Understanding performance features in activewear mesh involves evaluating how moisture-wicking, anti-microbial treatments, and breathability work together to optimize athlete comfort and endurance.

Many designers face the frustration of fabrics that look great on the rack but fail in the gym. Traditional materials often trap sweat against the skin, leading to heavy garments and restricted movement. This creates a significant risk of overheating and facilitates rapid bacterial growth, which results in permanent odors and skin irritation for the end-user. The ultimate solution is integrating high-performance athletic mesh fabric into your collection to ensure garments stay light, dry, and fresh during even the most intense training sessions.

Why choose performance athletic mesh fabric?

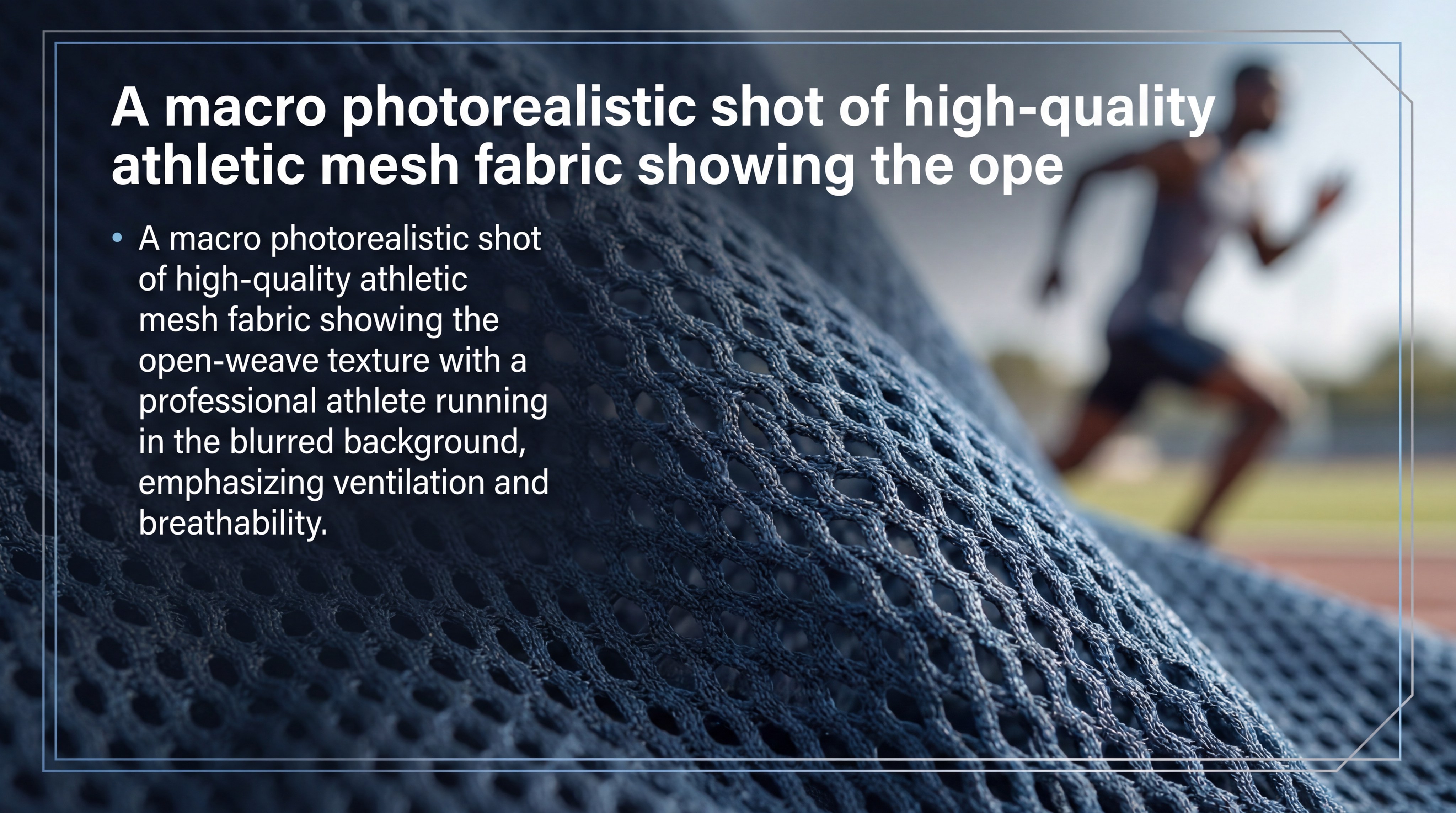

Choosing performance athletic mesh fabric is essential because its open-cell structure provides the critical ventilation needed to regulate core body temperature during peak physical exertion. This specialized fabric prevents the “cling” associated with sweat-soaked garments, allowing athletes to maintain their focus on performance rather than discomfort.

What are the primary benefits for athletes?

Here is the kicker: High-quality mesh does more than just look sporty; it functions as a second skin.

- Enhanced Airflow: Maximizes oxygen exchange at the skin level.

- Weight Reduction: Minimizes garment load during endurance activities.

- Temperature Control: Facilitates rapid heat dissipation.

How does breathability impact workout stamina?

But that is not all. When an athlete overheats, the heart works harder to cool the body, which can decrease muscle efficiency.

- Lower Heart Rate: Proper cooling reduces physiological stress.

- Reduced Fatigue: Less energy is wasted on thermoregulation.

Key Takeaway: Performance mesh serves as a physiological tool that helps athletes maintain peak output for significantly longer periods.

| Feature | Standard Mesh | Performance Athletic Mesh | |

|---|---|---|---|

| Air Permeability | Moderate | High | |

| Weight | Variable | Ultra-lightweight | |

| Durability | Low to Mid | High-Reinforced |

Analysis: Performance mesh outclasses standard alternatives by prioritizing high air permeability and reinforced durability, making it the superior choice for professional-grade gear.

Does athletic mesh fabric offer enough compression?

