Tulle is a lightweight, very fine netting characterized by its open, hexagonal weave and delicate structure. You might find that your design projects often lack the necessary volume without becoming cumbersome or heavy. If you choose the wrong material, your bridal veils may appear flat and your industrial filters might fail to capture fine particles. By mastering the tulle fabric definition , you can unlock the secret to ethereal aesthetics and high-performance technical applications.

What is the Tulle Fabric Definition?

The tulle fabric definition refers to a lightweight, fine netting made from various fibers that are woven into a distinct hexagonal pattern. You will notice that this specific geometry allows the material to retain its shape even when starched for maximum stiffness.

What materials form the base of tulle?

Nylon, polyester, and silk are the primary components used to manufacture this versatile netting. You should know this:

- Synthetic nylon provides durability.

- Polyester offers cost-effective color retention.

- Silk delivers unparalleled luxury.

How does the hexagonal weave function?

The hexagonal structure provides structural integrity by distributing tension evenly across the mesh surface. Think about it:

- It prevents tearing under pressure.

- The shape maintains uniform air permeability.

- Hexagons create a consistent visual texture.

Key Takeaway: The structural essence of tulle lies in its hexagonal pattern, which balances extreme lightness with surprising durability.

| Property | Description | |

|---|---|---|

| Material Base | Nylon, Polyester, Silk | |

| Hole Shape | Hexagonal | |

| Weight | Extremely Lightweight |

The data indicates that the material’s strength is derived from its geometric weave rather than the thickness of the threads.

Where Did the Tulle Fabric Definition Begin?

The historical tulle fabric definition traces its origins to the 18th-century lace-making traditions of Tulle, France. You will find that the city became synonymous with this fine netting because of its innovative production techniques.

Why is France the namesake of this fabric?

French artisans in the town of Tulle developed the initial techniques for creating this delicate mesh by hand. Believe it or not:

- Tulle was a hub for silk and lace.

- The name became a global standard.

- Early versions were strictly for the elite.

Key Takeaway: Tulle’s history is rooted in French craftsmanship, evolving from an artisanal luxury to a mass-produced industrial staple.

| Era | Production Method | |

|---|---|---|

| 1700s | Hand-woven silk lace | |

| 1800s | Mechanized bobbinet machines | |

| Modern | High-speed synthetic knitting |

Historical records show that the transition to mechanized production allowed tulle to move from high-fashion ballrooms to everyday applications.

How Does Tulle Fabric Definition Impact Fashion?

In the fashion industry, the tulle fabric definition translates to garments that possess volume, translucency, and an ethereal aesthetic. You can use this fabric to create everything from voluminous wedding gowns to the iconic structure of a ballet tutu.

Why is tulle essential for bridal wear?

Tulle provides a semi-transparent layer that adds mystery and elegance to veils and skirts without hiding the underlying design. Here is the deal:

- It creates a soft, diffused look.

- Multiple layers add “poof” without weight.

- It holds embellishments like beads well.

How do tutus maintain their shape?

The stiffness of starched nylon tulle allows tutu layers to stand out horizontally, resisting the pull of gravity. What does this mean for you?

- It provides the necessary stage presence.

- The fabric bounces back after movement.

- Layers can be trimmed without fraying.

Key Takeaway: Fashion relies on tulle for its unique ability to capture light and create structural volume that other woven fabrics cannot match.

| Application | Tulle Type | Function | |

|---|---|---|---|

| Bridal Veil | Soft Illusion Tulle | Translucency and drape | |

| Ballet Tutu | Stiff Nylon Tulle | Horizontal structure | |

| Evening Gown | Layered Polyester Tulle | Voluminous silhouettes |

The versatility of tulle in fashion stems from the variety of stiffness levels available to designers.

Which Tulle Fabric Definition Types Exist?

Determining which tulle fabric definition variant to use depends largely on your project’s requirements for drape and durability. You may want to choose the right mesh material fabric for your project to ensure the final product meets your performance standards.

What sets silk tulle apart from synthetic?

Silk tulle is the pinnacle of luxury, offering a fluid drape and a soft touch that synthetic fibers struggle to replicate. The truth is:

- It is more delicate than nylon.

