Stretch fabric is a textile specifically engineered with elastic fibers to allow for expansion and contraction without permanent deformation. For many B2B manufacturers, relying on traditional, rigid textiles creates significant barriers in product development and user satisfaction. This lack of flexibility often results in restrictive movements and discomfort, which can compromise the functional integrity of high-performance garments or industrial applications. By integrating 4-Way Stretch Mesh into your design pipeline, you provide the multidimensional elasticity required to meet modern ergonomic demands. You can discover more about these textile advancements on our blog .

What Defines the Utility of 4-Way Stretch Mesh?

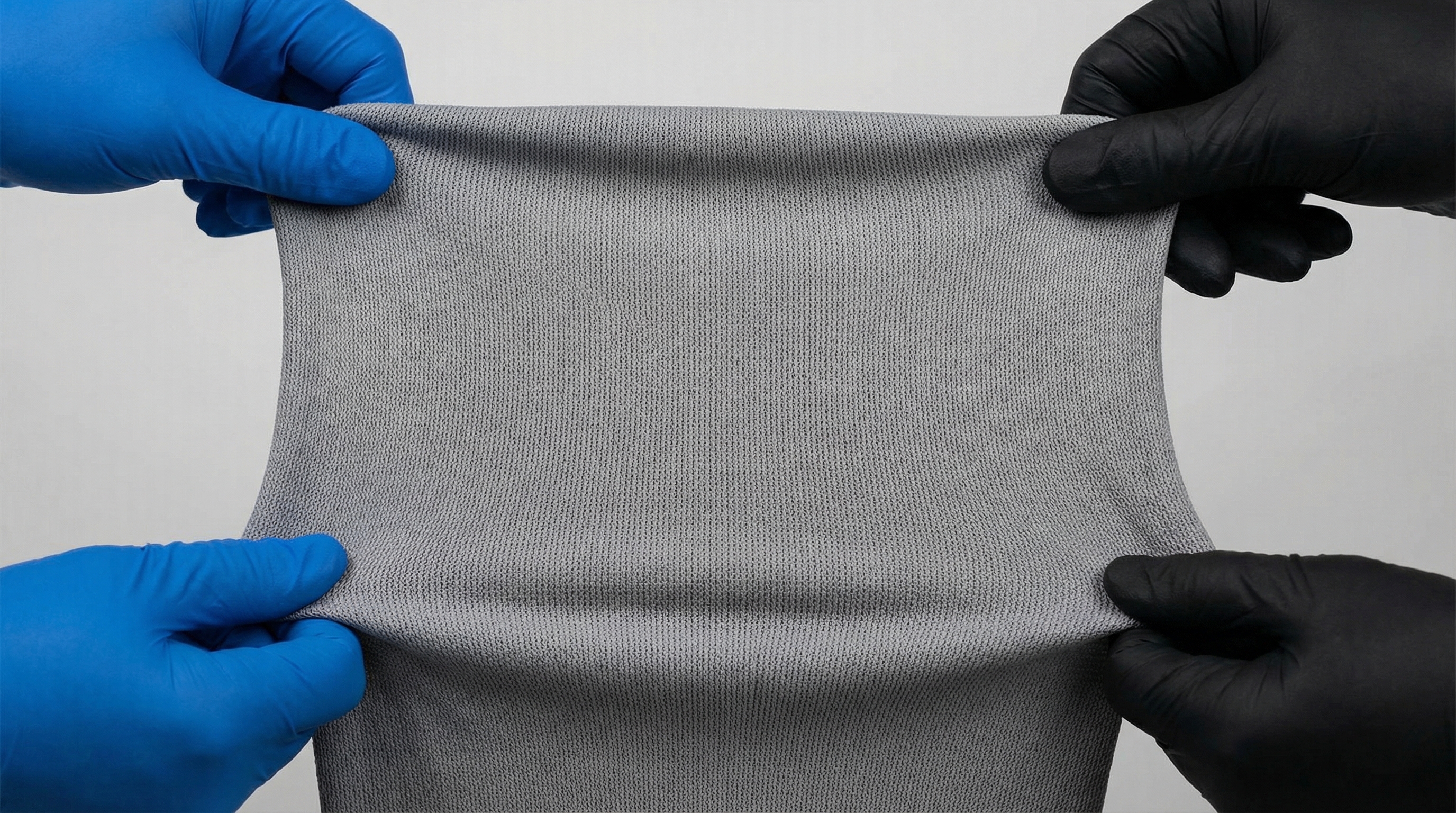

4-Way Stretch Mesh is defined by its ability to expand both crosswise and lengthwise, providing a full range of motion for technical applications. This material serves as the backbone for industries requiring high-performance textiles that move with the user. You will find that its porous structure also facilitates breathability, making it a dual-purpose solution for comfort and utility.

Essential Performance Characteristics

When you evaluate textiles for technical specifications, the multidirectional recovery of the mesh stands out as its most vital asset. It ensures that the fabric does not sag or lose its shape after repetitive cycles of stress.

- High tensile strength across both axes.

- Immediate recovery to original dimensions.

- Enhanced airflow through open-weave patterns.

The best part? You don’t have to sacrifice durability for the sake of flexibility when using premium technical knits.

Key Takeaway

The primary utility of this mesh lies in its balanced elasticity, which supports both horizontal and vertical movement simultaneously. To better understand the functional capabilities of this textile, consider the following performance metrics:

