Mesh fabric is a high-performance textile defined by its open-weave architecture and thousands of tiny, engineered holes. If you have ever felt stifled by heavy, non-breathable clothing during a workout, you know the frustration of poor thermal regulation. This discomfort isn’t just an annoyance; it can lead to overheating and decreased performance in both athletic and industrial environments. Fortunately, mesh solves this by prioritizing airflow and light penetration without sacrificing structural integrity. In this guide, you will learn why this material is the backbone of modern sportswear, medical technology, and industrial safety.

What is the basic definition and origin of mesh fabric?

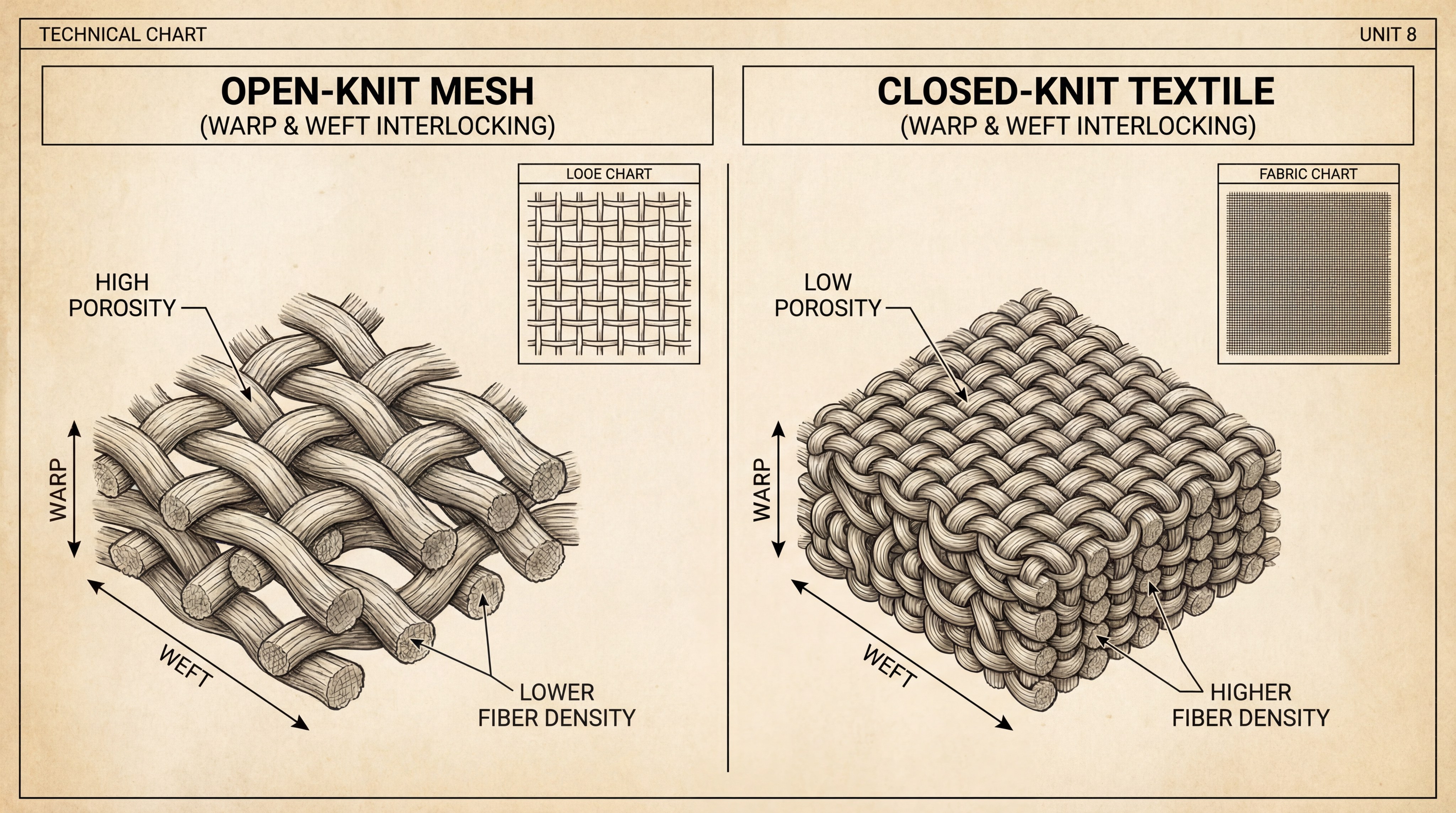

Mesh fabric is a textile distinguished by its net-like structure where the warp and weft yarns are looped or knotted to create stable, open spaces. When exploring different types of mesh fabric, it is important to understand that the concept of “netting” dates back to ancient civilizations using natural fibers for fishing and hunting. However, the modern mesh you recognize today emerged with the rise of synthetic polymer science in the mid-20th century. By shifting from organic materials to manufactured resins, producers were able to create uniform openings that could withstand significant tension and environmental stress.

