The ultimate guide to glitter fabrics is a specialized technical resource designed to help B2B buyers and fashion designers navigate the complexities of high-shine textiles. Many professionals struggle with inconsistent material quality, leading to manufacturing delays and compromised brand reputation. There is nothing more frustrating than seeing a masterpiece ruined by excessive shedding or fragile mesh that fails under the needle. This guide provides the industry insights necessary to master glitter tulle fabric for your next luxury collection. To discuss your specific wholesale requirements, please contact us .

What is the appeal of premium glitter tulle fabric?

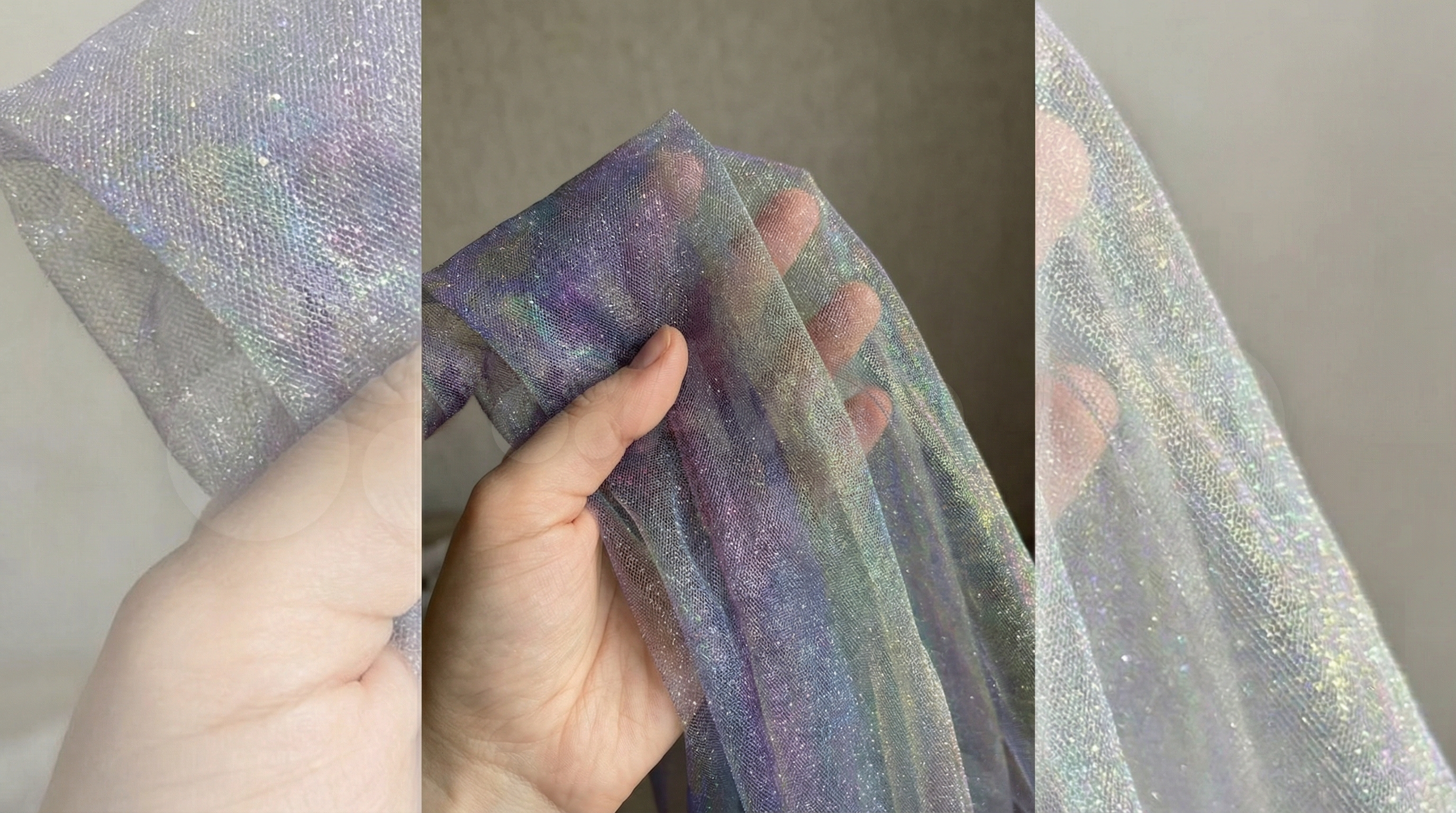

The primary appeal of high-quality glitter tulle fabric lies in its ability to provide structural volume combined with a multidimensional, radiant shimmer. Unlike traditional solid fabrics, this mesh allows light to pass through while catching the glint of individual particles, creating a “halo” effect. You will find that it is an essential component for bridal wear, evening gowns, and high-end costume design.

