A Complete Guide to Mesh/Netting Fabric is a comprehensive resource designed to help procurement specialists and product designers navigate the complexities of open-weave textiles.

Engineers and designers often struggle to find a material that balances extreme durability with high-level breathability. Heavy, solid textiles frequently trap heat and add unnecessary weight, leading to product failure in demanding environments like athletic wear or military gear. The solution lies in understanding the unique properties of netting, specifically addressing the common industry question: is mesh a fabric that can meet your technical specifications?

What Is Mesh Fabric and How Is It Defined?

Mesh fabric is a versatile textile characterized by an open-weave or knit structure that creates a consistent pattern of evenly spaced holes. When determining if is mesh a fabric suitable for your needs, it is important to recognize that its defining feature is the intentional gaps between the yarns. These gaps allow for maximum airflow while maintaining the structural integrity of the material.

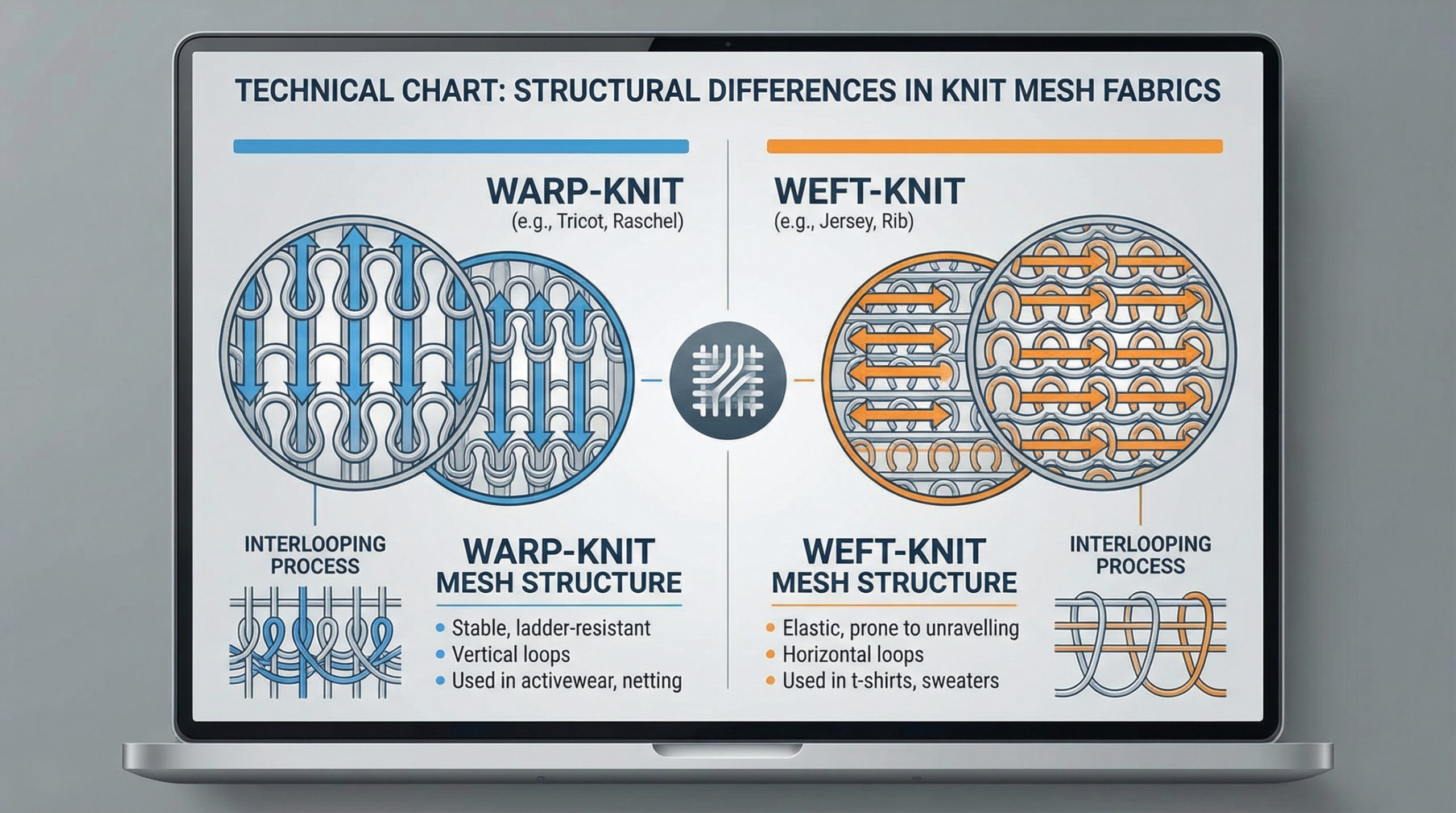

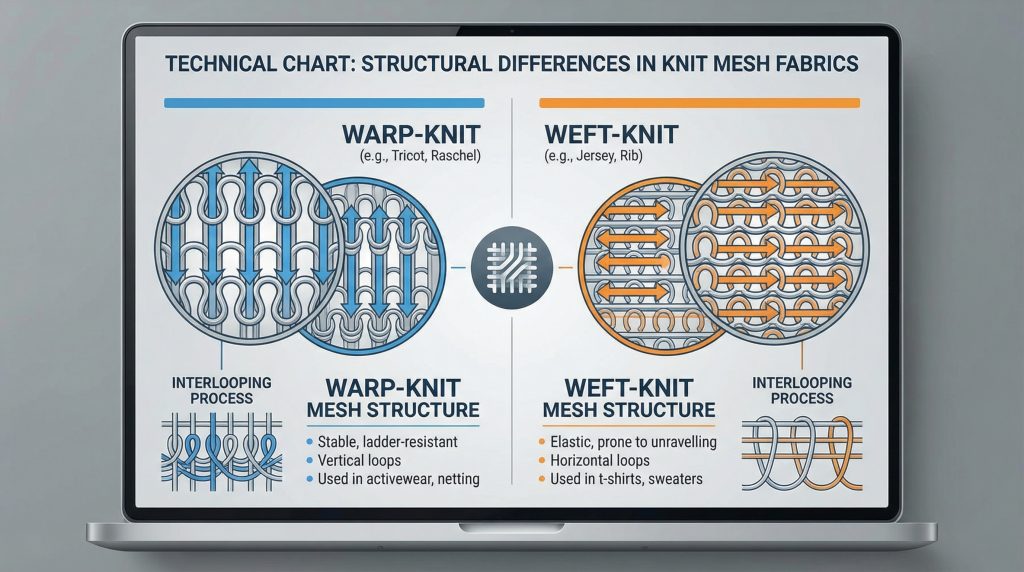

Defining the Open-Knit Structure

Think about this: the geometry of the holes is what dictates the performance of the textile. By adjusting the knitting process, manufacturers can create anything from fine, nearly transparent veils to heavy-duty industrial screens. The specific pattern of the interlocked yarns ensures that even if one strand is damaged, the entire sheet remains stable.

- Uniform hole size for consistent ventilation.

- Interlocking knit patterns to prevent unraveling.

- Varied thickness based on yarn denier.

- Adaptable transparency for diverse applications.

Key Takeaway: The open-knit structure of mesh provides a unique combination of lightness and stability that solid fabrics cannot replicate.

| Feature | Description | |

|---|---|---|

| Material Base | Usually synthetic (Polyester/Nylon) | |

| Structure | Open-weave/Knit | |

| Primary Benefit | Breathability and Lightweight |

Refer to the table above to understand the fundamental building blocks of standard netting materials.

Is Mesh a Fabric Suitable for Industrial Use?

Mesh is an exceptionally rugged fabric designed to withstand harsh industrial environments, ranging from construction sites to chemical filtration systems. Many project managers ask is mesh a fabric that can handle high-tension loads, and the answer is found in the specialized high-tenacity yarns used during production. These industrial variants are engineered for tear resistance and long-term durability under stress.

Industrial Durability and Load Support

Here is the deal: industrial netting is often coated or treated to resist abrasion and environmental degradation. This makes it ideal for safety barriers, cargo nets, and heavy-duty filtration where traditional textiles would fail. The ability to customize the tensile strength allows engineers to specify exactly how much weight the fabric can support.