Structural Anatomy of Mesh Netting

The anatomy of mesh involves a specific interlocking pattern that prevents the fabric from unravelling even when the holes are large. Unlike traditional solid weaves that overlap tightly to block light and air, mesh utilizes a “leno weave” or specialized knitting process to lock fibers in place. This creates a geometric grid that remains stable under pressure.

- Warp Knitting: Most modern mesh is warp-knitted, where the yarn zigzags along the length of the fabric.

- Aperture Size: The diameter of the holes determines the material’s breathability and transparency.

- Filament Density: Higher density filaments provide more strength, while lower density allows for maximum lightness.

- Grid Symmetry: Most industrial mesh uses a hexagonal or square grid for uniform stress distribution.

Think about it: without this specific interlocking geometry, the fabric would simply pull apart at the first sign of friction.

Synthetic Fiber Foundations

Synthetic fibers like polyester and nylon are the primary foundations of modern mesh because they can be extruded into incredibly thin yet strong filaments. These materials allow the fabric to remain lightweight while providing the chemical resistance needed for industrial and outdoor applications. While cotton mesh exists (often used in eco-friendly produce bags), synthetic versions dominate the market due to their superior performance metrics.

- Polymer Extrusion: Creating uniform strands that are resistant to fraying.

- Heat Setting: A process that “locks” the hole shapes so they don’t distort over time.

- Hydrophobic Nature: Most synthetic mesh fibers do not absorb water, allowing for rapid drying.

- UV Resistance: Coatings added during production protect the netting from sun damage.

But that’s not all; the origin of these fibers actually dictates how the fabric reacts to dyes and heat.

Summary: Mesh Definition and Origins

| Element | Description | |

|---|---|---|

| Basic Definition | A textile with an open, net-like structure formed by spaced-out yarns. | |

| Historical Origin | Evolved from ancient hand-knotted nets to machine-knitted synthetic textiles. | |

| Material Base | Primarily synthetic polymers like polyester, nylon, and spandex. | |

| Manufacturing | Utilizes warp knitting and leno weaving to ensure hole stability. |

What are the core characteristics of mesh textiles?

Core characteristics of mesh include exceptional breathability, a high strength-to-weight ratio, and rapid moisture-wicking capabilities. Understanding the different types of mesh fabric requires you to look beyond the holes and analyze how the material handles physical stress and environmental factors. Because the structure is mostly air, the material is naturally lighter than any solid-woven counterpart, making it the go-to choice for applications where every gram of weight matters.

