High-performance apparel and industrial applications demand materials that don’t just cover, but perform. Many textile manufacturers struggle with overheating and moisture retention in traditional weaves, leading to discomfort and reduced product lifespan. This lack of ventilation creates a barrier to peak performance and consumer satisfaction. Breathable mesh fabric offers the definitive solution, providing a lightweight, porous structure that facilitates maximum airflow and durability across diverse sectors. [Explore our comprehensive textile directory at tullemesh.com for more material insights.]

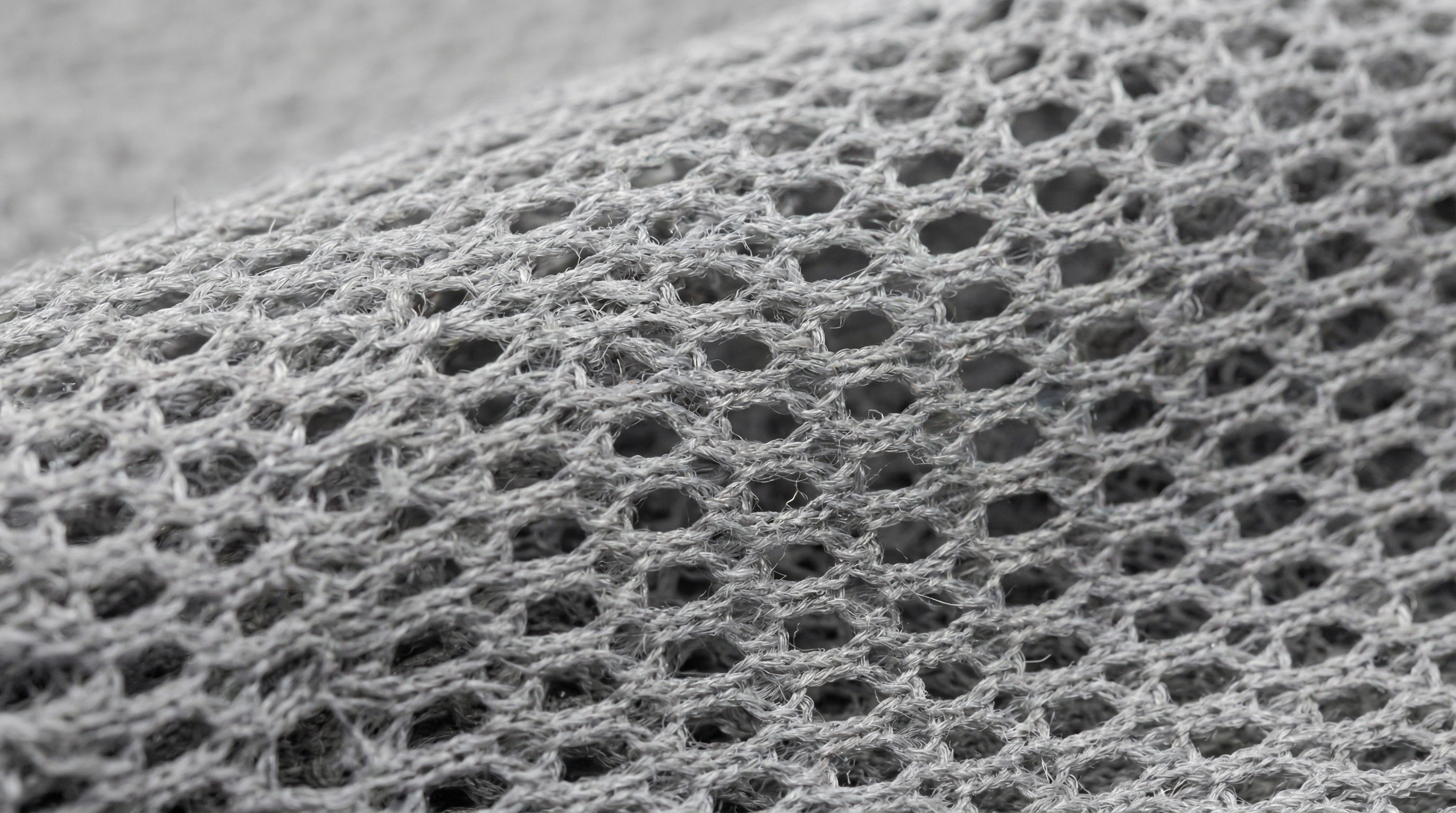

1. What exactly is breathable mesh fabric?

Breathable mesh fabric is a lightweight, permeable textile characterized by its loose weave and thousands of tiny holes that allow for superior air circulation. Unlike densely woven traditional fabrics, this material is engineered for transparency and ventilation, making it an essential component for any product requiring thermal regulation.

Why is the loose weave so important?

The loose weave is the engine of the fabric’s performance. By creating deliberate gaps between the warp and weft threads, you allow heat to escape and cool air to enter. This mechanical property is what prevents the “sauna effect” common in standard synthetic garments.

Is all mesh fabric made from synthetic fibers?

While the vast majority of industrial and athletic mesh is made from polyester or nylon due to their durability, you can find mesh in silk or even cotton. However, for B2B applications where moisture-wicking is a priority, synthetics remain the gold standard.

Key Takeaways: Core Characteristics

- Permeability: High airflow through consistent perforation.

- Weight: Significantly lighter than standard knits or weaves.

- Texture: Ranges from soft, silk-like finishes to rigid industrial nets.

- HPI Variations: Typically features 6 to 16 holes per inch (HPI).

