties of mesh fabric include extreme breathability, lightweight heft, and superior moisture management. Even with these functional benefits, many designers still ask, is mesh fabric stretchy, to ensure the material can withstand industrial washing without losing shape. For deeper technical insights, our blog provides extensive textile property guides.

Why is breathability its most famous feature?

Breathability is achieved because the physical holes allow for the immediate exchange of air between the body and the environment. It’s a simple fact:

- Airflow prevents heat buildup.

- Vapor escapes easily through the pores.

- It reduces the “clinging” sensation of sweat.

How does the fabric manage moisture and sweat?

While mesh itself is often non-absorbent, the synthetic fibers pull moisture away from the skin to the surface of the fabric. The process is efficient:

- Polyester fibers are naturally hydrophobic.

- Capillary action moves sweat to the outer layer.

- The open weave facilitates rapid evaporation.

Key Takeaway: Mesh combines the physical benefits of an open structure with the chemical durability of synthetics to create a high-performance textile.

| Property | Business Benefit | |

|---|---|---|

| Lightweight | Reduces shipping costs and wearer fatigue | |

| Quick-Dry | Ideal for high-intensity activity products | |

| Tear-Resistant | Increases the lifespan of the garment |

Which types of mesh fabric exist?

The most common types of mesh include polyester mesh, nylon mesh, power mesh, and various forms of soft tulle . Before selecting a variant, a common technical concern is is mesh fabric stretchy enough to meet the specific compression requirements of the final product. Each type offers a different balance of softness, strength, and opacity.

What makes power mesh different?

Power mesh is specifically designed for compression and body contouring, often featuring a high percentage of spandex. The difference is clear:

- It provides significant “recovery” after stretching.

- Commonly used in waist trainers and bras.

- It is much smoother against the skin.

How does tulle compare to sports mesh?

Tulle is a much finer, often stiffer mesh used for decorative purposes, whereas sports mesh is built for utility and comfort. Look at the contrast:

- Tulle has a hexagonal “honeycomb” look.

- Sports mesh has larger, breathable pores.

- Tulle is often used for volume in fashion.

Key Takeaway: The variety of mesh types allows manufacturers to pivot between decorative aesthetics and high-impact sports use.

| Mesh Variant | Primary Material | Texture | |

|---|---|---|---|

| Polyester Mesh | 100% Polyester | Soft/Durable | |

| Powernet | Nylon/Spandex | Firm/Compressive | |

| Air Mesh | Polyester | Thick/Cushioned |

Where is mesh fabric most commonly used?

Mesh is most frequently utilized in the production of athletic jerseys, medical slings, and industrial safety equipment. For companies producing goods for the safety industry , the main query is is mesh fabric stretchy, as the fabric must provide both support and flexibility. It serves as an essential component in everything from high-fashion accents to heavy-duty cargo nets.

Why is it a staple in modern activewear?

Activewear requires materials that can move with the body while managing the intense heat generated during exercise. It’s the industry standard:

- Jerseys allow team identification with airflow.

- Side panels in leggings provide ventilation.

- Linings in shorts prevent chafing.

How is it utilized in medical applications?

In the medical field, mesh is used for everything from surgical implants to breathable slings and bandages. Precision is required:

- Biocompatible mesh for hernia repairs.

- Breathable materials for orthopedic braces.

- Lightweight netting for wound protection.

Key Takeaway: The utility of mesh extends far beyond fashion, serving as a critical material in life-saving medical devices and industrial infrastructure.

| Sector | Specific Application | |

|---|---|---|

| Apparel | Basketball jerseys, Gym shorts | |

| Medical | Hernia mesh, Support slings | |

| Industrial | Safety nets, Filter screens |

Is mesh fabric environmentally friendly?

Mesh fabric is generally not considered eco-friendly because it is primarily made from petroleum-based synthetic polymers. When evaluating sustainable alternatives, you might ask, is mesh fabric stretchy if it is made from recycled ocean plastics instead of virgin oil. The production process involves chemical-intensive refining and energy-heavy extrusion.

What is the impact of synthetic polymers?

Synthetic polymers contribute to environmental degradation through the extraction of fossil fuels and the release of microplastics. The facts are sobering:

- Petroleum extraction is a non-renewable process.

- Manufacturing releases nitrous oxide into the air.