Why is texture important for designers?

Texture dictates how a garment feels and moves on the runway, making it a critical choice for B2B buyers. A premium mesh provides a crisp hand-feel that supports architectural silhouettes without being overly abrasive.

Here is the kicker:

- Hexagonal mesh structures offer superior stability.

- Fine-denier fibers ensure a lightweight finish.

- Heat-set glitter prevents the “scratchy” sensation common in lower grades.

Key Takeaway: Superior texture in glitter tulle fabric ensures that the garment maintains its shape and luxury appeal throughout the duration of an event.

How does light interact with the mesh?

Light interaction is the defining characteristic of any glitter-based material used in professional fashion. High-end mesh uses faceted glitter particles that reflect light at multiple angles rather than a flat, dull shine.

Think about it:

- Warm lighting enhances gold and champagne tones.

- Cool studio lights make silver and iridescent particles pop.

- Layering mesh creates a deep, “lit from within” glow.

Key Takeaway: Understanding light refraction helps you select the perfect glitter tulle fabric for specific venue environments and photography needs.

| Attribute | Benefit | Market Impact | |

|---|---|---|---|

| Light Refraction | Enhanced visual depth | Higher retail value | |

| Fiber Quality | Structural integrity | Reduced return rates | |

| Particle Type | Consistent sparkle | Brand consistency |

Selecting premium mesh is the foundational step in ensuring your high-fashion designs meet the rigorous standards of the luxury market.

How can you select the right glitter tulle fabric?

Selecting the right glitter tulle fabric involves assessing the weight, density of the mesh, and the specific bonding method used for the embellishments. You must determine if your project requires a soft, flowing drape for a veil or a stiff, rigid structure for a ballgown skirt. High-quality selections will have a uniform distribution of glitter without obvious bald spots or clumping.

Does the mesh density matter for durability?

Mesh density, or the size of the “holes” in the netting, directly impacts the fabric’s tensile strength and how much glitter it can support. A tighter weave generally offers more surface area for glitter adhesion, resulting in a more intense shine.

The reality is:

- Small-hole mesh is ideal for detailed embroidery.

- Wide “diamond” mesh provides maximum volume.

- Medium density is the most versatile for tiered skirts.

Key Takeaway: Matching mesh density to the garment’s structural requirements is vital for long-term durability in glitter tulle fabric.

Should you consider the drape of the fabric?

Drape determines how the fabric falls over the body, which is essential for creating elegant, fluid silhouettes in evening wear. While some glitter mesh can be quite stiff due to the adhesives used, premium versions maintain a degree of softness.

But wait, there is more:

- Soft-drape mesh is perfect for “naked” dress styles.

- Stiffer varieties are best for structured ruffles.

- Layering different drapes adds complex movement.

Key Takeaway: Prioritizing the drape of your glitter tulle fabric allows for more creative freedom in pattern making and silhouette design.

| Property | Rigid Mesh | Soft Mesh | |

|---|---|---|---|

| Primary Use | Ballgowns & Petticoats | Veils & Overlays | |

| Volume Level | Very High | Low to Moderate | |

| Comfort | Needs Lining | Skin-contact safe |

Balanced selection processes help you avoid costly mistakes during the sampling and production phases of your collection.