| Metric | Performance Level | Benefit | |

|---|---|---|---|

| Vertical Stretch | 50% – 100% | Longitudinal mobility | |

| Horizontal Stretch | 50% – 100% | Latitudinal expansion | |

| Breathability | High | Thermal regulation |

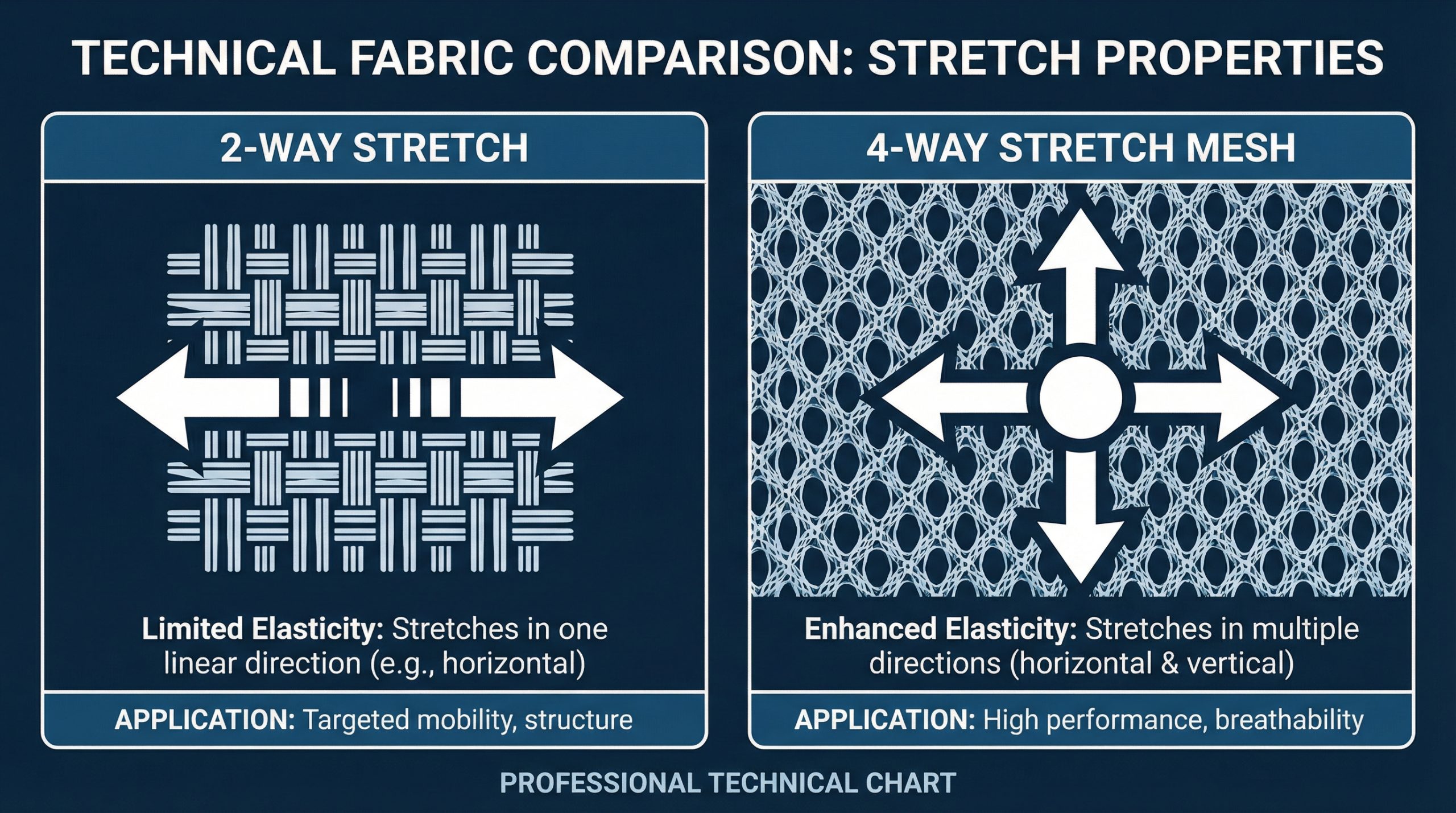

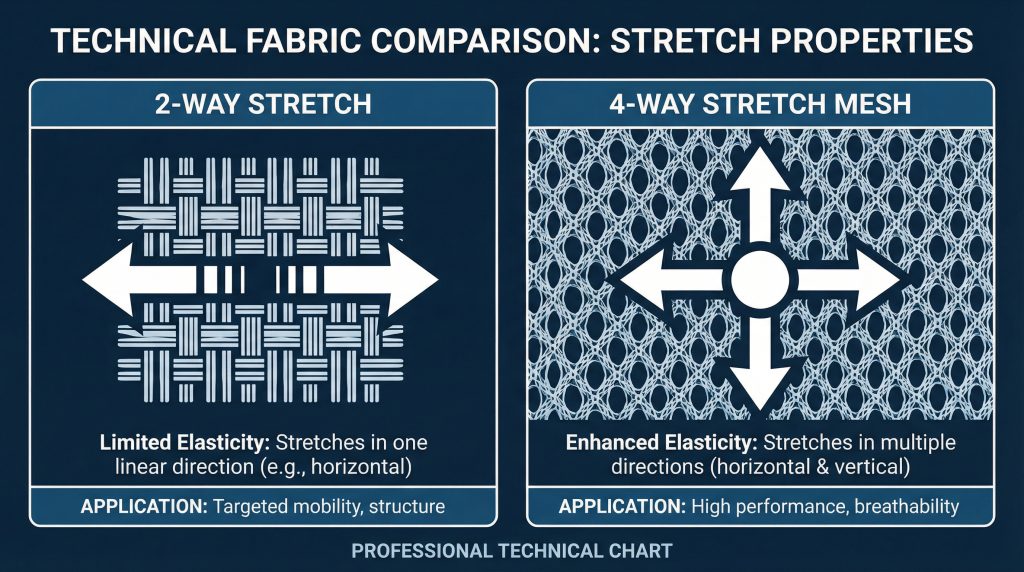

How Does 4-Way Stretch Mesh Vary from 2-Way Options?

4-Way Stretch Mesh differs from 2-Way options primarily in the number of directions it can expand, as 2-Way only stretches in one direction—usually from selvage to selvage. Understanding this distinction is crucial for your procurement strategy, as the wrong choice can lead to structural failure in specialized gear. You can learn more about our commitment to quality standards on our about page .

Comparing Dimensional Capabilities

The mechanical difference lies in the knitting process and the integration of elastane fibers throughout the weave. While 2-Way fabrics offer stability, they lack the “give” required for complex, three-dimensional forms.