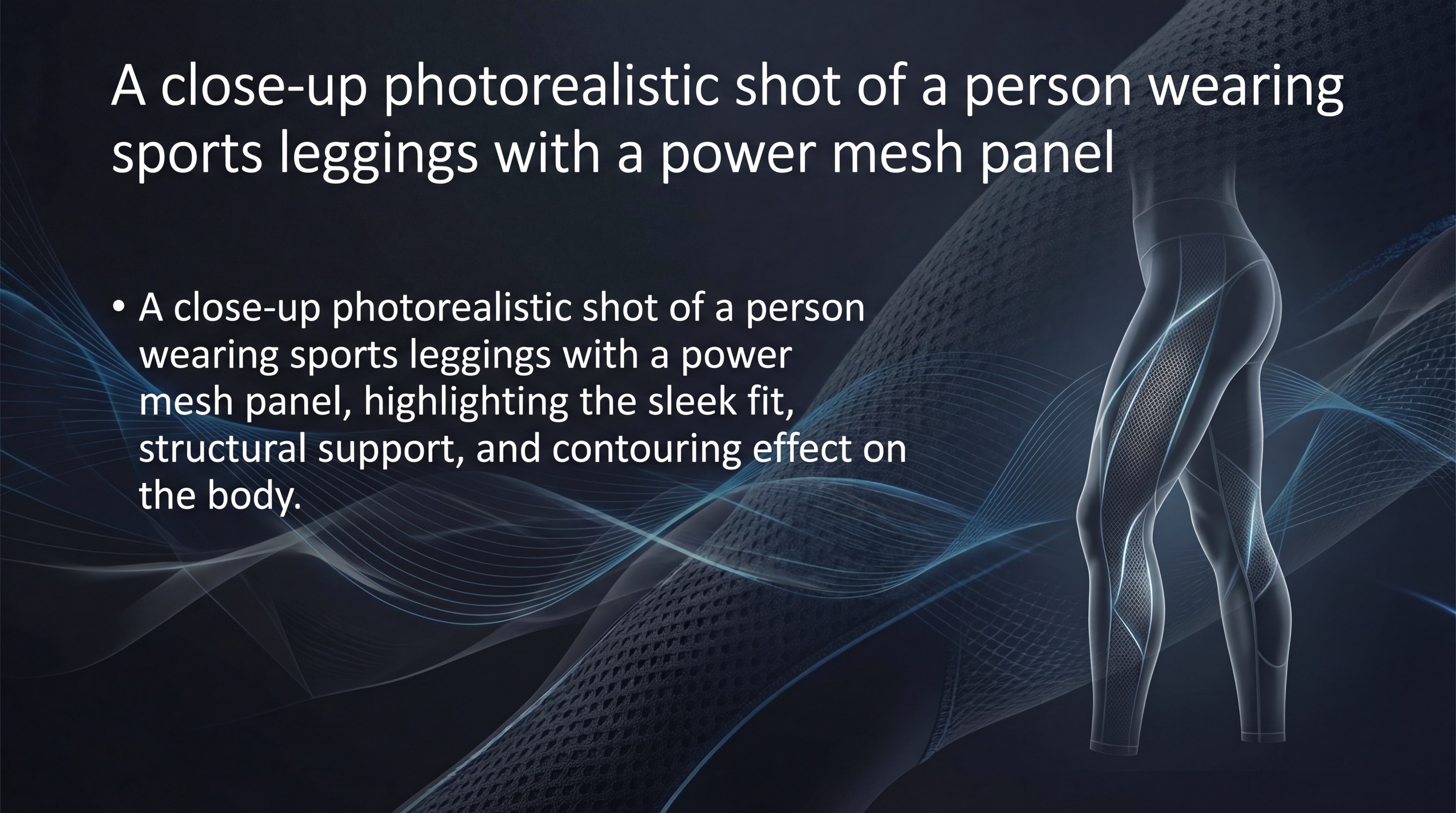

Athletic mesh fabric can provide exceptional compression and structural support when engineered with high spandex content, such as in power mesh varieties. These fabrics are specifically designed to snap back to their original shape, offering the necessary tension for high-impact activities.

How does power mesh improve garment fit?

It gets even better: Power mesh allows for targeted support without the bulk of traditional heavy-knit fabrics.

- Contouring: Provides a sleek, sculpted appearance.

- Stability: Keeps waistbands and straps securely in place.

- Flexibility: Moves dynamically with the body’s movements.

Can it provide muscle support during high impact?

Believe it or not. Compression mesh panels can reduce muscle oscillation, which is a major contributor to fatigue during running or jumping.

- Vibration Control: Stabilizes muscle tissues.

- Recovery Support: May improve blood flow during active use.

Key Takeaway: Modern compression mesh provides functional support and body-sculpting benefits without sacrificing the cooling advantages of a ventilated structure.

| Support Level | Purpose | Recommended Mesh Type | |

|---|---|---|---|

| Light | Overlays/Liners | Soft Tulle Mesh | |

| Medium | Ventilation Panels | Standard Performance Mesh | |

| High | Waistbands/Bras | Power Mesh |

Analysis: The variety in mesh density allows designers to choose specific support levels tailored to the garment’s functional requirements.

How does athletic mesh fabric manage moisture?

