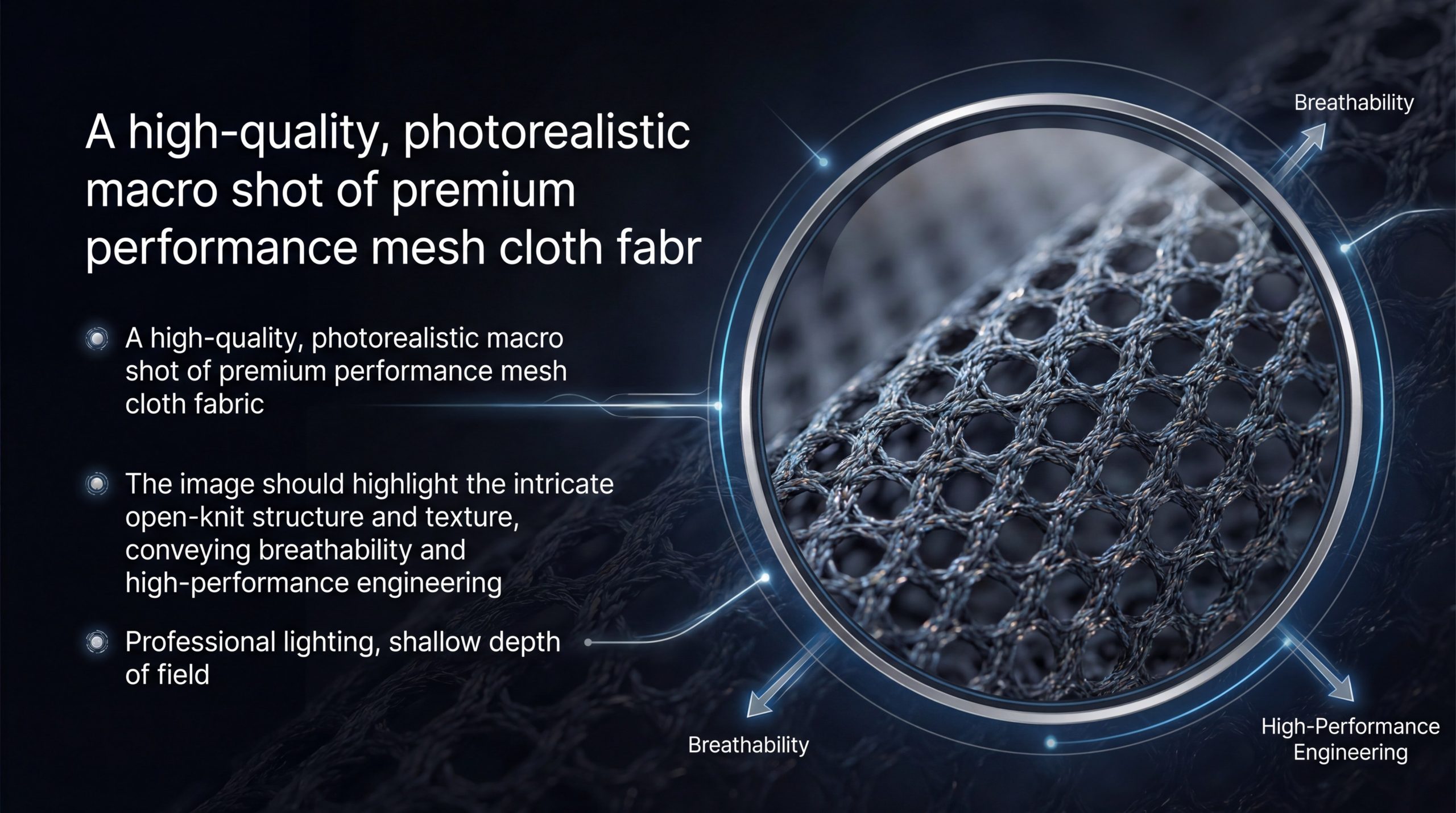

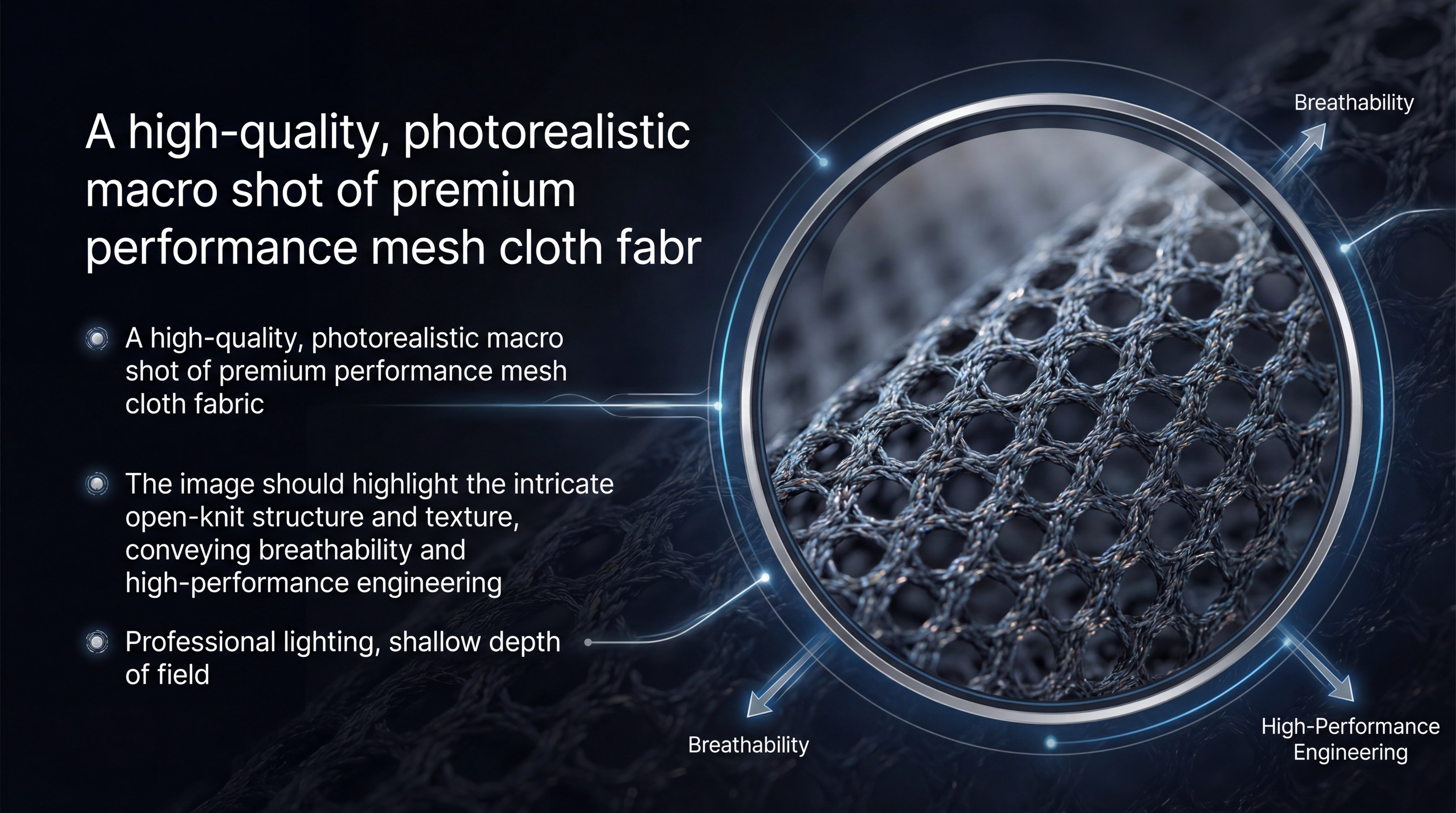

Mesh and netting fabrics are open-knit textiles designed with uniform apertures to provide breathability, lightweight support, and high tensile strength across industrial and fashion applications. Imagine a critical engineering or apparel project failing simply because the chosen material lacks proper ventilation. The resulting frustration of trapped sweat, excessive heat buildup, and rapid material degradation can ruin user experience and compromise safety. High-quality mesh cloth fabric is the ultimate fix, offering engineered airflow and structural integrity where standard textiles fail.

What is the benefit of high-quality mesh products?

High-quality mesh provides an optimal strength-to-weight ratio that ensures durability without adding unnecessary bulk to a project. These technical products are engineered to withstand significant stress while remaining remarkably light.