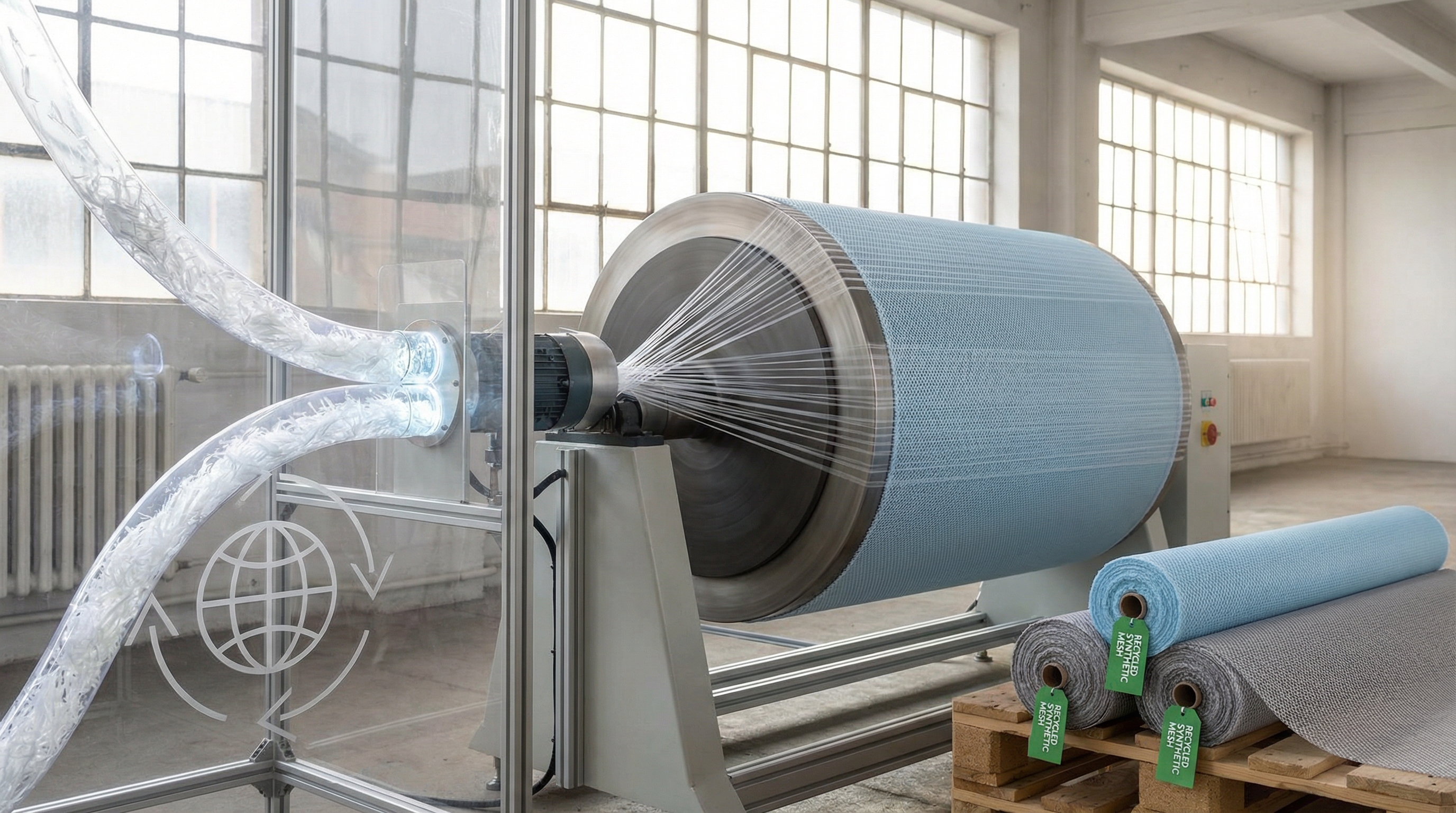

2. How is breathable mesh fabric manufactured today?

The manufacturing of breathable mesh fabric involves a sophisticated process of refining petroleum into polymer strands that are subsequently woven into specific, porous patterns. This high-tech extrusion process ensures that the resulting fibers are uniform and capable of withstanding the tension of high-speed industrial looms. [Learn more about modern manufacturing standards at tullemesh.com/shop.]

What is the role of spinnerets in production?

In your production chain, the spinneret is the critical point of origin. Molten polymer is forced through these tiny, showerhead-like nozzles to create continuous filaments. The shape and size of the spinneret holes determine the cross-section of the fiber, which can be modified to enhance wicking or sheen.

How do weaving patterns differ across types?

You will find that most mesh is knitted using a “raschel” machine, which allows for complex openwork patterns. Unlike standard weaving, these machines create pillars of stitches connected by inlaid yarns, ensuring the holes remain stable and do not fray.

| Production Phase | Process Description | |

|---|---|---|

| Extraction | Polyamide monomers are extracted from refined petroleum oil. | |

| Polymerization | Monomers react with acids to create solid polymers. | |

| Extrusion | Molten polymers are forced through spinnerets to create strands. | |

| Weaving | Strands are woven into square or hexagonal structures. |

3. In what applications is breathable mesh fabric used?

