Many designers struggle to find the perfect balance between structural integrity and delicate aesthetics in their luxury collections. Sourcing the wrong mesh can lead to sagging silhouettes or irritated skin for the end consumer. This lack of material precision often results in costly production delays and brand dissatisfaction.

Think about it.

By mastering the technical nuances of various netting options, you can elevate your designs from standard to couture. This guide provides a deep dive into the technical specifications and professional applications of these versatile textiles. It is time to transform your manufacturing process with expert material selection.

Key Takeaways

- Understand the mechanical differences between silk, nylon, and polyester variants.

- Identify the correct GSM (grams per square meter) for specific garment structures.

- Discover high-performance applications beyond traditional bridal wear.

- Learn professional handling techniques to minimize material waste during production.

What is tulle fabric and its historical origin?

The origin of this textile dates back to 18th-century France, specifically the town of Tulle. Originally handcrafted as a bobbin lace, it provided a lightweight alternative to heavy velvets and silks of the era. The invention of the bobbinet machine in the early 19th century revolutionized production for the global market.

Here is the deal:

Modern iterations have evolved significantly from their handmade lace ancestors. Today, manufacturers utilize sophisticated knitting machines to create the characteristic hexagonal mesh pattern. This evolution allows for greater scalability in B2B fashion production while maintaining the airy aesthetic.

Historical Evolution Points:

- Origin: Tulle, France (1700s).

- Invention: John Heathcoat’s bobbinet machine (1808).

- Transition: From silk-only to synthetic polymers.

- Impact: Enabled the mass production of tutus and veils.