Superior Breathability and Airflow

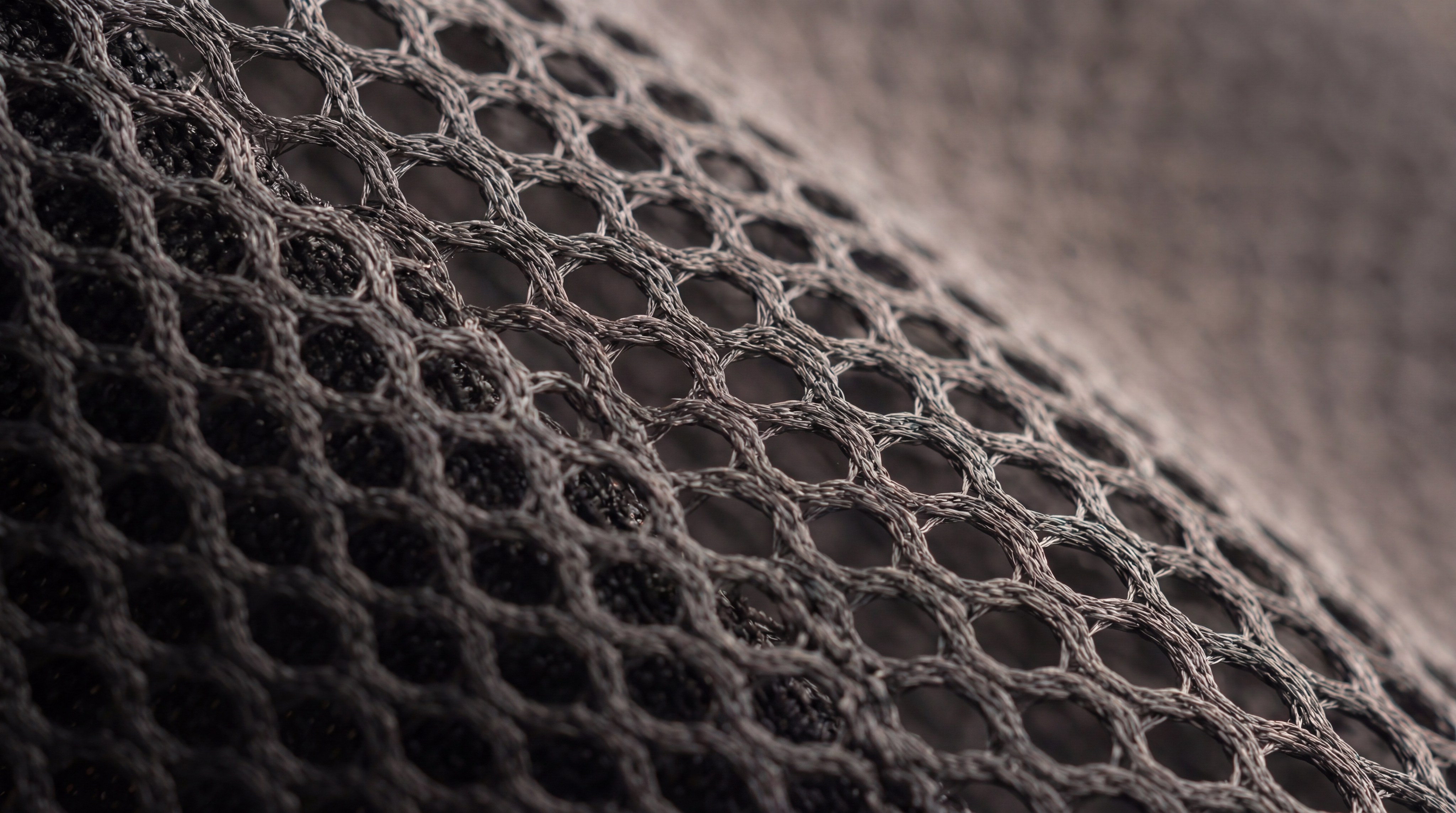

The most prominent characteristic of mesh is its ability to allow air to circulate freely through the textile layers. This ventilation is not accidental; it is a result of the high porosity engineered into the knit. When you wear a mesh-lined garment, the material acts as a heat exchanger, allowing body heat to escape while letting cooler ambient air reach the skin.

- Passive Cooling: Reducing the internal temperature of a garment without mechanical help.

- Vapor Permeability: Allowing sweat to evaporate through the holes rather than trapping it.

- Thermal Regulation: Helping the wearer maintain a steady core temperature during exertion.

- Odor Reduction: Increased airflow prevents the buildup of bacteria that thrive in damp, stagnant environments.

Believe it or not, the shape of the hole—whether round, square, or hexagonal—can actually change how much air moves through the fabric at different speeds.

Lightweight and Flexible Movement

Mesh is inherently lightweight because it uses significantly less raw material per square meter than solid fabrics. This lack of bulk translates directly into freedom of movement, as the material offers very little resistance when bent or folded. For you, this means a garment or piece of equipment that feels almost weightless, even when it covers a large surface area.

- Low Denier: The use of fine yarns keeps the overall mass extremely low.

- Pliability: Mesh can be draped or folded into complex shapes without creasing.

- High Strength-to-Weight Ratio: Despite its lightness, the material can support heavy loads in cargo applications.

- Compressibility: It can be packed into very small spaces, making it ideal for travel gear.

You might be wondering: does being lightweight mean it is fragile? In the case of high-quality mesh, the answer is a resounding no.

Rapid Moisture Wicking and Drying

Because most mesh is made from hydrophobic synthetic fibers, it does not hold onto moisture. Instead of absorbing sweat or rain, the fibers pull the liquid toward the surface where the massive surface area of the holes facilitates instant evaporation. This “wicking” effect is essential for keeping you dry and preventing the fabric from becoming heavy and waterlogged.