From professional athletic jerseys to medical-grade shapewear, breathable mesh fabric serves diverse functional and aesthetic purposes across the global market. Its utility extends far beyond simple apparel into specialized industrial sectors where weight-to-strength ratios are critical.

Why is it preferred for professional sportswear?

Athletes generate immense heat; you need a fabric that acts as a second skin without trapping moisture. Mesh provides the necessary surface area for sweat to evaporate quickly, keeping the wearer dry and focused on performance.

How is it used in industrial settings?

You might encounter mesh in filtration systems, safety netting, or even as reinforcement for composite materials. Its ability to maintain structural integrity while allowing fluids or gases to pass through is unmatched by solid textiles.

Common Applications:

- Athletic Apparel: Jerseys, shorts, and moisture-wicking gym wear.

- Shapewear: Elasticized “power mesh” used for body contouring.

- Accessories: Laundry bags, beekeeping veils, and fishing nets.

- Industrial: Screens for precision screen printing and tent ventilation.

4. Where is breathable mesh fabric primarily produced?

While the United Kingdom was the original pioneer of this textile, China now leads the global production of breathable mesh fabric by a significant margin. The infrastructure in East Asia allows for massive scaling, though high-end specialty meshes are still produced in Europe and the Americas. [Discover our global supplier network at tullemesh.com.]