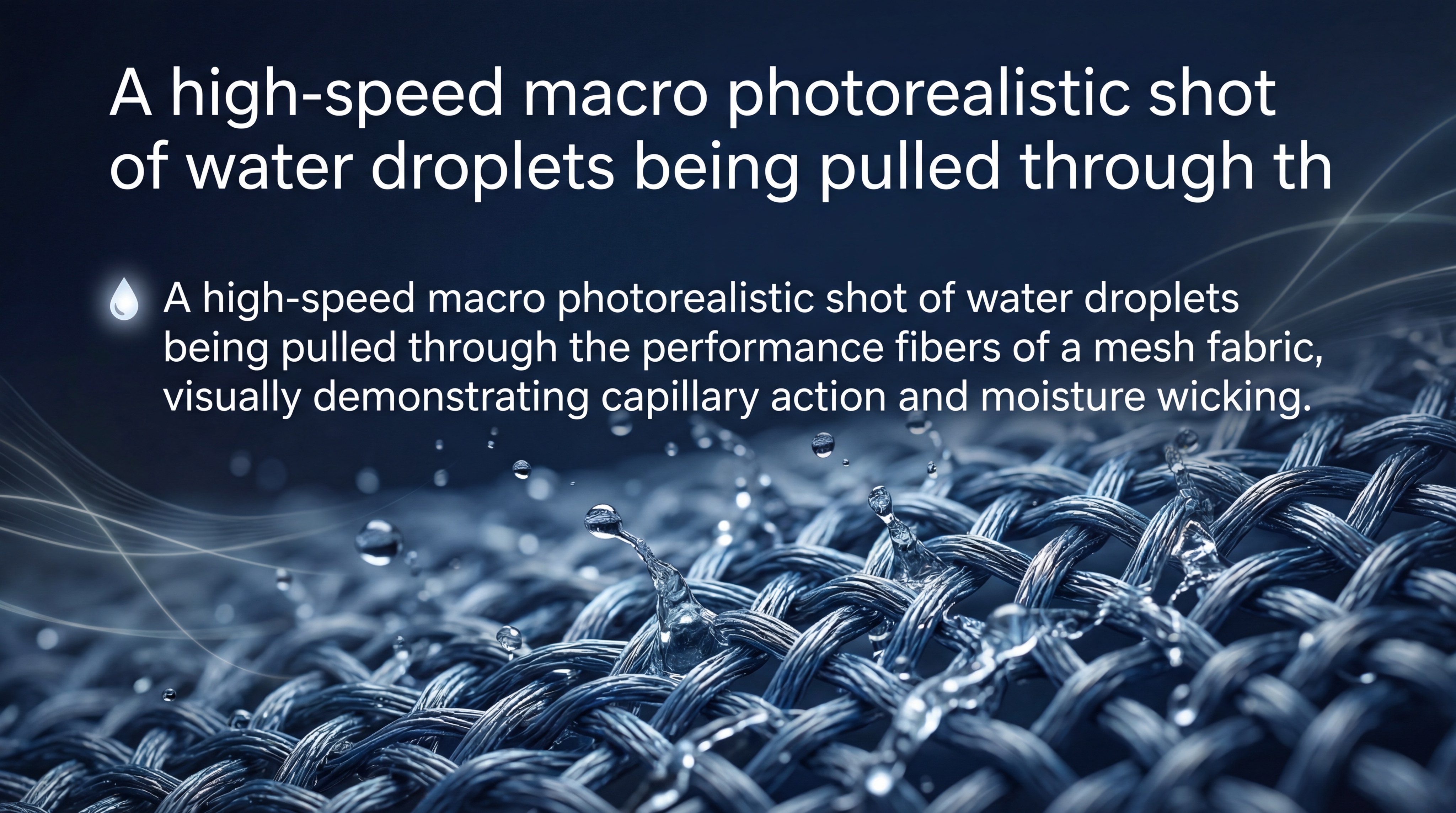

Managing moisture in athletic mesh fabric is achieved through advanced wicking technology that pulls perspiration away from the skin to the fabric’s outer surface. This mechanical process ensures that sweat evaporates quickly, keeping the wearer dry and comfortable throughout their workout.

What is the science behind capillary action?

Think about it: Capillary action involves fibers that are physically shaped to transport liquid via microscopic channels.

- Hydrophobic Inner: Repels water to keep the skin dry.

- Hydrophilic Outer: Attracts moisture to the surface for evaporation.

- Increased Surface Area: Speeds up the drying process.

Why is quick-dry technology essential for runners?

The best part? For long-distance athletes, a heavy, wet garment causes friction that leads to painful skin chafing.

- Friction Reduction: Dry fabric glides over the skin.

- Consistent Weight: Prevents the garment from becoming heavy mid-run.

Key Takeaway: Wicking is a fundamental performance feature that prevents post-workout “chilling” and protects the skin from irritation.

| Property | Function | Result | |

|---|---|---|---|

| Wicking | Moves sweat away | Skin stays dry | |

| Evaporation | Releases moisture | Fabric stays light | |

| Breathability | Cycles air | Body stays cool |

Analysis: Effective moisture management requires a balance of wicking and evaporation to ensure the garment never becomes a burden to the athlete.