- Capillary Action: Moving moisture away from the skin through the fiber gaps.

- Surface Area Maximation: The open structure provides more space for air-to-liquid contact.

- Non-Absorbent Fibers: Unlike cotton, synthetic mesh won’t “grow” heavy when wet.

- Mold Resistance: Fast drying times prevent the growth of fungi and mildew.

It sounds simple, but this characteristic is what makes mesh indispensable in humid environments.

Summary: Core Characteristics of Mesh

| Characteristic | Practical Benefit | |

|---|---|---|

| Breathability | Maximizes airflow and prevents overheating during activity. | |

| Lightweight | Reduces fatigue and allows for high-speed movement. | |

| Moisture Wicking | Keeps the wearer dry by evaporating sweat quickly. | |

| Durability | Resists tearing and environmental degradation despite the thin structure. |

How do polyester and nylon define mesh varieties?

Polyester and nylon define mesh varieties by offering different levels of durability, moisture resistance, and tactile softness. When you evaluate different types of mesh fabric, you will notice that polyester is typically matte and stiff, whereas nylon is often glossier and more elastic. These material differences aren’t just for show; they determine whether a fabric is best suited for a rough-and-tumble backpack or a delicate, moisture-wicking running jersey.

Polyester Mesh for Moisture Control

Polyester mesh is the industry standard for apparel that needs to stay dry under pressure. Because polyester is inherently hydrophobic, it repels water more effectively than almost any other fiber. This makes it the perfect candidate for athletic jerseys, where you need a material that won’t sag or become heavy as you sweat.

- Color Fastness: Polyester holds dye exceptionally well, resisting fading even after many washes.

- Wrinkle Resistance: It maintains its shape and doesn’t require ironing.

- Heat Stability: It can withstand higher temperatures during the printing process.

- Pilling Resistance: It is less likely to develop small fuzzy balls on the surface over time.

Think about it: have you ever seen a sports jersey that looked worn out after just one season? If it’s high-quality polyester mesh, it likely looks as good as new.

Nylon Mesh for Elasticity and Strength

Nylon mesh is prized for its incredible tensile strength and “bounce-back” elasticity. While it may absorb a tiny amount of water compared to polyester, its ability to stretch and return to its original shape is unmatched. This makes it the primary choice for heavy-duty gear like high-end backpacks, tactical vests, and certain types of high-compression shapewear.

- Abrasion Resistance: Nylon is much tougher against rubbing and scraping.

- High Elasticity: It stretches further than polyester before reaching its breaking point.

- Soft Hand-Feel: Nylon generally feels smoother and “silkier” against the skin.

- Glossy Finish: It often has a slight sheen that gives it a premium look.

But that’s not all; nylon’s strength makes it the ideal candidate for fine, nearly invisible nets that still need to hold their weight.

Summary: Polyester vs. Nylon Mesh

| Feature | Polyester Mesh | Nylon Mesh | |

|---|---|---|---|

| Moisture Management | Superior (Hydrophobic) | Good (Slight absorption) | |

| Strength | High | Exceptional (High Tensile) | |

| Stretch | Moderate | High Elasticity | |

| Appearance | Matte / Traditional | Glossy / Premium | |

| Best Use | Sportswear, Jerseys | Gear, Bags, Fine Netting |

Why is stretch capacity essential in mesh design?

Stretch capacity is essential because it allows the fabric to move with the body and provide compression without restricting blood flow. In the world of different types of mesh fabric, “stretch” usually refers to the addition of elastane or spandex fibers into the knit. Without this elasticity, a mesh garment would feel stiff and brittle, likely tearing at the seams as soon as you performed a complex movement like a squat or a reach.

Power Mesh and Spandex Blends

Power mesh is a specific category of textile engineered for high-performance recovery and support. By blending nylon or polyester with a high percentage of spandex, manufacturers create a fabric that can be stretched in four directions (horizontal, vertical, and diagonal) while always returning to its original dimensions. This is the secret behind garments that feel like a “second skin.”

- Four-Way Stretch: Providing equal flexibility in all directions.

- Recovery Power: The ability of the holes to snap back without becoming distorted.

- Sheer Support: Providing a lightweight look while still offering a firm hold.

- Skin Compatibility: Reducing friction through a smooth, elasticated surface.

