The primary difference is that tulle is a fine, soft mesh with tiny hexagonal holes, whereas netting is a coarser, stiffer fabric with larger apertures. Many creators find themselves confused by these overlapping terms, leading to expensive mistakes in material selection. Choosing the wrong texture can result in a garment that is either too scratchy for comfort or too limp to hold a silhouette. This guide clarifies the netting vs tulle debate so you can confidently select the right fabrics from our shop for your next masterpiece.

1. Why care about netting vs tulle for your sewing?

When evaluating netting vs tulle, you must consider how the weave density affects the structural integrity of your finished project. The weight and drape of these open-weave materials dictate whether a skirt will float ethereally or stand out with rigid geometry.

The impact of fabric choice on garment structure

Let’s face it. Your choice between these materials determines the level of support your garment provides. Netting offers a robust framework for heavy embellishments, while tulle provides a delicate surface for light layering.

You should choose based on these primary uses:

- Tutus and petticoats for maximum lift.

- Decorative overlays for a soft, hazy aesthetic.

- Structural interfacings to support heavier silks.

Key Takeaway and Summary Table

Using Stiff Tulle Fabric allows you to bridge the gap between these two categories by providing volume without the harshness of industrial net. Understanding these nuances ensures your project meets professional standards.

| Feature | Tulle Profile | Netting Profile | |

|---|---|---|---|

| Hole Size | Very Small | Moderate to Large | |

| Feel | Soft / Smooth | Stiff / Coarse | |

| Primary Use | Veils & Overlays | Petticoats & Structure |

2. Is there a physical difference in netting vs tulle?

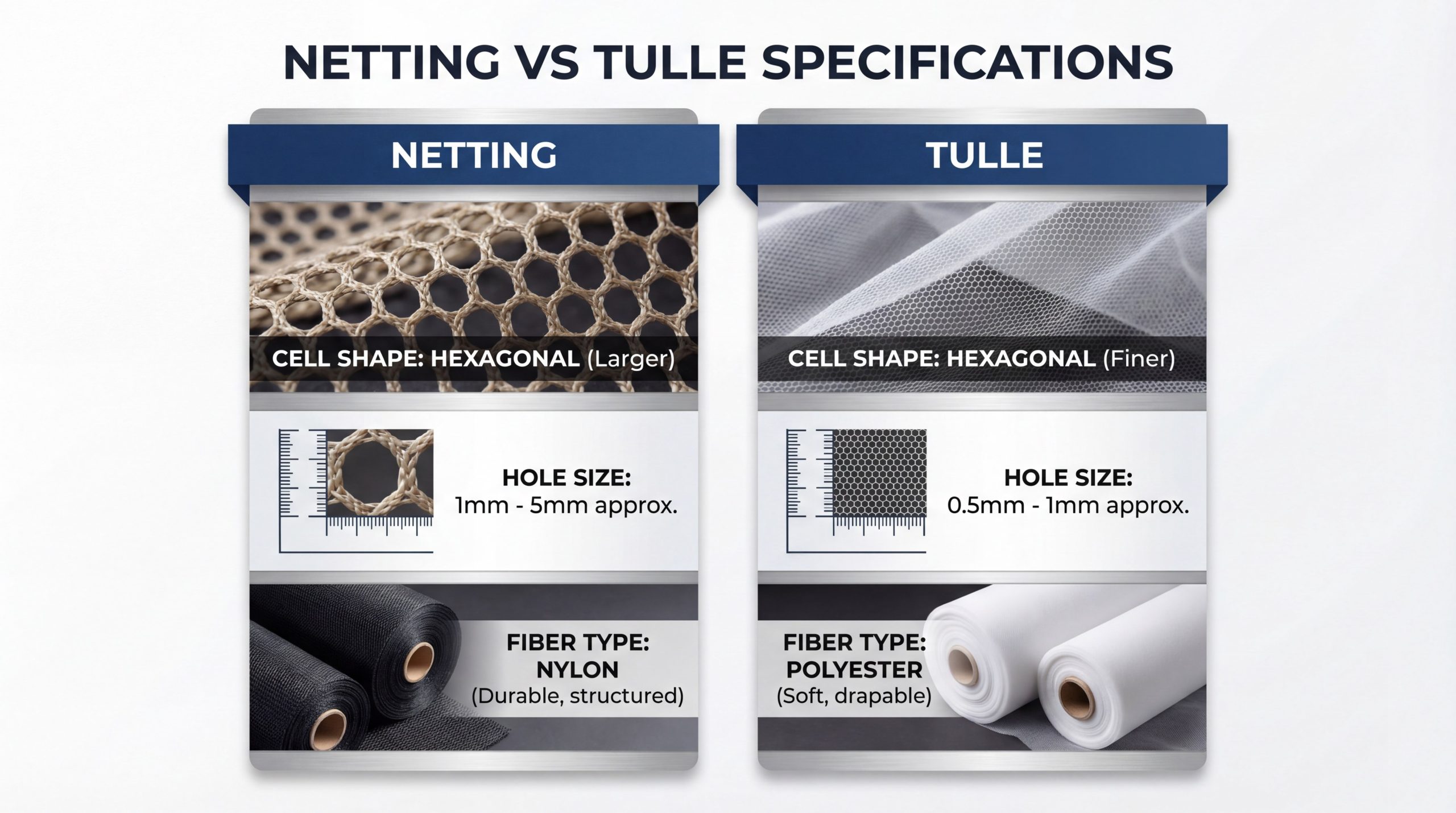

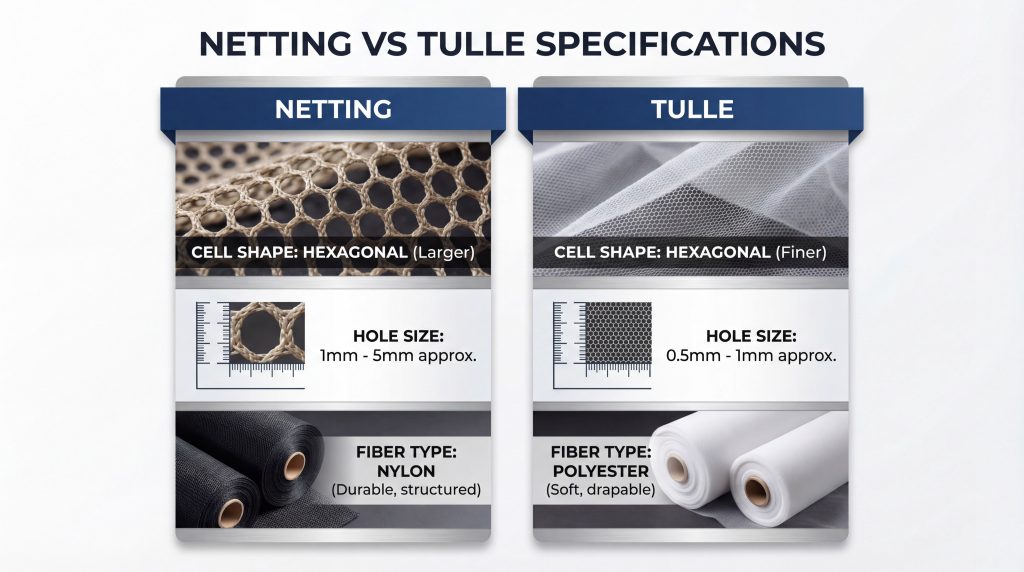