The shift is clear: production follows efficiency.

Which countries are emerging as major suppliers?

Vietnam and India are rapidly increasing their market share in the “athleisure” mesh segment. If you are looking for cost-competitive sourcing outside of China, these regions offer robust manufacturing hubs with increasing technical capabilities.

Why is production shifting back to Western nations?

There is a growing demand for “near-shoring” to reduce lead times and carbon footprints. You may find that specialized, high-performance power nets are increasingly being produced in localized boutique factories to serve high-end fashion and medical clients.

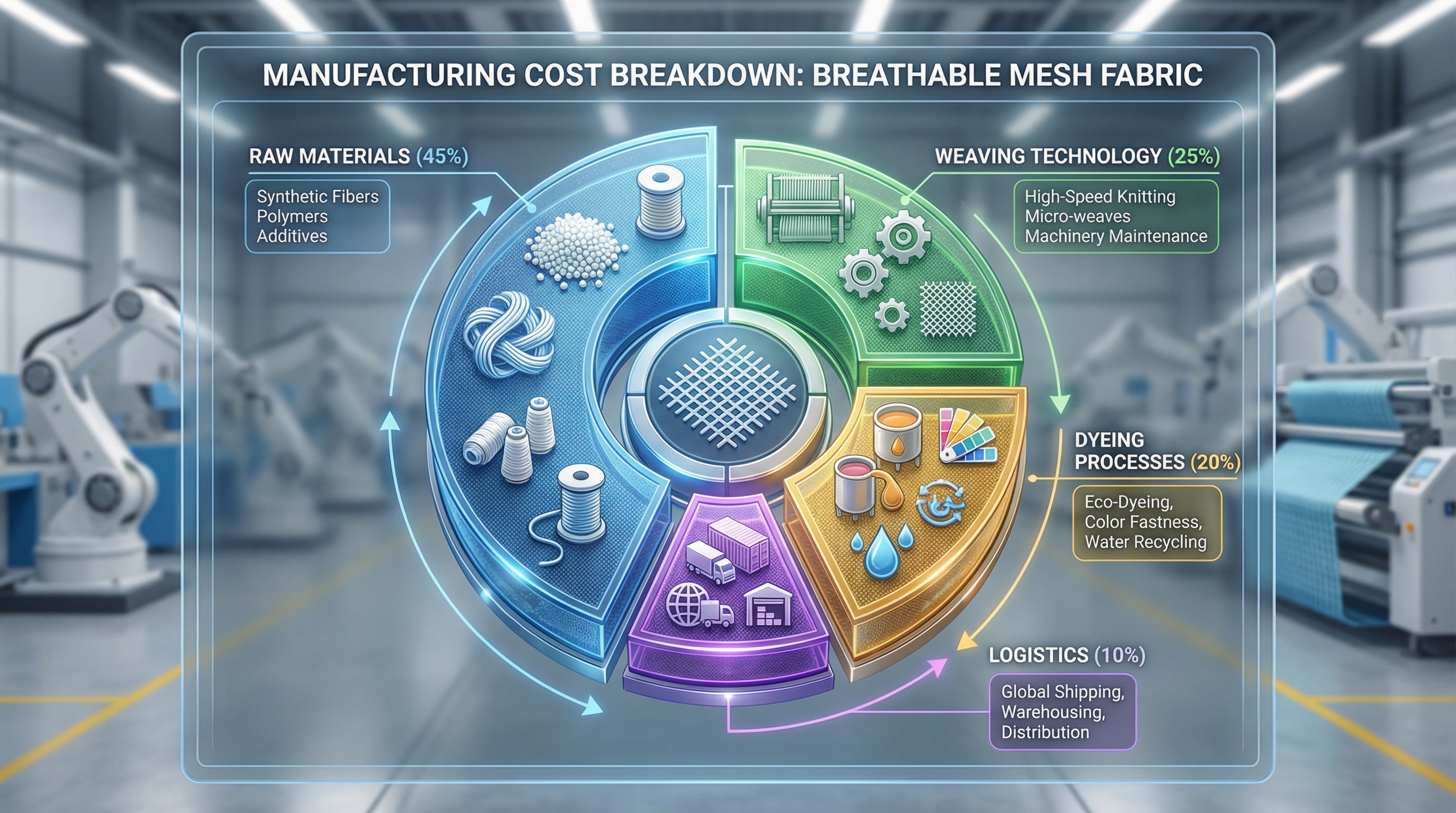

5. How much does breathable mesh fabric cost?

The cost of breathable mesh fabric varies based on the raw material source, dyeing complexity, and the specific geometry of the weave pattern. Generally, polyester-based mesh is the most economical, while specialty nylons or silk tulles command a premium.

Does material type impact the final price?

Absolutely. When you choose nylon over polyester, you are paying for increased tensile strength and a softer hand-feel. Conversely, choosing recycled polyester (rPET) may increase your initial costs but provides significant marketing value for sustainable brands.

Are there cost differences between regions?

Labor costs and energy prices are the primary drivers here. While Western-made mesh may cost 20-40% more, the reduced shipping costs and tariff benefits in certain trade blocks can balance the total landed cost.

Pricing Factor Summary Table:

| Factor | Impact on Cost | |

|---|---|---|

| Raw Material | Silk-based mesh is significantly more expensive than polyester. | |

| Dyeing | Brightly dyed or fluorescent patterns increase processing costs. | |

| Weave Style | Complex hexagonal Tulle patterns carry a premium over square weaves. | |

| Sourcing | Domestic Western production typically incurs higher labor costs. |

6. Which types of breathable mesh fabric are available?

Market options for breathable mesh fabric range from high-stretch power nets to delicate silk-based tulles, each designed for specific mechanical requirements. Identifying the right type is the first step in ensuring your final product meets user expectations. [Compare different textile types in our guide at tullemesh.com/shop.]