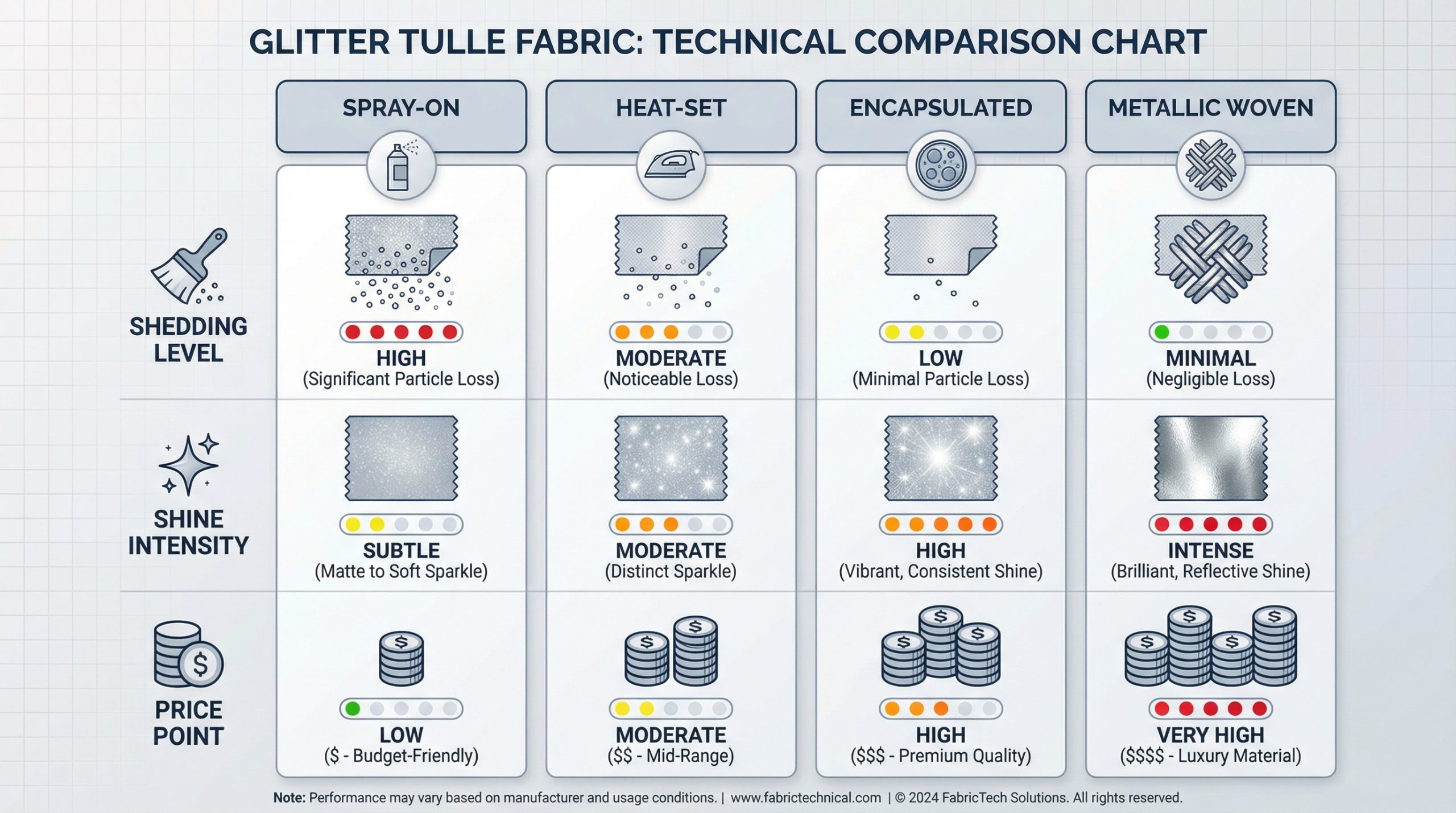

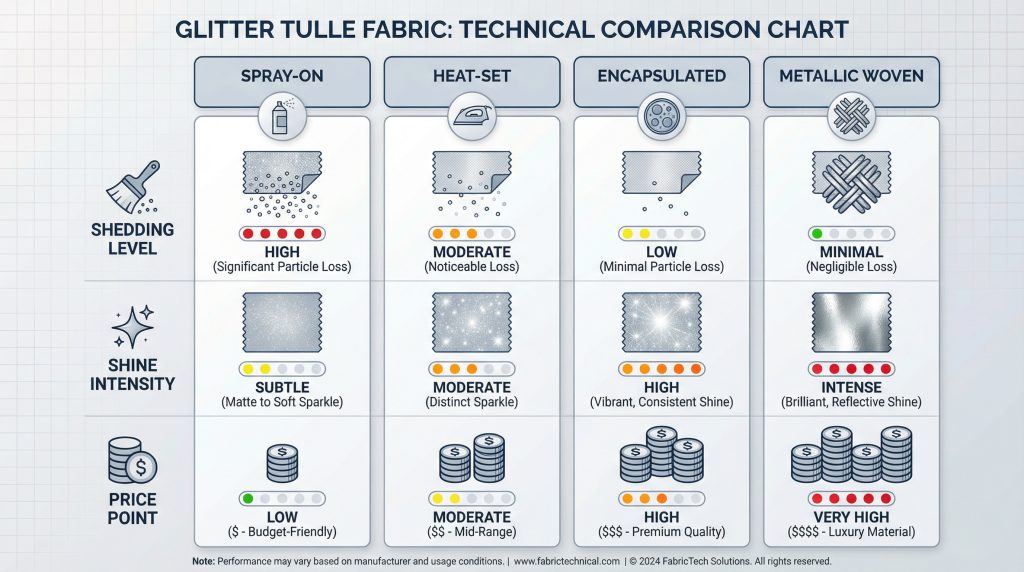

Which glitter tulle fabric offers the lowest shedding?

The lowest-shedding glitter tulle fabric is typically produced using an encapsulated or heat-set bonding process. You should look for materials where the glitter particles are fused into the fiber rather than simply sprayed onto the surface with a temporary adhesive. Testing a sample by rubbing it against dark cloth will quickly reveal the quality of the bond.

What is heat-set bonding for textiles?

Heat-set bonding involves using high temperatures to melt a specialized resin that locks the glitter onto the nylon or polyester mesh. This industrial process ensures that the sparkle remains intact even after multiple wearings or light cleaning.

Here is the deal:

- Fewer particles are lost during the cutting stage.

- The fabric maintains its luster after shipping.

- Workspace cleanup is significantly reduced.

Key Takeaway: Investing in heat-set glitter tulle fabric saves your production team time and protects your workshop environment.

Can sealants prevent particle loss?

Some manufacturers apply a microscopic clear sealant over the glitter to provide an extra layer of protection against friction. This “top-coat” is often invisible but can be felt as a slightly smoother texture on the surface of the mesh.

The bottom line?

- It provides a more “luxury” feel to the touch.

- It prevents glitter from snagging on delicate jewelry.

- It extends the lifespan of the garment’s shine.

Key Takeaway: Sealants are a hallmark of high-end glitter tulle fabric intended for the premium bridal and red-carpet markets.

| Bonding Type | Shedding Level | Durability | |