| Feature | Handmade Tulle | Machine-Made Tulle | |

|---|---|---|---|

| Production Speed | Slow / Artisan | Rapid / Industrial | |

| Uniformity | Natural Variations | High Consistency | |

| Material | Pure Silk/Linen | Nylon/Polyester/Silk | |

| Cost | High Premium | Scalable |

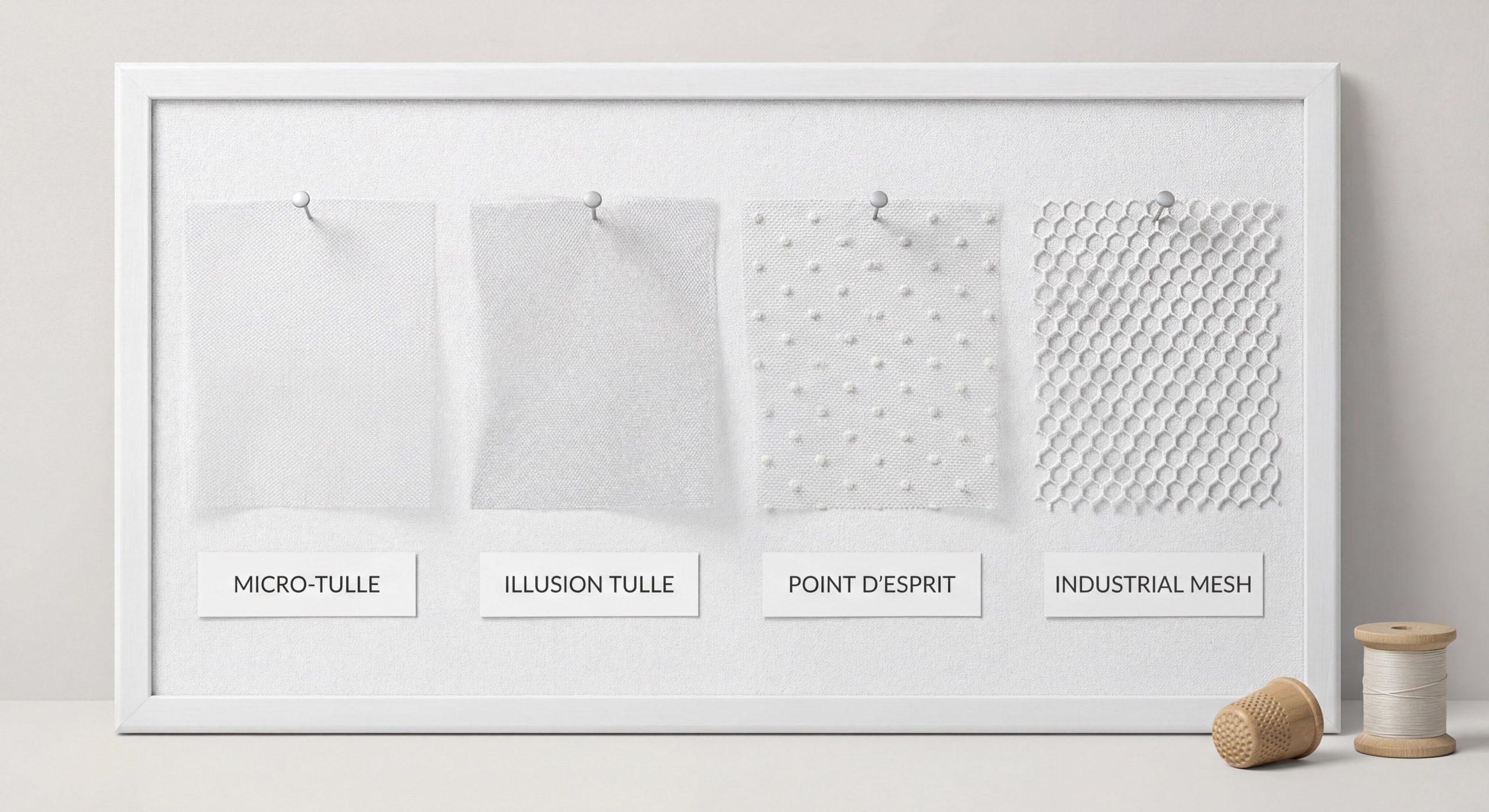

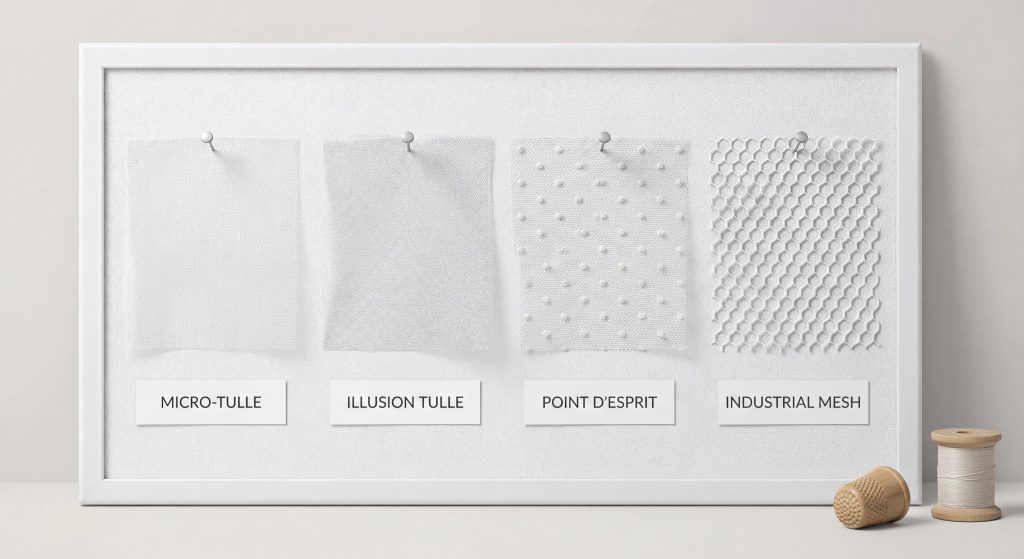

What is tulle fabric density and how is it measured?

Density in mesh textiles is primarily determined by the size of the holes and the weight of the yarn used. Professionals measure this using GSM (Grams per Square Meter) to ensure consistency across different batches. A higher GSM typically indicates a stiffer, more structural material suitable for volume-heavy garments.