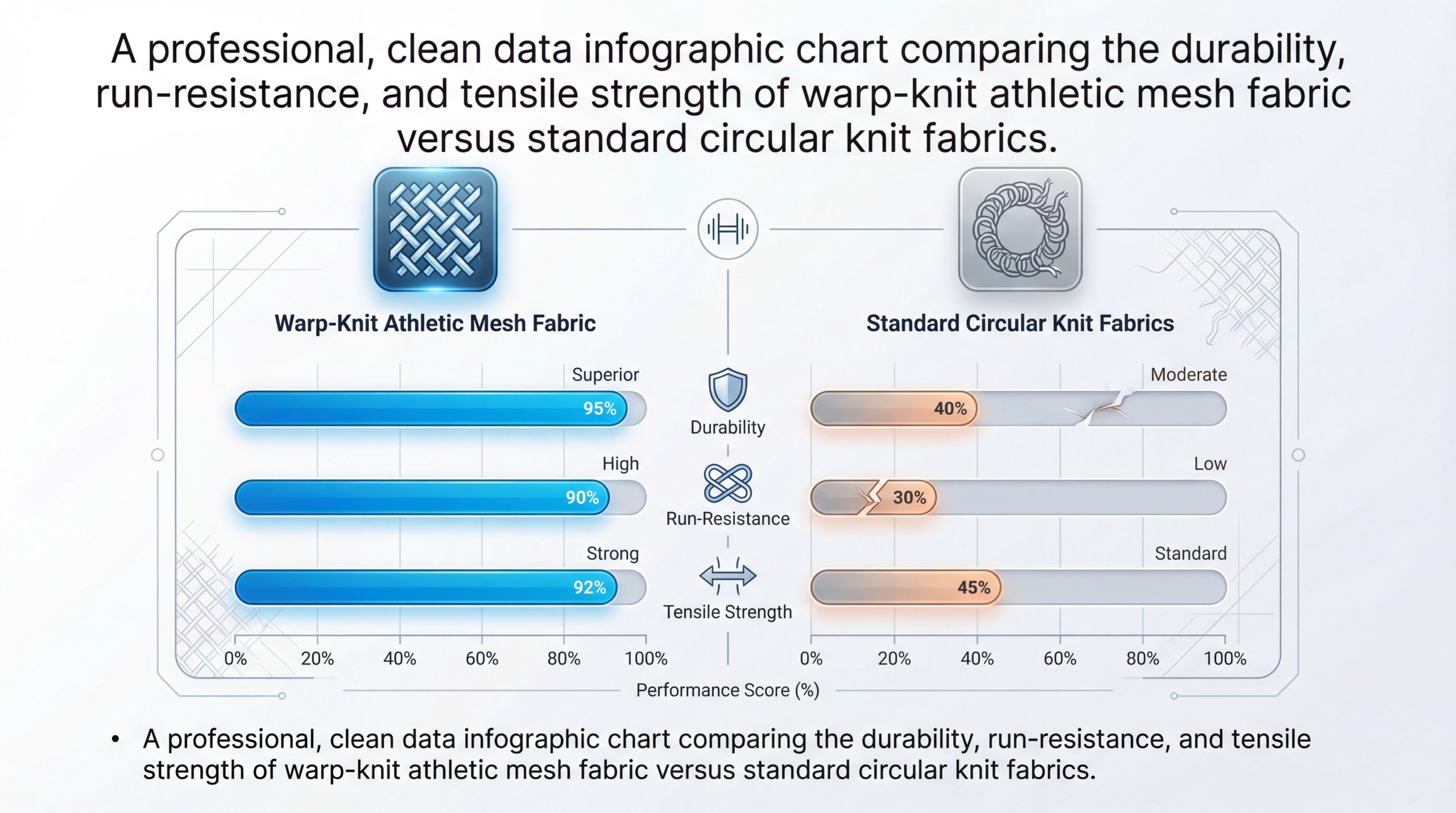

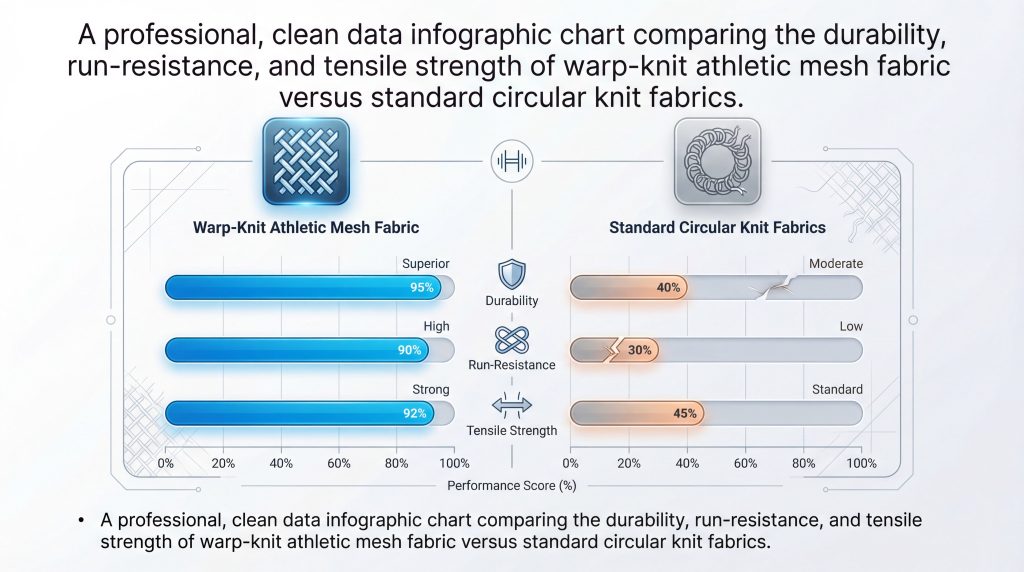

Is warp knit athletic mesh fabric more durable?

Warp knit athletic mesh fabric is significantly more durable than circular knit alternatives due to its unique zigzag stitch construction that prevents unraveling. This structural integrity makes it the gold standard for garments exposed to high levels of friction and abrasion.

Why does the knit structure prevent running?

Make no mistake: The way the yarns are interlocked in warp knitting creates a “run-resistant” fabric that maintains its shape.

- Locked Loops: Prevents small snags from becoming large holes.

- Dimensional Stability: Resists stretching out over time.

- Tear Resistance: Ideal for contact sports and outdoor activities.

Does it hold up against frequent industrial washing?

Check this out. Professional team uniforms must withstand aggressive washing cycles without losing their vibrant color or structural strength.

- Launderability: Maintains performance features after 50+ washes.

- Shape Retention: Does not “bag out” at the knees or elbows.

Key Takeaway: Investing in warp knit mesh ensures a higher lifecycle for the garment, providing better value for the consumer and the brand.

| Knit Category | Durability Score | Stretch | Best Application | |

|---|---|---|---|---|

| Warp Knit | 95% | 2 or 4-way | Pro Sports Gear | |

| Circular Knit | 40% | High 4-way | Fashion Athleisure |

Analysis: Warp knit technology is objectively superior for high-performance applications where garment failure is not an option.