What distinguishes polyester from nylon mesh?

Polyester is your workhorse; it’s hydrophobic, meaning it won’t absorb water, making it perfect for intense cardio gear. Nylon mesh is more durable and has a better drape, often preferred for high-end fashion accents or industrial netting that faces heavy abrasion.

When should you use power mesh vs. powernet?

If you are designing light-support shapewear, go with power mesh. If you need maximum compression and structural support—such as in surgical garments or heavy-duty lingerie—powernet is the superior choice due to its denser, more rigid construction.

- Polyester Mesh: The standard for sportswear; lightweight and moisture-wicking.

- Nylon Mesh: Extremely durable; used for beekeeping veils and tent screens.

- Tulle: A fine, often hexagonal mesh used in dancewear and accents.

- Power Mesh: Highly elastic material used for compression and shapewear.

- Powernet: A denser variant of power mesh used in high-support lingerie.

7. How does breathable mesh fabric affect the environment?

Due to its petroleum-based origins, breathable mesh fabric has a significant environmental footprint related to manufacturing emissions and long-term non-biodegradability. As a B2B buyer, you must be aware of the lifecycle impact of these synthetic materials.

What are the risks of synthetic microfibers?

Every time you wash a synthetic mesh garment, it sheds microplastics. These tiny fibers bypass most filtration systems and end up in the ocean. Selecting high-quality, long-staple fibers can help mitigate this shedding.

How does adipic acid affect the atmosphere?

The production of nylon requires adipic acid, which releases nitrous oxide (N2O)—a greenhouse gas significantly more potent than carbon dioxide. Modern manufacturers are implementing thermal abatement systems to capture these emissions.

Key Takeaways: Environmental Impact

- Resource Depletion: Dependence on non-renewable petroleum.

- Atmospheric Impact: Production of nylon releases nitrous oxide (N2O).

- Water Contamination: Cooling processes during extrusion can pollute local hydrospheres.