Want to know the secret?

Selecting the wrong density can ruin the drape of a high-end gown or the comfort of activewear. Illusion mesh requires a very low GSM and fine denier for maximum transparency. Conversely, industrial-grade mesh used in luggage requires a much higher density for durability and load-bearing.

Density Measurement Standards:

- Fine Mesh: 10-20 GSM (Used for veils and lingerie).

- Medium Mesh: 25-40 GSM (Standard for fashion overlays).

- Heavy Mesh: 50+ GSM (Structural tutus and industrial use).

- Hole Shape: Hexagonal vs. Diamond (Affects stretch and recovery).

| Density Type | Common GSM | Primary Application | |

|---|---|---|---|

| Illusion | 12-15 | Bridal necklines | |

| Standard | 28-32 | Skirt overlays | |

| Stiff | 45-60 | Ballet tutus | |

| Technical | 80+ | Cargo pockets |

What is tulle fabric used for in bridal wear?

In the bridal industry, this material serves as the foundation for veils, overlays, and structural underskirts. Silk variants are highly prized for their soft “hand” and graceful drape during wedding ceremonies. Designers often use it as a canvas for intricate embroidery and beadwork to create a luxury feel.

But wait, there’s more.

The transparency of the mesh allows for “tattoo” lace effects where patterns appear to float on the skin. It also provides the necessary volume for ballgown silhouettes without adding excessive weight to the wearer. For more information on premium bridal options, visit tullemesh.com/products .

Bridal Applications:

- Veiling: Single or multi-tier cathedral lengths.

- Appliqué Base: Supporting heavy lace and pearl embellishments.

- Structural Crinoline: Providing lift to A-line and ballgown skirts.

- Illusion Panels: Creating “invisible” necklines and back details.

| Bridal Component | Recommended Fabric | Key Benefit | |

|---|---|---|---|

| Wedding Veil | Soft Nylon/Silk | High Transparency | |

| Skirt Volume | Stiff Polyester | Shape Retention | |

| Bodice Insert | Illusion Mesh | Skin-Tone Blending | |

| Train Overlay | Embroidered Tulle | Aesthetic Detail |

What is tulle fabric application in performance arts?

The performance arts sector relies heavily on the mechanical properties of stiffened netting for costuming. Classical tutus require a specific type of starched mesh that can support its own weight horizontally. This ensures that the dancer’s movements remain visible and unencumbered by sagging fabric.

Look:

Durability is critical because stage costumes undergo significant stress and frequent laundering. Nylon is the preferred fiber here due to its resilience and ability to hold a permanent crisp finish. You can explore the history of stage textiles at tullemesh.com/blog .

Performance Needs:

- Stiffness: Measured by the ability to hold a horizontal “plate” shape.

- Elasticity: Necessary in the bodice-to-skirt transition for movement.

- Color Saturation: Needs to withstand intense stage lighting without washing out.

- Resilience: Ability to bounce back after being packed in travel trunks.

| Costume Type | Mesh Layers | Required Stiffness | |

|---|---|---|---|

| Classical Tutu | 10-12 | Extremely High | |

| Romantic Tutu | 3-5 | Soft/Medium | |

| Character Skirt | 1-2 | Medium | |

| Headpieces | Various | High (Malleable) |

What is tulle fabric role in high-fashion runways?

High-fashion designers use mesh to push the boundaries of volume and avant-garde silhouettes. Neon dyes and architectural layering turn a simple textile into a bold statement piece for international runways. It allows for the creation of massive, cloud-like structures that remain surprisingly lightweight for the models.

The best part?

Modern technology allows for the integration of LED lights and other smart tech directly into the mesh layers. This creates a multidimensional effect that captures attention during digital and physical fashion shows. Innovation in this space is constant, driven by the desire for visual impact.

Runway Design Trends:

- Extreme Volume: Oversized ruffles and tiered layering.

- Neon Saturation: Utilizing synthetic fibers for vibrant, “electric” colors.