- The price point is significantly higher.

- It is highly breathable for skin contact.

Key Takeaway: Selecting the right fiber—silk for drape or nylon for structure—is the most critical decision in tulle sourcing.

| Tulle Type | Primary Benefit | Common Drawback | |

|---|---|---|---|

| Silk | Superior softness/drape | High cost and fragility | |

| Nylon | Excellent shape retention | Can feel scratchy | |

| Polyester | Best for color vibrant dyes | Lower heat resistance |

Choosing between these types requires a balance of budget, tactile feel, and the desired structural outcome of the garment.

How Does Tulle Fabric Definition Compare?

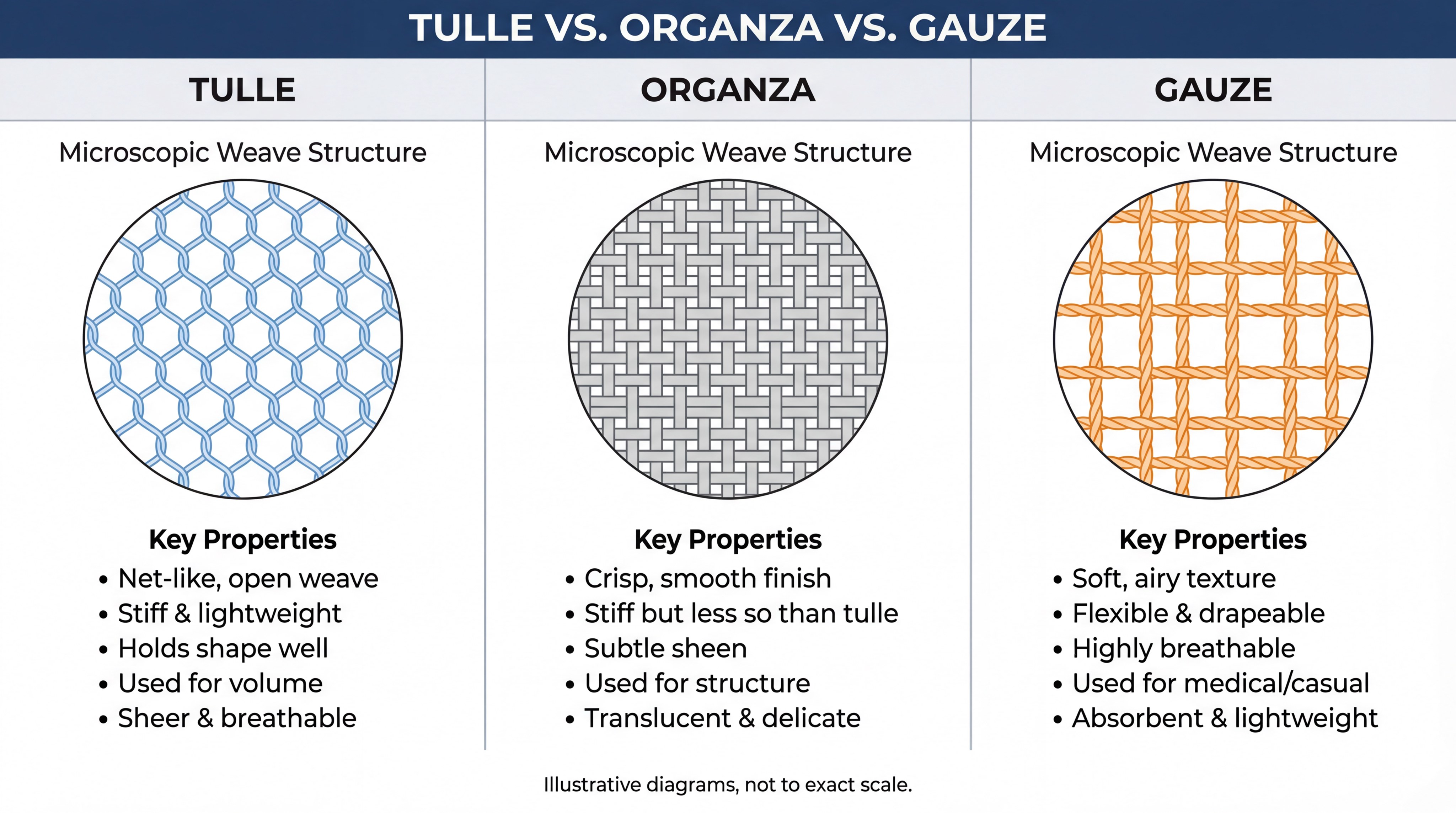

When evaluating the tulle fabric definition, it is helpful to compare it against similar materials like organza and gauze. You will find that while they all offer transparency, their construction methods lead to very different physical behaviors.