- 2-Way: Stretches in one direction only.

- 4-Way: Stretches in both length and width.

- 4-Way: Offers superior body-contouring properties.

Here is the kicker: Choosing 2-Way stretch for a high-mobility joint area often leads to premature tearing or user restriction.

Key Takeaway

The fundamental difference is the axis of elasticity, with 4-way providing the comprehensive coverage needed for ergonomic excellence. The following comparison highlights the operational differences you will encounter during the manufacturing process:

| Feature | 2-Way Stretch | 4-Way Stretch Mesh | |

|---|---|---|---|

| Directionality | Mono-axial | Bi-axial | |

| Application | Waistbands/Cuffs | Full-body gear | |

| Complexity | Low | High |

Why Is 4-Way Stretch Mesh Ideal for Ergonomic Design?

4-Way Stretch Mesh is ideal for ergonomic design because it conforms to the natural contours and movements of the human body without resistance. In professional sports and medical rehabilitation, the fabric must act as a second skin to ensure maximum efficiency. By reducing the force required to move, this mesh minimizes fatigue for the end-user.

Human-Centric Textile Engineering

Ergonomics isn’t just about comfort; it is about optimizing the interface between the human body and the product. This fabric allows for a personalized fit across a wide range of body types within a single size run.

- Reduces friction against the skin.

- Supports dynamic muscle expansion.

- Maintains consistent pressure during movement.

But wait, there’s more. The adaptability of the mesh also simplifies the pattern-making process for complex geometric designs.

Key Takeaway

Ergonomic success depends on the fabric’s ability to mirror human biomechanics, a task perfectly suited for multidirectional textiles. The data below illustrates why ergonomic designers prefer multidirectional elasticity for technical apparel:

| Design Factor | Impact of 4-Way Mesh | User Experience | |

|---|---|---|---|

| Range of Motion | Unrestricted | Enhanced performance | |

| Pressure Points | Evenly distributed | Reduced irritation | |

| Fit Consistency | High | Professional aesthetic |

Can 4-Way Stretch Mesh Withstand Heavy Industrial Use?

4-Way Stretch Mesh is engineered to withstand heavy industrial use through the use of high-denier synthetic fibers and reinforced knit structures. Whether utilized in safety harnesses or automotive seating, it maintains structural integrity under significant load. You can explore our specific industrial case studies to see these materials in action.

Industrial Durability and Resilience

The resilience of the mesh is tested against abrasion, puncture, and chemical exposure depending on the specific industrial requirement. It provides a lightweight alternative to heavier textiles without sacrificing the strength necessary for safety protocols.

- Resistant to repeated mechanical stress.

- High colorfastness under UV exposure.

- Chemical resistance for specialized environments.

Make no mistake: Durability in a stretch fabric is a result of precise engineering rather than sheer thickness.

Key Takeaway

Industrial-grade stretch mesh provides a unique combination of flexibility and ruggedness that standard knits cannot match. Analyze the industrial performance markers below to determine suitability for your specific environment:

| Stress Test | Result | Industrial Application | |

|---|---|---|---|

| Abrasion Resistance | 50,000+ Cycles | Heavy-duty upholstery | |

| Tensile Strength | High | Load-bearing gear | |

| Elastic Fatigue | Low | Long-term seating |

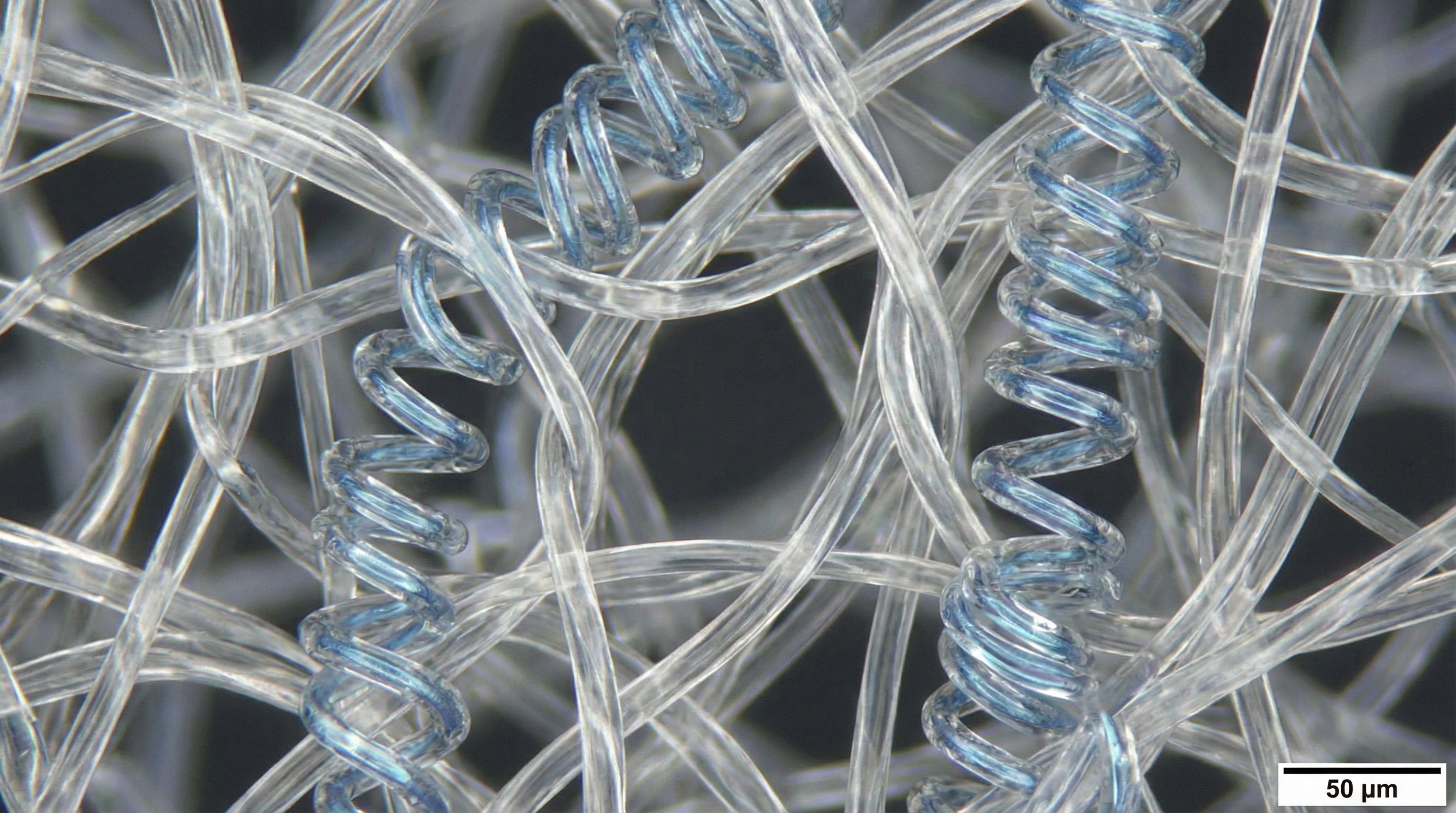

What Fibers Create the Best 4-Way Stretch Mesh?

4-Way Stretch Mesh is typically crafted from a blend of polyester or nylon paired with a high percentage of Spandex or Lycra. The synthetic base provides the necessary strength and moisture-wicking properties, while the elastic component provides the “bounce.” Selecting the right ratio of these fibers is the first step in achieving your desired hand-feel and performance.

Fiber Blend Optimization

The choice between nylon and polyester often depends on the final application’s requirements for soft touch versus durability. Nylon blends tend to be softer, while polyester blends offer superior resistance to shrinking and stretching over time.

- Spandex/Elastane: The source of elasticity.

- Polyester: Provides durability and moisture management.

- Nylon: Adds softness and high-strength properties.

But that’s not all… The weight of the fiber, measured in denier, also plays a critical role in the transparency and weight of the final mesh.