|---|---|---|---|

| Spray-on | High | Low | |

| Heat-set | Low | High | |

| Encapsulated | Minimal | Very High |

Selecting a low-shed material is the most effective way to ensure professional results and customer satisfaction in B2B textile procurement.

Can you sew glitter tulle fabric on industrial machines?

You can absolutely sew glitter tulle fabric on industrial machines, provided you use the correct needle type and maintain a strict cleaning schedule. The abrasive nature of the glitter can cause friction heat, which may lead to thread breakage or needle dulling if not managed properly. Using a high-speed industrial setting requires precision to avoid melting the synthetic mesh fibers.

What needle types are recommended?

A sharp Microtex or Titanium-coated needle is best for piercing the glitter-bonded areas without causing the mesh to tear. You should change your needle every few hours of continuous sewing to ensure the point remains sharp enough for the delicate netting.

It gets better:

- Size 70/10 is ideal for lightweight mesh.

- Size 80/12 handles heavier glitter density.

- Titanium coatings reduce friction and heat buildup.

Key Takeaway: Using the right needle ensures that your glitter tulle fabric seams remain clean and free from puckering or structural damage.

How do you protect the feed dogs?

The glitter particles can act like sandpaper on your machine’s feed dogs and presser foot over time. Using a Teflon foot or applying a small piece of masking tape to the underside of a standard foot can prevent the glitter from scratching the metal surfaces.

Wait, there’s more:

- Clean the bobbin area every 30 minutes.

- Use compressed air to remove glitter dust.