Wait until you see how this technology is used in high-end shapewear; it completely changes the silhouette without causing the wearer any distress.

Compression and Support Mechanics

Stretch mesh isn’t just about comfort; it’s about mechanical support for the muscles and skin. In athletic and medical contexts, compression mesh helps increase blood circulation and reduce muscle vibration during high-impact activities. For those interested in intimate apparel, understanding what are the best mesh fabric types for shapewear is vital for selecting materials that provide the right “gram-force” of compression.

- Muscle Stabilization: Reducing fatigue by keeping muscle tissues tight.

- Post-Surgical Support: Holding dressings or tissues in place during healing.

- Contouring: Shaping the body by distributing pressure evenly across the surface.

- Breathable Compression: Offering support without the “suffocating” heat of solid spandex.

You might be surprised to learn that the density of the knit actually dictates how much “power” the stretch has.

Summary: Stretch and Compression Factors

| Stretch Type | Composition | Main Application | |

|---|---|---|---|

| Static Mesh | 100% Polyester/Nylon | Laundry bags, window screens, jerseys. | |

| Two-Way Stretch | Synthetic blend | Lightweight summer tops, ventilation panels. | |

| Four-Way Stretch | Spandex/Elastane blend | Activewear, leggings, swimwear. | |

| Power Mesh | High Spandex content | Shapewear, medical support, athletic gear. |

How do aesthetic finishes distinguish mesh fabrics?

Aesthetic finishes distinguish mesh fabrics by transforming them from purely functional industrial materials into luxury fashion components. When you look at different types of mesh fabric, you will see a massive spectrum ranging from the “gritty” look of a construction vest to the ethereal mist of a bridal veil. These visual differences are achieved through varied knit patterns, fiber fineness (denier), and post-production treatments like flocking or glitter application.

Tulle and Fine Netting for Formalwear

Tulle is the most famous aesthetic variant of mesh, known for its incredibly fine holes and lightweight drape. Unlike the sturdy mesh found in a gym bag, tulle is designed to be layered to create volume and softness. Designers must be meticulous in their selection process, often researching how to choose soft tulle fabric for bridal wear to ensure the material doesn’t irritate the wearer’s skin or snag on jewelry.

- Micro-Hole Structure: Openings so small they appear like a mist or cloud.

- Voluminous Layering: The ability to stack layers for a “poof” effect in skirts.

- Soft Hand-Feel: High-quality tulle uses ultra-fine filaments to avoid scratchiness.

- Transparency: Creating a “nude” or “illusion” look in high-fashion gowns.

Imagine the difference between a mosquito net and a wedding veil; the core concept is the same, but the aesthetic execution is worlds apart.

Decorative Patterns and Color Vibrancy

Modern manufacturing allows for mesh that features intricate patterns directly “built” into the knit. This isn’t just about printing a design on top of the fabric; it’s about varying the hole sizes and densities to create floral, geometric, or abstract visuals. These decorative meshes are staples in the lingerie and luxury eveningwear industries, where the texture of the fabric itself is the main design element.

- Jacquard Mesh: Patterns created through complex knitting machine movements.

- Embroidered Netting: Adding 3D elements like sequins or threadwork to the mesh base.

- Flocked Mesh: Applying tiny fibers to the surface to create velvet-like patterns.

- Iridescent Coatings: Giving the mesh a metallic or holographic shimmer.

But that’s not all; the way these fabrics catch the light can completely change based on whether the fibers are trilobal (shiny) or round (matte).

Summary: Aesthetic Mesh Variations

| Mesh Type | Aesthetic Quality | Common Fashion Use | |

|---|---|---|---|

| Standard Tulle | Crisp and stiff | Tutus, petticoats, floral arrangements. | |

| Soft Tulle | Draping and silky | Bridal veils, overlay dresses. | |

| Point d’Esprit | Dotted/Patterned | Vintage-style blouses, hosiery. | |

| Fishnet | Large, bold holes | Alternative fashion, hosiery, layering pieces. |

In what ways is apparel influenced by mesh types?

Apparel is influenced by mesh through enhanced thermal regulation, improved moisture management, and the ability to create targeted ventilation zones. In the context of different types of mesh fabric, designers use these materials to solve the age-old problem of sweat buildup in clothing. By placing mesh panels in areas of the body that produce the most heat—such as the underarms, back, and chest—manufacturers can significantly increase a wearer’s comfort during physical activity.