Key Takeaway

The synergy between strength fibers and elastic fibers determines the ultimate functionality of the stretch mesh. Review the following fiber characteristics to guide your material selection process:

| Fiber Type | Primary Benefit | Common Percentage | |

|---|---|---|---|

| Polyester | UV Resistance | 80% – 90% | |

| Nylon | Abrasion Resistance | 75% – 85% | |

| Spandex | Ultimate Elasticity | 10% – 25% |

How Do You Measure 4-Way Stretch Mesh Performance?

4-Way Stretch Mesh performance is measured through standardized laboratory tests that evaluate elongation, recovery, and burst strength. These metrics provide you with the empirical data needed to guarantee product safety and longevity. Our technical experts often collaborate with various industry partners to refine these testing standards for global markets.

Standardized Testing Protocols

Testing ensures that every yard of fabric meets the rigorous demands of professional-grade applications. Professionals look specifically at “power” and “stretch” values to determine if the fabric provides enough compression for its intended use.

- ASTM D4964: Tension and elongation testing.

- Recovery Percentage: Ability to return to 0% stretch.

- Bursting Strength: Resistance to force before failure.

Believe it or not: Even a 5% deviation in recovery can lead to significant product defects in high-compression garments.

Key Takeaway

Rigorous testing is the only way to ensure that your multidirectional mesh performs consistently in the field. The table below outlines the critical testing parameters used to validate textile quality:

| Test Method | Objective | Target Result | |

|---|---|---|---|

| Elongation | Measure max stretch | > 80% | |

| Recovery | Measure shape retention | > 98% | |

| Colorfastness | Measure dye stability | Grade 4.0+ |

What Role Does 4-Way Stretch Mesh Play in Medical Wear?

4-Way Stretch Mesh plays a critical role in medical wear by providing consistent compression and breathability for orthopedic braces and post-surgical garments. In these applications, the fabric must support the body’s healing process by promoting circulation and reducing edema. Its ability to stretch in all directions ensures that medical devices stay securely in place during patient movement.

Therapeutic Compression and Support

The mesh structure is particularly valued in medical settings for its moisture-wicking properties, which keep the skin dry and prevent infection. It allows for the integration of therapeutic inserts or padding while maintaining a low-profile fit under clothing.

- Supports joint stabilization.

- Facilitates airflow to wound sites.

- Provides graduated compression for vascular health.

Think about this: Patient compliance increases significantly when medical garments are both comfortable and functional.

Key Takeaway

In the medical field, the multidimensional stretch of the mesh is a vital component of patient recovery and comfort. The following table highlights the medical applications and their specific requirements:

| Application | Benefit | Requirement | |

|---|---|---|---|

| Orthopedic Braces | Joint support | High modulus | |

| Surgical Wraps | Breathability | Non-irritating fiber | |

| Compression Socks | Blood flow | Consistent tension |

How Can 4-Way Stretch Mesh Optimize Production Yields?

4-Way Stretch Mesh can optimize production yields by allowing for more efficient marker making and reducing the impact of grain line constraints. Because the fabric stretches in both directions, you have more flexibility in how pieces are laid out on the cutting table. You can find more tips on manufacturing efficiency by visiting our blog .

Manufacturing Efficiency Gains

Using multidirectional fabrics can often reduce the amount of waste generated during the cutting phase. It also simplifies the assembly process, as the fabric can accommodate slight variations in seam tension without distorting the final product.

- Flexible grain line alignment.

- Reduced fabric scraps during cutting.

- Fewer assembly errors due to fabric “give.”

Here is the secret: Smart layout strategies using stretch fabrics can improve your bottom line by reducing raw material costs.

Key Takeaway

Operational efficiency is a hidden benefit of adopting 4-way textiles in large-scale production environments. The data below demonstrates the potential efficiency improvements in a production setting:

| Production Factor | Impact of 4-Way Mesh | Result | |

|---|---|---|---|

| Marker Efficiency | Increased layout options | 5-10% waste reduction | |

| Sewing Speed | Accommodates minor errors | Faster throughput | |

| Inventory | Versatile size fitting | Reduced SKU count |

Does 4-Way Stretch Mesh Improve Luxury Apparel Fit?