Analyzing the weave of netting vs tulle reveals that the physical differences are rooted in the fiber diameter and the size of the hexagonal cells. You can easily find high-quality tulle fabric options that emphasize these distinct mechanical properties.

Comparing hole size and hexagonal cell shapes

But wait, there’s more. While both fabrics typically feature a hexagonal “honeycomb” structure, the scale of these cells varies dramatically between the two types. Tulle cells are often nearly invisible to the naked eye, whereas netting cells are clearly defined.

- Tulle: Usually 0.5mm to 1mm apertures.

- Netting: Usually 1mm to 5mm apertures.

- Fiber: Nylon is standard, but silk offers a luxury alternative.

Key Takeaway and Summary Table

The cell size directly impacts the transparency and airflow of the material. By matching the hole size to your specific project needs, you avoid issues with snagging or structural collapse.

| Property | Tulle Specification | Netting Specification | |

|---|---|---|---|

| Aperture | Fine (Honeycomb) | Open (Grid-like) | |

| Flexibility | High Drape | Low Drape | |

| Durability | Delicate | High Resistance |

3. Which is better for volume: netting vs tulle?

Creating volume with netting vs tulle requires a strategic understanding of how each material reacts when gathered or pleated. While one provides a cloud-like puff, the other offers a structural “kick” that supports heavy outer fabrics.

Achieving structural loft with traditional dress net

Think about it. If you are designing a 1950s-style circle skirt, you need the rigid support of a classic dress net to keep the shape from sagging. This material is intentionally starched or treated to maintain its “loft” even under the weight of several yards of fabric.

- Layer multiple tiers for a graduated lift.

- Use horsehair braid at the hem for extra flare.

- Mix weights to achieve custom silhouettes.