Performance Enhancement in Sportswear

In the world of high-performance sports, mesh is more than just a fabric; it’s a tool for optimizing the body’s cooling system. Athletes lose a significant amount of energy trying to cool themselves down; if their clothing traps that heat, their performance drops. Mesh jerseys and shorts allow for convection (air movement) to carry heat away from the skin instantly.

- Zone Mapping: Placing mesh precisely where the body sweats most.

- Drag Reduction: Some micro-meshes are designed to be more aerodynamic than solid fabrics.

- Weight Minimization: Keeping the uniform as light as possible to prevent fatigue.

- Sublimation Printing: Allowing for vibrant team colors without clogging the holes.

Think about it: have you ever noticed how professional athletes rarely look “drenched” in sweat compared to someone wearing a standard cotton t-shirt? That is the power of engineered mesh.

Summer Fashion and Ventilation

Beyond the gym, mesh has become a staple of summer street fashion. Its “see-through” nature allows for creative layering while providing a cooling effect that solid linen or cotton cannot match. However, selecting the right material is a technical challenge, and knowing how to choose the right mesh fabric types for apparel is essential for ensuring the garment is both stylish and durable enough for daily wear.

- Layering Potential: Using mesh as an outer shell over more opaque garments.

- Textural Contrast: Mixing smooth silks or denim with the “gritty” texture of mesh.

- Beachwear Cover-ups: Providing sand-resistance and instant drying after a swim.

- Accessory Accents: Using mesh for breathable hats, footwear, and gloves.

Wait until you feel the difference between a solid polyester shirt and a mesh-backed polo on a 90-degree day; the difference is life-changing.

Summary: Apparel Applications

| Apparel Category | Role of Mesh | Specific Benefit | |

|---|---|---|---|

| Activewear | Core material or panels | Maximum sweat evaporation. | |

| Footwear | Upper linings and outer shells | Reduces foot sweat and blister risk. | |

| Intimate Apparel | Foundations and accents | Breathable support and aesthetic appeal. | |

| Outdoor Gear | Hat vents and jacket linings | Airflow without losing structural protection. |

How are industrial and safety sectors using mesh?

Industrial and safety sectors use mesh to provide high-visibility, lightweight protection, and efficient filtration in harsh working environments. When discussing different types of mesh fabric, the industrial versions are often much coarser and stronger than those used in fashion. These materials are engineered to meet strict safety standards, such as flame resistance or high-tensile load capacities, ensuring they can protect workers and equipment alike.

High-Visibility Safety Equipment

The most common industrial use of mesh is the high-visibility (Hi-Viz) safety vest. In construction and roadside work, heat exhaustion is a major risk; a solid plastic vest would be unbearable in the summer sun. Mesh allows for the necessary neon colors and reflective strips to be worn without trapping body heat, keeping the worker safe from both traffic and the elements.

- ANSI/ISEA Standards: Ensuring the mesh meets specific visibility and durability ratings.

- Tear-Away Designs: Engineered to break away if caught in machinery to prevent injury.

- Weight Distribution: Allowing for heavy tool belts to be worn over the lightweight vest.

- Breathability: Crucial for workers performing manual labor in hot climates.

You might be wondering: can a fabric with holes really be tough? In the industrial world, these meshes are often reinforced with high-tenacity coatings that make them nearly impossible to rip.

Filtration and Screening Systems

Beyond clothing, industrial mesh serves as a critical component in filtration systems. From large-scale HVAC units to fine water purification filters, the “holes” in mesh are precisely measured in microns to allow specific substances through while blocking others. Professionals often look for guidance on how to select mesh fabric types for industrial applications to find the exact micron rating and chemical resistance needed for their specific machinery.

- Debris Blocking: Keeping leaves and trash out of industrial drainage systems.

- Air Filtration: Trapping dust and particles in factory ventilation.

- Cargo Containment: Using heavy-duty netting to secure loads on trucks and ships.

- Chemical Resistance: Using specialized polymers that won’t melt when exposed to oils or solvents.

But that’s not all; learning how to use different types of mesh fabric for industrial applications ensures that the material is oriented correctly to handle the pressure of the fluid or gas passing through it.