Tulle vs. Organza: What is the difference?

While organza is a plain-weave fabric, tulle is a netted mesh, making tulle much more effective at creating airy volume. Think about it:

- Organza has a crisp, solid surface.

- Tulle allows more air to pass through.

- Tulle creates a “cloud-like” effect.

Key Takeaway: Tulle is a netted material, giving it a superior volume-to-weight ratio compared to woven alternatives like organza.

| Feature | Tulle | Organza | Gauze | |

|---|---|---|---|---|

| Weave | Hexagonal Net | Plain Weave | Loose Weave | |

| Structure | High Volume | Crisp Stiffness | Soft Drape | |

| Edge | Does not fray | Frays easily | Frays easily |

The comparison shows that tulle’s non-fraying edge and netted structure make it the most versatile for raw-edge designs.

What Is the Tulle Fabric Definition for Care?

A proper tulle fabric definition for maintenance emphasizes gentle handling to preserve the delicate hexagonal structure of the mesh. You should learn how to care for mesh type fabric to extend its lifespan so that your delicate items remain pristine for years.

Can you wash tulle in a machine?

Machine washing is generally discouraged because the agitation can snag the fine threads and ruin the uniform hexagonal pattern. Keep this in mind:

- Hand washing in cold water is safest.

- Use only mild detergents.

- Avoid wringing or twisting the fabric.

How do you remove stubborn wrinkles?

Steam is the only recommended method for removing wrinkles, as a direct iron can instantly melt the synthetic fibers. The secret is:

- Use a handheld steamer.

- Keep the steamer at a distance.

- Hang the garment to air dry.

Key Takeaway: Heat and friction are the primary enemies of tulle; always opt for steaming and hand-washing to preserve the fabric.

| Care Task | Recommended Method | Risk of Failure | |

|---|---|---|---|

| Cleaning | Cold hand wash | Snags/Tears | |

| Drying | Air dry (flat or hung) | Melting/Shrinkage | |

| De-wrinkling | Gentle steaming | Burned holes |

Following these guidelines ensures that the starch or chemical finishes on the tulle remain intact, preserving its bounce.

Is Tulle Fabric Definition Sustainable?

The traditional tulle fabric definition relies heavily on petroleum-based synthetic fibers, which poses challenges for eco-conscious brands. You are likely seeing a shift in the market toward recycled polyester versions that aim to reduce environmental impact.

Are there eco-friendly tulle alternatives?

Manufacturers are now producing tulle from recycled plastic bottles and biodegradable polymers to meet the demand for sustainable fashion. Believe it or not:

- Recycled tulle looks identical to virgin nylon.

- It reduces landfill waste significantly.

- Bio-based options are in development.

Key Takeaway: While traditional tulle has a high footprint, the industry is moving toward recycled and bio-synthetic alternatives.

| Factor | Standard Tulle | Eco-Tulle | |

|---|---|---|---|

| Source | Virgin Petroleum | Recycled PET | |

| Recyclability | Low | Higher | |

| Energy Use | High | Lower |

The transition toward eco-tulle allows brands to maintain their aesthetic standards while fulfilling corporate social responsibility.

Can Tulle Fabric Definition Be Industrial?

The technical tulle fabric definition makes it an ideal candidate for industrial filtration and event decor due to its uniform openings. You may need to choose mesh cloth fabric for industrial use when precision and lightweight properties are the top priorities.

How is tulle used in filtration?

The consistent size of the hexagonal holes allows tulle to act as a primary filter for debris in air and water systems. Here is the deal:

- It offers low resistance to flow.