Key Takeaway and Summary Table

For those seeking a softer romantic look, Bridal & Dress Tulle provides volume through sheer quantity of layers rather than individual fiber stiffness. This creates a more fluid movement when you walk.

| Goal | Tulle Method | Netting Method | |

|---|---|---|---|

| Loft Type | Soft Cloud Effect | Rigid Architectural Lift | |

| Layering | 10+ Layers Needed | 2-4 Layers Sufficient | |

| Movement | Fluid and Airy | Bouncy and Structured |

4. Does netting vs tulle affect bridal wear choices?

Brides often struggle with netting vs tulle decisions because the fabric sits so close to the skin and hair during the ceremony. You must browse through netting fabric collections to find the exact balance of transparency and comfort required for a wedding day.

Selecting the perfect material for veils and trains

The best part? Tulle is the traditional choice for veils because it drapes beautifully over the shoulders without obscuring the bride’s features. Conversely, netting is often used for the hidden structural layers of the skirt to prevent the gown from becoming a trip hazard.

Consider these bridal factors:

- Skin sensitivity (soft tulle is less itchy).

- Photography (finer mesh creates a better blur).

- Weight (netting can be lighter for massive skirts).

Key Takeaway and Summary Table

Selecting the wrong mesh for a veil can result in a stiff, “crunchy” look that ruins the romantic aesthetic. Balance the soft exterior with a sturdy interior net for the best results.

| Application | Tulle Preference | Netting Preference | |

|---|---|---|---|

| Veils | Primary Choice | Rarely Used | |

| Underskirts | For Softness | For Structure | |

| Illusion Necks | Extra Fine Only | Not Recommended |

5. Can you find stretch in netting vs tulle fabrics?

Stretching your options with netting vs tulle becomes necessary when you are designing for the body in motion. While traditional varieties are quite stable, modern innovations like Stretch / Power Mesh have changed the way we view these materials.

The mechanics of power mesh and four-way stretch

Check this out. Most standard tulles have very little give on the grainline but offer a slight mechanical stretch on the bias. If your project requires true elasticity, you must look for fabrics specifically engineered with elastane fibers.

- Power Mesh: High recovery for shapewear.

- Stretch Tulle: Softness combined with mobility.

- Usage: Ideal for dancewear and activewear inserts.

Key Takeaway and Summary Table

Using a non-stretch net in a tight-fitting bodice will lead to restricted movement and potential fabric tearing. Always test the stretch percentage before cutting your pattern.

| Category | Standard Tulle | Power Mesh / Net | |

|---|---|---|---|

| Elasticity | Minimal / Bias Only | High (4-Way) | |

| Recovery | Poor | Excellent | |

| Best For | Skirts & Decor | Body-con Garments |

6. Is glitter better applied to netting vs tulle?

Adding sparkle to netting vs tulle creates a magical effect, but the longevity of that sparkle depends on the base material’s surface area. You can find more tips on maintaining embellished fabrics on our fabric blog .

Evaluating sparkle retention and shed rates

Believe it or not. The tiny fibers of a fine tulle provide more “anchor points” for glitter adhesive than the wide, open spaces of a coarse net. This means glitter tulle typically sheds less than its netting counterpart while providing a more uniform shimmer.

- Glitter Tulle: Fine, misty sparkle.

- Sequin Net: Larger accents for stage wear.

- Durability: Both require gentle handling to prevent loss.

Key Takeaway and Summary Table

Sparkle fabrics are perfect for adding dimension, but they require specific sewing techniques to avoid damaging your machine. Choose tulle for a refined glow and net for bold, theatrical shimmer.

| Aesthetic | Tulle Glitter | Netting Accents | |

|---|---|---|---|

| Sparkle Density | High / Uniform | Sparse / Bold | |

| Shedding | Moderate | High | |

| Visual Effect | Romantic Shimmer | High-Contrast Glint |

7. What are the industrial uses for netting vs tulle?

Industrial safety uses netting vs tulle for everything from debris barriers to filtration systems. When browsing industry applications , you will see that technical specifications far outweigh aesthetic concerns in these sectors.

Technical mesh for filtration and safety barriers

The bottom line. Industrial netting is designed for tensile strength and UV resistance rather than hand-feel. It is often used in construction or agriculture where a fine tulle would simply disintegrate under environmental pressure.

- Cargo nets for securing heavy loads.

- Safety barriers for industrial machinery.

- Fine mesh filters for liquid processing.