Engineered Performance Standards

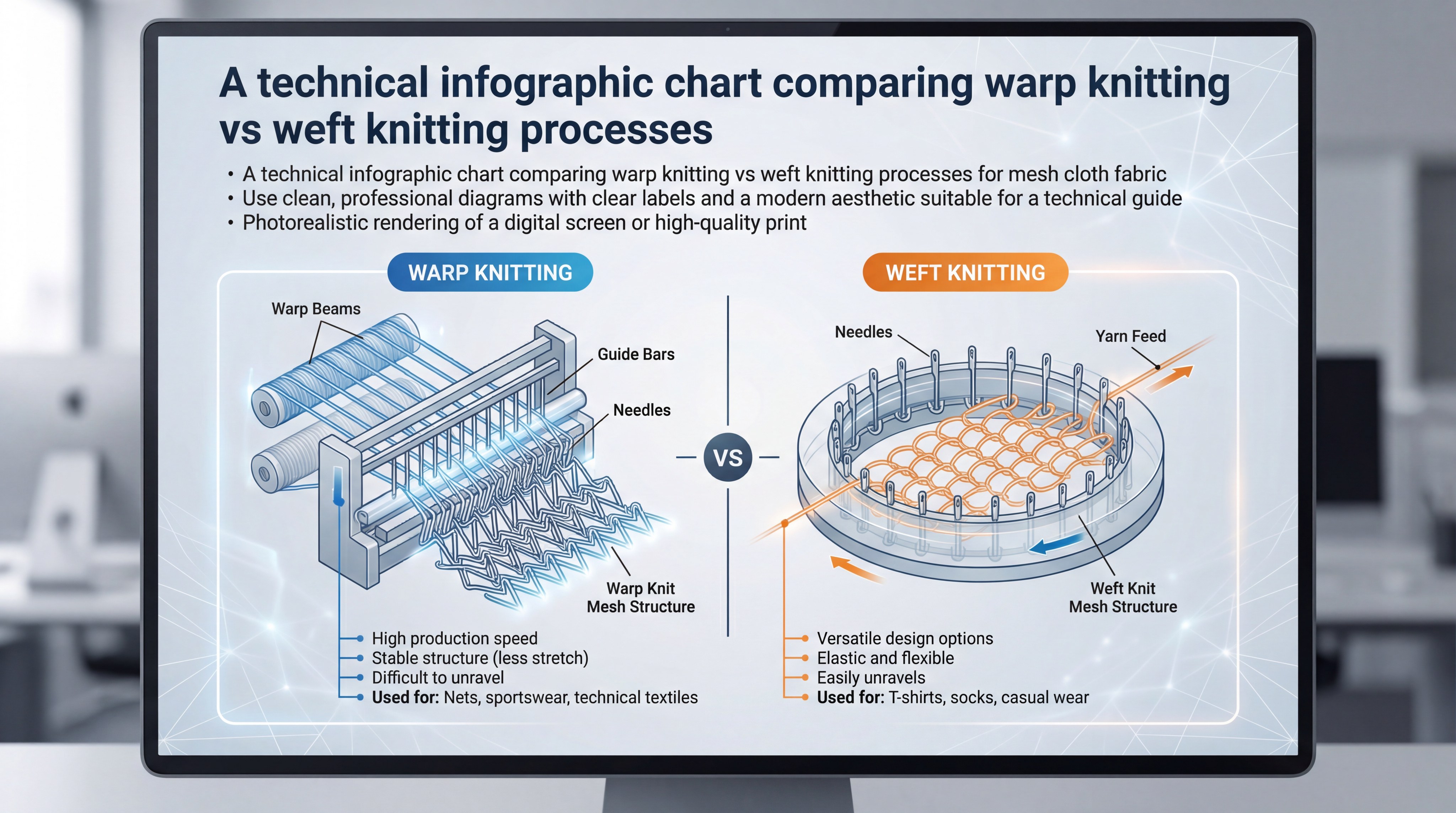

Technical mesh is manufactured to meet specific load-bearing requirements measured in pounds per square inch. This allows engineers to select materials that offer both transparency and ruggedness for high-stakes environments.

Check this out:

- High tensile strength yarns

- Uniform hole distribution

- Minimal weight footprint

- Tear-resistant properties

Best of all: the versatility of these fabrics allows them to transition from industrial safety gear to high-performance athletic wear without sacrificing integrity.