- It is easy to clean and reuse.

- The material is resistant to most chemicals.

Why use tulle for event decorating?

Tulle is perfect for large-scale decorations because it can cover massive areas with volume while remaining extremely light and affordable. Think about it:

- It diffuses stage lighting beautifully.

- Ceiling swags won’t strain support wires.

- It comes in massive roll widths.

Key Takeaway: Beyond the runway, tulle serves as a high-performance material for technical filtration and large-format event design.

| Industrial Use | Key Benefit | |

|---|---|---|

| Medical | Breathable bandage backing | |

| Filtration | Uniform hexagonal debris capture | |

| Agriculture | Lightweight insect protection |

The data confirms that tulle’s utility is limited only by the imagination of the engineers and designers using it.

How to Scale Tulle Fabric Definition Brands?

Understanding the tulle fabric definition allows you to select high-quality materials that align with your brand’s aesthetic and functional goals. When you are ready to scale, you must incorporate mesh type fabric into your product line by choosing reliable bulk suppliers.

What are the indicators of high-quality tulle?

Consistent hole size, even dyeing, and a lack of “runs” or snags in the roll are the primary indicators of premium tulle. Don’t forget:

- Check for uniform starch application.

- Verify the width consistency.

- Inspect the edge for structural tears.

Key Takeaway: Quality control at the sourcing stage is the most effective way to ensure your tulle products meet professional standards.

| Quality Metric | Good Tulle | Poor Tulle | |

|---|---|---|---|

| Hole Symmetry | Perfectly hexagonal | Distorted or elongated | |

| Dye Level | Saturated and even | Streaky or blotchy | |

| Hand Feel | Smooth or crisp | Sticky or unevenly scratchy |

Investing in higher-quality tulle reduces production waste and improves the final customer experience of your brand.

Why Explore the Tulle Fabric Definition?

Understanding the tulle fabric definition empowers you to push the boundaries of design, whether you are creating couture or industrial components. You should also choose mesh fabric based on stretch for activewear if your products require flexibility alongside tulle’s volume.

Can tulle be used for innovative packaging?

Many high-end brands use tulle for gift wrapping because it adds a layer of luxury that paper or plastic cannot achieve. Believe it or not:

- It is reusable for the customer.

- It conforms to any product shape.

- It provides a peek at the contents.

Does tulle work for acoustic diffusion?

In certain studio settings, layers of tulle can help diffuse high-frequency sounds when used over heavier acoustic foam. What does this mean for you?

- It adds aesthetic value to studios.

- It doesn’t block the foam’s function.

- It provides a professional, clean finish.

Key Takeaway: Tulle is a multi-domain material that offers structural, aesthetic, and even acoustic benefits when used correctly.

| Creative Use | Resulting Benefit | |

|---|---|---|

| Packaging | Enhanced unboxing experience | |

| Interior Design | Softened light and privacy | |

| Activewear Trim | Ventilation with a feminine touch |

The analysis suggests that as tulle becomes more sustainable and varied, its presence in global industries will only continue to grow.

Frequently Asked Questions

Can I dye synthetic tulle at home?

Yes, you can dye synthetic tulle using disperse dyes specifically designed for polyester or nylon. These pigments are necessary because standard dyes won’t bond with plastic-based fibers.

What’s the best way to prevent fraying?

You don’t actually need to do anything to prevent fraying because tulle is a netted fabric rather than a woven one. This means you can cut it in any direction and the edges will remain clean.

Can I iron tulle on a low setting?

No, you should never iron tulle directly, even on the lowest setting, as the heat can cause the mesh to melt or shrivel. Steaming is the only safe way to remove wrinkles without damaging the integrity of the netting.

What’s the best way to store tulle garments?

The best way is to hang them in a cool, dry place with plenty of room to breathe. Folding tulle for long periods can create permanent creases that are difficult to remove even with heavy steaming.

Can I use tulle for outdoor decorations?

Yes, nylon and polyester tulle are quite resistant to the elements, making them great for outdoor events. However, you should be aware that direct sunlight will eventually cause the colors to fade over time.

For more information on sourcing high-quality netting or to request a sample, please contact us today .