4-Way Stretch Mesh improves luxury apparel fit by allowing designers to create sleek, body-conscious silhouettes that remain comfortable throughout the day. In the high-fashion sector, the challenge is often balancing a structured look with the mobility required for modern lifestyles. This mesh provides the internal structure needed for complex draping while remaining virtually weightless.

High-End Aesthetic and Comfort

Luxury brands utilize this material for lining, paneling, and even as a primary outer fabric to achieve a refined, contemporary aesthetic. It adds a technical edge to traditional couture, bridging the gap between athletic performance and high-end design.

- Smooths body lines for a tailored look.

- Enhances the drape of delicate outer fabrics.

- Provides a “shapewear” effect without bulk.

You might be surprised: Many of the most iconic red-carpet looks rely on hidden stretch mesh panels to maintain their perfect shape.

Key Takeaway

In luxury fashion, the mesh acts as a silent partner that ensures a flawless fit without compromising on movement. Consider these luxury design elements when integrating stretch textiles:

| Design Goal | Application | Result | |

|---|---|---|---|

| Invisible Support | Lining / Under-structure | Sleek silhouette | |

| Texture Contrast | External panels | Modern aesthetic | |

| All-Day Comfort | Gussets / Flex zones | High user satisfaction |

Why Is 4-Way Stretch Mesh the Future of Smart Textiles?

4-Way Stretch Mesh is the future of smart textiles because it provides the ideal substrate for embedding flexible electronics and biometric sensors. As wearable technology evolves, the need for fabrics that can maintain constant contact with the skin is paramount. Our recent case studies highlight how these materials are being integrated into the next generation of connected devices.

Integrating Technology and Textiles

The open structure of the mesh allows for the easy integration of conductive threads and sensors without affecting the fabric’s natural stretch. This creates a platform for garments that can monitor heart rate, temperature, and movement in real-time.

- Accommodates flexible circuit boards.

- Maintains sensor contact during activity.

- Protects delicate electronics with a resilient knit.

The bottom line: The marriage of advanced textiles and digital technology is only possible through highly adaptable materials.

Key Takeaway

Multidirectional mesh is the foundational layer upon which the future of wearable technology will be built. The following table explores the intersection of textiles and technology:

| Technology | Mesh Function | Outcome | |

|---|---|---|---|

| Biometric Sensors | Skin-tight contact | Accurate data | |

| Conductive Yarn | Structural carrier | Integrated circuits | |

| Haptic Feedback | Vibration transmission | Immersive experience |

Conclusion

Understanding the nuances of stretch fabrics is essential for staying competitive in today’s B2B landscape. We have explored how 4-Way Stretch Mesh solves the critical problem of movement restriction, offering a solution that enhances comfort, durability, and technological integration. Our vision is to empower designers and manufacturers with the highest quality technical textiles to push the boundaries of what is possible in their respective industries. If you are ready to elevate your product line with superior elasticity and performance, contact us today to discuss your specific requirements.

FAQ

Can I use 4-way stretch mesh for heavy-duty industrial covers?Yes, provided the denier and fiber blend are specifically selected for high-tensile resistance and environmental exposure.

What’s the best way to prevent 4-way stretch mesh from fraying?Using a ball-point needle and a zigzag or overlock stitch is the most effective method to maintain seam integrity and prevent unraveling.

Can I substitute 2-way stretch for 4-way stretch mesh in athletic leggings?No, because 2-way stretch lacks the vertical expansion necessary for movements like squatting or running, which will lead to a poor fit.

What’s the most durable fiber for 4-way stretch mesh?Nylon blended with a high-quality elastomer typically offers the best balance of abrasion resistance and long-term recovery.

Can I print custom logos on 4-way stretch mesh?Yes, sublimation printing is highly effective on polyester-based meshes, as it allows the ink to bond with the fibers without clogging the mesh pores.