Key Takeaway

High-quality mesh maximizes efficiency by providing structural support while minimizing material weight.

| Feature | Advantage | |

|---|---|---|

| High PSI Rating | Exceptional load-bearing capacity | |

| Open Knit | Maximum breathability and airflow | |

| Synthetic Yarns | Resistance to environmental degradation |

Modern engineering relies on these specialized textiles to bridge the gap between heavy-duty protection and user comfort.

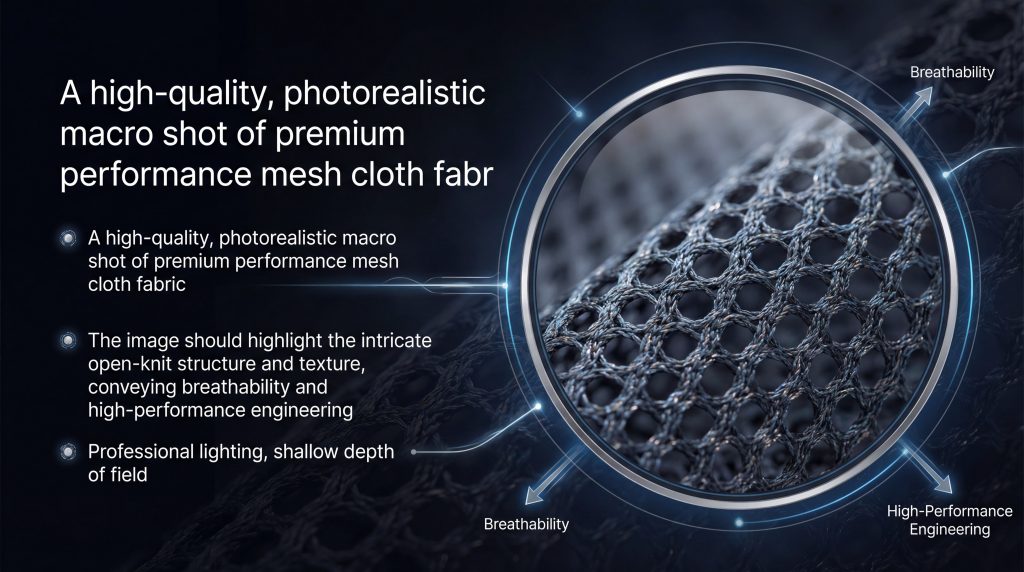

What is the benefit of warp knitting in mesh production?

Warp knitting creates a stable, zig-zagging loop structure that prevents the fabric from unraveling even if it is snagged or cut. Unlike weft knitting, which can run or ladder, warp knit structures provide superior dimensional stability.

Dimensional Stability and Durability

The interlocking nature of warp knit mesh ensures that the fabric maintains its shape under tension. This is critical for applications like safety netting or structural supports where consistency is non-negotiable.

Look at this:

- Reduced risk of fabric runs

- Precise aperture control

- Enhanced lateral strength

- Rapid production capability

The bottom line: warp knitting is the gold standard for creating reliable, industrial-grade netting that lasts through rigorous use.

Key Takeaway

Warp knitting ensures the long-term reliability of mesh fabrics by creating a non-run structural matrix.

| Knit Type | Benefit | Application | |

|---|---|---|---|

| Warp Knit | Non-unraveling | Industrial Netting | |

| Weft Knit | High Elasticity | Casual Apparel |

The technical superiority of warp knitting provides the foundation for all high-performance mesh applications today.

What is the benefit of using nylon and polyester tulle?

Selecting nylon or polyester tulle fabric allows designers to balance specific technical needs like UV resistance and elasticity with aesthetic transparency. These materials are chosen based on their unique chemical properties to meet the demands of the end environment.

Material Specific Advantages

Polyester is prized for its colorfastness and resistance to ultraviolet rays, making it ideal for outdoor applications. Nylon 6,6 offers a higher melting point and superior abrasion resistance for heavy-duty industrial use.

Consider this:

- Polyester resists moisture absorption

- Nylon provides superior stretch

- Both are highly durable

- Easy to dye and finish

Best of all: these synthetic polymers can be engineered with specialized finishes to enhance their natural performance characteristics further.