- Synthetic fibers do not biodegrade.

Can mesh be made from recycled plastics?

Many manufacturers are now offering mesh made from rPET, which is polyester derived from recycled plastic bottles. There is a catch:

- It reduces the need for virgin oil.

- The energy for recycling is still significant.

- It still sheds microplastics during washing.

Key Takeaway: While recycled options are becoming more available, standard mesh production remains heavily reliant on the petroleum industry.

| Material | Eco-Friendliness | Durability | |

|---|---|---|---|

| Virgin Polyester | Low | High | |

| Recycled Polyester | Medium | High | |

| Natural Silk Mesh | High | Low |

How much does mesh fabric cost to produce?

The production cost of mesh fabric is relatively low compared to natural fibers, though prices vary based on complexity. If you are budgeting for a large-scale apparel run, you might wonder is mesh fabric stretchy at a lower price point. You can view our case studies to see how bulk manufacturing helps keep the cost per yard competitive.

Which factors influence the price per yard?

The primary drivers of cost include the fiber type, the weight of the fabric (GSM), and any specialty coatings. Watch for these costs:

- Nylon is typically more expensive than polyester.

- Adding spandex increases the price significantly.

- Custom colors require minimum order quantities.

Where are the global hubs for mesh production?

China remains the world’s leading producer of synthetic mesh, followed by other textile-heavy nations like India and Vietnam. The landscape is shifting:

- China offers the best infrastructure for synthetics.

- Vietnam is growing in high-performance apparel.

- The US is seeing a return in niche industrial mesh.

Key Takeaway: Mesh is one of the most affordable performance fabrics on the market when sourced from established synthetic manufacturing chains.

| Factor | Cost Impact | |

|---|---|---|

| Spandex Content | Increases Price | |

| Hole Complexity | Increases Price | |

| Bulk Ordering | Decreases Price |

How should you care for mesh garments?

Mesh garments should ideally be hand-washed or placed in a protective bag during a cold machine cycle. A common concern for consumers who own these items is is mesh fabric stretchy after being exposed to high heat in a dryer. Proper maintenance ensures that the open-weave structure remains intact and the fibers do not lose their tensile strength.

What is the safest way to wash mesh?

The safest way to wash mesh is to use cold water and a mild detergent to avoid damaging synthetic fibers. Follow these steps:

- Turn the garment inside out.

- Use a mesh laundry bag.

- Avoid fabric softeners that clog pores.

How can you prevent snags and tearing?

Snags often occur when mesh comes into contact with zippers, Velcro, or rough surfaces during the wash cycle. Keep this in mind:

- Wash mesh separately from heavy hardware.

- Check the machine drum for rough spots.

- Trim any loose threads immediately.

Key Takeaway: Proper care, particularly avoiding high heat and friction, is essential for maintaining the transparency and breathability of mesh.

| Care Action | Recommended | To Avoid | |

|---|---|---|---|

| Washing | Cold/Delicate | Hot/Aggressive | |

| Drying | Air Dry | High Heat Dryer | |

| Ironing | Steam Only | Direct Hot Iron |

FAQ

Can I use mesh fabric for outdoor applications?Yes, mesh is highly suitable for outdoor use because synthetic versions like polyester are naturally resistant to moisture and UV degradation.

What’s the best way to prevent mesh from fraying?The most effective way is to use a knitted mesh, which naturally resists running, or to finish edges with binding tape.

How do I choose the right hole size for my product?You should base your choice on the balance of breathability and opacity; smaller holes offer more coverage while larger holes maximize airflow.

Can mesh fabric be printed on?Yes, mesh is frequently used in screen printing, and polyester mesh can be sublimated with high-definition colors that won’t fade.

Is mesh fabric itchy on the skin?While some industrial meshes can be rough, modern apparel mesh is treated with softeners and designed with smooth knit patterns for comfort.

Conclusion

Mesh fabric remains an indispensable tool for the modern manufacturer, offering an unparalleled combination of breathability and durability. Whether you are developing athletic gear or sourcing materials for industrial filtration, understanding the nuances of fiber content is key to success. We invite you to explore our extensive catalog of high-quality textiles and contact us today to find the perfect solution for your next project. Our vision is to empower global brands with the most innovative and reliable mesh solutions in the industry.