- Texture Play: Combining rougher meshes with smooth satins.

- Architectural Shapes: Using horsehair braid and wire to support the mesh.

| Trend | Fabrication Technique | Visual Impact | |

|---|---|---|---|

| Layering | Gradient Tones | Depth & Movement | |

| Ruffling | Pleated Edges | Maximum Texture | |

| Lighting | Integrated LEDs | Futuristic/Tech | |

| Transparency | Minimalist Lining | Edgy/Modern |

What is tulle fabric functionality in activewear?

In the athletic world, specialized mesh is essential for moisture management and thermal regulation. “Power mesh” variants provide compression while allowing the skin to breathe during high-intensity workouts. These fabrics are usually blended with spandex to ensure a full range of motion.

It gets better.

Strategically placed mesh panels help dissipate heat in high-sweat zones like the back and underarms. This functional application has crossed over into the “athleisure” market, where aesthetics meet performance. Manufacturers prioritize antimicrobial finishes in these specific mesh types.

Activewear Requirements:

- Breathability: High airflow through the hexagonal structure.

- Compression: Supporting muscles while maintaining shape.

- Moisture Wicking: Pulling sweat away from the body to the surface.

- Durability: Withstanding friction and frequent machine washing.

| Activewear Item | Mesh Placement | Functional Goal | |

|---|---|---|---|

| Sports Bra | Racerback Panel | Ventilation | |

| Leggings | Side/Calf Inserts | Breathability | |

| Running Top | Underarms | Cooling | |

| Gym Bags | Exterior Pockets | Airflow/Dryness |

What is tulle fabric utility in industrial and outdoor gear?

Industrial-grade mesh is a far cry from the delicate fabrics found in bridal salons. These textiles are engineered for high tensile strength and resistance to environmental abrasion. They are commonly used in tactical gear, backpacks, and outdoor equipment for their lightweight visibility.

You might be wondering:

Why use mesh instead of solid nylon for tactical gear? The answer lies in weight reduction and the ability to see contents through pockets without opening them. It also allows wet gear to dry quickly, preventing mold and mildew in outdoor environments.

Industrial Features:

- Tensile Strength: High resistance to tearing under heavy loads.

- UV Resistance: Coatings that prevent degradation from sun exposure.

- Abrasion Resistance: Withstanding contact with rocks and rough surfaces.

- Drainage: Essential for marine or rainy environment utility.

| Industrial Item | Mesh Type | Key Requirement | |

|---|---|---|---|

| Tactical Backpack | Heavy-Duty Mesh | Tear Resistance | |

| Fishing Net | Knotted Polypropylene | Water Permeability | |

| Safety Vest | High-Visibility Mesh | Airflow | |

| Camping Tent | No-See-Um Mesh | Insect Protection |

What is tulle fabric used for in interior design?

Interior designers utilize sheer textiles to manipulate light and create ethereal atmospheres in large spaces. Large-scale ceiling draping can soften the acoustics of a ballroom while hiding unsightly structural elements. It provides a cost-effective way to transform a venue for high-end corporate events.

Let’s dive in.

Beyond events, flame-retardant mesh is used for window treatments and bed canopies in luxury hospitality. The fabric’s ability to catch light makes it ideal for pairing with fairy lights or chandeliers. To learn more about our company’s history in textile supply, see tullemesh.com/about .

Interior Design Uses:

- Ceiling Swags: Creating a sense of intimacy in large halls.

- Window Sheers: Diffusing harsh sunlight while maintaining views.

- Event Backdrops: Providing a soft texture for photography.

- Acoustic Softening: Reducing echoes in hard-surfaced rooms.

| Interior Element | Design Style | Practical Benefit | |

|---|---|---|---|

| Ceiling Draping | Romantic / Grand | Hides Infrastructure | |

| Table Overlays | Sophisticated | Adds Texture | |

| Canopy Beds | Ethereal | Insect/Dust Barrier | |

| Wall Panels | Modern | Backlit Effects |

What is tulle fabric sewing and handling advice?