Key Takeaway

Choosing the correct synthetic polymer is the first step in ensuring a fabric meets the environmental challenges it will face.

| Material | Key Property | Common Use | |

|---|---|---|---|

| Polyester | UV Resistance | Outdoor Equipment | |

| Nylon 6,6 | High Melting Point | Automotive Components |

A deep understanding of fiber chemistry ensures that the selected mesh will perform predictably under specific stressors.

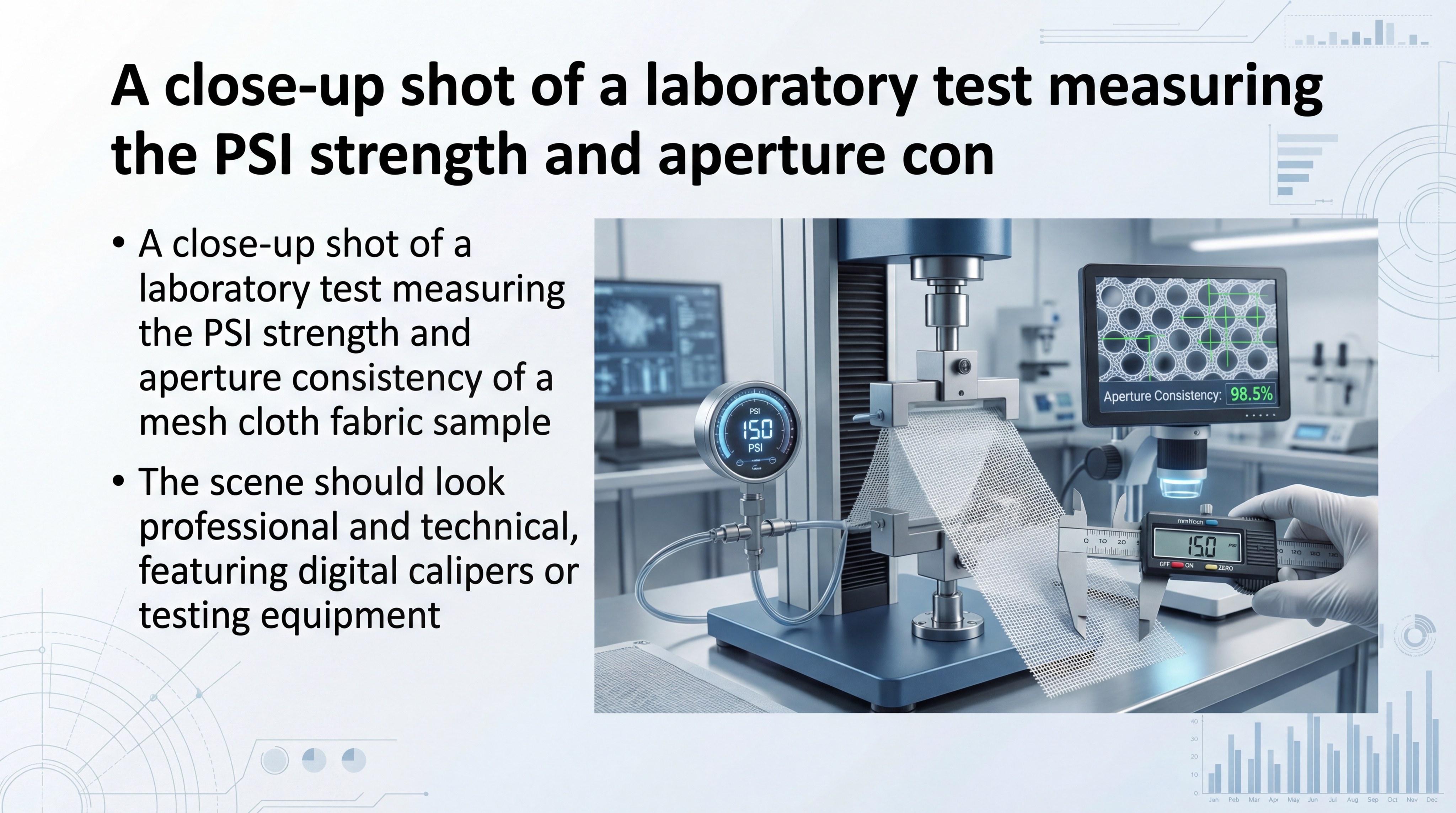

What is the benefit of consistent aperture size in mesh?