Key Takeaway and Summary Table

Utility and safety require a mesh that can withstand friction and tension. While tulle is relegated to aesthetic roles, industrial netting serves as a critical component in infrastructure and logistics.

| Metric | Industrial Net | Technical Tulle | |

|---|---|---|---|

| Strength | Very High | Low | |

| Weathering | UV Resistant | Sun-Sensitive | |

| Standard | Load-Bearing | Decorative |

8. How do experts decide between netting vs tulle?

Experts distinguish between netting vs tulle by performing “hand-feel” and “scrunch” tests to determine the fabric’s memory. You can explore our full tulle catalog to see how different finishes react to these professional evaluations.

Drape testing and hand-feel evaluations

Here is the kicker. A designer will often “scrunch” a handful of fabric to see if it bounces back immediately or remains crushed. Tulle typically has a softer memory, while stiff netting will fight back against the hand, indicating its structural potential.

- Softness Test: Rub against the inner wrist.

- Memory Test: Squeeze and release to check wrinkles.

- Sheer Test: Overlay on colors to check opacity.

Key Takeaway and Summary Table

The “hand” of the fabric refers to how it feels and moves. Mastering this sensory evaluation allows you to predict how the fabric will behave once it is sewn into a complex garment.

| Test | Tulle Result | Netting Result | |

|---|---|---|---|

| Scrunch | Soft Collapse | Resilient Bounce | |

| Friction | Smooth Glide | Rough / Catchy | |

| Drape | Elegant Fold | Angular / Sharp |

9. Which handles heavy loads: netting vs tulle?

For heavy gear, netting vs tulle is a one-sided competition where durability is the only metric that matters. Specialized Bag & Luggage Mesh is engineered to carry significant weight without stretching out of shape or tearing at the seams.

Specialized utility mesh for bags and luggage

As a result. You will find that high-denier nylon netting is the gold standard for backpack pockets and laundry bags. Tulle is far too delicate for these applications and would tear the moment it was caught on a zipper or sharp edge.

- Abrasion Resistance: High for coated nets.

- Visibility: Excellent for finding items in luggage.

- Ventilation: Essential for sports and gym gear.

Key Takeaway and Summary Table

Utility mesh must balance weight with strength. While it may look similar to dress net, luggage mesh is often thicker and coated with PVC or similar polymers for maximum lifespan.

| Feature | Utility Netting | Fashion Tulle | |

|---|---|---|---|

| Weight Capacity | High | Negligible | |

| Coating | PVC / Polyurethane | Uncoated | |

| Abrasion | Resistant | Very Susceptible |

10. How do you sew with netting vs tulle successfully?

Sewing through netting vs tulle can be a nightmare if you don’t adjust your machine’s tension and needle size. Interestingly enough, the very holes that make these fabrics beautiful are what cause machines to “eat” the fabric at the start of a seam.

Optimizing machine settings and needle selection

To prevent your machine from chewing the fabric, you should always start your seam on a small piece of water-soluble stabilizer. Using a sharp needle ensures that the tip pierces the fine fibers rather than pushing them down into the needle plate.

- Needle: Size 60/8 or 70/10 Sharps.

- Stitch: Narrow zigzag for stretch, straight for stable.

- Thread: High-quality polyester for strength.

Key Takeaway and Summary Table

Finishing the edges is purely aesthetic as these fabrics do not fray. However, using bias binding on the raw edges of stiff netting is highly recommended to prevent skin irritation.

| Component | Tulle Setup | Netting Setup | |

|---|---|---|---|

| Needle Type | Microtex / Sharp | Universal / Sharp | |

| Stitch Length | 2.0mm – 2.5mm | 2.5mm – 3.0mm | |

| Edge Finish | Raw or Rolled | Bias Bound / Taped |

Conclusion

Mastering the netting vs tulle distinction solves the common problems of garment discomfort, structural failure, and sewing frustration. By understanding the technical differences in hole size, stiffness, and load-bearing capacity, you can ensure every project—from a bridal veil to an industrial barrier—is built for success. For expert guidance on your specific material needs or to inquire about bulk orders, please contact us today.

Frequently Asked Questions (FAQs)

- Can I machine wash these fabrics safely?Most nylon-based versions are safe in a mesh bag on a delicate cycle, but air drying is mandatory.

- What’s the best way to cut narrow strips?A rotary cutter paired with a metal ruler provides the cleanest, most professional edges.

- How do I know if the heat will melt it?Assume all synthetic mesh will melt; always use a pressing cloth and the lowest iron setting.

- Can I use these for outdoor event decor?Yes, but stiff netting is superior for holding shapes against the wind and resisting UV damage.

- What’s the best needle for fine mesh?A size 60/8 Sharp needle is the ideal choice to prevent snagging the delicate cell structure.