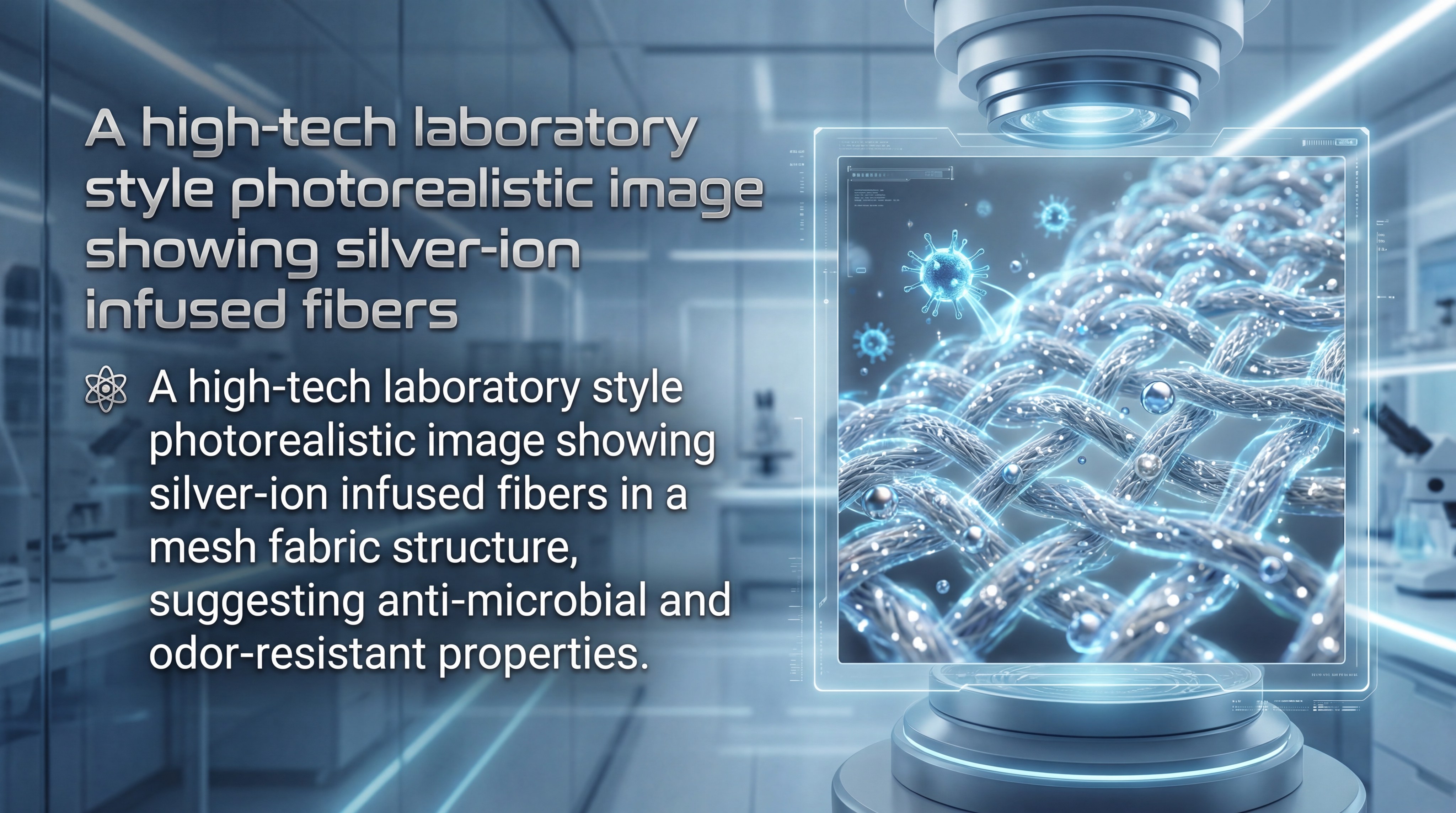

Can athletic mesh fabric prevent odor buildup?

Modern athletic mesh fabric can effectively prevent odor buildup by incorporating anti-microbial treatments that inhibit the growth of odor-causing bacteria. These finishes target the microscopic environment where bacteria thrive, ensuring the garment smells fresh even after intense use.

How do silver-ion finishes kill bacteria?

Wait, there is more: Silver-ion and zinc-based treatments disrupt the cellular membranes of microbes to stop them from multiplying.

- Odor Suppression: Stops the “gym smell” at the source.

- Hygienic Surface: Keeps the fabric cleaner between washes.

- Long-lasting Protection: Often lasts for the entire life of the garment.

Will anti-microbial treatments wash out over time?

What does this mean for you? High-end performance meshes have the anti-microbial properties embedded within the fiber itself rather than just coated on the surface.

- Wash Permanence: Retains efficacy after dozens of laundry cycles.

- Eco-finishes: Newer options use plant-based extracts for a greener profile.

Key Takeaway: Anti-microbial features are a powerful marketing tool for premium brands catering to athletes who “wear more and wash less.”

| Finish Type | Mechanism | Sustainability | |

|---|---|---|---|

| Silver Ion | Chemical disruption | Moderate | |

| Zinc Based | Mineral barrier | High | |

| Botanical | Natural acid | Exceptional |

Analysis: Integrating anti-microbial technology adds a layer of invisible value that significantly enhances the long-term wearer experience.