Standardized aperture size ensures that airflow and visibility remain uniform across the entire surface of the textile. Consistency in the “hole” size is a primary indicator of a high-quality manufacturing process and reliable performance.

Precision Engineering for Airflow

In filtration or ventilation applications, even a slight variation in aperture size can lead to performance failure. Manufacturers use rigorous quality control to ensure that every millimeter of the fabric performs as expected.

Check this out:

- Predictable ventilation rates

- Uniform aesthetic appearance

- Consistent filtration levels

- Reliable transparency

The fact is: without strict aperture control, technical mesh cannot meet the safety standards required by medical or military sectors.

Key Takeaway

Aperture consistency is vital for maintaining the technical integrity and functional performance of specialized netting.

| Metric | Importance | Result | |

|---|---|---|---|

| Hole Diameter | High | Uniform Ventilation | |

| Pattern Density | Moderate | Aesthetic Balance |

Consistency in manufacturing eliminates the variables that lead to material failure in high-pressure environments.

What is the benefit of mesh in industrial weight reduction?

Technical mesh netting reduces overall weight in cargo and aerospace applications while maintaining the high tensile strength needed for containment. Every gram saved in these sectors translates directly into increased fuel efficiency and operational capacity.

Optimizing Load Efficiency

Industrial mesh replaces solid materials in barriers and containers to shed unnecessary mass. This weight reduction does not come at the cost of safety, as modern fibers can support thousands of pounds.

Check this out:

- Lower transportation costs

- Easier material handling

- Enhanced visibility through barriers

- Rapid deployment capability

Best of all: the lightweight nature of mesh makes it the preferred choice for tactical gear where speed and agility are paramount.

Key Takeaway

Industrial mesh is a strategic tool for enhancing operational efficiency through significant weight reduction.

| Application | Benefit | Impact | |

|---|---|---|---|

| Cargo Netting | Weight Reduction | Higher Fuel Efficiency | |

| Tactical Vests | Mobility | Improved User Safety |

The ability to provide high-strength containment without bulk is what makes mesh indispensable in logistics.

What is the benefit of power mesh in modern apparel?

Power mesh in modern apparel provides essential structural support and elegant transparency for garments ranging from compression wear to high-fashion gowns. Its four-way stretch capabilities allow for a perfect fit that moves with the body.

Comfort and Compression

The open structure of power mesh ensures that the user stays cool, even during high-intensity activity. It is the primary fabric used in shapewear and surgical compression garments due to its soft yet firm support.

Look at this:

- Four-way elastic recovery

- Superior moisture management

- Discreet structural support

- Soft hand-feel against skin

The bottom line: power mesh combines the technical benefits of athletic textiles with the aesthetic requirements of contemporary fashion.

Key Takeaway

Power mesh offers the unique combination of high-stretch recovery and maximum breathability for apparel.

| Fabric Type | Stretch Property | Use Case | |

|---|---|---|---|

| Power Mesh | High Recovery | Compression Gear | |

| Soft Tulle | Low Stretch | Bridal Veils |

Integrating elastic fibers into the mesh structure creates a versatile textile that supports the body while allowing it to breathe.

What is the benefit of choosing flame retardant mesh?

Specialized flame retardant finishes provide a critical layer of safety by preventing the fabric from supporting combustion in hazardous environments. These finishes are essential for materials used in public spaces, aerospace, and military about-us operations.

Safety-First Material Engineering

Flame retardant mesh is tested against stringent fire safety standards to ensure it self-extinguishes upon removal of a heat source. This property is vital for protective clothing and environmental barriers.

Consider this:

- Compliance with safety codes

- Reduced risk of fire spread

- Durable through multiple washes

- Essential for tactical environments

Best of all: modern fire retardant treatments do not compromise the breathability or the lightweight feel of the original mesh.

Key Takeaway

Flame retardant finishes are non-negotiable for any application where fire safety and human life are involved.

| Standard | Environment | Requirement | |

|---|---|---|---|

| FR Rating | Industrial/Military | Self-extinguishing | |

| UV Rating | Outdoor/Survival | Material Longevity |

Ensuring that a mesh is treated for fire resistance is a fundamental step in risk management for professional projects.

What is the benefit of routine technical mesh maintenance?