- High tensile strength for load-bearing applications.

- Resistance to chemicals and corrosive substances.

- UV-stabilized coatings for outdoor longevity.

- Tear-resistant borders and reinforced edges.

Key Takeaway: Industrial mesh is a high-performance solution for safety and containment that prioritizes strength without adding bulk.

| Industrial Property | Benefit | |

|---|---|---|

| High PSI Rating | Supports heavy weight | |

| Abrasion Resistance | Reduces wear in friction zones | |

| Custom Finishes | Adapts to specific environmental hazards |

Use this summary of industrial properties to evaluate the suitability of mesh for heavy-duty projects.

How Does Mesh Fabric Offer Increased Visibility?

Mesh fabric provides increased visibility by utilizing large, uniform hole sizes that allow light and sightlines to pass through the material almost unimpeded. When evaluating is mesh a fabric appropriate for safety or aesthetic transparency, the “openness factor” is the primary metric used to determine how much of the background remains visible. This characteristic is essential for everything from sporting enclosures to high-visibility safety vests.

Transparency and Functional Visibility

The best part? You can achieve high levels of transparency without sacrificing the protective barrier the mesh provides. For instance, in sports stadiums, spectators need to see the action clearly while being protected from stray balls. The fine diameter of the yarns used in high-visibility mesh creates a “screen door” effect that is easy on the eyes.

- Ideal for stadium and court fencing.

- Essential for architectural screening and dividers.

- Used in pockets for backpacks and luggage.

- Critical for safety apparel in construction zones.

Key Takeaway: The transparency of mesh is a functional design choice that balances the need for a physical barrier with the requirement for clear sightlines.

| Application | Visibility Requirement | |

|---|---|---|

| Sports Netting | High (Spectator clarity) | |

| Luggage Pockets | Medium (Content identification) | |

| Safety Vests | High (Back-lighting and contrast) |

This table outlines how different visibility requirements influence the choice of mesh construction.

Why Is Strength-to-Weight Ratio Important for Netting?

The strength-to-weight ratio is vital because it allows for the creation of components that are incredibly light yet capable of resisting massive forces. If you are questioning is mesh a fabric that can reduce your product’s overall mass, you should look at how these textiles perform in aerospace and military sectors. By eliminating excess material through the open-weave design, manufacturers can shed weight without compromising safety.

Maximizing Efficiency with Lightweight Netting

It gets better: using high-performance fibers like nylon 6,6 in a mesh configuration creates a textile that is stronger than steel on a pound-for-pound basis. This efficiency is critical for soldiers carrying tactical vests or for automotive seating where fuel economy depends on weight reduction. The mesh structure provides the necessary support while allowing the product to remain nimble and breathable.

- Reduces user fatigue in wearable technology.

- Lowers shipping costs due to reduced bulk.

- Enhances performance in competitive sports gear.

- Maintains structural integrity under high-speed wind loads.

Key Takeaway: A superior strength-to-weight ratio makes mesh the preferred choice for industries where every gram of weight matters.

| Material Type | Weight | Relative Strength | |

|---|---|---|---|

| Nylon Mesh | Ultra-Light | Very High | |

| Polyester Mesh | Light | High | |

| Solid Canvas | Heavy | Moderate |

Compare the efficiency of mesh versus solid alternatives using the data provided in this table.

Which Finishes Enhance High-Quality Mesh Fabric?

High-quality mesh fabric can be enhanced with a variety of specialized finishes, including antimicrobial, flame retardant, and moisture-wicking treatments. When considering is mesh a fabric that can meet specific regulatory standards, the application of these chemical and mechanical finishes is often the deciding factor. These treatments are bonded to the fibers, ensuring that the mesh maintains its protective properties even after repeated use and laundering.

Functional Treatments for Specialized Use

Wait, there’s more: beyond simple durability, finishes can transform mesh into a “smart” textile. For example, silver-ion coatings can be applied to medical mesh to prevent bacterial growth in sterile environments. Similarly, UV coatings are used on outdoor screens to prevent the sun from turning the fibers brittle over time.