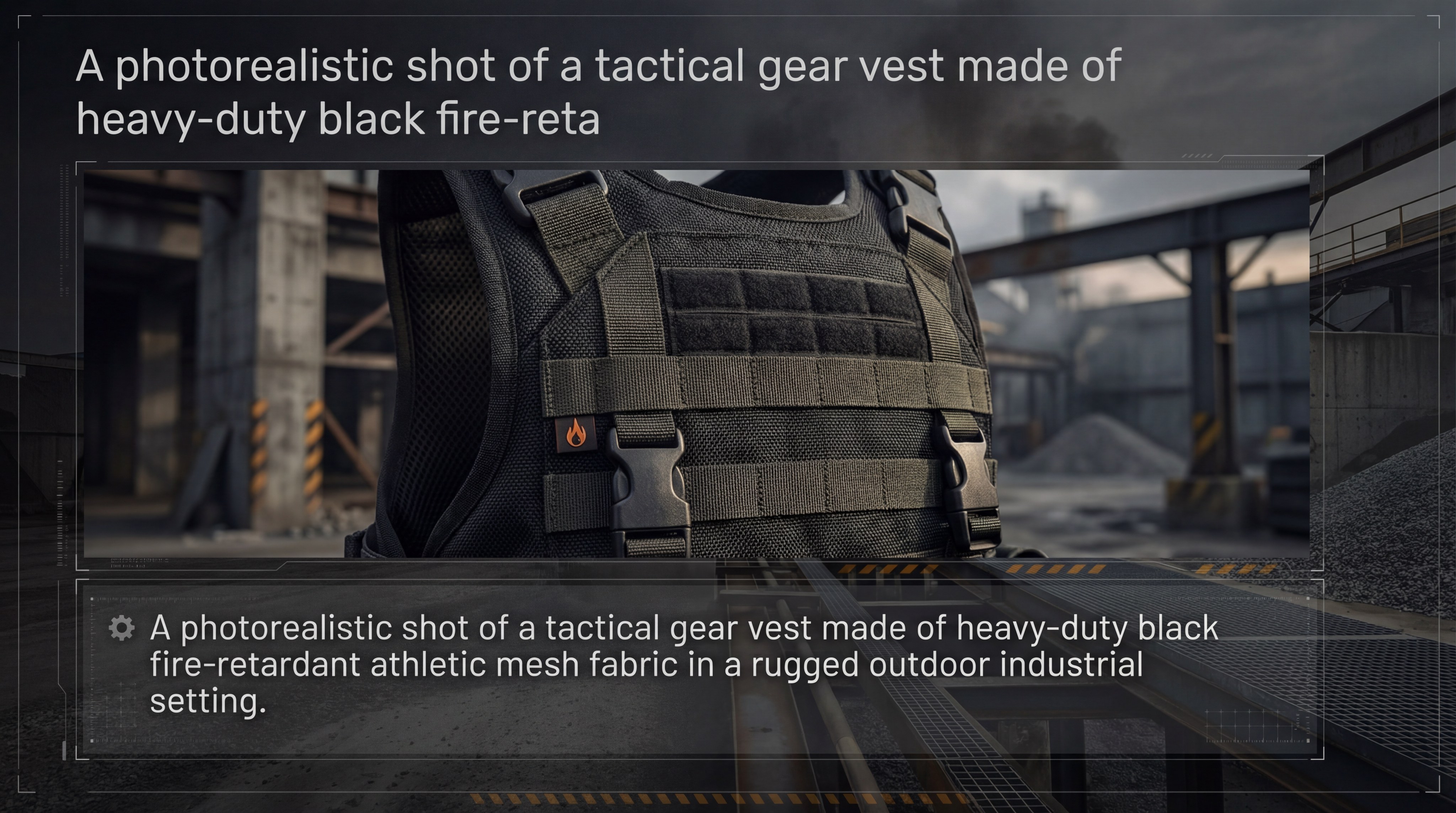

Is fire-resistant athletic mesh fabric necessary?

Fire-resistant athletic mesh fabric is a specialized requirement for industries such as motor racing, military training, and high-risk industrial safety sectors. While not standard for a yoga studio, these fabrics provide a life-saving barrier in environments where heat and flame exposure are daily risks.

Which industries require FR certifications?

Here is the kicker: Sectors that prioritize safety above all else rely on mesh for its breathability during dangerous tasks.

- Auto Racing: Base layers for drivers under fire suits.

- Tactical Gear: Cooling panels in heavy-duty vests.

- Industrial Safety: High-visibility vests for utility workers.

Does safety treatment affect the fabric hand-feel?

But that is not all. Modern FR technology has advanced to ensure that safety certifications do not result in a stiff or scratchy texture.

- Soft Hand-feel: Maintains comfort for long shifts.

- Lightweight Specs: Does not add unnecessary bulk to gear.

Key Takeaway: For tactical and safety niches, FR certification is a non-negotiable performance feature that ensures professional compliance.

| Sector | Requirement | Performance Priority | |

|---|---|---|---|

| Military | FR + Anti-Odor | Durability | |

| Motorsport | FR + Wicking | Thermal Protection | |

| Public Safety | FR + High-Vis | Breathability |

Analysis: FR mesh bridges the gap between protective industrial gear and the comfort requirements of athletic performance.