- Oil your machine more frequently during production.

Key Takeaway: Protective measures for your machinery are essential when running high volumes of glitter tulle fabric through a professional workshop.

| Component | Recommendation | Maintenance Frequency | |

|---|---|---|---|

| Needle | Microtex 70/10 | Every 4-6 hours | |

| Presser Foot | Teflon or Non-stick | Inspect daily | |

| Thread | High-strength Polyester | Continuous check |

Proper machine setup and maintenance are non-negotiable for designers who want to achieve couture-level finishes with embellished mesh.

What is the secret to cutting glitter tulle fabric?

The secret to cutting glitter tulle fabric accurately is using a high-quality rotary cutter combined with heavy pattern weights to prevent the mesh from shifting. You should avoid using pins, as they can snag the fine netting or become bent when they strike large glitter particles. Cutting in a single layer is always recommended to ensure that the glitter doesn’t “lock” the layers together and cause uneven edges.

Should you use rotary cutters?

Rotary cutters provide a constant downward pressure that keeps the glitter tulle fabric flat against the cutting mat. This method is far superior to using shears, which lift the fabric and can cause the slippery mesh to distort during the cut.

Keep this in mind:

- Use a dedicated blade for glitter materials.

- Change the blade immediately if it starts to skip.

- Always cut away from your body for safety.

Key Takeaway: Rotary cutters are the industry standard for achieving the precise edges required for high-end glitter tulle fabric designs.

How do you manage layout shifting?

Managing the shift of lightweight mesh is one of the biggest challenges in the cutting room. Using a “grippy” cutting mat or laying a thin layer of tissue paper beneath the tulle can provide the friction needed to keep the fabric stable.

Here is the kicker:

- Pattern weights are safer than pins.

- Trace patterns with a tailor’s chalk or marker.

- Check alignment every few inches.

Key Takeaway: Stability during the cutting process is the only way to ensure that multi-panel glitter tulle fabric garments fit together perfectly.

| Tool | Purpose | Pro Tip | |

|---|---|---|---|

| Rotary Cutter | Clean, flat edges | Use 45mm blades | |

| Weights | Fabric stabilization | Space every 6 inches | |

| Cutting Mat | Surface protection | Self-healing type is best |

Precision in the cutting room translates directly to a smoother assembly process and a more professional final product.

How do you maintain the shine of glitter tulle fabric?

Maintaining the shine of glitter tulle fabric requires a strict avoidance of traditional laundering and heavy heat. You should never put these garments in a washing machine, as the agitation will destroy the delicate mesh and strip the glitter. Instead, focus on gentle steaming and localized spot cleaning to keep the fabric looking brand new for every client.

Is steaming safer than ironing?

Steaming is the only recommended method for removing wrinkles from glitter tulle fabric without risking damage to the adhesive or the mesh. A steamer allows the fibers to relax through moisture and gentle heat without the direct contact of a hot metal plate.

The secret is:

- Keep the steamer head 6 inches away.

- Steam from the inside of the garment.

- Avoid over-saturating the mesh with water.

Key Takeaway: Professional steaming preserves both the structural integrity and the brilliant sparkle of your glitter tulle fabric creations.

What about spot cleaning?

Spot cleaning is necessary for removing small stains like makeup or perspiration without submerging the entire garment. You should use a very mild detergent and a soft microfiber cloth to gently dab the area, avoiding any scrubbing motion that could dislodge the glitter.

The bottom line?

- Test cleaning agents on a hidden swatch.

- Use distilled water to avoid mineral spots.

- Air dry the garment flat on a towel.

Key Takeaway: A “less is more” approach to cleaning is essential for protecting the longevity of high-impact glitter tulle fabric.

| Care Method | Recommended? | Reason | |

|---|---|---|---|

| Ironing | No | Risk of melting | |

| Steaming | Yes | Gentle and effective | |

| Dry Cleaning | With Caution | Chemicals may dissolve glue |

Proper maintenance guidelines are a value-added service you can provide to your B2B clients to ensure garment longevity.

Is glitter tulle fabric comfortable for sensitive skin?

While glitter tulle fabric is visually stunning, it can be abrasive if the raw edges come into direct contact with the skin. You can easily solve this problem by incorporating soft linings and using advanced seam-finishing techniques. Designers who prioritize wearer comfort often find that their pieces are more popular for long-duration events like weddings and galas.