- Antimicrobial finishes for healthcare and activewear.

- Flame retardant (FR) treatments for aerospace.

- Moisture management for high-intensity athletics.

- Anti-abrasion coatings for industrial safety.

Key Takeaway: Specialized finishes allow standard mesh to perform in extreme environments that would otherwise degrade the base polymer.

| Finish Type | Primary Application | |

|---|---|---|

| Flame Retardant | Military & Aerospace | |

| Antimicrobial | Medical & Hygiene | |

| UV Resistant | Outdoor & Automotive |

The table above categorizes common finishes by their primary industrial application.

What Are the Main Differences Between Polyester and Nylon Mesh?

The primary differences between polyester and nylon mesh lie in their moisture absorption, elasticity, and resistance to ultraviolet light. If your team is debating is mesh a fabric made of polyester better than nylon, the answer depends on the end-use environment. Polyester is generally better for outdoor use due to its UV resistance, while nylon is preferred for its superior strength and elastic recovery.

Comparing Synthetic Polymer Performance

Look no further: choosing the right polymer is the first step in successful product development. Polyester is hydrophobic, meaning it won’t absorb water or stretch when wet, which is perfect for marine environments. Nylon, however, has higher abrasion resistance and can withstand much more friction before the fibers begin to pill or break.

- Polyester: Superior UV and colorfastness.

- Nylon: Higher tensile strength and elasticity.

- Polyester: Quick-drying and wrinkle-resistant.

- Nylon: Better resistance to wear and pilling.

Key Takeaway: Polyester is the go-to for stability and sun exposure, while nylon is the winner for strength and flexibility.

| Property | Polyester Mesh | Nylon Mesh | |

|---|---|---|---|

| Elasticity | Low | High | |

| UV Resistance | High | Moderate | |

| Wet Strength | Excellent | Good |

Review this comparison to determine which synthetic fiber aligns with your technical requirements.

Is Mesh a Fabric Frequently Used in Apparel?

Mesh is a staple in the apparel industry, particularly in the production of sportswear, dancewear, and intimate apparel. Designers often ask is mesh a fabric that provides both style and substance, and the answer is evident in the rise of “athleisure” trends. It offers a unique aesthetic texture while providing the ventilation necessary for temperature regulation during physical activity.

Fashion and Performance Integration

Check this out: mesh is no longer just for the lining of gym shorts; it is now a primary exterior material for high-end fashion. Its ability to drape comfortably while maintaining its shape makes it ideal for layering. Additionally, the development of sustainable recycled polyester mesh allows brands to meet eco-friendly goals without sacrificing performance.

- Moisture-wicking panels in running shirts.

- Breathable linings for jackets and windbreakers.

- Sheer overlays for evening gowns and veils.

- Compression layers in athletic leggings.

Key Takeaway: Mesh in apparel serves the dual purpose of enhancing airflow and creating a modern, technical aesthetic.

| Apparel Type | Mesh Usage | |

|---|---|---|

| Activewear | Ventilation & Stretch | |

| Outerwear | Breathable Lining | |

| Couture | Texture & Transparency |

This table illustrates the diverse ways mesh is utilized across the garment industry.

How Does Power Mesh Differ from Standard Netting?

Power mesh differs from standard netting by incorporating high percentages of elastane (spandex) to provide four-way stretch and significant compression. When professionals ask is mesh a fabric capable of supporting body contours, they are usually referring to power mesh. This specialized variant is designed to “snap back” to its original shape, making it essential for shapewear and medical support garments.

The Mechanics of Compression and Recovery

Believe it or not: power mesh can offer firm control while remaining surprisingly lightweight. The “power” comes from the density of the knit and the quality of the elastic yarns used. This allows for a fabric that moves with the body but provides enough tension to support muscles or smooth silhouettes.

- Four-way stretch for maximum mobility.

- High recovery rates to prevent sagging.

- Smooth hand-feel for direct skin contact.

- Available in various weights for different compression levels.