Sewing fine mesh requires specialized tools and techniques to avoid snagging or puckering. Professionals recommend using a brand-new “microtex” or “ballpoint” needle to navigate the holes without breaking fibers. Using a walking foot can also prevent the layers from shifting during high-speed production.

Here is the deal:

Seam finishing is crucial because raw edges can be itchy or prone to unraveling. French seams or binding with satin ribbon are the preferred methods for luxury garment construction. Always test tension settings on a scrap piece before starting the final assembly.

Professional Handling Tips:

- Needle Choice: 60/8 or 70/10 Microtex needles are ideal.

- Thread Type: Fine polyester or silk thread to match fiber content.

- Cutting: Use a rotary cutter and weights instead of pins.

- Pressing: Use low heat and a pressing cloth to avoid melting.

| Challenge | Solution | Tool Required | |

|---|---|---|---|

| Fabric Slippage | Tissue Paper Layer | Walking Foot | |

| Snagging | New Needle | Microtex Needle | |

| Raw Edge Irritation | French Seams | Overlocker | |

| Puckering | Reduce Tension | Adjustable Tension Dial |

What is tulle fabric future regarding sustainability?

The textile industry is shifting toward “circular fashion” by developing mesh from recycled ocean plastics. These sustainable variants offer the same performance characteristics as virgin nylon but with a significantly lower carbon footprint. Brands are increasingly demanding GRS (Global Recycled Standard) certified materials for their collections.

But wait, there’s more.

Bio-based polymers derived from corn or sugar are also entering the market as biodegradable alternatives. These innovations ensure that the beauty of sheer fabrics does not come at the cost of environmental health. Staying ahead of these trends is vital for any modern fashion enterprise.

Sustainability Milestones:

- Recycled Content: Using post-consumer plastic bottles (rPET).

- Water Reduction: Utilizing dry-dyeing technologies.

- Biodegradability: Developing fibers that break down in landfills.

- Certification: Achieving OEKO-TEX and GRS compliance.

| Innovation | Source Material | Environmental Impact | |

|---|---|---|---|

| Recycled Nylon | Ghost Fishing Nets | Ocean Cleaning | |

| Bio-Tulle | Plant-Based Sugars | Carbon Neutral | |

| rPET Mesh | Plastic Bottles | Waste Diversion | |

| Natural Dyes | Plant Minerals | Non-Toxic Runoff |

FAQ

How do I clean high-end tulle garments?Hand washing in cold water with a mild detergent is the safest method for preserving the delicate mesh structure. Avoid wringing the fabric; instead, lay it flat on a towel to air dry, as mechanical dryers can melt synthetic fibers.

Why does my tulle feel scratchy against the skin?Scratchiness is usually a result of using low-quality polyester fibers or high-GSM structural netting. For garments touching the skin, designers should specify “soft-hand” nylon or silk-blend meshes with a finer denier.

What is the difference between tulle and net fabric?While the terms are often used interchangeably, tulle is technically a finer, smaller-gauge version of netting. “Net” usually refers to coarser, larger-hole textiles used for utility or heavy structural support.

Can I dye synthetic tulle at home?Standard nylon mesh can be dyed using acid dyes or all-purpose dyes at simmer temperatures. However, 100% polyester mesh requires specialized disperse dyes and high heat, which may damage the delicate structure.

Is tulle fabric prone to fraying?Because it is a knit textile, it does not fray in the same way woven fabrics do. However, the raw edges can snag or catch on jewelry, so finishing edges with binding or rolled hems is recommended for longevity.

Conclusion

Selecting the appropriate textile for your collection requires a deep understanding of weight, fiber content, and intended use. From the historical workshops of France to the sustainable innovations of today, this fabric remains a cornerstone of both fashion and function. By applying these technical insights, you can ensure your products meet the highest standards of quality and durability.

Ready to elevate your next collection with premium materials? For bulk inquiries, custom swatches, or technical consultations, please contact us today. Our experts are standing by to help you find the perfect mesh solution for your specific needs.