- Persistence: Synthetic fibers can remain in ecosystems for centuries without degrading.

8. Are certifications available for breathable mesh fabric?

Manufacturers of breathable mesh fabric can obtain certifications like GRS, ISO 9001, and ANSI to verify quality, safety, and recycled content. These labels are your assurance that the material meets international performance and ethical standards. [Check for certified manufacturers here at tullemesh.com/shop.]

What does the Global Recycle Standard verify?

The GRS verifies not only the recycled content of your mesh but also the social and environmental practices of the factory. It ensures that the “recycled” label isn’t just greenwashing but a traceable, audited fact.

Why is ISO 9001 important for B2B buyers?

ISO 9001 ensures consistent quality management. When you are ordering thousands of yards of mesh, you need to know that the tensile strength and hole diameter of the first roll match the last.

9. How do you care for breathable mesh fabric?

Maintaining breathable mesh fabric requires cold water washing or hand-washing to preserve the integrity of the synthetic fibers and prevent heat-related damage. Because these materials are essentially plastic, heat is their greatest enemy.

Can you use a dryer for mesh garments?

You should avoid the dryer whenever possible. High heat can cause the polymer strands to melt or warp, leading to a permanent loss of elasticity and shape. Air drying is the safest way to ensure product longevity.

How do you prevent pilling in mesh fabric?

Pilling occurs when fibers break and tangle. To prevent this, you should wash mesh garments inside out and avoid mixing them with heavy, abrasive fabrics like denim or items with exposed zippers that can snag the delicate holes.

Maintenance Guidelines:

- Wash Temperature: Always use cold water settings.

- Method: Hand-washing is preferred for delicate tulles and power nets.

- Detergent: Use mild, non-abrasive cleaners to avoid fiber breakdown.

- Drying: Air dry only; high heat from dryers can melt synthetic strands.

10. How do you select the best breathable mesh fabric?

Selecting the right breathable mesh fabric depends on balancing specific HPI (holes per inch) requirements with the desired level of elasticity for the end-use application. You must match the material’s mechanical properties to the stresses it will encounter in the field.

What HPI is best for your specific project?

A low HPI (larger holes) is ideal for maximum ventilation in items like basketball jerseys. A high HPI (smaller, denser holes) is better for printing logos or when you need a more opaque finish for fashion items.

How do you evaluate moisture-wicking needs?

Check the fiber blend. If you need maximum moisture management, ensure the mesh is 100% polyester or a poly-spandex blend. Pure nylon, while strong, can hold onto more moisture than polyester.

Selection Criteria Matrix:

| Requirement | Recommended Mesh Type | |

|---|---|---|

| High Compression | Powernet / Power Mesh | |

| Maximum Airflow | Low HPI Polyester Mesh | |

| Durability/Utility | Nylon Mesh | |

| Decorative/Accent | Tulle (Silk or Polyester) |

Strategic ConclusionThe versatility of breathable mesh fabric makes it an indispensable asset in modern B2B textile procurement. By understanding the nuances of manufacturing, material types, and care requirements, brands can deliver superior products that meet the highest standards of ventilation and durability. Our commitment to textile excellence ensures you have the data needed to make informed sourcing decisions. [Connect with our specialists at tullemesh.com today to start your next project.]

Frequently Asked Questions

- Can I use breathable mesh fabric for medical applications? Yes, specifically power mesh variants are often used in medical-grade compression garments and braces.

- What’s the best way to source recycled mesh? Look for suppliers with Global Recycle Standard (GRS) certification to ensure the fibers are 100% post-consumer waste.

- Can I print logos directly onto mesh? Yes, but a denser weave (higher HPI) is recommended to ensure the graphic remains legible and does not distort.

- What’s the best material for outdoor use? Nylon mesh is generally preferred for outdoor applications like tents or veils due to its superior abrasion resistance.

- Can I dye mesh fabric after it is woven? While possible, it is most cost-effective and color-fast to purchase pre-dyed fibers or fabric directly from the manufacturer.