Can you use a soft lining?

Using a high-quality silk, satin, or soft jersey lining is the most effective way to protect the wearer from the texture of the glitter mesh. The lining acts as a smooth barrier that prevents irritation while allowing the outer layer of tulle to provide the desired volume and shine.

Consider this:

- Match the lining color to the mesh base.

- Use breathable fabrics for summer events.

- Ensure the lining is slightly larger for movement.

Key Takeaway: A well-chosen lining transforms glitter tulle fabric from a purely aesthetic material into a wearable luxury textile.

How should you finish the seams?

Finishing seams with bias binding or “French seams” hides the “poky” ends of the mesh and the sharp glitter particles. This is particularly important around the neckline, armholes, and waistbands where the fabric is most likely to rub against the skin.

Think about it:

- Satin bias tape adds a couture touch.

- Enclosed seams prevent fraying and itching.

- Soft thread reduces friction at the seam line.

Key Takeaway: Technical seam finishes are essential for ensuring that glitter tulle fabric meets the comfort expectations of high-end clientele.

| Comfort Feature | Function | User Benefit | |

|---|---|---|---|

| Silk Lining | Friction reduction | All-day wearability | |

| Bias Binding | Edge protection | No skin irritation | |

| Soft Tulle Base | Buffer layer | Breathable volume |

Comfort is just as important as aesthetics in the B2B fashion market, as it directly impacts the end-user’s experience.

How does glitter tulle fabric compare to sequins?

When comparing glitter tulle fabric to sequin materials, the most significant difference is the weight and the type of light reflection. Glitter mesh is exceptionally lightweight and offers a diffused, “stardust” glow, whereas sequin fabrics are much heavier and provide sharp, metallic flashes. Designers often choose the glitter variant when they want to achieve a romantic, ethereal look without the bulk of plastic discs.

Which is more lightweight for gowns?

Glitter mesh is significantly lighter than even the most delicate sequin fabrics, making it the superior choice for high-volume skirts. This allows you to layer multiple yards of fabric to create a princess-style silhouette that the wearer can still move in comfortably.

Here’s the deal:

- Less strain on the garment’s hangers.

- Easier to ship in bulk for B2B orders.

- More comfortable for performers on stage.

Key Takeaway: The lightweight nature of glitter tulle fabric makes it a more practical choice for grand, voluminous designs.

Does the sparkle type differ significantly?

The sparkle of glitter is much finer and more uniform than the chunky, disjointed reflection of sequins. This creates a “mist” of light that is often perceived as more sophisticated and modern than traditional sequin embellishments.

The reality is:

- Glitter is better for daytime shimmer.

- Sequins are best for high-contrast stage lighting.

- Combining both adds incredible texture.

Key Takeaway: Choosing glitter tulle fabric over sequins allows for a more subtle and romantic aesthetic in evening wear collections.

| Feature | Glitter Tulle | Sequin Fabric | |

|---|---|---|---|

| Weight | Very Light | Heavy | |

| Drape | High | Moderate to Low | |

| Production Speed | Fast | Slow (seam prep needed) |

Understanding these distinctions allows B2B buyers to select the material that best aligns with their design goals and production budgets.

What are the newest trends for glitter tulle fabric?

The newest trends for glitter tulle fabric involve sophisticated ombré colorways and the use of the material in 3D floral appliques. Designers are moving away from simple flat panels and toward complex, multi-layered constructions that change color and intensity as the wearer moves. You will also see an increase in “shimmer-on-shimmer” techniques where glitter mesh is layered over metallic lamé for maximum impact.

Are ombré effects in high demand?

Ombré glitter mesh is currently dominating the bridal and prom markets because it adds a sense of movement and artistry to simple silhouettes. By transitioning from a dark, heavily glitzy hem to a light, airy bodice, you can create a visually stunning vertical line.

The bottom line?

- It creates a “custom” look for B2B brands.

- It simplifies the design of gradient gowns.

- It appeals to younger, trend-conscious buyers.

Key Takeaway: Incorporating ombré glitter tulle fabric is a powerful way to modernize a classic evening wear collection.