Key Takeaway: Power mesh is an engineering marvel that combines the breathability of netting with the powerful support of compression wear.

| Mesh Type | Stretch Capability | Common Use | |

|---|---|---|---|

| Standard Net | Minimal/Fixed | Safety & Lining | |

| Power Mesh | High/4-Way | Shapewear | |

| Utility Mesh | Moderate | Backpacks |

Refer to the table above to distinguish between standard netting and high-compression power mesh.

What Role Does Mesh Play in Medical and Safety Applications?

In medical and safety sectors, mesh serves as a critical component for implants, wound dressings, and high-visibility protective gear. Many clinicians wonder is mesh a fabric that is truly biocompatible, and the answer lies in medical-grade polymers that are non-reactive and sterile. These fabrics are often used to provide internal support during surgeries or to create breathable barriers for long-term patient care.

Critical Safety and Medical Functions

Simply put: mesh is a life-saving material in many technical applications. In automotive safety, mesh is used in seat construction to ensure air circulation, reducing driver fatigue during long trips. In healthcare, the open structure allows wounds to breathe while the mesh provides the necessary tension to hold dressings in place.

- Surgical mesh for hernia and tissue repair.

- Breathable orthopedic braces and supports.

- High-visibility mesh for emergency responders.

- Flame-resistant mesh for firefighting gear.

Key Takeaway: The functional openness of mesh makes it indispensable for applications where airflow and structural support are equally required for safety.

| Application Sector | Key Mesh Function | |

|---|---|---|

| Healthcare | Biocompatible Support | |

| Automotive | Ergonomic Ventilation | |

| Public Safety | High-Contrast Visibility |

This summary highlights the diverse roles mesh plays in protecting and supporting human life.

How Do You Select the Right Mesh for Your Project?

Selecting the right mesh requires an analysis of the environment, the required tensile strength, and any necessary chemical finishes. When choosing is mesh a fabric that fits your budget and performance needs, you must start with the “Application Driven Design” approach. This ensures that the yarn type, hole size, and weight are all optimized for the specific task at hand.

Critical Selection Criteria for Procurement

As it turns out: the most expensive mesh is not always the best one for your specific project. You must consider the friction levels, exposure to UV light, and whether the fabric needs to stretch or remain rigid. Consulting with a textile expert can help you navigate these variables to find a cost-effective solution that doesn’t compromise on quality.

- Determine the required PSI for load support.

- Select the fiber (Nylon vs. Polyester) based on UV exposure.

- Identify the necessary hole size for ventilation or visibility.

- Verify compliance with industry safety standards (ISO/FR).

Key Takeaway: Successful mesh selection is a balance of material science, environmental awareness, and structural engineering.

| Selection Step | Key Question | |

|---|---|---|

| Environment | Will it be used indoors or outdoors? | |

| Load | How much weight must it support? | |

| Compliance | Does it require FR or Antimicrobial finishes? |

Follow this logical sequence to ensure the mesh you select meets all project specifications.

Frequently Asked Questions

Can I use polyester mesh for outdoor safety fencing?Yes, polyester is highly resistant to UV rays and environmental degradation, making it ideal for outdoor use.

What’s the best mesh for compression garments?Power mesh with high spandex content is the best choice for compression due to its 4-way stretch and recovery.

Can I get mesh fabric with fire-retardant properties?Yes, most industrial-grade mesh can be treated with flame-retardant finishes to meet safety regulations.

What is the difference between mesh and netting?In a B2B context, the terms are often used interchangeably, though “mesh” often refers to finer knits and “netting” to larger holes.

Can I customize the hole size of the mesh for my project?Yes, manufacturers can adjust the knitting parameters to create custom hole sizes and shapes.

Selecting the right textile is a critical decision that impacts the safety, durability, and performance of your final product. At Tulle Mesh, we believe in providing precision-engineered solutions that solve your most complex material challenges. Our commitment to innovation and quality ensures that every roll of fabric we deliver meets the highest international standards. Whether you are designing the next generation of athletic wear or developing critical industrial safety systems, our team is here to support your vision with expert guidance and superior materials. For personalized assistance and technical specifications, contact us today .