Summary: Industrial and Safety Uses

| Application | Material Priority | Success Metric | |

|---|---|---|---|

| Safety Vests | Breathability & Color | Reduction in heat-related workplace injuries. | |

| Cargo Netting | Tensile Strength | Prevention of load shifting during transport. | |

| HVAC Filters | Micron Precision | Efficiency in trapping airborne pollutants. | |

| Pest Control | Fine Aperture | Keeping insects out while allowing air in. |

Can mesh be used in medical and household items?

Mesh is widely used in medical and household items due to its biocompatibility, transparency, and barrier-protection qualities. In your search for different types of mesh fabric, you will find that “medical grade” mesh is perhaps the most highly regulated textile in the world. Domestically, the same principles that keep a surgeon’s patient safe—airflow and protection—are used to keep your home free of insects and your laundry protected during a wash cycle.

Surgical Mesh and Wound Care

In the medical field, mesh is a miracle material for tissue support. It is used internally for hernia repairs and externally for wound dressings. The porous nature of surgical mesh allows the body’s own cells to grow into the material, creating a reinforced layer of tissue that is much stronger than a simple stitch.

- Biocompatibility: Using materials like polypropylene that the body won’t reject.

- Tissue Integration: Allowing “ingrowth” to permanently secure the mesh in place.

- Sterile Packaging: Ensuring the material is free of all pathogens before use.

- Breathable Dressings: Allowing air to reach a wound to speed up the healing process.

Believe it or not, the flexibility of medical mesh is what allows patients to regain their full range of motion after major surgery.

Insect Barriers and Home Screening

At home, you likely interact with mesh every day through your window screens. These fine nets are engineered to be nearly invisible while providing a physical barrier against mosquitoes and other pests. Because the mesh is mostly air, it doesn’t block your view or the breeze, making it the perfect compromise between safety and comfort.

- Pet Carriers: Providing ventilation and visibility for animals during travel.

- Laundry Bags: Protecting delicates from the friction of a washing machine.

- Food Protection: Covering fruit or baked goods to keep flies away.

- Bed Netting: Providing a safe sleeping environment in malaria-prone regions.

Think about it: without mesh, summer nights indoors would either be stiflingly hot or filled with unwanted buzzing guests.

Summary: Medical and Household Mesh

| Context | Specific Product | Key Function | |

|---|---|---|---|

| Medical | Surgical Hernia Mesh | Reinforcing weakened physiological tissue. | |

| Medical | Tubular Bandages | Holding dressings in place on limbs. | |

| Household | Window Screens | Barring insects while admitting fresh air. | |

| Household | Laundry Bags | Preventing snags on delicate clothing. |

How should users maintain and clean mesh fabric?

Maintenance of mesh fabric requires gentle washing cycles, mild detergents, and an absolute avoidance of high heat. When you deal with different types of mesh fabric, you are dealing with synthetic polymers that are essentially a form of plastic. If you expose these fine filaments to the intense heat of a dryer or a hot iron, they can melt, shrink, or become brittle, destroying the carefully engineered hole structure.

Washing Guidelines for Synthetic Nets

The best way to wash mesh is to treat it like a delicate garment, even if it is a “tough” industrial vest. The friction of a heavy-duty wash cycle can cause the edges of the mesh holes to fray or snag on other items like zippers and buttons. Using a mesh laundry bag to protect your mesh clothing is a wise, albeit ironic, best practice.

- Cold Water: Preventing the breakdown of synthetic fibers.

- Gentle Cycle: Reducing the mechanical stress on the knit pattern.

- Mild Detergent: Avoiding harsh chemicals that can strip away UV coatings.

- Inside Out: Washing garments inside out to protect the outer aesthetic finish.

You might be tempted to use bleach on white mesh, but be careful; bleach can weaken the polymer bonds and lead to yellowing or tearing.

Drying and Heat Sensitivity Management

Air-drying is the only recommended method for preserving the life of mesh textiles. Because mesh is so porous, it dries incredibly quickly on its own, usually within an hour or two in a well-ventilated room. If you must use a dryer, you should only use the “no heat” or “air fluff” setting to avoid warping the fabric.

- Drip Drying: Hanging the item so water can fall away naturally.

- No Ironing: Steamers are a safer way to remove wrinkles if absolutely necessary.

- Avoid Sunlight: Long-term exposure to direct, harsh sun can degrade the fibers.

- Flat Drying: Laying heavy mesh items flat to prevent them from stretching out of shape.

Wait until you see how much longer your athletic gear lasts when you stop putting it in the dryer; the elasticity will stay “snappy” for years.