How is 3D applique evolving?

Modern designers are cutting individual shapes out of glitter mesh and layering them to create dimensional flowers, butterflies, and geometric patterns. This technique adds a tactile element to the shine, making the garment look much more expensive and handcrafted.

Wait, there’s more:

- Laser cutting ensures precise shapes.

- Scattered glitter petals add romantic flair.

- It’s a great use for high-quality fabric scraps.

Key Takeaway: 3D applications of glitter tulle fabric represent the pinnacle of current couture textile manipulation.

| Trend | Market Segment | Design Impact | |

|---|---|---|---|

| Ombré Gradient | Bridal/Prom | Vertical elongation | |

| 3D Florals | Haute Couture | High-end texture | |

| Layered Shine | Red Carpet | Maximum reflection |

Staying ahead of these trends ensures that your B2B offerings remain competitive and inspiring to your design clients.

Where should you source high-end glitter tulle fabric?

Sourcing high-end glitter tulle fabric requires finding a supplier that specializes in technical textiles for the bridal and evening wear industries. You should look for partners who provide detailed specifications on their bonding processes and offer consistent dye lots for large-scale production. A reliable supplier will also provide swatch cards and sample yardage so you can test the material’s performance before committing to a bulk order.

Why choose specialized suppliers?

Specialized suppliers understand the unique challenges of glitter fabrics and only stock “low-shed” varieties that meet professional standards. They can provide expert advice on which mesh weights are best suited for your specific design goals, saving you from costly trial and error.

Here is the kicker:

- Access to exclusive colors and patterns.

- Lower defect rates in bulk shipments.

- Expert technical support for your team.

Key Takeaway: A specialized partner is your best defense against the quality issues that often plague the glitter tulle fabric market.

Should you order bulk samples?

Ordering sample yardage of at least 5 yards allows you to perform “real-world” tests, including sewing, steaming, and wear-testing on a mannequin. This is a critical step for B2B buyers to ensure the fabric performs as expected under industrial manufacturing conditions.

Think about it:

- It confirms color accuracy in different lights.

- It reveals the true “shed” level during cutting.

- It allows for accurate cost-per-garment calculation.

Key Takeaway: Thorough sampling of glitter tulle fabric is the hallmark of a professional and successful fashion production workflow.

| Sourcing Factor | Importance | Strategy | |

|---|---|---|---|

| Dye Lot Consistency | Critical | Buy by the bolt | |

| Sample Testing | Essential | 5-yard minimum | |

| Technical Data | Helpful | Request spec sheets |

Strategic sourcing is the final piece of the puzzle in mastering the use of glitter fabrics for the global fashion market.

This guide has addressed the critical problems of inconsistent material quality, excessive shedding, and manufacturing difficulties that often deter designers from using embellished mesh. By following the technical advice provided, you can now confidently integrate these materials into your collections to achieve a luxury, high-shine finish. We invite you to explore our premium selections and contact us today to elevate your next design project with the finest textiles available. Our commitment to quality ensures that your brand always shines on the global stage.

Frequently Asked Questions

Can I iron glitter tulle fabric?No, you should never apply a hot iron directly to glitter mesh as it will melt the nylon and the adhesive. Always use a professional steamer or hang the garment in a high-moisture environment to remove wrinkles safely.

What’s the best way to hem a glittery skirt?A rolled hem or the addition of horsehair braid is the most effective way to finish the edge of a glitter mesh garment. These methods provide a clean look while giving the hem the structural “kick” needed to maintain a full silhouette.

How do I know if the glitter is high quality?Perform a simple rub test by briskly dabbing a sample against a dark piece of fabric; a high-quality bond will leave almost no visible particles behind. You should also check for a uniform shine and a “clear” mesh base that isn’t cloudy from excess glue.

Can I use glitter tulle for children’s wear?Yes, but you must ensure that all internal seams are soft-lined or bound to protect sensitive skin from irritation. It is also important to verify that the glitter particles are non-toxic and securely bonded to prevent accidental ingestion.

What’s the best thread for sewing this material?A high-quality 100% polyester thread is the best choice because it offers the strength and slight “give” required for mesh fabrics. Avoid cheap threads that may fray or snap when they come into contact with the abrasive glitter particles.