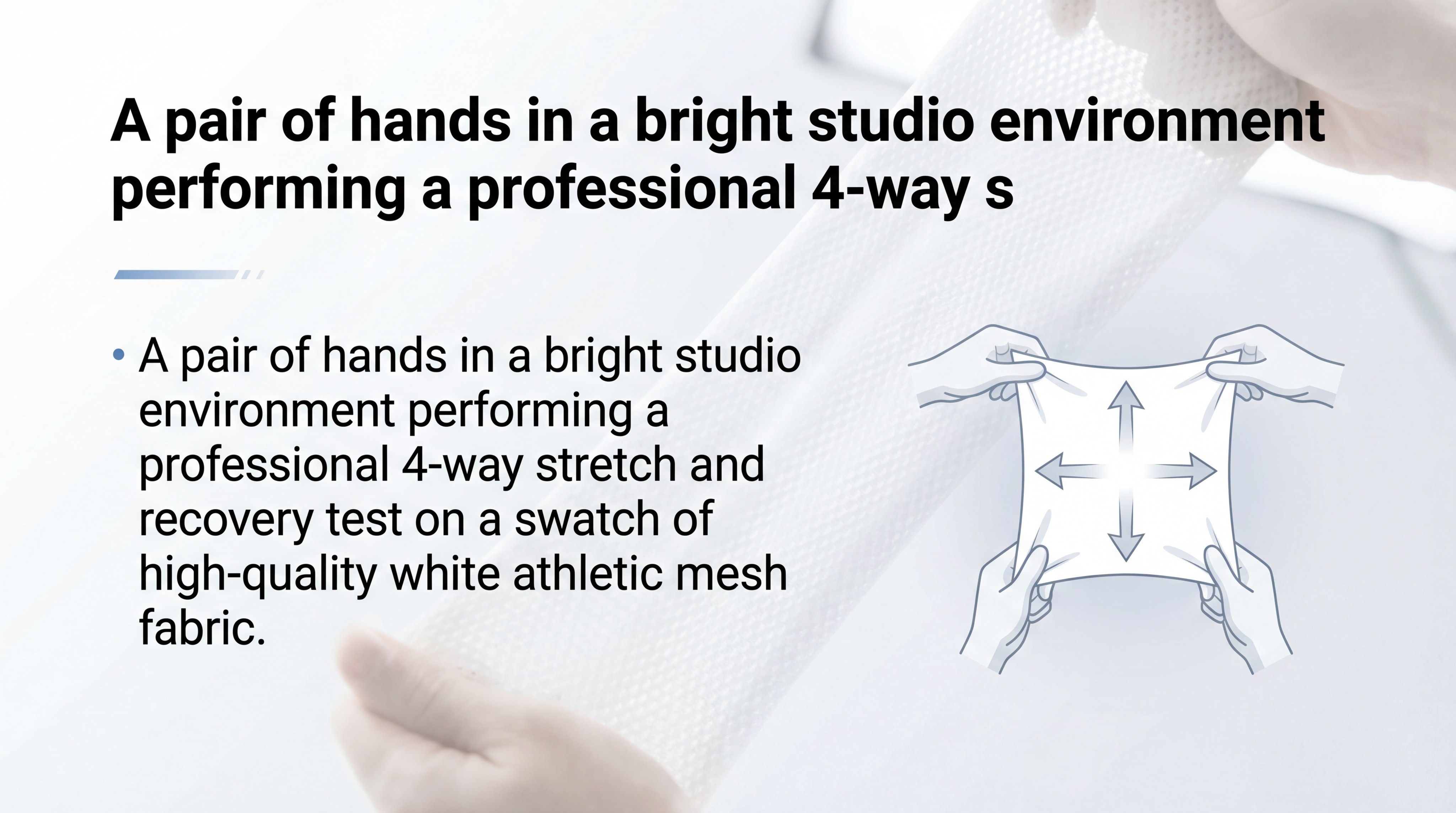

What defines quality in athletic mesh fabric?

Quality in athletic mesh fabric is defined by its ability to maintain stretch and recovery metrics while providing consistent opacity and colorfastness. Professional testers look for fabrics that return to their original dimensions after being stressed, ensuring the garment doesn’t lose its shape over time.

How do you measure stretch and recovery?

It gets even better: The industry standard for high-quality mesh is a recovery rate of at least 75% to 90% after stretching.

- ASTM Testing: Standardized methods to verify fabric limits.

- Elastic Longevity: High-grade spandex ensures the fabric doesn’t snap.

- Load Capacity: How much tension the mesh can hold without tearing.

What weight is best for performance leggings?

Check this out. The GSM (grams per square meter) determines whether the fabric is suitable for a liner or a primary structural panel.

- Light (80-120 GSM): Best for interior lining.

- Mid (150-200 GSM): Ideal for ventilation panels.

- Heavy (220+ GSM): Suitable for full-garment construction.

Key Takeaway: Always verify the technical data sheets (TDS) for stretch and recovery to prevent brand-damaging garment failure.

| Metric | High Quality | Low Quality | |

|---|---|---|---|

| Recovery | 90% | < 60% | |

| Colorfastness | Level 4-5 | Level 2-3 | |

| Shrinkage | < 3% | > 8% |

Analysis: High-quality mesh is characterized by superior recovery and minimal shrinkage, ensuring a long-lasting professional fit.