Summary: Maintenance Tips

| Action | Recommended Method | Reason | |

|---|---|---|---|

| Washing | Cold water / Gentle cycle | Protects hole integrity and prevents fraying. | |

| Protection | Use a laundry bag | Prevents snagging on zippers or hooks. | |

| Detergent | Neutral / Mild | Preserves fiber strength and colors. | |

| Drying | Hang dry / Air dry | Prevents melting or shrinking of synthetic fibers. |

What is the environmental impact of mesh production?

The environmental impact of mesh production is significant due to its reliance on petroleum-based synthetics and the potential for microplastic shedding. However, as you examine different types of mesh fabric in the modern market, you will find a growing sector dedicated to sustainability. While the traditional “virgin” polyester process consumes high amounts of energy, new circular manufacturing methods are helping to mitigate the industry’s carbon footprint.

Synthetic Production and Plastic Concerns

Most mesh is essentially a plastic product, meaning its production begins with the extraction of fossil fuels. The process of turning oil into polyester or nylon pellets and then into yarn is energy-intensive and releases various volatile organic compounds (VOCs). Additionally, when synthetic mesh is washed, tiny fibers (microplastics) can break off and enter the water system.

- Carbon Footprint: High energy usage during polymer extrusion and heat-setting.

- Non-Biodegradability: Traditional mesh can take hundreds of years to break down in a landfill.

- Microplastic Shedding: Small particles entering the ocean during the laundry process.

- Chemical Runoff: Dyeing and finishing processes that require careful water management.

Think about it: every piece of mesh ever made still exists in some form today unless it was specifically incinerated or recycled.

The Rise of Recycled Mesh Solutions

The good news is that mesh is one of the easiest textiles to produce from recycled materials. “rPET” (recycled polyethylene terephthalate) is created by melting down old water bottles and spinning them into new mesh yarn. This process uses significantly less water and energy than creating virgin polyester, and it helps clean up plastic waste from our oceans and landfills.

- Circular Economy: Using post-consumer waste to create high-performance gear.

- Ocean Plastic Mesh: Fabrics made specifically from reclaimed marine debris.

- Reduced Emissions: Lowering the CO2 impact of the manufacturing chain.

- Eco-Friendly Coatings: Moving away from harmful PFAS in water-resistant treatments.

But that’s not all; many brands are now using “closed-loop” dyeing systems that recycle 99% of the water used, making the process much cleaner.

Summary: Environmental Impact Comparison

| Metric | Virgin Synthetic Mesh | Recycled (rPET) Mesh | |

|---|---|---|---|

| Raw Material | Crude Oil / Petroleum | Plastic Bottles / Ocean Waste | |

| Energy Usage | High | 30-50% Lower | |

| Water Waste | Moderate | Significantly Reduced | |

| End of Life | Landfill (Non-degradable) | Recyclable in specific streams |

Frequently Asked Questions

Is mesh fabric itchy to wear?It depends on the fiber quality and denier. While industrial mesh can be stiff, modern apparel mesh uses ultra-fine synthetic filaments and “soft-touch” finishes to ensure it is comfortable even against sensitive skin.

Can I sew mesh at home?Yes, but you need the right tools. Because mesh is slippery and has holes, you should use a ballpoint needle, a “walking foot,” and perhaps some tissue paper as a stabilizer to prevent the fabric from being sucked into the throat plate of your sewing machine.

Does mesh provide UV protection?Generally, no. Because of the holes, UV rays can pass through to your skin. If you are wearing mesh for sun protection, look for specialized “UV-rated” mesh that has a protective coating on the fibers.

Why does my mesh clothing smell after a workout?While mesh is breathable, synthetic fibers like polyester can trap body oils. If you don’t wash your mesh gear with a detergent designed to break down oils, bacteria can grow on those residues and cause a persistent odor.

Is mesh fabric waterproof?No. By definition, mesh has holes that allow water to pass through. However, the fibers themselves are usually water-resistant, meaning the fabric won’t absorb the water and will dry almost instantly once out of the rain.

Strategic Summary: Finding the Perfect Mesh

Choosing the right mesh requires a balance of function, durability, and aesthetics. Whether you are a designer looking for the perfect drape or a project manager sourcing industrial safety gear, understanding the underlying material science is key to long-term success.

If you are ready to explore high-quality options for your next project or need professional guidance on material selection, contact us today to find the perfect textile solution for your needs.