Proper maintenance of synthetic mesh ensures that technical treatments like antimicrobial coatings remain effective throughout the product’s life cycle. Regular cleaning prevents the buildup of debris that can clog apertures and reduce ventilation.

Preserving Technical Properties

Most synthetic mesh fabrics are machine washable, but they require specific care to preserve flame retardant or moisture-wicking finishes. Using the correct temperature and detergents prevents premature degradation of the fibers.

Check this out:

- Extended material lifespan

- Sustained airflow performance

- Odor control via cleaning

- Retention of elastic properties

The fact is: a well-maintained mesh product will outperform and outlast a neglected one, saving money on replacement costs over time.

Key Takeaway

Routine care is essential for maintaining the specialized chemical and physical properties of technical textiles.

| Care Step | Purpose | Outcome | |

|---|---|---|---|

| Cool Wash | Fiber Protection | Maintained Strength | |

| Air Dry | Finish Preservation | Coating Longevity |

Maintenance protocols should be followed strictly to ensure the fabric continues to meet its original performance specifications.

What is the benefit of high-visibility industrial netting?

Industrial mesh improves safety by offering high visibility and physical protection in construction zones and hazardous industrial-mesh areas. Its transparent nature allows for monitoring of work zones while providing a physical barrier.

Visual Safety and Site Control

High-visibility colors can be integrated into the mesh to signal caution or define restricted areas. Because the mesh is breathable, it does not create a “wind sail” effect that could knock over solid barriers.

Look at this:

- Enhanced site visibility

- Weather-resistant barriers

- Lightweight and portable

- Configurable hole sizes

Best of all: mesh fencing is easy to store and reuse, making it an eco-friendly and cost-effective solution for site safety.

Key Takeaway

The combination of transparency and high-visibility colors makes mesh the ideal material for site safety management.

| Barrier Type | Benefit | Limitation | |

|---|---|---|---|

| Mesh Netting | Air Permeable | Partial Privacy | |

| Solid Tarp | Full Privacy | Wind Sensitive |

Utilizing mesh for safety barriers ensures that workers remain protected without sacrificing site awareness.

What is the benefit of moisture-wicking mesh properties?

Moisture-wicking mesh properties significantly improve user comfort by drawing sweat away from the body and facilitating rapid evaporation. This is achieved through the use of hydrophobic synthetic fibers and an open-knit structure.

Heat and Sweat Management

In high-performance garments, the mesh acts as a heat exchange system. It allows hot air to escape while moving moisture to the fabric’s surface where it can dry quickly.

Consider this:

- Prevents dampness and chafing

- Regulates body temperature

- Antimicrobial odor control

- Lightweight during activity

The bottom line: moisture-wicking technology is what separates professional-grade athletic mesh from standard consumer fabrics.

Key Takeaway

Moisture-wicking mesh is essential for any application involving physical exertion or high-temperature environments.

| Technology | Action | Benefit | |

|---|---|---|---|

| Hydrophobic Fiber | Repels Water | Stays Lightweight | |

| Open Weave | Air Exchange | Cooler Skin |

The integration of these properties ensures that users remain dry and comfortable even under extreme conditions.

Frequently Asked Questions

Can I use mesh fabric for heavy-duty load bearing?Yes, high-quality polyester and nylon mesh are engineered with high PSI ratings specifically for load-supporting applications in the automotive and aerospace sectors.

What’s the best way to prevent mesh from fraying?Selecting a warp-knit mesh is the most effective way to prevent fraying, as the interlocking loops are designed to remain stable even when the fabric is cut.

Is mesh fabric resistant to UV damage?Polyester mesh offers naturally high resistance to UV rays, though specialized finishes can be added to any synthetic mesh to further enhance its outdoor longevity.

How do I choose between nylon and polyester mesh?Choose nylon if you require higher elasticity and abrasion resistance; choose polyester if you need better colorfastness and moisture resistance.

Which mesh is best for mosquito protection?A fine-aperture mesh with consistent hole sizes is best for mosquito protection to ensure that insects cannot pass through while airflow is maintained.

In summary, the right mesh can transform your project from a standard design to a high-performance solution. Whether you are looking for industrial safety, fashion-forward transparency, or tactical durability, understanding these technical properties is key. To find the perfect textile for your specific requirements, contact us today .