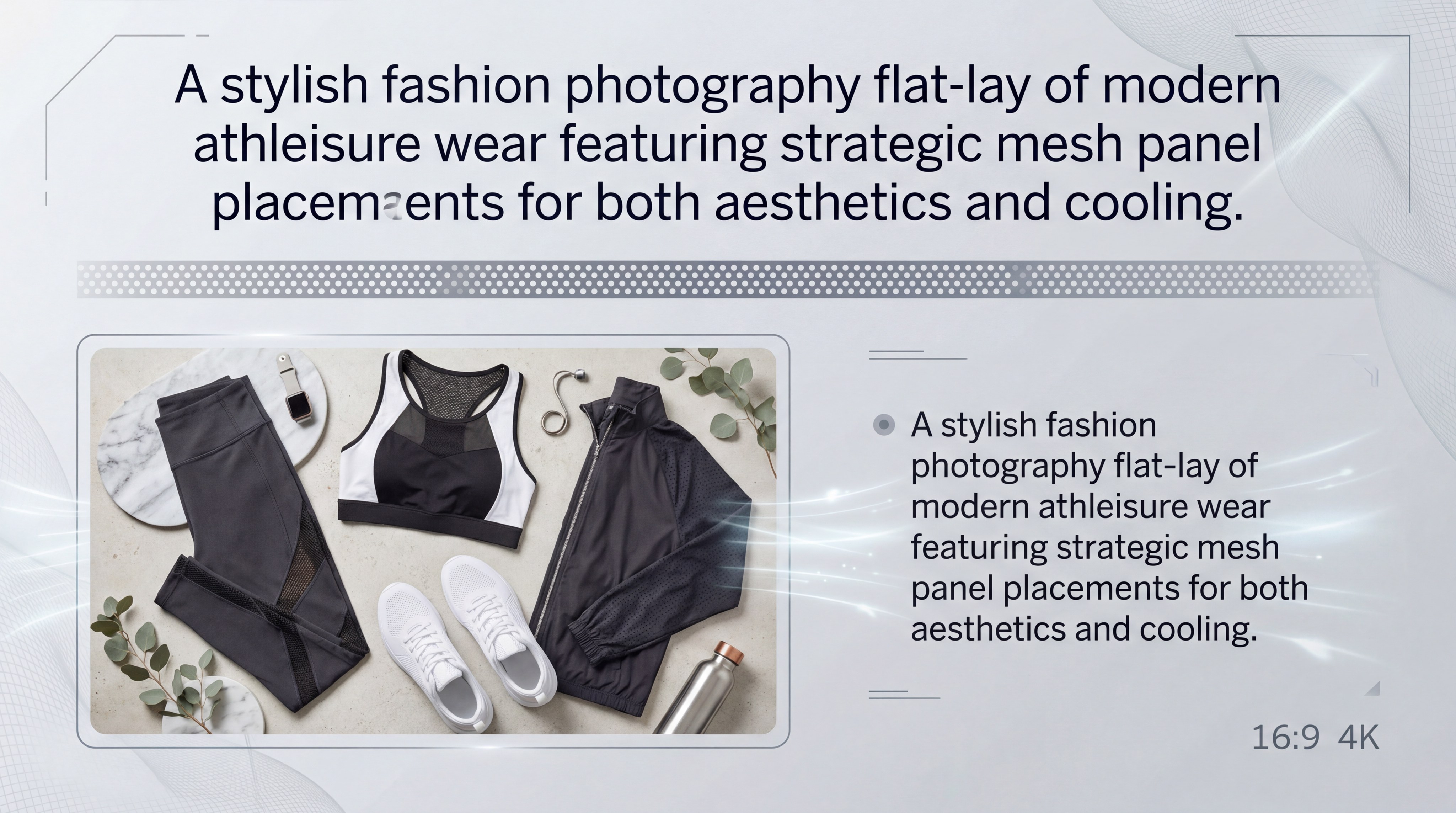

How to style athletic mesh fabric in designs?

Styling athletic mesh fabric involves more than just aesthetics; it is about placing ventilation in high-heat zones to maximize the garment’s functional efficiency. Designers use mesh to create visual interest while providing the cooling benefits that consumers expect from modern athleisure.

Are mesh panels better for ventilation or aesthetics?

Think about it: Strategic placement of mesh can slim the silhouette while serving a critical cooling function.

- Heat Zones: Placed behind knees, under arms, and along the spine.

- Visual Contrast: Mixes textures for a technical, high-end look.

- Layering: Provides depth in multi-piece outfits.

Can you sublimate prints onto performance mesh?

The best part? Polyester mesh is an excellent canvas for sublimation, allowing for vibrant, custom-branded designs without clogging the holes.

- Permanent Ink: Won’t fade or peel during exercise.

- Breathable Prints: Maintains the fabric’s air permeability.

Key Takeaway: Strategic mesh placement increases both the retail price point and the actual performance rating of the garment.

| Design Goal | Best Placement | Impact | |

|---|---|---|---|

| Cooling | Underarms/Upper Back | Maximum Airflow | |

| Slimming | Side Leg Panels | Visual Contouring | |

| Support | Inner Waistband | Hidden Compression |

Analysis: Mesh is a versatile design tool that allows for a perfect marriage of high-fashion aesthetics and technical performance.

Is eco-friendly athletic mesh fabric available?

Eco-friendly athletic mesh fabric is widely available today, primarily through the use of GRS-certified recycled polyester (rPET) derived from post-consumer plastic bottles. This shift toward sustainability does not require a compromise on performance, as recycled fibers offer the same wicking and durability as virgin materials.

What are the benefits of recycled polyester?

Believe it or not. Using recycled materials drastically reduces the carbon footprint of your production line.

- Resource Savings: Uses significantly less water and energy.

- Waste Diversion: Keeps plastic bottles out of landfills and oceans.

- Market Appeal: Attracts the growing demographic of eco-conscious buyers.

Does sustainable mesh maintain high performance?

Wait, there is more: Modern manufacturing ensures that recycled fibers are indistinguishable from virgin polyester in terms of strength and hand-feel.

- Identical Specs: Maintains wicking and anti-microbial capabilities.

- Global Standards: Certified by the Global Recycled Standard (GRS).

Key Takeaway: Transitioning to recycled mesh allows your brand to market “performance with a conscience,” a powerful narrative for modern consumers.

| Material | Energy Savings | Water Savings | Performance | |

|---|---|---|---|---|

| Virgin Poly | 0% | 0% | High | |

| Recycled Poly | 30-50% | 20% | High |

Analysis: Recycled mesh offers an identical performance profile to virgin polyester while providing significant environmental benefits.

Where to source premium athletic mesh fabric?

Sourcing premium athletic mesh fabric directly from specialized manufacturers ensures you receive the highest technical standards and the most competitive pricing. Working with a factory-direct partner allows for custom specifications, lower minimum order quantities, and consistent quality control across production batches.

Why is factory-direct sourcing more efficient?

Make no mistake: Cutting out the middleman gives you direct access to the engineers who understand the fabric’s performance limits.

- Custom Development: Request specific weight or stretch profiles.

- Faster Lead Times: Direct communication speeds up production.

- Quality Assurance: Access to OEKO-TEX and Bluesign certifications.

How can you request custom color matching?

Check this out. Most premium suppliers use Lab Dips to ensure your brand’s specific color palette is perfectly replicated across different fabric types.

- Pantone Matching: Consistent results across your entire line.

- Physical Swatches: Test the color under different lighting conditions.

Key Takeaway: Always request a performance sample to personally test the wicking and anti-microbial claims before committing to a large order.

| Source Type | Pricing | Customization | Quality Control | |

|---|---|---|---|---|

| Wholesaler | Higher | Low | Variable | |

| Factory Direct | Lower | High | Direct/Strict |

Analysis: Factory-direct sourcing is the most strategic path for B2B brands looking to scale with consistent quality and custom technical features.

Ready to Elevate Your Activewear Line?

Understanding the intricacies of wicking, anti-microbial finishes, and knit structures is what separates a basic garment from a performance powerhouse. If you are ready to source high-performance mesh that meets these rigorous standards, contact us today to request samples or a custom quote for your next project.

FAQ

Can I use mesh for the entire garment?Yes, but ensure the GSM is high enough for opacity or use strategic lining in critical areas.

What is the best way to clean performance mesh?Wash in cold water with similar colors and avoid fabric softeners, which can clog wicking fibers.

Can I print my brand logo on anti-microbial mesh?Absolutely, sublimation and high-quality screen printing work well without compromising the anti-microbial treatment.

Is power mesh the same as standard stretch mesh?No, power mesh has a significantly higher spandex percentage and is designed for structural compression.

What is the minimum order quantity for custom colors?MOQs typically start at 100 to 500 meters depending on the factory and the specific fabric type.